Spyros

Members-

Posts

955 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Spyros

-

Electric creasing iron? This is my experience FWIW:

-

Bag with Art Deco motifs

Spyros replied to WyattEarp's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That looks flawless to me, pretty much like everything else you've posted so far. Stunning! -

I'll be honest I have no idea what I'm looking at, but I absolutely love this leather colour combination, and your stitching and hardware looks great as well!

-

Ι'm in trouble then LOL I've definitely breathed way more than that in the past. I'm much more careful these days, but yeah

-

Honest question: is a tiny amount of glue on a watch strap really that dangerous? I don't know the answer. But I'd look for some expert advice on this first before I made any decisions. The problem I have with devices that move air efficiently is that the ones that actually do their job well are not small, or cheap, or quiet. Wall or window mounted vents are an elegant & cheap solution with basically no footprint, the problem is that along with the air that they extract they also extract any warmth you would have built up in your room. Which I would think is a problem in the winter in Sweden. Anyway sorry I don't have a solution but if there is a practical one I'd also like to know. I'm just suspicious of small cheap devices that make big claims when it comes to moving and filtering air, from experience with woodworking dust I know that they simply don't work. But dust is dust and fumes are fumes, maybe it's a whole different story.

-

How do you sharpen a round blade for a 1 in 1?

Spyros replied to SheltathaLore's topic in Sharpen it!

Yeah well, and I push things with my hands against spinning blades every day without freaking out about it, like millions do. Table saw, band saw, circular saw... Big spinning blades LOL -

I don't know. Do you eat your steak with a set of forks? I ordered a fork, gave me a fork, billed me a fork

-

How do you sharpen a round blade for a 1 in 1?

Spyros replied to SheltathaLore's topic in Sharpen it!

Yeah very jealous... I'd rather shovel shit than having to sharpen a diamond shaped needle -

How do you sharpen a round blade for a 1 in 1?

Spyros replied to SheltathaLore's topic in Sharpen it!

By definition anything you sharpen by hand you risk changing the bevel of the angle. But somehow these people here are supposed to sharpen round knives and microscopic stitching awl bevels by hand. -

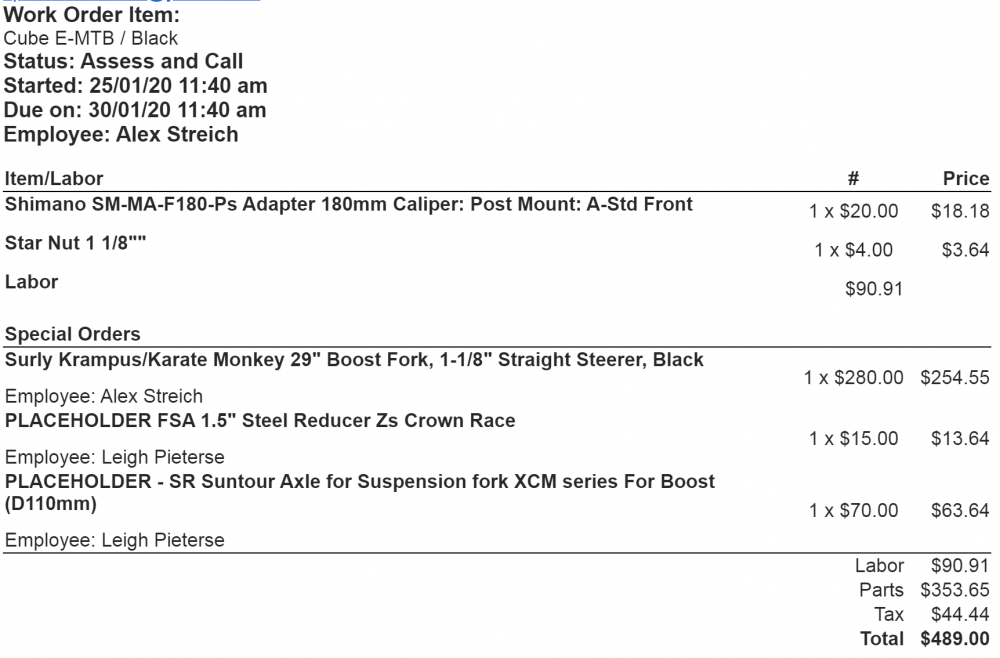

There's no set of forks, just a front fork

-

How do you sharpen a round blade for a 1 in 1?

Spyros replied to SheltathaLore's topic in Sharpen it!

Thats a good attitude :D Yeah that's how I'd do it: find a large bolt, threaded all the way to the bolt head, put it through the cutter hole with a large steel washer on each side of the cutter, and tighten it all up with a couple of nuts. Then put the bolt on a drill press (ideally) or a just drill held steadily somewhere, and then spin it. you don't have to spin it too fast, once it starts moving you will be able to tell straight away what is the state of the blade. If it looks straight and sharp without any cuts and bruises so to speak, all you need to do is carefully hold some sandpaper or a sharpening stone on the side of the blade for a few seconds, then flip the blade over and do the same on the other side, and then work you way up the grits. Repeat the process until you're happy with the result. If the blade is in a bad shape and you need to shape it first then you'll have to start with a file or a low grit stone. Make sure to mount the bolt tightly on the drill chuck, and start the spinning very slowly, until you're 100% certain everything is secure and firmly in place, and the blade doesn't wobble and it won't go flying on you. Anyway you choose to do it, take your time and be careful. If you feel uncomfortable at any point just leave it and send it to a pro to sharpen, our fingers are more important than our blades -

Biker wallet

Spyros replied to WyattEarp's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

TBH honest mate everything you posted is way above my skill level to even comment on! FWIW I think they look awesome! -

Well it depends on two things, how long you want the mold to last and how often you're going to use it. Even if you leave it uncoated it will generally be ok for a very long time, many years, as long as you give the timber sufficient time to dry after you've used it. Might expand or contract a little or even develop a slight twist/warp, but that's probably insignificant for the intended purpose, it will still work as a mold. But if it stays almost permanently wet because you use it back to back then it will need something. Even a coat of cooking oil will help a fair bit, but a coat of epoxy resin will make it practically water proof for a fairly long time. Or you can go to your local hardware store and ask what they recommend for outdoor furniture and use that. Personally I made a few different molds for pen cases and leathermans and I didn't bother coating them with anything, but I only use them rarely.

-

well considering the bike mechs were not taking the job it means they actually believed it was complicated. The fork I wanted simply did not fit the frame.

-

You mean you learned to understand Scottish??? (jk this is a great video)

-

Oh. Hang on, I'm confused now. Isn't an arbor press and a clicker press two different things? I wouldn't dream of replacing a clicker press with a drill press.

-

Well one known black hole of the universe that sucks items forever is located next to your car seat between the seat and the hand break... there's probably like a million dollars worth of coins there LOL I'm still to find where all the lost socks go, there must be a mountain of them somewhere in the galaxy.

-

yeah it wasnt that simple. You see the part of the fork that goes in the frame sometimes has a taper, and you have to match the taper with the frame. Problem is there is no standard taper, every fork manufacturer uses a different one, and sometimes they don't even tell you in the specs you kinda have to guess or go by trial and error. And the specific bike frame was meant for a different taper, so i needed an exact taper reducer and a couple of boosters that all work with eachother, plus some accurate cutting and an obscure axle that would work with this fork and my wheel. And the geometry of course, the new fork was a touch shorter and that affects steering, you never know how sharply the bike will turn or what will be your body position on the bike until you do all the above and take it for a spin. So I needed someone willing to start over in case I didn't like it. Most guys guys i asked were like yeah.... nah LOL

-

How do you sharpen a round blade for a 1 in 1?

Spyros replied to SheltathaLore's topic in Sharpen it!

Sorry I'm not familiar with this blade, I can see a photo on google, but how big is it? Reason I'm asking, maybe you could mount it with a bolt and a couple of nuts and washers in a drill or drill press, spin it, and carefully run a file and then some sandpaper along the edge. Carefully though, this thing looks dangerous. -

- Boing! - Ouch!

-

I don't know, there's a lot of expensive bikes out there... I have an e-bike and a chromoly gravel bike and I need my local bike shop at least once a year, mostly because I can't be bothered servicing disk brakes. There's also a lot of specialised work out there, i was trying to put a rigid fork on a bike that was meant for a suspension fork, which is not easy because you're messing with the geometry of the bike, and I had to go to the other side of the city to find a bike shop that would take the job. Everybody else said no, they didn't want it. And although what you're saying is true, the market has definitely changed and people shop cheap bikes online etc, a lot of bike shops failed because they just dont know how to run a business. Most of them are bike enthusiasts themselves, and get sucked into doing all the interesting work for hours, and in the end they forget what the customer actually wanted. Looking at them as a customer, most of them are just terrible, but I keep going back because they have the same love for bicycles as me, I enjoy the chat etc. The bike shops that had solid customer service and knew how to run a business survived and are still doing well.

-

So what are the jobs that require a lot of pressure from the arbor press?

-

Αhhh ok you're not a fan, I thought everyone over there would be after the Raps won it all last year. ECF= eastern conference finals, they beat the Milwaukee Bucks last year and it's shaping up to be the same pair again this year, only the Raps have lost their best player whose contract expired and opted to go home to LA. Playoffs start next week

-

Bucks Raptors ECF, who ya got?

-

Little did I know at the time... I was all about woodworking