-

Posts

483 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by cdthayer

-

Wholesalers don't need Retailers any more with the internet. Look for more of this coming......in a variety of markets..... CD in Oklahoma

-

Hi Lee. I haven’t been on Treadle-On since Cindy took over. Your Singer 42-5 looks like it’s set up for more leather than my Singer 16-41, but the feeds look to be similar if not the same. I wonder if the 42 was designed due to the number of guys complaining about the small bobbin capacity and maybe the punching power of the 16? (My 16 takes the same bobbin as a 31-15 (2996).) You’ve got a very nice-looking machine there. I’ll be keeping my eye out for one of those to add to my collection. Since I really like using treadles, I’ve been playing with the 16-41 and enjoying the sound of it. It’s a distinctive sound with its click when the outer foot snaps forward. It kind of reminds me of my Singer 29K70 machines, although it’s a different sound. I like the unique sounds these old machines make when they’re stitching. Singer old iron is just fun! I bought another possible treadle machine, a Singer 78-3 that I’ve only seen photos of (daughter and son-in-law have it in OKC for me) that is old Singer iron, but will be even less of a leather machine than your 42-5 or even my 16-41. It’s a needle-feed machine with no feed dogs. It might do alright for light leather, but I’ll probably use it for wovens. It’s got a nice husky balance wheel on it that should lend itself well to treadle operation, and I’ll probably let it share the Frankentreadle with the 16 unless I get lucky and find yet another Singer Industrial Treadle Stand. I’ve bought the last 4 that I’ve seen in my area, but they don’t come up very often. I have all of mine taken up (Singers 31-15 roller foot, 96-40 darning foot, 95-40 ss/20U zz that share a small cut-out, and the 16-41) I can’t wait to hear what a 78-3 sounds like when it’s stitching. Back to your 42-5, I had a really nice White Sit-strate Treadle stand that I was saving for a project, but made the mistake of storing it double-stacked on top of another treadle cabinet. It got bumped off onto a concrete floor and busted one end into pieces back in 2010. It’s a shame, since they’re really nice treadle stands. I haven’t done anything with it, and I’m not sure that I even found all of the pieces or where they’re at. CD in Oklahoma

-

Thanks guys. After hearing from you, I don't think that removing the face plate will be all that dramatic now. But, I didn't mind checking with knowledgeable people before proceeding. CD in Oklahoma

-

Sorry Singermania, I missed this post while I was yakin.... What I wish to know, is can I take the face plate off without dislodging any parts within? Is it similar to taking the face plate off of a Singer 31-15 or 96-40? The four screws make me think that the plate is holding something together in there.... CD in Oklahoma

-

Ok Mike. I had to go to wiki to look up cromulent. I hadn't ever run into that word before, but it appears that it means the same thing as "Awright" in Oklahoma? CD in Oklahoma

-

LOL, yea, it won't be the first time that I've torn into something that I didn't know anything about. But as I get older, I just hate those long hours using a magnet in my shop to find launched parts that I think sounded like it hit that wall and then something else, or maybe it was the ceiling and then the wall, but it didn't seem like it was the right sound for hitting the ceiling, so maybe it hit that other wall and then the toolbox........ CD in Oklahoma

-

Thanks Singermania. I’ve been watching for a Singer 16-188 to come along near me, but this one will be just as much fun. I’m most impressed with the smooth bottoms on the feet. There wasn’t a mark one on the leather that I test-sewed. I’m just a little “goosey” about that outer foot that snaps forward after a stitch. Some type of spring must be popping it forward, and I hope it’s not dependent on the face plate to keep it in position. I can just see me taking those 4 screws out and having all kinds of parts fall out onto my bench, or flying off into never-never land with no idea of where they came from, or where they went.... CD in Oklahoma

-

I squirted oil into the face of the machine through all of the openings as best I could. I use a long hypodermic needle and syringe to do my oiling, so I got some in there a good ways. If I don’t hear from someone that’s worked with one of these, I’ll just have to tear into it and find out what’s in there. If it’s full of debris, it could get damaged. In the mean time, I got it mounted in my “Frankentreadle” that I cobbled together using a 12-inch domestic flywheel and pitman rod. I cut and spliced the rod to lengthen it. The table top on this one was used as a spray painting surface by some previous owner, and has white and black overspray on it. That just adds to the “Franken” part of its nickname. It looks pretty rough, but it holds up a machine. And the Singer 16-41 sews! I had to schounch (is that a word?) the existing needle down a tad to get it to pick up the bobbin thread, and I have some new needles coming, but it puts a pretty good stitch into a piece of 6-7 ounce oak tan leather with the old dull needle. I’m getting just a hair under 5spi. I’m trying this machine out using the small flywheel to see if I get an improvement in slow-speed control. I’m not sure yet if I’ll be giving up punching power by doing it. The balance wheel has a nice-sized 4-inch pulley on it, so that’s good. I felt a little slippage of the 1/4 inch round leather belt while I was experimenting, but it’s brand-new belting that I just put on it. I know it will stretch and I’ll have to shorten it, maybe more than once, as time goes on. It may be just a bit small for the balance wheel pulley, and a bit large for the domestic flywheel pulley, but I thought it was the best choice. CD in Oklahoma

-

Thanks Tinker. This one is a 16-41. I'm not sure if it's the same as a 16-141 or not. This one has alternating pressers, but the needle and inside foot don't move back with the feed. The inside foot just holds the work down while the needle is making its trip down and back up. The outside foot and feed dog are the only things that move to feed the work. The outside foot seems to have a spring that returns it to the forward position while it's up off of the work. CD in Oklahoma

-

I just picked up a Singer 16-41 and am cleaning and lubing it to put into a treadle stand. Before I remove the face plate (four screws), I’d like to hear from someone that knows these machines. I can’t seem to locate a parts or adjusters manual on this model, so I don’t know how things are set up in there, and I don’t want the surprise of parts falling out or springs zinging off across the room. Can anyone give me any information on this? CD in Oklahoma

-

Keeping A Sewing Shop Going During Grid Outages

cdthayer replied to cdthayer's topic in Leatherwork Conversation

I hear you. For most of my life, even if my own power wasn’t off, I’d regularly be awaken by a phone call, have to pat Mom on the rump, say goodby, roll out of bed, get dressed, and go out into the rain and cold anyway. All for someone else. That’s what I did, as a Lineman, and I liked it. I was a regular “OT Hound” because I learned more about the electric system that I was working on during overtime outages than I ever did when it was working properly, and the overtime paid for all of the things that me and my family wanted/needed at the time. I went out whenever I could. No regrets. So, even if my power was also out, I couldn’t hang around home attending to a generator to keep my house powered. That job would have fallen to my wife and kids. I had to go out on the line. My wife and I talked about having a generator several times over the years, but decided against it for several reasons, a couple of which you mentioned. Generators aren’t the “solve-all” answer to grid failure that some people seem to think. Just ask the spouse of a local first responder.....you may find them out yanking on that starter rope in the rain while the better half is out saving the world for everybody else. We decided instead to find ways to do without electricity during grid failure, and even now that I’m no longer with the power companies, we don’t see any reason to change. But, unannounced grid failures aside, and bending back around to planned power outages, brown-outs, or black-outs, your being off-grid to begin with shouldn’t affect you much at all. Or will it? CD in Oklahoma -

Keeping A Sewing Shop Going During Grid Outages

cdthayer replied to cdthayer's topic in Leatherwork Conversation

CaptQuirk, since you’re off-grid and do leather work, do you use a sewing machine to sew your holsters, or do you just sew by hand? I envy you being able to live off of the grid, but I don’t want to join you. Off-grid living can be a lot of work. And after spending most of my adult life working to keep the grid up and running (ex-highliner), I have no desire leave it. I’m concerned with continuing my lifestyle if the grid leaves me for some reason. CD in Oklahoma -

Keeping A Sewing Shop Going During Grid Outages

cdthayer replied to cdthayer's topic in Leatherwork Conversation

I had a gas station back in the 70s, and yea, when the power was out, I was pretty much out of business. I had a manual cash register back then, but couldn’t pump gas to need it. There were few portable generators in use back then, and I certainly didn’t have one. Credit cards were recorded on “knuckle buster” manual carbon copy stamping machines, so I could take cards, but I seldom did because I couldn’t pump gas. Today, with a fabric and sewing shop instead of a gas station, we have an electric cash register, but can open it manually to make sales. During a power outage, we use a battery-powered calculator to add things up, and we write everything down on paper to ring up later, but there’s usually not much selling going on during those times. The shop gets too dark to see good for shoppers, so they don’t usually hang around for long. If the cell phone tower is still on, we can take credit cards with our smart phone, but usually there is no need. But, we have continued sewing during power outages a time or two. The machines that we normally use are mostly electric, but we have a couple of hand crank machines standing by to use if we want to wait the outage out. One’s a straight stitch and the other is a zigzag (sewing clothing mostly, not leather). We roll a small table with one of the portables on it over to the front windows to take advantage of the daylight to see. I have my Singer 29K70 on wheels and it’s totally manual, but I’ve never been caught using it when the power went out. Although, there have been times when I have wheeled it out onto the front sidewalk to sew things when I had something really big or really dirty to work on. I’ve done the same thing with our electric Consew 225 on wheels (when there’s not an outage). It is good advertising. People going by really notice it, but then we’re in a small rural town and it may not work that well in other places. I have noticed several online tourist videos of small sewing shops in foreign countries that have their manually-operated machines out in front of their shops. Like some of the video posters, I too wonder if it’s for better lighting, or to advertise their service, or both. A lot of the sewing that I do at home (both treadle and electric) is done out on the patio for several reasons; because I don’t have room inside, the natural lighting outside helps to see, or the object that I’m sewing is dirty enough that I don’t want to get dirt and debris inside of the house. I don’t get much advertising here at the house if I’m out where I can be seen from the street. Hardly anyone ever comes by while I’m out there. CD in Oklahoma -

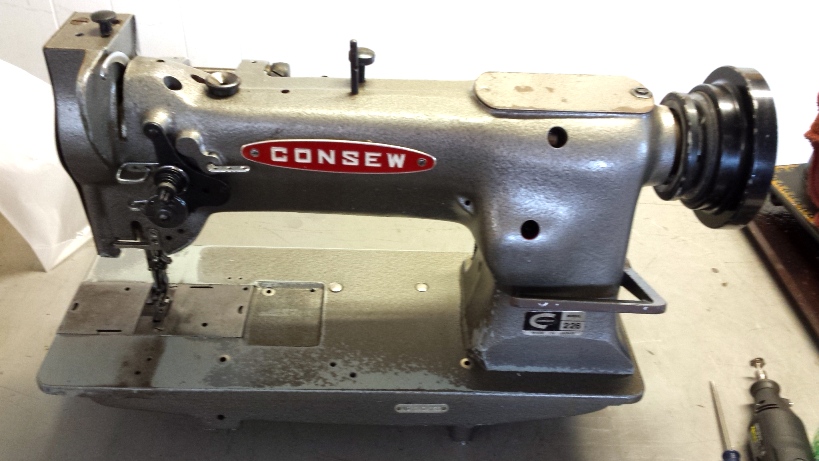

My daughter’s Consew 226 looks a lot better with the correct balance wheel on it that I got from Gregg. I gave it a spin in my Singer Industrial Treadle Stand and snapped a photo of it. It should make a nice machine for my daughter, once she gets it mounted into her K-leg power stand, and gets the new servo motor that just arrived from Bob hooked up to it. She’s still re-arranging her furniture in an attempt to get her machine worked in with the common “too much stuff - too small of a house” problem, so no telling when it may actually get to sewing, but it’s ready for her. Thanks to Leatherworker(dot)net for having such good Vendors on-hand to introduce me to. Gregg and Bob have been great to work with for these parts. I may never have met them if it hadn’t been for this forum. CD in Oklahoma

-

Keeping A Sewing Shop Going During Grid Outages

cdthayer replied to cdthayer's topic in Leatherwork Conversation

Since wide-spread electrification has been around in most areas of the USA for over 75 years now, I would imagine that most folks running a sewing shop today (in most industrialized countries) would probably consider a generator first to keep their shop running if need be. I doubt that many sewing shops keep manually-operated machines around in case of grid problems (other than me, maybe). Except for the guys with old Singer 29s or a Tippmann Boss, I’d imagine that there are few manually-operated sewing machines in use (or even standing by for use) today. What do you think? Those that don’t have a shop, but make all or some of their living with a sewing machine are welcome to add their comments please. Some of the Singer 29 users probably have motors on their machines, even if the manual equipment is still mounted on the machine. One of mine came to me with a motor on it that I took off. Everything was there to convert it back to manual operation, so I did. I just wonder how many, if any, would scramble to convert their old motor-powered 29 back to manual operation during grid failure, and what the conditions would have to be for them to do so? That’s why I was wondering if anyone had been through planned/scheduled blackouts before, or if they knew of anyone that had. Here in rural Oklahoma, some of the gas stations and Quick Stops keep a portable generator handy for power outages that they know will happen. They just don’t know when. Nearly all of the emergency response agencies around me have generation for them to continue operation during an area-wide outage, but I don’t know about the other retail and service shops. I’d say that most shops just close up and send everyone home to tend to their outage management issues at home. I’m wondering if most leather sewing shops would do the same? I probably should add that my wife and I have never owned a generator, and don’t plan on getting one. In our 40+ years of marriage, living in several different rural areas in two states, have not ever suffered enough power failures that caused us to discard enough spoiled food to buy even the cheapest portable generator. We’ve always had at least one freezer full of food (sometimes two), and a full refrigerator, so it’s not like we didn’t have anything to lose. We’ve always cooked most of our meals at home, and always keep a generous supply of fresh and frozen foods on hand. And for many of those years, I had a gas-powered generator on my work trucks for the 29 years that I worked power lines, but they never powered anything at my home. They, nor I, were seldom home during a power outage most of those years anyway. Anyone else have a “grid problem plan”? CD in Oklahoma -

I don’t believe that it’s a repaint. I think that machine is called a Singer 66-18. The crinkle finish makes it a dash 18, and I think that it came out of the factory that way. The model before it that had the “Japanned Finish” (glossy black) was a 66-16, the only two versions that I know having had a back-tack. It dates back to the late 40s and early 50s. The crinkle finish was very popular during that period of time, on all sorts of metal things, especially equipment/tool boxes. Not only did the public think that the finish was really cool, as far as I know, the finish was cheaper and easier to apply during those years after WWII when everyone was trying to recover from the war. Nice machine. I have one, but converted it to treadle/handcrank operation by substituting a spoked balance wheel. As far as I know, this version of the model 66 (the 66s were called the “Twentieth Century Machine” since it first came out around 1900) didn’t come out much as a treadle or hand crank, if at all. Electrification was fairly wide-spread by the time the dash 18 became the current version of that model. Mine dates to 1950. Yours is probably earlier because of the style of bobbin winder. CD in Oklahoma

-

Is there a list of the Leatherworker(dot)net advertisers somewhere, or do we just have to try to catch them on the banner rotation? CD in Oklahoma

-

Keeping A Sewing Shop Going During Grid Outages

cdthayer replied to cdthayer's topic in Leatherwork Conversation

I just noticed that I missed getting this thread started in “Leatherwork Conversation” forum, so my apologies to the “Purses, Wallets, Belts and Miscellaneous Pocket Items” forum folks. Maybe Administration can move it please? A large standby generator would certainly keep a shop going, but unlike a home, would the expense be justifiable for just a workshop, especially if the workshop was not part of the home nor near the home? I wonder if sewing shops in those places where planned blackouts have occurred used even small portable generators to supplement their power needs? CD in Oklahoma -

Have any machine users had to deal with rolling blackouts like they were having in Venezuela recently and in some states back a few years ago, where they shut your electricity off for a period of time each day? Are there any members of this site in Venezuela, or does anyone have contact with someone who is there, or in another country where the problem exists? I would like to hear how they’re coping with trying to get some production done with the power going off so often. If the shop is equipped with manual-operated sewing machines, the sewing might continue but lighting and possibly heating/cooling or ventilation would still have to be provided. But is there even that much business in most sewing shops during the times when electricity is intermittent, especially during economic hardship like in Venezuela? Do you think that regular rolling blackouts could ever effect your shop location? Have you thought about what you would do to keep your operation going? Would you want to or need to? If you have electric machines, could you sew during power on and do some other task during power off? I’ve assembled a group of manual machines that can do the job of most of our electric machines in our little sewing shop (wife and I), but I don’t know if they will be of any need for that use. I don’t know if people will still need much sewing done under those conditions or not. I suspect that all of my treadles and hand cranks exist mainly just for my own amusement. We’ve used our manual machines for one outage in 10 years, and only because we had a hint that the power would only be off for a short time, and it was. Otherwise, we close up and stay closed for the longer outages like the 5-day ice storm last December. Except for the kids in cars and pickups that were playing on the icy streets, most people stayed home like we did and waited for the ice to clear off and the power to come back on. We did get five days worth of quiet sewing done on our manual machines at home, but it was sewing our own things. CD in Oklahoma

-

Didn't the Old-timers call the -64 needle-feed style a "jump foot" machine? CD in Oklahoma

-

31-15 Roller Foot Conversion--parts don't add up!

cdthayer replied to oxeyenyc's topic in Leather Sewing Machines

I have roller foot #12264, needle plate #5709, and feed dog #5708 on my 1939 Singer 31-15, and it works just fine. I made no changes to the presser bar position. For what it’s worth: I had a problem putting the same combination on my 1936 Singer 96-40 machine, and finally determined that the after-market lower thread guide (on the needle bar) stuck out and interfered with adjusting the roller to the dog. Since then, I’ve turned the 96-40 into a darning machine with a different Ft/NP/FD combination on it, but now know why I was having problems with the roller. CD in Oklahoma -

Thanks for responding Gregg, and I appreciate the parts book. The short reverse feed levers on mine don’t appear to match either of the two levers in the parts book, so I’m going to have to study the differences between the actual mechanisms. I was hoping that photos might help in the identification, but you probably need to see under them. I don’t really need to know more about the age of my machines. I was just curious if they were Seiko or something else. I’d say that they were made some time between 1960 and 1982, because I have the 1960 issue of the Consew “New Industrial Sewing Machines, Parts, and Accessories” and while the 225 was in the lineup as the newest thing, the 226 wasn’t even mentioned. My wife and I have depended on our 225 for the bulk of our combination feed sewing for the past 10 years, and will probably continue to do so. We do mostly just alterations and repairs, and it’s been an excellent machine for that purpose. I’m going to need to get a balance wheel for my daughter’s 226 machine and then it will be ready for her. Later on, I’ll see what the other two are going to need. Thanks again. CD in Oklahoma

-

I’ve come up with three old basket-case Consew 226 machines, and would like for Gregg or someone else to expand a little more on identifying the differences between the older and newer machine castings. I don’t know what the “'old style' reverse that dates back the '60s” looked like, and since parts are so readily swapped from one machine to another (even from Singers), I’m hoping that the castings will help date them. Ignore the balance wheel on the first machine (596). It’s not the correct wheel, and causes the belt to rub the near side of the belt slot. The power stand that it was in has a “smoked” black spot on the side of the belt groove where it was rubbing pretty hard. It rubbed on the belt slot of my treadle too. The set screws are inside the belt groove (three set screws and a fourth oil hole), throwing the belt groove too far to the left when positioned for the set screw to be on the “flat” on the upper shaft. There is not a “'notch', or flat above near the take up Lever” on this machine, but more of a domed or rounded area. It has a large reverse lever, but those can be swapped out too. Does the domed vs flat area mean that this machine is newer than the ones with the flat area? Serial number is WB8404192. The second machine (597) with the narrow wheel has two set screws in the belt groove, a flat area above the take-up lever, and a short, stubby, more plain reverse lever. Serial number is MH6404073. The third machine (598) with the narrow wheel (chipped deep into the belt groove and not useable) has two set screws in the shoulder of the wheel to the left of the belt groove (like my Singer 111s). Maybe it’s got a Singer wheel on it? And it too has a flat area above the take-up lever and a short, stubby, more plain reverse lever. Serial number is WB6907098. All three machines have tags on them that only say “226” without any “R” or anything else following the numbers. From what I understand, all of the Consew 226 machines had reverse. The first machine (with the wrong balance wheel) test sewed good after adjustments (in my treadle, on a pair of insulated coveralls) and will go to my daughter in OKC. She has one of the two power stands that came with these machines. It will need a servo motor. She’s active in a Chevy “square body” club, and has expressed an interest in learning about auto upholstery, so I’m trying to help get her going. I’ll keep the other two and see what I come up with for me (maybe one good machine out of the two?). CD in Oklahoma

-

This machine doesn’t have the slot for the reverse lever, but your idea would work for one that did. This one just has a lever attached to a shaft on the right end of the machine, and has a spring inside the pillar to hold the linkage in the up position when not reversing. I never have grown very fond of machines that have reverse levers or buttons that need to be held while backtacking or sewing in reverse (mostly domestic home-use machines, but some industrials). I prefer the ones that have a lever that will stay put until I’m ready to move it and sew the other way. I think my daughter’s power stand has a peddle rigged up on it to activate the reverse with a foot, so she’ll be ok. I’m having my problems because I’m fiddling with it in a treadle stand just to play with it and make sure it sews well for her. I have a couple of power stands that I could try it in, but I’m just having too much fun with it in the treadle. Vinyl and woven upholstery fabric can be sewn with the 226 fairly well in a treadle. Maybe I can hang a pork chop from the lever, and train my little shop dog Rex to take a bite from it when I need reverse? That would take some serious training, and I don’t know if either one of us is up to that.... CD in Oklahoma

-

As to LoveToLearn treadling and cranking.... Have you found a treadle to use with your machine yet? And a spinner knob for cranking it? I’ve been test-sewing an old Consew 226 that I’m setting up for my daughter (she’ll use it in a power stand for upholstery) using the bobbed-off Singer treadle shown in photos of my earlier post. It will work fine for vinyl and woven fabrics while in the treadle, except I’m having trouble with the reverse feature. It’s the first reversible machine that I’ve tried to use in my treadle. I guess I need to rig up a webbing strap to use my toe on the reverse lever, or something else. It gets real busy when starting a stitch line, because it’s tough to hold the threads with my left hand, turn the balance wheel with the my right hand to make sure that the machine turns the proper way, and hold the reverse lever down at the same time.....Maybe a parachute cord from the lever down under my right leg and back up to my teeth. Once the stitch is started, I could spit the cord out.....(spputt) CD in Oklahoma