-

Posts

776 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Mulesaw

-

@BlackDragon Sorry about the link, I have asked my son to send me the pictures, so I can upload them here. Thanks for the input. So far we are not looking into having employees, it's just Gustav and me, but that said we still need to look after ourselves as well. the idea about observing how someone else is doing things is good. When I made the first shabrack holders (they look like a rope ladder), I riveted the leather strop on each "step" both sides. But Gustav wanted to try, and he just tried doing all three steps in one side first, then flipping all over and then did the other side of them all, and that cut down probably a couple of minutes, and less fuzzing abot. I like to be able to give him some good inputs since he will be the one who will be running the company at some point (hopefully in a very distant future), but if I can teach him just a little then it might be the difference between make or break at some point. At first I had to explain to him that if we produced something ourselves, then we should still be able to make a decent hourly wage of the product. So that was why I was noting the time each operation took. I felt kind of like Scrooge McDuck, but there is no point in lying to him, and while it is OK to spend a long time on something if it is your hobby, you just have to operate with another mindset if it is for a business. We are planning on making a dedicated leather/canvas shop in the old green house in our garden (it was originally a brick structure, so it isn't a flimsy aluminum thing), so far the plans go for a well insulated wooden floor, lots of natural light, a wood burning stove to keep a decent temperature in the colder months, and it will be out of the regular wood workshop so there won't be a problem with dust settling as much. But that is for the future. We are not trying to make a living out of the company yet, so we are mainly trying to do a soft start without getting into debt. But the entire organization and planning of e.g. those serial productions fascinate me.

-

RESTORING ANTIQUE LEATHER SADDLES by Alain Eon

Mulesaw replied to MikeRock's topic in Leatherwork Conversation

I tried to google a bit, and I found this https://www.horsejournals.com/riding-training/tack-gear/western/restoring-vintage-western-saddles That is form 2013, and they are linking to Alain Eons homepage.: http://alain.eon.free.fr/ Our net out here is so slow that I can't seem to load the page completely. So I don't know if it is possible to order directly form Alain home page. -

@chuck123wapati Hi Chuck, thanks for your very thorough answer. It is pretty much along those lines I have been thinking, except hat I had forgotten needles and thread since I figured I already have it on hand, but that supply will also need to be replenished at some time. When we made the first shabrack holder and the first headstall holder, We made jigs and fixtures as we went along, so we could produce the next part faster and more accurate. Then once we had made the prototype we have made a small production run of say 10 units. And half the fun was to see if I had guessed sort of correct on the time it took for producing one item. I can't find out how to get the pictures from or IG account over to my computer, so here's a link to our Instagram page. In case you want to see the holders. https://www.instagram.com/p/CkNDdE3DP9d/?igshid=YmMyMTA2M2Y= The hammock production will most likely be made to order, with a couple of extras being made to go into stock. Here at the ship I think we restock once per year or thereabouts, and I guess it is the same on the other training ships. (At the moment they also buys from the same supplier). On our ship we often hear that trainees who have sailed with us would like to buy a hammock, but as it is now, we are not able to sell any since the supplier only delivers a minimum of what we need just for our own use, so I was planning to change that, so that there would be some for sale as well, not by me, but by the ship (I would still supply all of them but they could resell them and make a profit that way). At the current point in the planning, I am going to end up with a strip of canvas that's 14" wide that is not needed for the production itself (scrap), so I am toying a bit with the idea of making rigger bags out of that. That would fit very well into the ships stuff that we sell, so I think that I might sell it in larger quantities compared to the hammocks. I could also make something else out of it, so it doesn't just count as waste. The canvas is originally 60" wide, and the finished hammock should be 40" wide. The edges needs to be folded and doubled so that takes a bit of the width too. I am really looking forward to getting started once I get home in a couple of weeks time. Brgds Jonas

-

I sent you a PM. brgds Jonas

-

Great gift and a really great idea to repay a good friend with such a beautiful piece of work. Friendship is a dear thing, so I am all in favour of doing something good for a friend! The world needs more people who acknowledges and remembers friendship.

-

Good luck with your project, and the best wishes for the coming season of Thanksgiving, Christmas and New Year.

-

My son and I started a company in February, so far our main income has come from repairing riding boots and repairing horse blankets. However, we have also started a production of head stall holders and shabrack holders, where the hanging system is made out of leather Plus leather grease to care for your horse gear. We make a nice classic version of stitching horses, though so far no sale of those yet (we aren't that big in marketing) But as the title says , I am planning for making a production run of hammocks similar to those that we use on this ship. Our current supplier is well into his 70'ies, and I'd like to be ready to take over once he decides to stop. So far I have found a supplier of a fitting type of canvas, and a supplier of the correct rope and brass eyelets etc. And I find myself drawn to calculating all the time and trying to guestimate how fast I can make those hammocks and if I could do it a bit different to be more efficient etc. And so far I haven't even ordered the canvas (since I am out at sea). So I was wondering if there are any other that routinely try to organize a production run in their head of some projects that you already do or perhaps would like to do? It doesn't matter if you ever get around to do so, but I just like to occupy my mind in thinking about stuff like that. Like what I could do to utilize that small pieces of scraps. what the most logic or most efficient sequence of operations is etc. It could be that you have made one holster and you think about ways to do it efficiently if you should make perhaps a 1000 pieces of the same holster. Or in your head you are going to expand your belt production to a level where you can supply all Walmart stores. Let's hear it if you ever think about organizing a production, and what it should be (and you don't need to actually do it, just thinking about the process because it is interesting)

-

Hest & Hus Aps Danish company (me and my son) Stitching horses based in Denmark

- 10 replies

-

I really don't think it looks that bad. There is a lot of dust n it, but that can be cleaned away with a bit of soap and water and then a light oiling will help. It looks like it has been stored in a dry place, so there is just a bit of rust on the cast parts below the table, but as long as the mechanics haven't been subjected to water it'll be good. In short, a great find! looking forward to see the progress. brgds Jonas

-

Some of the hunters I know are getting sausage made from the deer they shoot, so I think they use all the tallow themselves, but it couldn't hurt to ask them. But also the deer over here are SO small, so there isn't much "meat" on them anyway. The standard weight of a 3 year old animal is between 32 - 45 lbs. Unless you manage to find a sika deer or a red deer. But those aren't as common where I live.

-

After my initial test I bought 40 lbs of beef tallow food grade. that was just something like 35-40 $ According to a friend of mine who runs a restaurant, it is sometimes used in steak houses for frying a steak, as it gives bit of taste compared to e.g. cooking oil or butter. But getting some scraps from a butcher will still give plenty tallow for a nice sized portion (and happy dogs as a bonus). I have tried to look at a lot of those leather greases that are available over here, and quite a lot of them have got petroleum jelly in them. I can't say that it is bad, I just think that natural grease from the same animal ought to be better for the leather. Plus it is kind of neat to make your own stuff :-)

-

Darn. elk tallow is just SO exotic for someone like me :-) I guess that if you lived in a really warm climate, you could change the ratio of tallow to NFO, but I like that I can easily apply the grease even if it is stored in the unheated workshop in the barn. I haven't tried it in super cold temperatures like freezing though, but I reckon it will still be soft enough to apply.

-

@TomE Thanks, the dogs definitely found it to be a rewarding experiment. The tallow was quite pricey like this. I think I paid DKK 50,- (around 7$) for 4 lbs of tallow scraps. After boiling etc. I think I ended up with just over one lb. (I have already forgot the exact number). And it took a while for boiling, but I think it is fun to try all the way from scratch. Since I moved up to production scale I have fund that the NFO is the most expensive in the recipe. I haven't found a wholesale supplier for that so far, but I think its OK despite of that. My production costs are roughly 2$ per jar, and a jar contains 250 mL. (slightly more than a US cup). That price includes the jar and the lid and I also ad a bit of pine needle oil just for a nice smell. But technically it isn't needed. Sheep tallow should be good I reckon, and I haven't heard of anyone using that for anything except old time lubricating of wooden planes soles. I have tried to make black grease by adding some lamp black, and that works like a charm, so I also tried to make some brown using burnt umbra .(I haven't tested that one yet coming to think of it) Both these are intended to be for boots since few people I know want to use anything with colouring on their saddles. Most competitions still require white riding pants, so no need to risk getting those more dirty. Here's a picture of one of my friends equipment after applying the grease. She bought a jar of the neutral coloured and a jar of black leather grease. She is not into regular competition riding, so it would be fair to say that her equipment isn't always super shiny. But the boots look like a million $ now, and she was very pleased with the product.

-

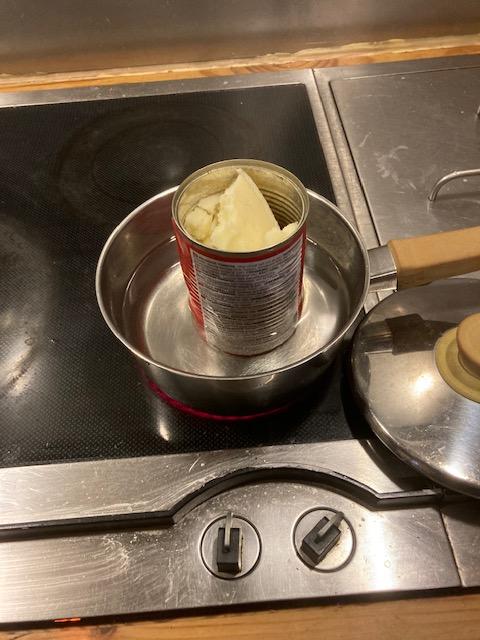

I found this recipe for harness oil in "The Harness makers illustrated manual". @Alexis1234 kindly referred to the book in a post about a fabulous goat driving harness that she made. The book can be found online, and in the end of the book there are a bunch of recipes. The easiest one was for harness oil that is actually more of a leather grease. I have made a production run of it, and so far I am very pleased. The grease is soft and absorbs easy into the leather. It doesn't leave a residue on the surface of the leather. My first test was made from absolute scratch, later on I have bought food grade tallow since it was a lot cheaper and easier compared to extract it myself. But then again, I am making a large production so I can sell some of the grease to other horse people. I like the idea of using animal based ingredients since I believe that it ought to be the most natural kind of grease for another animal product. The recipe calls for 3 lbs of beef tallow, and 1 lb of neatsfoot oil. the tallow is melted and the NFO is slowly poured into the melted tallow. all is stirred well until it is cold. The recipe also suggests adding a bit of lampblack to the mixture. I have only tried using beef tallow, but I guess that elk, moose, or deer tallow would be similar, so if you are a hunter or knows one then it could be an interesting experiment to try to use a wild source of tallow. The pictures show my process from the first experiment. No black was added to the mixture. 1 + 2) I bought some tallow scraps from the local butcher and these were boiled for a couple of hours in water. 3 + 4) The liquid tallow and water was transferred to a clean bowl and left to solidify in the cellar until next morning. The solid pieces of meat were given to the dogs (who seemed to like this experiment). 5) The solidified tallow was lifted onto a plate and the underside was rinsed under some water to remove any soup. The actual soup was also distributed to the dogs. 6) I used an old can to melt the tallow and NFO in. I weighed 240 gram of tallow and 80 gram of NFO. 7) I melted the tallow and NFO in a water bath, so I didn't have to clean up a pot when I was done. 8) All melted and stirred thoroughly. 9) Poured into an old tin. 10) After cooling and solidifying. the grease is ready to use.

-

Hi Scott It is a creamy paste, and that makes it easy to apply on saddles and headstalls as I see it. The two items are heated up and stirred, and if done correctly they don't separate (or at least that's what the recipe says). I haven't had any separation problems, but my experiment is only about a month or so old. In the Harness makers illustrated manual, the product is described as harness oil, but they say that it will be a smooth and soft grease which is also my experience. The author writes that you should heat up the tallow slowly and then stir the NFO thoroughly into the mixture until it is cooled. I ad both ingredients at the same time, and slowly heat it up to all the tallow has melted, stirring along the way. That has worked fine for me.

-

I found an old recipe in the Harness makers illustrated manual. 3 lbs of tallow (beef), 1 lb of neatsfoot oil. The recipe suggests adding a bit of lamp black to the mixture. I have made a large batch of it and I find it very easy to apply and it softens the leather as it is supposed to do. I mainly use it on saddles and horse gear. I got 40 lbs of food grade tallow. I also tested with adding a bit of brown (burnt umbra) to the mixture to make a brown leather grease. the idea being to use the black and the brown to boots and neautral coloured on the saddle and headstalls. (to avoid getting the white riding pants blackened by mistake). I don't want to put in beeswax in order to not increase the friction of the leather surface. If you ride a nervous horse, the squeeking sound of the boots rubbing against the saddle flaps can sometimes be enough to stress the horse. So far I haven't got enough experience with the product to see if it cancels all noise, but I am pretty optimistic though. Also I am thinking that since leather is mostly made from cows, beef tallow and NFO must be the most natural ingredients used to reapply grease to the leather.

-

Great find! I prefer my treadle version over the electric version, since I find it so much easier to sew really slow using foot power. But I also use the low "gear" pulleys all the time.

-

Advice on building a new shop/building as part of business

Mulesaw replied to desullivan's topic in Getting Started

If you ever do direct sale to customers like in that they come and visit your shop, then I'd make like a small part in the front that look "business like", with a counter or a table for wrapping up the stuff that they buy, and potentially for selling the odd can of leather grease/conditioner to their products. ' Maybe also a place where you can make a small display of standard things that you sell (I am only guessing here): belts, dog collars, wallets, dog leashes etc. Stuff that a lot of people could use either for themselves or as gifts. Also check with local regulations regarding if there can be a step into the shop or if it has to be wheelchair friendly. Good luck. Brgds Jonas -

@TomE That set look fantastic! The creasing looks perfect, and I really like the small detail with the thread going around the side for the first stitch near the bar of the buckle. It gives a really neat and tidy look in my opinion.

- 9 replies

-

- bridle leather

- equine tack

-

(and 1 more)

Tagged with:

-

Little sheath for my marlin spike knife

Mulesaw replied to Gezzer's topic in Gun Holsters, Rifle Slings and Knife Sheathes

@Gezzer It looks great now! The knot is easily recognisable and I really like the contrast of the stained strands on the light background. Is there a belt loop on the back of the sheath? I was just wondering, cause I once made a sheath for a thin pocket knife years ago where the idea was to just have something to keep pocket dust out of the mechanism of the knife. So the sheath just protected the knife from the harmful environment of my pocket. -

Little sheath for my marlin spike knife

Mulesaw replied to Gezzer's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That makes sense to me, I couldn't quite recognize the knot. The good thing is that there are so many knots that would look good, so it is just to pick one that will look niec and isn't too difficult to recreate on leather (I think I'd stay away from a 5 strand Turkish knot :-) -

Little sheath for my marlin spike knife

Mulesaw replied to Gezzer's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Great little project! The knife looks like a really nice tool. Being a sailor my only critique is the knot. It looks a bit like the upper end split in two. So it is kind of hard to follow which strand goes where. But on the other hand, it has kept me studying the sheath and the knot for quite a long time to see if it was me who got it wrong, ind of those optical illusions that capture your eye and you follow the lines around and still doubt your own eyes. -

I don't know how I managed to miss this post, but the harness is stunning! In Norse mythology, the thunder god Thor uses two male goats for pulling his wagon across the sky which makes the thunder and lightning. Thanks for the tip on the book as well

-

A set of suspenders would look great I think To me it looks kind of like the Y shape on a military basis carry system (probably another name in America).