-

Posts

1,431 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Stetson912

-

Purse lining help/ideas

Stetson912 replied to Stetson912's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I'm hand stitching so it will be stitched from the outside only along the top of the bag. I'm going to try a single gusset but it may be a 3 piece gusset. Im going to welt the bag as well and turn it. My concern is that I will get wrinkles at the top in the lining because of the curve of the bag. Or that the curve won't lend itself u to being turned or bound. The edges I want bound, So I would do a turned lining if I could get away with it. But I could also do a drop in with bound edges too. I may add a few pockets too. -

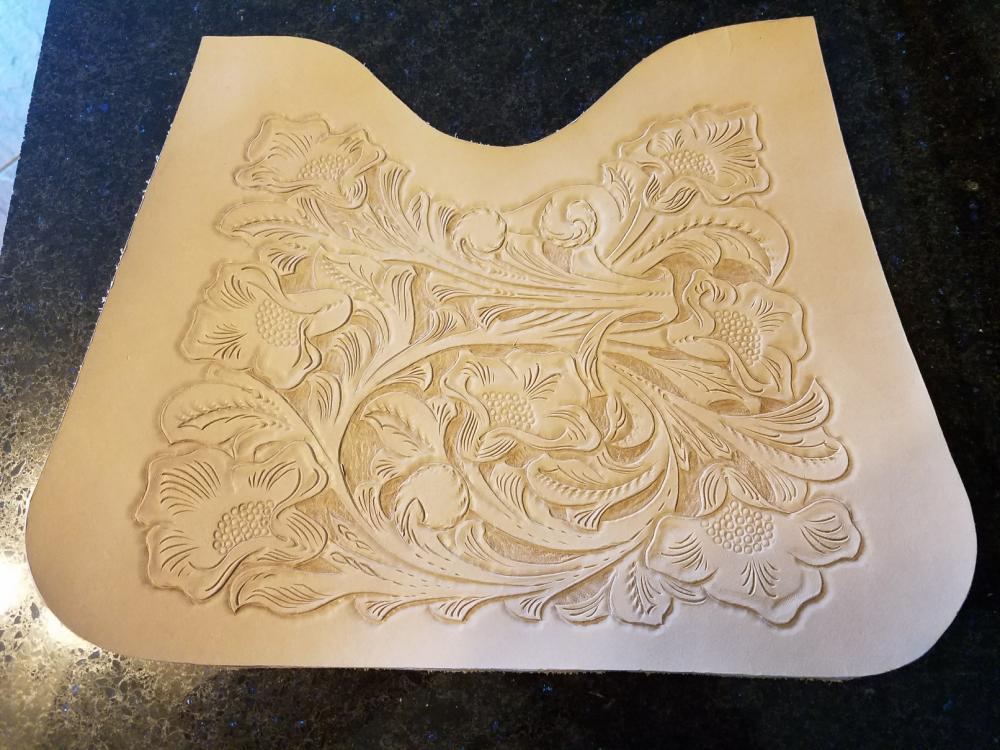

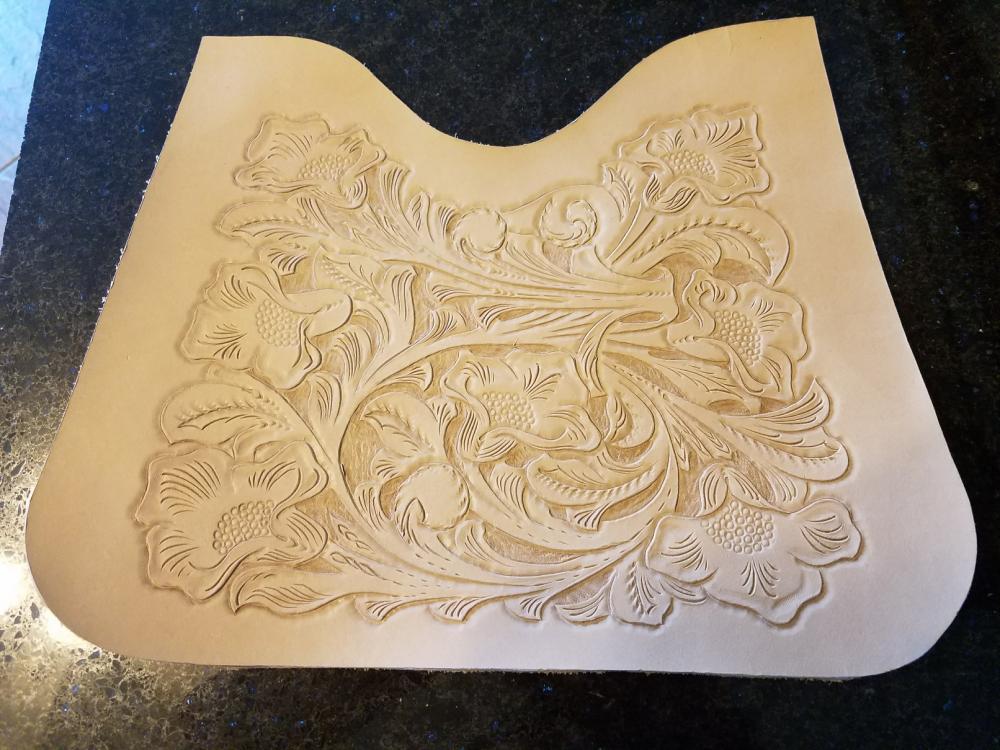

I've posted on other parts of the forum but haven't had any ideas come my way. So I thought I might try this section too. I'm trying to figure out the best way to line a bag that is this shape. I don't know if a turned lining would work, or if a drop in lining would be better? I'm worried the shape won't lend well to either of these and I may have to bind the edge a different way. Here is the front panel. Thanks!

-

I'd recommend ventilation. The good dyes like driving oil dyes and such do smell and aren't good to breathe. You could try ecoflo dyes and waterstains. It's just my preference and opinion that I don't really care for them. The dyes aren't bad I just prefer feibings. Also, if you use contact cement it's good to have ventilation. That is nasty stuff. I can't remember the name of it but there is a water based cement that Lisa Sorrell uses and sells. You may want to check it out.

-

I'm in the process of making a bag and have the front and back panels dyed and got to thinking of the liner o want in it. I'm going to use a garment leather for this and was wondering how to attach it. The bag shape has a "dip" in the middle of the front and back panels and I'm wondering if a drop in liner would work around that curve. Or if I can bind a drop in liner or if I can even do a turned lining. I hope I can pick your brains for ideas on how to do this thanks.

-

Getting back into Braiding - Dog Leash

Stetson912 replied to motocouture's topic in Collars, Cuffs, Leashes and Leads

I love Bruce grants encyclopedia. I think if anyone wants to start to learn how to braid they should pick that up. Ron Edwards is great too, I have a few of his whip making books. I use paracord for my braiding and plaiting but I mY have to invest in lace or kangaroo, I've been wanting to make a leather whip haha. The lead looks great motocouture -

Not sure what leather is used in baseballs or if it's even leather anymore. Maybe some heat? Like a low iron or something and then placing it under some old text books.... Or, if you really mean business and either have or know someone who has a hydraulic press.... Hehehe

-

I'm making a bag. I posted this in the critique section as well but thought I would put it here for some more input. I can trace and follow a pattern but when it comes to pear shading and decorative cuts I'm at a loss. This is 5/6 oz tandy leather and I used a Barry king knife with thin 3/8" blade. The leather probably isn't ideal but I think the majority of issues are because I'm not very good haha. Any resources or tips that may help me improve are very welcome thanks!

-

Have an idea but not sure how to do it

Stetson912 replied to Windrider30's topic in How Do I Do That?

If you have a Dremel they make router bits for them. Might work a lot faster haha. Not sure if you need any attachments or what not though. -

I agree with motocouture, see if you can get a hold of some of Ron Edwards books. Also, I believe David Morgan has a book on leather braiding. And there is always the famed "Encyclopedia of leather and rawhide braiding" by Bruce grant which has a plethora of knowledge in it, everything from flat and round braids to turksheads and other projects. As for that particular "triangle" shape, it is an Australian technique. You actually begin the belt at the end and finish at the buckle. This is covered in all of the literature described but you can also try and Google "starting Australian flat braids" and see what that gets you.

-

Have an idea but not sure how to do it

Stetson912 replied to Windrider30's topic in How Do I Do That?

So you want to inlay leather with chain maile much the same way a woodworker would inlay a piece of wood with another? Hmm, sounds interesting. What if you used a French skiver to hollow out the square? Perhaps even chisels could work. If its a simple shape I think the French skiver would work best -

Awesome!

-

56 videos is what YouTube says.. you were just being modest! Haha. I've subscribed to your channel. Thanks for the information!

-

Thanks madmax, I ordered the 3/8" thick and thin to try em out. I don't do a ton of tooling but if I end up doing more then I probably will invest in more knives. I just need a good one to start with to replace the Tandy ones I have. The blades just don't cut it.... Hehe

-

Thats a helpful video @gmace99, thanks for sharing. Do you have a YouTube channel?

-

Haha, we all do it. Just takes practice. If you just take your time and try and do every step of your project the best you can and know how to do, you'll improve. And loads of people here are willing to help too.

-

Thanks oltoot, I ordered my knife today and got one of each of the 3/8" blade. I'm thinking I'll like the thicker blade better than the thinner one but I figured it wouldn't hurt to just try em both out to see which I like. And a spare blade is good to have. I found a few threads on here dealing with the subject and most people recommend the thicker 3/8" blade. So now I'm impatiently awaiting my new toy haha.

-

I think so. It'll make a nice sturdy holster

-

Dunluce, check Ian atkinson a videos on YouTube. He has a 15minute video that shows him making a turned edge wallet. It isn't instructional but you can still learn from it. He also has a video on edge turnings and bindings which is a great video too. He uses a "safety" beveler for skiving so that aspect he may not be able to help with. However, Lisa Sorrell has a short snipit on YouTube as well about skiving knives and skiving which may also be beneficial. Cheers

-

Howdy folks, I'm seriously considering a Barry king knife. I've sharpened my Tandy blades but they still don't cut well. So I figured I'd upgrade. Then I discovered all the many types of blades that are available just from Barry king. My question is, does each blade have a different purpose? Should I get a 1/4" or 3/8" or both, angled or straight, thick or thin, red or blue... Ok the last option was a joke but still, for a novice it's a daunting decision. I would like to have a variety of carving abilities from big western floral pieces to intricate Sheridan pieces. So my thoughts were getting a 1/2" or 5/8" barrel and a 3/8" and 1/4" thin straight blades (because that's what I'm used to) Thanks a mucho

-

Do you have any of stohlmans case making books? I'd recommend them. It really depends on the project, you could take a strap of leather you are using for the gusset and wrap it around the main panel of the bag to measure it. I would use a fabric tape and measure around the panel and then make a single gusset a little longer to trim later. A three piece gusset is might be easier. You could attach one side at a time and then you can stitch the sides to the bottom after. Skiving thick leather would help you bend over the edges 90degrees to attach to the bag face, in this case I would do the whole length of the gusset. As for the corners, if it's a real sharp corner you can't use a single gusset, but for round gentle corners you just have to stick it out and bend it around and try and keep it in place before stitching it. I recommend binder clips or contact cement or basting tape. Hope it helps.

-

I I'm not familiar with machines. I don't own one nor can use one I'm afraid. If you are infact referring to venator's pictures then please ignore this haha. And apologies if I overstepped my bounds here, I'm still trying to get used to the forum etiquette.

-

It is soft and nice leather. I also have trouble stitching thinner leather. I tend to over-tension it

-

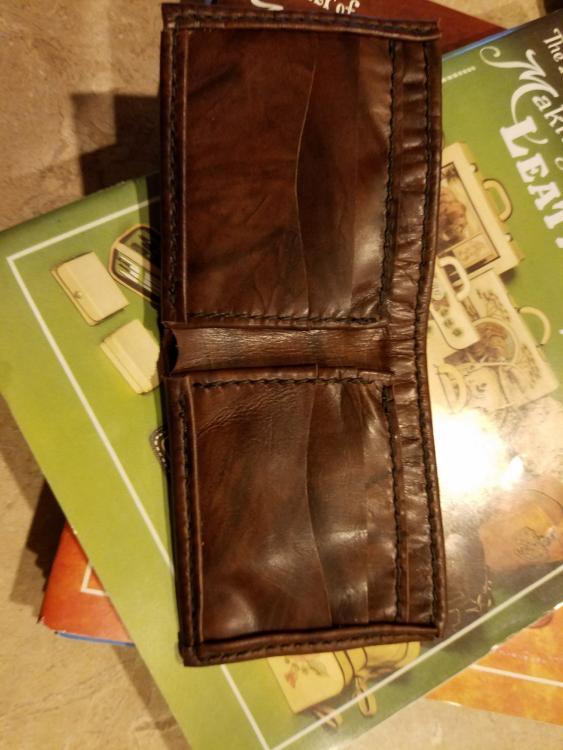

This is my latest attempt. The alignment is off and the binding wasn't good either. It ended up being too short to cover enough of the edge to stitch right and it's a mess internally with the pockets. It's all 2/3 oz leather so maybe I need to use thicker leather for the back. Thanks also wrinkles on the face when folded which isn't fun.and cards don't fit in the pockets either... At least not easily haha But hey, live and learn.

-

I feel your pain, I'm no good at wallets, but Ill keep trying until I get it. It is frustrating but it'll pay off one day.

-

Sweet. Nice to see a fellow zona crafter.

.jpg.d60258221c476480a6e073a8805645bb.jpg)