-

Posts

483 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by cdthayer

-

Singer 31-15 Tension breaks the thread

cdthayer replied to iknowit101's topic in Leather Sewing Machines

Ok, I tried. Best of luck to you. CD in Oklahoma -

Shimming the race out may solve the binding problem, but the hook may still hit the needle without some shimming behind the hook as well. I’ve had a real problem trying to make the new replacement parts work on old machines, and in some cases, just had to throw them away and find usable parts from an old machine. CD in Oklahoma

-

It sounds to me like the new replacement casting is just a tad thinner than the old original race, or the new hook is just a tad thicker than the original hook. Have you tried mounting the new hook with one or all of the old cast races? If they also bind the machine up, I would think that the new hook is too thick. If so, you might try making a shim of some sort to keep the casting set out just a little when tightened down. CD in Oklahoma

-

Singer 31-15 Tension breaks the thread

cdthayer replied to iknowit101's topic in Leather Sewing Machines

Four years ago, I tried to get Harry to take another look at his bull$hit about how “the Needle Crank lever should press the Tension release lever to push the pin that release the tension during the stitching cycle” (my post is at his Youtube video), and he didn’t reply. He replied to another guy and said that he no longer had the machine and couldn’t look into that person’s problem. Your needle crank shouldn’t hit the tension release linkage at all. Look elsewhere for your thread-breaking problem. CD in Oklahoma -

How did you get into leather work?

cdthayer replied to Rolandranch's topic in Leatherwork Conversation

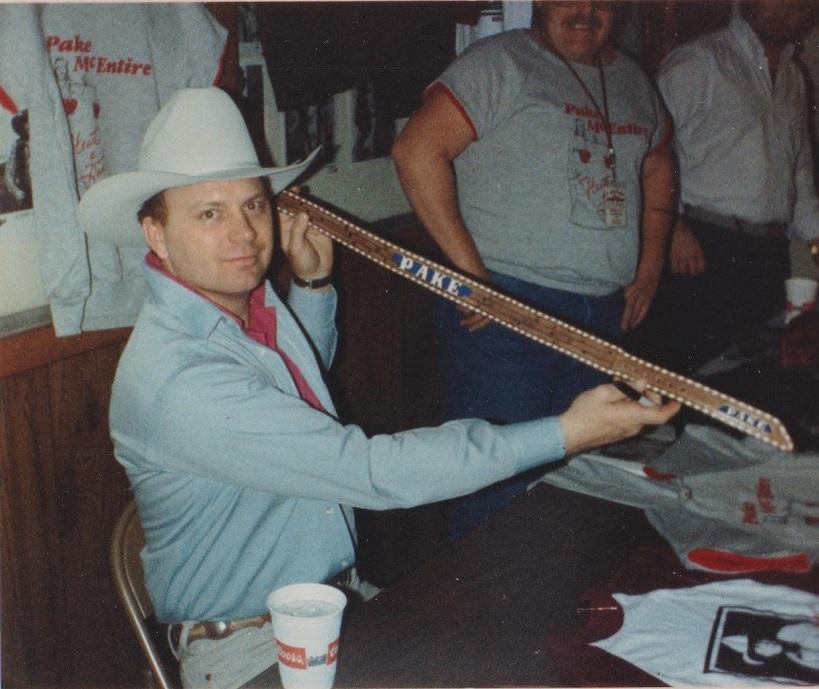

I got my start in 1965 when a SW Colorado rancher’s wife, Sara Masco, an excellent leather tooler, taught basic tooling leathercraft to a bunch of us 13-14yo knotheads in 4H. She relied on Tandy kits for projects for beginners the first year, and let 2nd year students branch out from there. I don’t remember my first project, but I recall vividly a belt that I made my second year. It featured a very dramatic footprint storyline of a barefoot man walking in sand with a bear falling in behind him to later consume the man and walk off alone. The judge at the County Fair made a special note on my entry card. “What happened? Did little brother spill dye on your belt?” (my red dye simulated blood). Pffft, not much of a judge. Hell, I don’t even have a brother. No more leatherwork for years except repairing horse tack, and then I took up leather tooling again after 20 years in 1985 in Oklahoma. With a wife and three children, I made belts, covered belt buckles, wallets, clutch purses, knife sheaths, and purses for my family and friends. I tooled and laced most items. Nowadays, three of the little belts that I made for my children have been converted into a paper towel holder in our kitchen. I got to thinking that I was getting pretty good at leather work (I even made a belt for Country Singer Pake McEntire), so I consigned some things to a popular Westernwear Store near my home. A few months later, I went and got it all and brought it home. I still have most of it boxed up somewhere. I’ve puttered with tooling leather a bit through the years, tooling and buckstitching electrical linemen climbing gear “gut straps” and making a few more laced checkbook covers and clutch purses. Eventually, I quit tooling and got into wet-forming folding-knife sheaths and plier holsters that I sewed by hand with waxed thread. Now that I have great leather sewing machines on hand, I haven’t gotten back into production at all, and use my machines to make repairs to mostly woven materials. I use my machines for some leather mending, but ironically, hand-sewing or hand lacing has usually been the best method to repair leather items that have come through the door at my sewing shop. Fake leather (yes?, no?, umm probably) purses are the exception. I usually use a machine to mend them, whatever they’re made of. I don’t see me getting back into production leatherworking for the public at all. I still have all of my hand tools boxed up if I ever change my mind. For now, I enjoy the challenge of mending someone else’s work, and besides, there’s more money in repairs, at least in my experience. Your mileage may vary. CD in Oklahoma -

I should add, that it was sold to a leatherworker.net member. Thank you leatherworker.net for your help. CD in Oklahoma

-

Sold.

-

Thanks Greg. I’ll probably use a little sewing machine oil to rub the painted surfaces to see if I can get any more of the rust stains off of it, but that’s probably about it. I’m not too much into aesthetics (as you can tell by looking at my machines). I’m much more into function, and will be fiddling with the tension and pretension assemblies as I go. I know that it has definitely been over-oiled, and that could cause problems down the line if it’s allowed to set idle. I have it near a traffic area and can give it a few cranks whenever I walk by it to keep it limbered up so that the oil doesn’t dry out. It’s missing one of the springs in the race, and has one shorter replacement spring that doesn’t match the other two (one of those is bent). I’ll be looking to get a new set of them (part # 068 00 183 0)? Do you have those? CD in Oklahoma

-

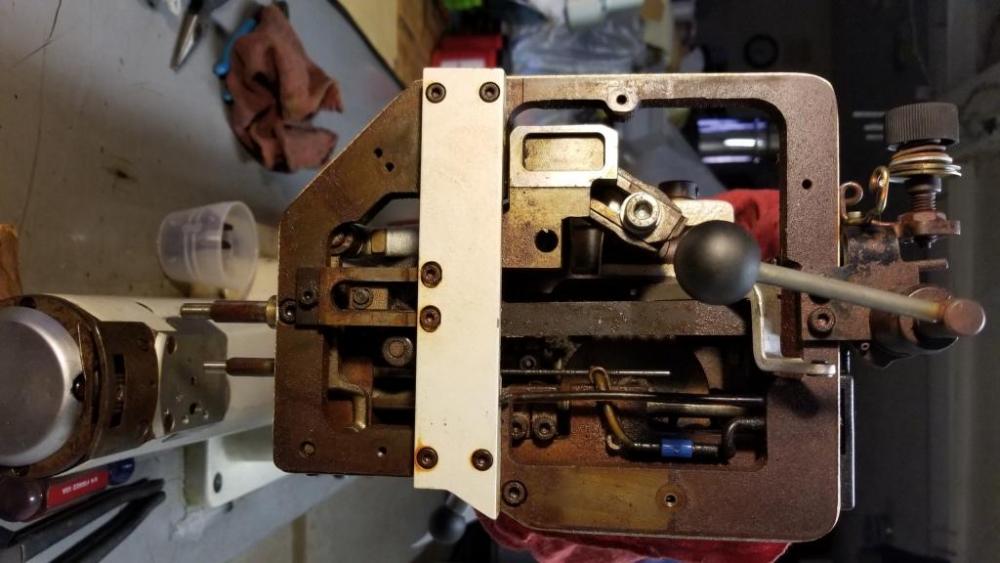

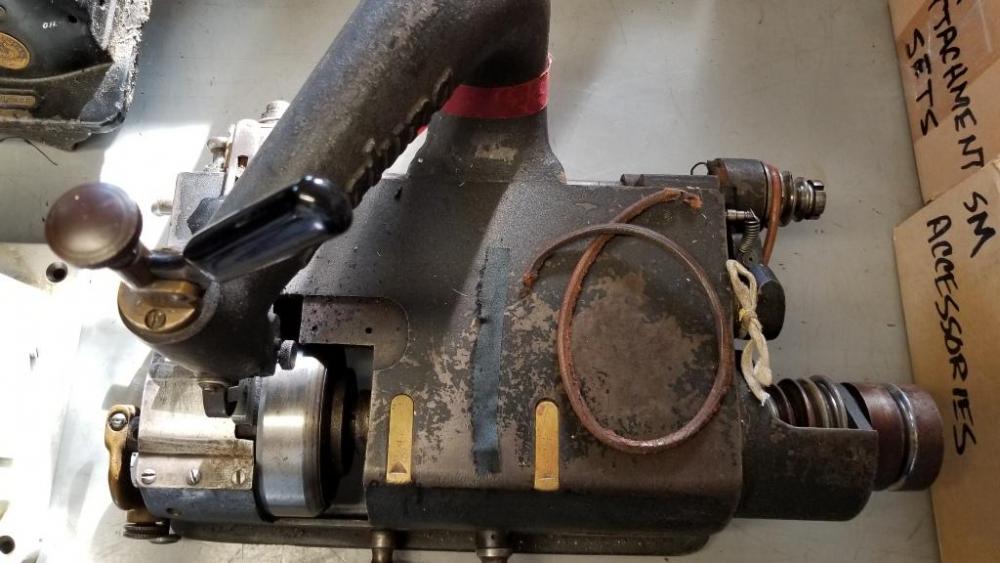

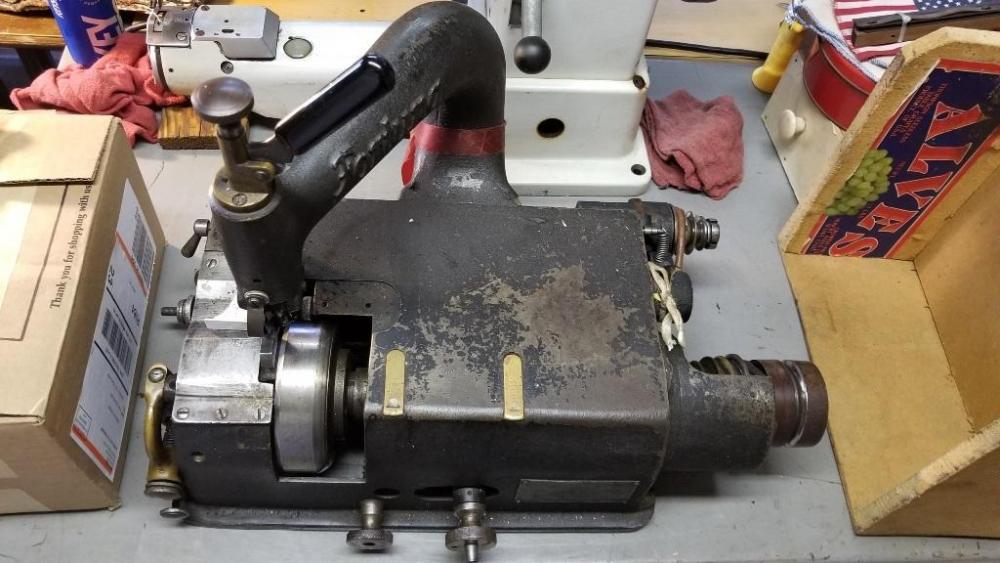

I came up with a basket-case Adler 205-370 that had set out in the weather for a lengthy time. It was locked up tight, but still had all of its parts. I began the process of restoring it to useable condition back at the end of August 2018 when I removed the active Yellow Hornet nest just inside of the top inspection cover. I had hornets everywhere, and managed to keep from getting stung. Once I settled back down from that experience, I applied Lilly White sewing machine oil using a syringe and a small Singer squirt bottle to what I could reach easliy, and let it set. I oiled all of the keepers for the covers and feet, and after a few days, I removed the remaining covers to get oil further into the end of the head. Every few days I applied more oil and checked the hand wheel for movement. On the last day of November (3 full months later), I got the first tiny movement of the hand wheel. I oiled everything again and worked the hand wheel back and forth then with more frequency, and finally got one full revolution 5 days later. With both upper and lower shafts free, I turned my attention to the outer presser bar that was still seized tightly in the tension adjustment thumb nut. After lots of oil and some heat from a hair dryer, I hadn’t gained anything by the middle of April (4 more months), so I gave it a big shot of PB Blaster, let it set for a day, and got out the Vise-grips. I hadn’t broken anything yet, but that thumb nut was going to break free or be destroyed. One firm twist of the vise-grips and the thumb nut popped loose from the presser bar with no damage. On April 25, 2019 the machine was totally free with everything operating as it should. The tension and pretension assemblies came to me in a sandwich bag and have been cleaned and reassembled. I didn’t take any other linkages apart. I have set this machine up for another mending and repair machine for my business. The bulk of my mending is woven or vinyl materials. The machine came with a #230 spacer, and I added a 7x3-26 round-point needle, Tex350 Bonded Nylon thread, new #28092 bobbin, set of Weaver harness feet, and a #22209 Agri-Direct Spinner knob for propulsion. It sews just fine, and other than still shedding excess oil that I put in/on it, it’s ready to tackle its first mending job. Thank you to all of the forum people that have talked about and provided videos about DA205-370 machines that helped me get this machine going again. CD in Oklahoma

-

SEIKO - What kind of sewing machine is this?

cdthayer replied to Seom's topic in Leather Sewing Machines

I like the idea of a flat surface under a cylinder bed machine, but sometimes the open space is required. Nearly all of my sewing (mainly repairs) that I do on my handcrank Adler 205-64 doesn’t require under the bed space, and I have one of those across-the-bed adjustable-height hospital tables that I setup under the arm to help hold the work up for sewing. I’m in the process of adding another Adler 205 handcrank to my herd, and have decided (from this thread) that I’m going to mount it with only one bolt onto my motorcycle air table so that I can use it with the arm over the table, or pivot the arm out past the table when I need the under-arm space. CD in Oklahoma- 29 replies

-

- seiko

- sewingmachine

-

(and 2 more)

Tagged with:

-

-

I have an older model Fortuna skiving machine complete with stand. The head is a Fortuna Model G, serial number 16098. I know nothing about the machine, except that it is currently non-operable because the round leather (speed?) belt on the right-side multi-pulleys is broken. The motor belt is good. It had been used locally in a home wallet-making business that shut down due to health a few years ago. A small box of spare parts and tools is included. I know so little about this type of machine that I’m not sure if the parts are any good, or if they even go with this machine. Please see the parts photo. The stand is a converted recent K-leg with what appears to be a modified green serger plywood and Formica top, 1-phase 2850/3450rpm 120V 1/2hp clutch motor, and home-built flashing waste discharge chute under the left side. A home-made wooden right-side belt cover is included. The head is being stored inside in my sewing area, and the stand is being stored outside covered on my carport. Note: The motor shown setting on the stand top in some of the photos is not part of this machine, and neither are the electric fan, light, and other clutter on the stand top. The bad motor is off of his 31-15 sewing machine and not included in this package. (Those photos were taken at the seller’s location.) Price is $300 for all as-is un-tested, pickup only at my home in Frederick Oklahoma by appointment, no shipping. (Frederick is approximately 29 miles north of Vernon Texas, 20 miles from US Hwy 287, and approximately 67 miles NW of Wichita Falls Texas.) Please post questions to this thread. CD in Oklahoma

-

SEIKO - What kind of sewing machine is this?

cdthayer replied to Seom's topic in Leather Sewing Machines

I think it’s interesting that the original table has no cut-out under the arm, but appears to maybe be a drop-down? CD in Oklahoma- 29 replies

-

- seiko

- sewingmachine

-

(and 2 more)

Tagged with:

-

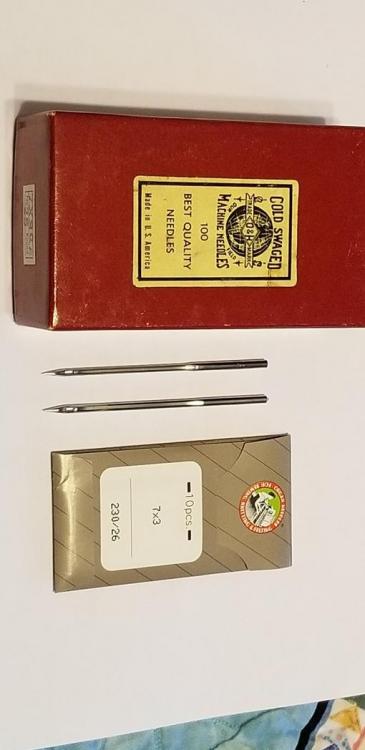

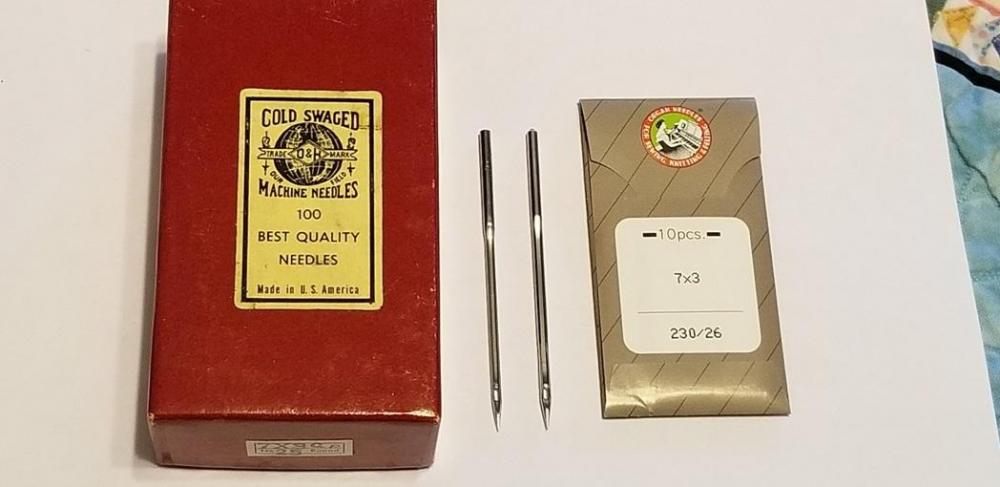

I tried putting an old style (new condition) 7x3-25 “Cold Swaged” machine needle in my Durkopp Adler 205-370, but the shank is too big to go into the hole in the needle bar. It’s just a hair big enough that it won’t go in. Organ 7x3-26 needles go in fine. I don’t know the age of the old style needle (looks like “D&H Trade Mark” brand), but I’m wondering if they were manufactured prior to development of the 794 needle system, and that today’s 7x3 size compromises to cover multiple needle systems? I don’t know what the “C.P.” designation means, but I assume it indicates the point style. Anyone know? CD in Oklahoma

-

Rusty Adler 67-73 t w/ ac motor, do or don't?

cdthayer replied to Badem's topic in Leather Sewing Machines

Gotcha Glenn. Right now, I plan to keep and use it. CD in Oklahoma -

Rusty Adler 67-73 t w/ ac motor, do or don't?

cdthayer replied to Badem's topic in Leather Sewing Machines

Badem, How did you come out with your "winter project"? My machine finally broke completely free (outside presser bar stayed seized all winter) yesterday after I put some major pressure to it. I was to the point that something was going to have to give after five days short of eight months using gentle persuasion. I'm happy to say there are no broken parts. Now, I just need to find all of the covers that I took off, and figure out in what order they all need to go back on. I hope you had success with your 67? CD in Oklahoma -

My portable compound-feed machine is a Singer 111G156 powered by hand (automotive steering wheel spinner knob), transported place-to-place inside or outside by a surplus folding wheel chair, and used on any sturdy flat surface. It weighs about 65 pounds. Photo shows it setting on a motorcycle air-lift table being used to reattach a purse strap (Tex90 thread). CD in Oklahoma

-

Nope. CD in Oklahoma

-

Looks like a mini walking foot machine to me. Good find. CD in Oklahoma

-

I worked on a Thompson Mini WF PW-103 back in 2007 (had to fabricate a replacement tension release tab), but it is a completely different model than what we’re talking about. Other than that, I don’t have any experience with any other mini walking foot machines, Thompson or otherwise. I think they’re cool little portable machines though. CD in Oklahoma

-

Did Sailrite take over the Thompson Mini Walker? Seems like maybe they did. Anyone know? CD in Oklahoma ETA: If he has a receipt that is 20 years old, he could have an interesting machine on his hands.

-

It would be kind of fun if it is a model that was taken over by Thompson and then renamed, but it could also be a knock-off of Thompson’s design. Can you get a photo of the foot and needle plate area, and one of the back side of the machine? CD in Oklahoma

-

It looks a lot like a Thompson PW-500Mini Walking Foot Sewing Machine, but I can't see the presser foot area clear enough to see if it's a walking foot. The "Mini Brut" label is not familiar to me. CD in Oklahoma

-

You'll have better luck doing searches for information if you spell sowing as "sewing". CD in Oklahoma