-

Posts

2,706 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Frodo

-

I sent you a right and left foot both have heat shrink on them

-

I found the lever to raise the foot on the backside of the machine a total pita my patcher came with 2 thread tension disc assemblies, I removed the one for the bobbin winder and drilled the hole out 1/8” Handle modification

-

accessing a gun on your hip from a seated position is very difficult. With a chest rig you can plow the field and kill the snakes without having to stop gun sits center chest. This rig is left hand or right hand , fully adjustable

-

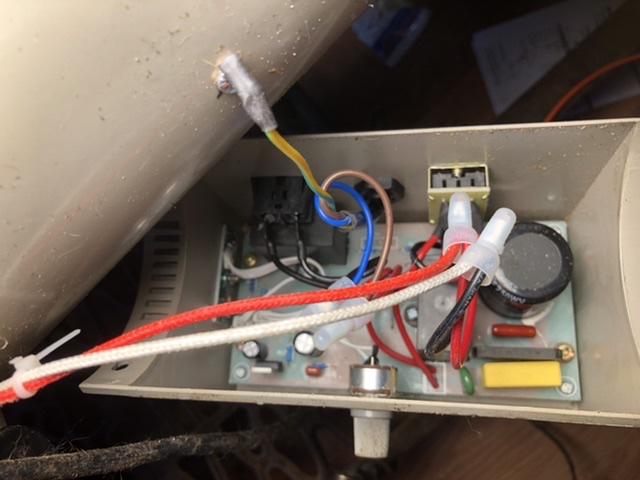

The white wires on the left is the magnet scanner black to the right of that is a 120 outlet to the right of that is forward / revesef

-

The Enduro servo uses a magnet on the linkage arm that passes by a sensor I personally do not like a sensor type of control I want to keep the forward/reverse and the potentciomentor (sp) or rpm selector I would like to bypass the magnet control and hook up a simple foot pedal instead of dealing with linkage piccture of the inside of control box in a minute

-

Servo set at 350 I want to go very slow around corners and such as that 30 per minute or less

-

looks like according to the calculations 2”” then a 6”” next to an 8”” that goes to a 6” and the machine is 3”

-

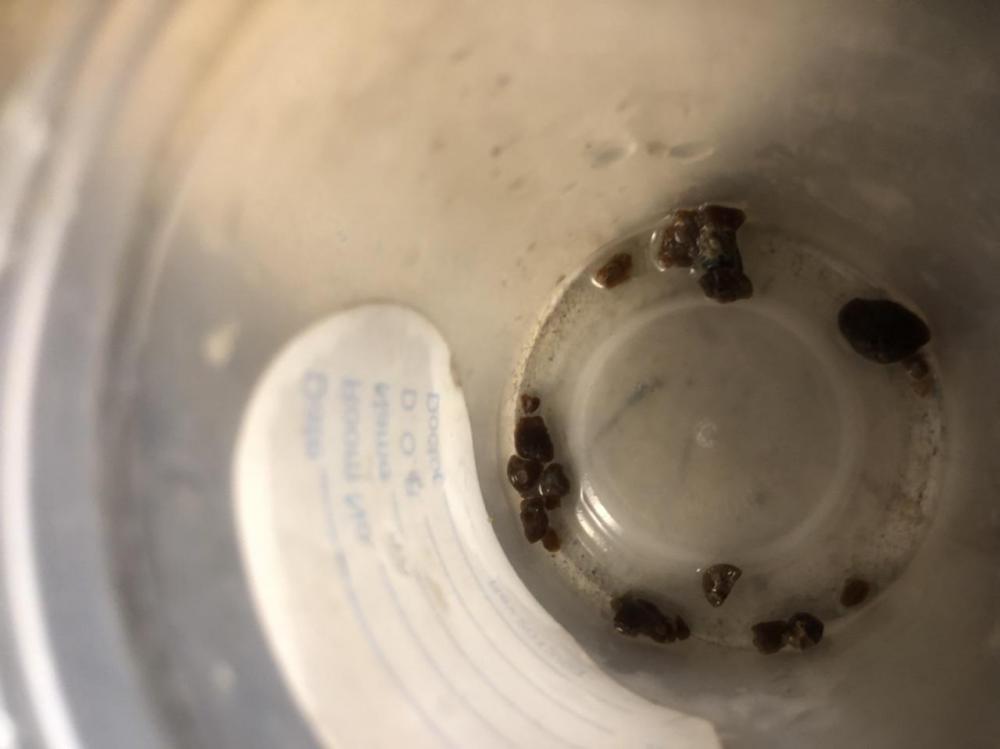

Thank you kgg could not get back yesterday I was at the hospital giving birth to kidney stones

-

My servo pulley is 2” the jack shaft has a 5” pulley on one side with no pulley on the other the machine head has a 3” pulley on it if I set the pulleys up in this order servo2” 5” jack shaft X size jack shaft To 3” head pulley would X pulley need to be 2”? if the slave pulley (x) is larger than the master (5) would that defeat the of rpm?

-

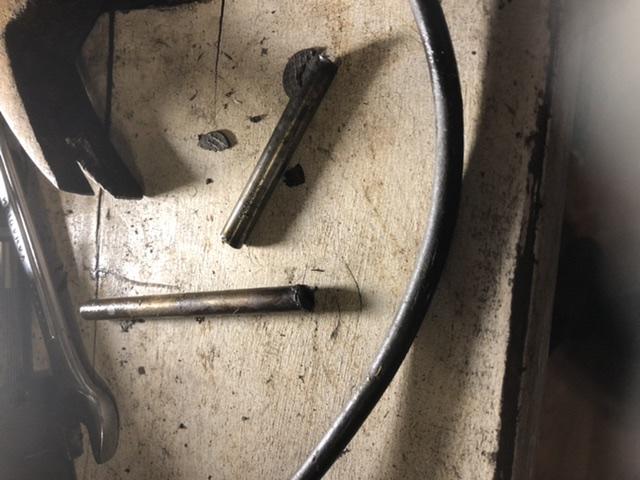

Got it out, I am not a sewing machine technician by ANY means. This was hard. Tried oiling and penetrating oil over nite nope Tried heat, NOPE Drilled out some angle iron, drilled holes and inserted all thread. Tightened the nut and push the bar up NOPE so I cut it in 3 pieces, chamfered the middle piece and used it as a drift pin to drive the top piec out HURRAY !!! It is out

-

Update Road trip yesterday and we picked up the Rex. The machine was froze upthpe whelk would move about a 1/4” Brought it home and poured penetrating oil all over it. Then removed the needle bar cover the needle bar seems to be bent like something dropped on the machine. I disconnected the needle bar and the machine will make revolutions so, question is how am I going to remove that needle bar? Bent at the top I am thinking about cutting it in half and going that route. Suggestions?

-

It is not tapping out, I suspect that whoever removed the spring may have installed the pin backwards or the wrong pin. When Wiz first said it was a drift pin I was concerned. The head of the pin on both sides was mushroomed making it difficult to determine which end to tap I removed the mushroom. And have tapped the pin with sharp taps i will heat it after the sun comes up and I grab my torch off of the truck

-

Ordered some parts. Shout out to Bob the drift pin seems to be a bit stubborn so I ground down what looked to be mushroom on both sides tje front side shows signs of slight movement How much “whooping” will this u bracket attached to the needle bar withstand? should I stop and drill the pin out or just go full gorilla on it?

-

Nice detail on how to fix the problem looks like I am going to be replacing some parts

-

Whats your recommendation new paddle spring ot new paddle spring and needle bar? on a chi chi patcher, removing that assembly is pretty straight forward is it comparably the same on the 29k?

-

-

-

EC 974118 is on the brass plate directly below the 29k62 brass plate picture of the top adjustment below are 2 pictures, one at the top of rotation. The other at the bottom of rotation

-

-

Mod, video did not upload correctly please delete it from this thread to avoid confusion

-

Shouldn’t this thread loop be taunt ? if so, how do I adjust it? IMG_3850.MOV

-

Mostly compact 380’s I am using chrome tan and foam padding for 2 reasons, stop. Chemical reaction and the foam is a selling point, it hides the outline of the firearm

-

Happy Holidays where ever you are from and what ever you believe or do not believe Happy Holidays, may this day in your life be filled with laughter, love, kindness, and good company Brian aka Frodo

-

I am starting to see a trend around my area and am wondering if any of you are seeing it also. The younger concealed carry crowed are asking me to make a pouch like holster that looks more like a cell phone holder or a old school Fanny pak to carry their gun instead of a traditional holster. Are you experiencing the same thing?

-

Gary, as a rifle or 4 owner I have to Say I say I apreciate the fact you are using a strap on one end that is not connected to the shoulder piece, why? That strap is a week point. The fold around the attachment hardware is a spot that can and will split by making it separate you have made it easier to repair, that is a good detail