-

Posts

2,706 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Frodo

-

My enemy my friend tension how to achieve a happy middle ground. just when I thought I had this cat by the tail up pops tension issues my understanding of. Tension is pretty straight forward, both threads should be equal . Only problem with that is my idea of equal and my machines idea of equal are not the same asking for tips, tricks, and knowledge 69651400628__DC6CBB51-4C4C-463C-AEA2-992236EECA79.MOV

-

When a woman says the word friends hit the door and do not look back period. No discussion, she had put you in the friend slot and you are not getting out

-

A trick for aligning pillow blocks do their is no bind no adjustment, set it and forget it insert a 3/8” nut into the shaft. Tap it in insert a 3” long 3/8” allthread and a lock nut chuck the all thread in your drill, as you are positioning the pillow blocks keep the drill turning at a low rpm the pillow blocks and bearings will align themselves.

-

-

My lowest speed is great for tight corners 2” pulley on motor drives an 8” pulley on a jack shaft with pillow blocks. This drives a 3” pulley up to the machine on a 6” pulley which is sandwich mounted on the hand factory wheel 69647670839__BF295F46-A9A7-425A-B7B1-2E094B2BD0D9.MOV

-

Thanks for the words i know enough to be dangerous anything else that happens along the way is pure luck and s surprise

-

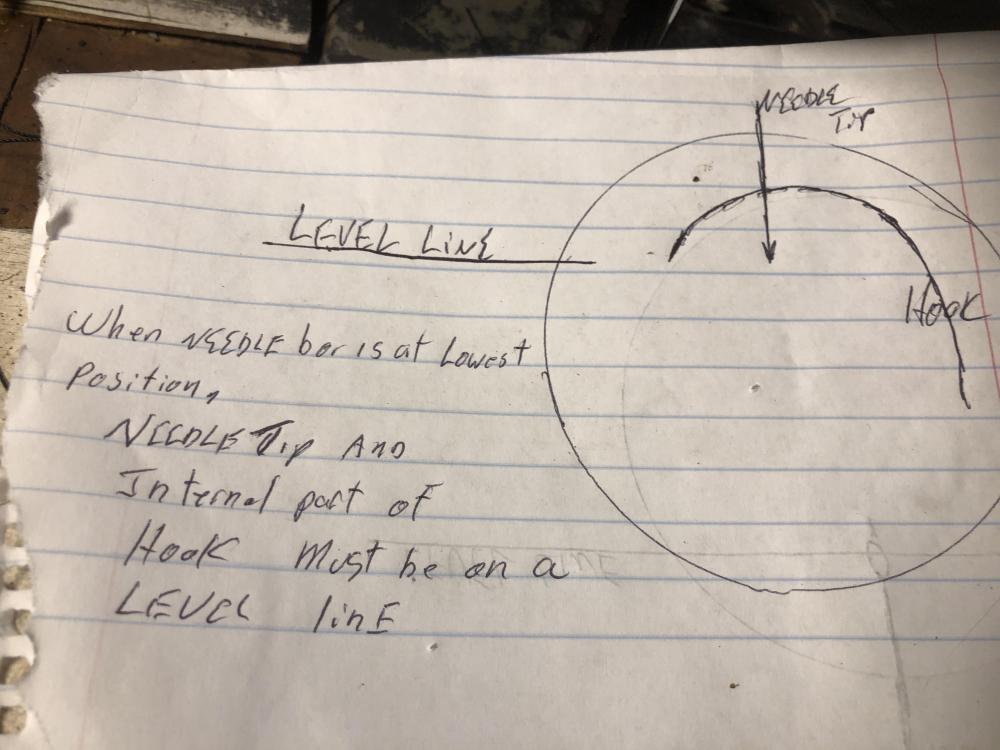

Man Ii hate not being able to edit here is the whole wording from the manual when needle bar at its lowest position, needle TIP and internal part of shuttle hook ( inside diameter of hook/ bottom edge) must be on level line. when needle bar is raised and hook point of shuttle comes on the center line of needle a distance between hook and EYE of needle must be 1.6mm. / 1/16”

-

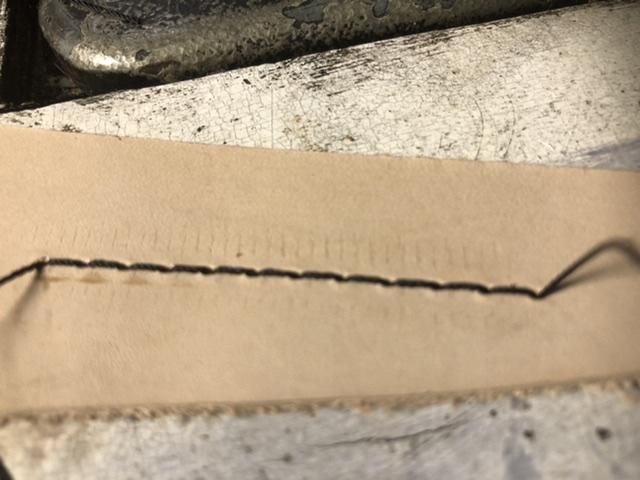

I am not saying What I did is perfect or right. I followed what I think the wording of the manual says when the needle is at its lowest position the TIP of the needle must be on a level line with the bottom of the hook when that is achieved then the next paragraph becomes true I was asked to show the tension using different thread colors Top black bottom green

-

I think I got the timing correct and moved on to tension here us what and where I am at now Top bottom

-

Shat Back to the rats nest again

-

-

According to the manual Constabulary provided (Thank you). When the eye of the needle is at its lowest position it should be on a level line with the tip of the hook I am there, the needle picks up the Bo in thread first try but when I sew all I get is loops under the leather with no horizontal bobbin thread Remove the leather, and the needle picks up the bobbin first time

-

Good stuff!!!! Thank you Constabulary

-

I just spent 3.5 hours getting the hook Timmy right if any has any tricks, i’M all eats

-

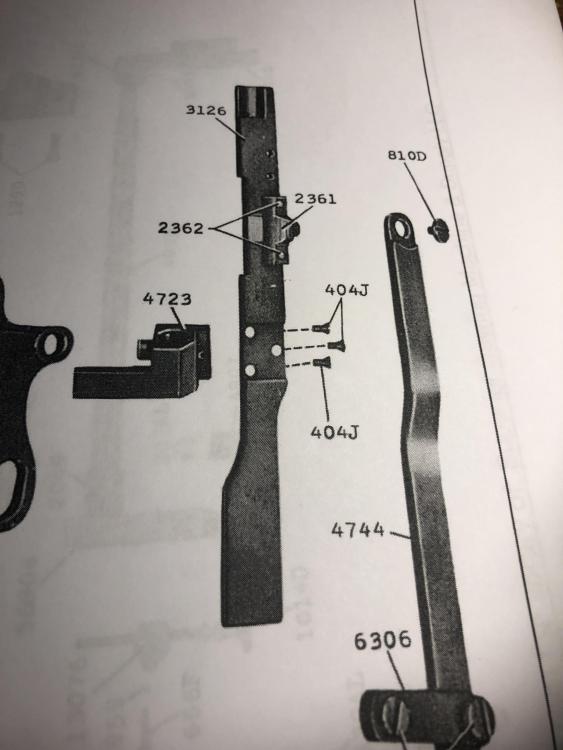

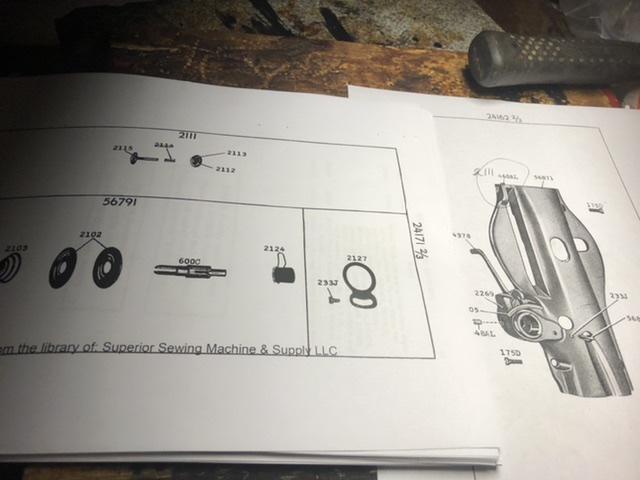

Update The presser foot bar I find is binding up. I ordered a new one The flat bar was binding up where it went through the outer case of the machine I polished them till they slide smoothly. Then I noticed the top of the flat bar was touching the cover plate. And it looks like that cover is not original. So I cut a slight notch to clear the outer housing I found in the list of singer parts a set of tension plates that are missing. Part #2111 Heads Up Mr Bob I will be ordering even without the correct tension I threaded the machine and tried it out the bobbin was picked up on the first try and it sewed a 12” stitch line

-

Come on guys, please! I can not do it with out you !!!!

-

I am leaning towards 1 of 2 things Rusted or bent the guide bar for the walking foot any professional opinions ? I am just a plumber, and do not know squat about what I am doing

-

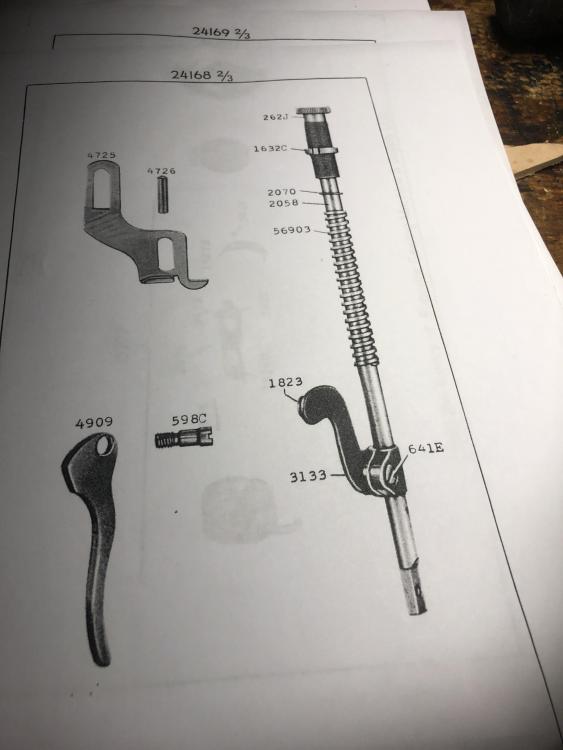

this is interesting the lock nut on the tension adjustment when in the locked position is in the way of the foot bar guide as you can see in the picture

-

With the foot tension adjustment knurl bob all the way down, I can get the foot to walk still no lift on the foot raise bar assembly suggestions ? 69604116814__524DFCA2-AFB0-40FB-85B6-AC5923327635.MOV

-

Walking foot lift lever what would keep this assembly from not working? please excuse the dirty hand, When you play with oil you get dirty 69603948068__57580C34-F105-4928-835A-34FFA2C390D5.MOV

-

-

Last week I had to cut the needle bar out of this machine with a dermal. Ordered new parts from Bob rr at Toledo sew machine sales The parts game in and I started putting the machine together while having an eye out for any parts that may be damaged, This machine sat outside in a shed for years everything was going fine till I noticed the v walking foot guide bar was not lifting when it walked nor did the lifting handle budge it. So I took the parts out to have a look. Guide bar seems to be ok just dirt cleaned oiled and started to reassemble the whole machine is jammed up. I looked inside where I was working and no tools or parts were left inside what would cause this? Before dismantling it was freely moving 69603650968__AA4CA708-5940-43FA-BDF5-E840457BFDAA.MOV

-

The machines are designed to sew a max 3” line in order to patch a shoe, Ot was not designed to sew a purse or to make a leather vest. In all honesty, It was the best $120.0 I ever spent. Not on sewing leather but the education I received on how a machine works how a bobbin works was well worth more than I paid little advice for Chi chi patcher owners use your chisels to punch your holes adjust your stitch length to match your chisel ide the patcher to see through the pre-punched holes