-

Posts

483 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by cdthayer

-

"Make America Great Again" and the leather trade

cdthayer replied to TinkerTailor's topic in Leatherwork Conversation

Before we get too far away from the original thread label of "Make America Great Again" and the leather trade, I have a question for the production people (I’m not in production, just repair and mending). I read an article the other day that suggested that the Baby Boomer retirees are causing the luxury item industry to branch out into travel and amenities. It seems that the current retirees aren’t spending as much of their money to buy items, but more for services these days. If so, I’ve wondered if the custom leathercraft community has seen a real decline in “retirement spending” for their high quality leather items? On a side note, I had a police officer come into the shop the other day to get some minor repairs done to his duty rig, and I remember commenting to him at the time that there wasn’t one bit of leather on the entire rig. Everything that used to be leather on a rig was a man-made material of one kind or another on his. He said it’s what officers are mostly using now. The increased non-use of leather for traditional applications has got to be hurting the leather industry. CD in Oklahoma -

Check your upper threading again. Better yet, take the upper thread completely out and re-thread it. Something as simple as missing the check spring when threading can cause missed stitches. CD in Oklahoma

-

What's the sub-number if your Adler 205? Grab a third needle and try it to see if it makes any difference. CD in Oklahoma

-

"Make America Great Again" and the leather trade

cdthayer replied to TinkerTailor's topic in Leatherwork Conversation

I think that it’s totally possible to build new infrastructure from the ground up. The USA has done that a lot of times, all over the world. (Think of the various countries that we’ve blasted back into the dark ages over the years and then rebuilt them.) And when thinking about building new infrastructure in America today, I wonder if the thought of “high tech” sometimes clouds our perspective of what can be done. If we’re going to rebuild our infrastructure, do we have to use the latest technology to do so? The geeks that buy and sell stock for some of us 401K people seem to think so (do those stock traders grow any vegetables or ever get any dirt under their fingernails?). Caterpillar Company stock was down before the election, and now it’s showing good gains with all of this infrastructure rebuild talk. It only takes one guy/girl to run a large piece of construction equipment to move a mountain (and a bunch of dollars to pay for the equipment) nowadays, but can the same results be made using lower tech and more people? Can we put people to work using old technology? Think back to the days when my Grandfather worked on the WPA project in southwest Colorado. He milked his cows before daylight, saddled up his horse, rode several miles to the bridge project, and did some kind of work (I don’t have a clue what actual work, but it was surely hand labor), rode his horse back home after work, milked the cows, and then soon turned in for the night. He got up the next morning and did it again. The guys that hired out their teams to move dirt, and the guys that herded their sheep back and forth to compact the fill dirt probably camped near the project most nights while their wives and kids did the milking. I don’t think that we can go back to horse-drawn equipment to build bridges and roads, but do we have to use the latest technology in earth-moving equipment? And it occurs to me, that the place where we have the largest shortage of workers is in the agriculture field (ah, growing food) where the farmers can’t seem find enough workers to harvest their labor-intensive crops. I’m sure that some enterprising individuals have came up with lots of ways to harvest those crops with machines, only to be told that their “high tech” solutions are too expensive, so the low tech method is still preferred. Is there a way to make those labor-intensive tasks more desirable to our young workers that can’t seem to find a decent job? It’s going to take more than a YouTube video saying how “rad” it is... What about the leatherwork that you do? Do you consider it high tech? Sure, maybe the machines that you use today are the latest in sewing machine technology (not me, I have old iron), but aren’t you still using mostly the same technology to cut and tool your leather that has been used for decades? Old technology? Old tools are prized, right? When you look at all of the tools that you use to create a design on leather, does it ever enter your mind that there is a high tech way of creating a design on leather using an electric motor to feed a piece of leather through an embossing machine and get a design imprinted on the leather? Of course not, that stuff is garbage, and not real leatherwork/too easy/not my style. Craftsmen are craftsmen, and usually by using old proven technology. How do we get the population to recognize craftsmanship again? And can old technology be combined with craftsmanship, giving our citizens pride in accomplishment, to rebuild the American infrastructure? CD in Oklahoma -

"Make America Great Again" and the leather trade

cdthayer replied to TinkerTailor's topic in Leatherwork Conversation

Trump campaigned that he would concentrate on building up the American infrastructure. Global markets caught that, and I see this morning that copper and other commodity metals are seeing yuge gains world-wide. An aluminum maker in Russia jumped by the most on record, making me glad that I began stock-piling cast iron (sewing machines) and aluminum (empty beer cans) a decade ago, back in 2006. I think that the transportation industry will eventually take itself out of the equation, as the west coast strike a while back, and the Hanjin problems recently, seem to indicate how fragile the “just in time” delivery system really is. CD in Oklahoma -

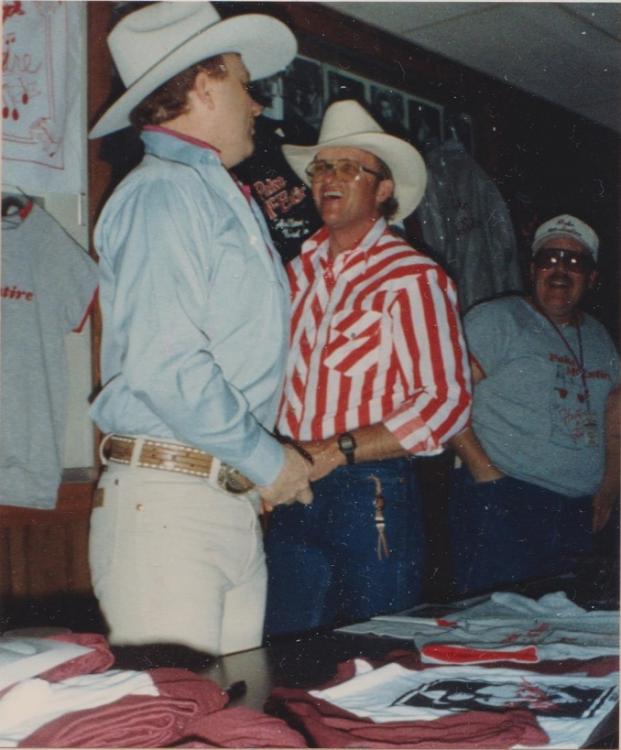

Ok, even though I’m not calling it my “specialty” now-a-days, I do claim to have tooled leather back in the 1980s. I did, and here are some old photos from back around 1987 (29 years ago) of a belt that I made for Pake McEntire (Reba’s brother) and presented it to him at the dance hall one night in Foss Oklahoma. He liked it! And he even wore it for at least one set of his performance that night (I was too busy dancing with my wife to see if he wore it for all of his sets, but I have one photo of him on stage wearing it). Ah, those were the days...... CD in Oklahoma

-

New to industrial sewing machines Juki LU-562

cdthayer replied to jshep's topic in Leather Sewing Machines

I agree. CD in Oklahoma -

Oops! You are correct. I should have said “I don’t consider any of my 15 machines as industrial, but they’re not bad for really light leather work.” Sorry, I was thinking of the common household-use 15s when I made that statement. CD in Oklahoma

-

I don’t consider any of the 15 machines as industrial, but they’re not bad for really light leather work. I fixed up my only Singer 15-30 with a handcrank for a friend of mine to use for sewing thin leather wallet interiors, and it works great for that. I’ve got a bunch of beater 15s on hand, but I don’t ever do anything with them (2 15K80, a 15-88, 2 15-90, and 9 15-91s). Few if any of them are “pretty”, and the majority of the 15-91s need to be rewired. I may eventually do something with the 80s and 88 since they have spoked balance wheels on them, but I’ve been into hand or foot-powered machines for the last few years, and don’t want to do the electrical work on the 91s anymore. This area is saturated with 15-91s and 201-2s (I’ve got 4 of those too), so there isn’t much call for them locally for any kind of sewing. I see on Craig’s List and eBay a guy down in north Texas converting 15-91 and 201-2 machines into handcranks with his own design of a crank to use for light leather work. They’re a one-to-one crank ratio per stitch like some folks don’t care for, but for small light leather work, I can see them being very productive machines. I have several of my machines set up to handcrank on a 1-to-1 ratio, including walking foot machines, and for the mending and repairs that I do, they work just fine. CD in Oklahoma

-

Unsewing tool aka heavy duty seam ripper

cdthayer replied to hackish's topic in Leather Sewing Machines

Good idea, Tinker. CD in Oklahoma -

Thanks machinehead. I think that you’re right. I haven’t ever run into those models before. I think Singer “cut a fat hog” when they bought W&W. Singer got a bunch of great heavy old iron with the W&W designs. CD in Oklahoma

-

I have seen two Singer 115 machines in my area, one that I have in operating condition with a hand crank, and a rusty one that I’ve been soaking with oil since October 2014 hoping to get it going again. (Not that it takes that long to get it freed up, it’s just one of those projects that got put way on the back burner and buried out of site. I’ll get back on it one of these days.) I have never fell into “like” with my 115. I don’t know why, but I don’t care much for any of the 15s for some reason. Just a “thing” with me I think. I’m trying to get over that with my like for my 16 that I just got. While I don’t use my 115, it’s interesting to me because it has parts of two different decal sets on it (Paperclip decals on arm and bed, knots and rectangles on the border.) It’s obviously a rebuilt machine, but I’m curious about who did the rebuild, and amused at the decals. CD in Oklahoma

-

Keeping A Sewing Shop Going During Grid Outages

cdthayer replied to cdthayer's topic in Leatherwork Conversation

Slip a small piece of wire in with it if it doesn’t clamp good. You can bend the wire for a tiny handle that stays out of the way while aligning the needle eye and in use. You’ll just have to figure out where to put the wire to make the needle align where it needs to be. I wasn’t aware that the Chinese Patcher used 15x1 needles. That’s interesting. Thanks for chiming in. I was sure that there are sewers (sewists?) having to deal with intermittent electrical service trying to get things done. Welcome to the forum. I would like to hear any “war stories” that you may have while trying to complete a sewing project when the electricity suddenly goes out. CD in Oklahoma -

Good advice if you use your machine regularly, but be cautious if you’re in a high humidity environment (like Oklahoma) and only use your machine sporadically or put it into storage. Unless the fabric is totally saturated with oil, and even then, sometimes the oil has enough evaporation that the fabric can absorb moisture out of the air and rust the needle plate, foot, and even the needle. CD in Oklahoma

-

I agree. It gives the oil time to leach where it needs to go, and any excess can get drained off for a wipe-up. Test-sewing the machine on a piece of scrap to avoid oil contamination on the work also confirms that the machine is threaded right and the tensions are still set good. I got to use my Singer 16-41 to make a little income for me yesterday. I sewed a badge holder onto a winter jacket that has a squirmy lining inside of it. CD in Oklahoma

-

The face plates look kind of like a W&W D-9 and a Singer 9W, but did they have those models with knee-lift presser bar linkage on the back of the arm? Also, it looks like only one of the machines has decal decorations on the inside of the pillar. I don’t see any trace of decals on the other machine pillar. Are you referring to the Singer 115? CD in Oklahoma

-

Singer 114W103 Chainstitch Embroidery Machine

cdthayer replied to GPaudler's topic in Leather Sewing Machines

I have an older blue Singer 20U machine that only has the linkage for raising the presser bar, and I have a blue Singer 20U33 that has both linkages. I don’t know what model they added the second set of linkage for swinging the needle bar with your knee. And for what it’s worth, I don’t actually know what my old 20U is, whether it’s just a “20U”, a 20U11, a 20U13, or something else. It has a label on it that simply says “20U”. CD in Oklahoma -

Interesting. I learned something new. CD in Oklahoma

-

Could they be a nipper and crimper for small telephone wire work? CD in Oklahoma

-

Walking Foot Material Feed Problem -- Shifting

cdthayer replied to JJDD's topic in Leather Sewing Machines

Is that a new machine or an older one? I’ve got a worn 1959 Singer 111G156 that doesn’t like to sew thin materials. It kind of turns the work curving the stitch line, and has even puckered the top layer at times. I found out that the inner foot was not lifting cleanly off of the work before starting its movement forward and lightly drags on the top layer. It may just be an adjustment, but it’s got a lot of slop when I wiggle the foot, so I think that it’s wear. The machine sews fine on thicker or firmer materials that don’t seem to be affected by the light drag. CD in Oklahoma- 20 replies

-

- edgesewing

- materialfeed

-

(and 2 more)

Tagged with:

-

Good advice TinkerTailor, but I’ve learned that a little oil goes a long way, and too much tends to just attract lint and dirt build-up. Now that I know what things look like inside the head on this one, it’ll be easier to feel confident that everything gets oiled from the access holes. I use a syringe with a long needle to draw oil out of a bottle and direct it to the points in the machines. Later on, I’ll still be popping the face plate off once in a while to clean out the lint, and give everything personalized oil attention then. I’ve found that if I raise the take-up lever to its highest point on a lot of machines, the oil points tend to line up the best with the outer oil holes. This one looks like it’s going to be the same way. I have an old broom in my shop that has small enough straws on it to fit my relatively small needle eye holes (lots of 18s and 20s in my shop). I align the needle eye with a straw in it, and then save the straw when I can. Sometimes they get away from me and I have to go to the broom for another one. My broom should last long enough for me to expire. And I have a good excuse to not sweep anything with it..... I learned something else about this 16-41. I think it’s got a substitute needle bar in it. It’s missing the thread guide that rides on the bar at the needle clamp, so I dug around in my parts and found a guide and mounting screw. But the needle bar travels up into the head to where the screw hole almost disappears, so the screw interferes with the bar travel. That’s why there isn’t a thread guide on it. So, I’d say that the bar came out of a different machine. I’ll dig around and see if I can find a good needle clamp that has a thread guide built into it, or just leave it like it is without that guide. It will sew fine without it. One thing about firing these old machines back up, is that they’ve sometimes been a lot of places, sewn a lot of things, by a lot of operators, worked on by a lot of mechanics, and had a lot of parts replaced. Sometimes, the “proper” part wasn’t available, so a substitute was made that worked. That’s what mechanics used to do. You never know what you’re going to run into on the old iron. CD in Oklahoma

-

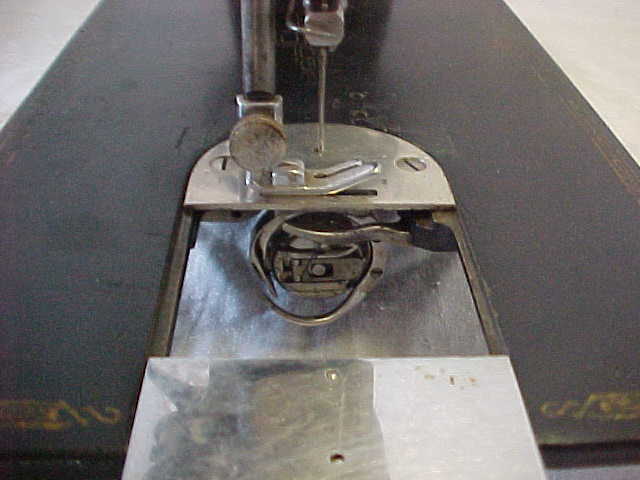

OK, I removed the face plate on my 1917 Singer 16-41, and here’s the scoop... There are only three screws attaching the face plate instead of the “4” that I mentioned earlier. Nothing can “fly out” of the head when the face plate is removed, but be heads-up, the presser bar hand-lift lever can fall out if the outer foot linkage is allowed to swing outwards. The lift lever simply pivots on a round stub, and the foot linkage keeps it on that stub. The face plate keeps the foot linkage from swinging out. I reset the needle bar height with the needle clamped in the proper position while I was in there. The needle bar clamp is the type of clamp that has one center screw that is accessed through a hole in the head casting under the arm. Straight access to the screw head is provided when the bar has reached BDC and came back up to intersect with the hook. With the needle plate off, the hook and needle are plainly visible to set the bar height. There’s no scarf on the Organ 16x63-18 needles that I got to use in it, so I just eye-balled it with the thread hole in the needle. It test-sewed just fine. Everything in the head looked good, but a few things didn’t get oil when I oiled from the outside. Next time I’ll give it more oil to make sure that it leaches to everything that needs oil. I just hate putting in too much and having oil running down the feet and needle, so I try to oil sparingly. All of the rollers are free-turning and don’t show any flat spots, so I think the machine has been well maintained even though it looks like it has been used pretty hard. I appreciate the past owner or owners for breaking it in for me. It really turns over freely. Just what I need for treadle operation. CD in Oklahoma

-

Interesting. A Singer 31K with an inlay medallion in the bed. CD in Oklahoma

-

Interesting old photos. Thanks for showing them. Any idea what models of machines those are? One looks like a Wheeler and Wilson, and the other one is a Singer, but what model? CD in Oklahoma