-

Posts

116 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by CdK

-

@MikeG I use these narrow zipper feet to sew close to molded pieces when I make briefcase molded handles using my 1341 clone. These may fit the LU-563 but I'm unfamiliar with it. The H&E narrow foot set is nice and works well with the narrow feed dog & plate for the 441 machines when doing holsters.

-

You can use a VFD (variable frequency drive) to convert single phase to 3 phase.

-

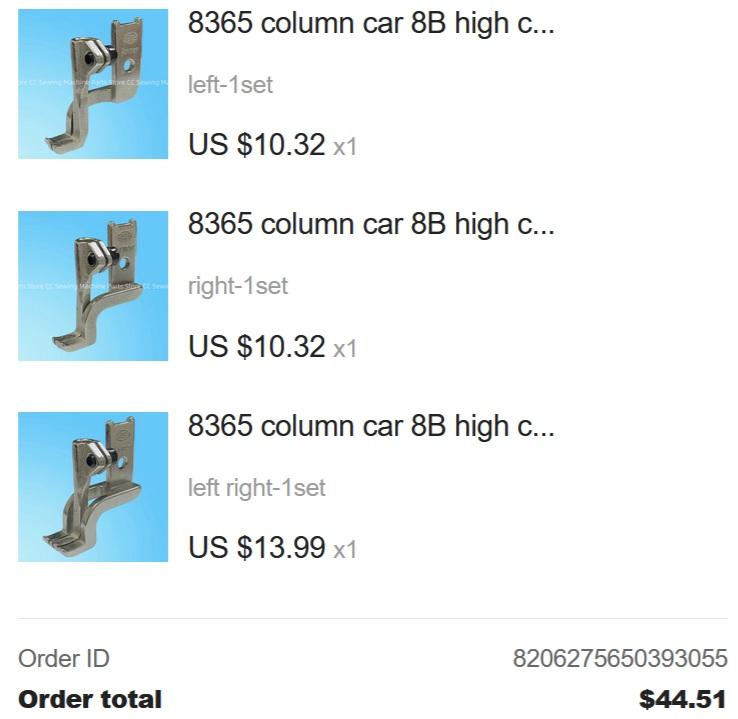

I received the 3 sets I ordered today. The L & R and needle feet fit fine but there is a difference in design and finish between the L & R but should work as intended. The "both" foot needed a touch with a Dremel stone to open up the width of the fork by the screw hole to allow the screw to pass through the hole, about 0.1mm. I've had this with some other feet sets in the past so no surprise.

-

Similar to how I do it. I machined an arbor for the 60mm blades which I spin in a lathe and sharpen using a post grinder. I use a very fine grit stone which is followed up with a leather strop. I have about 20 blades and I sharpen a batch when about 1/2 of them need sharpening. Yeah, I know these blades are not pricey but my Dutch genetics won't allow me to waste money.

-

@Constabulary Variations like what you found seems to be somewhat common with some items I got from the orient in the past. Also the lack of good finish on parts, such as presser feet for the 801 bell skiver, have been a minor irritation but not uncommon even from touted & expensive US manufacturers/resellers. I'm fortunate that I have the tools and skills to finish or modify items to get them to work properly. BTW, the items I ordered are now in country and should arrive in about a week.

-

I know this is an old thread but I noticed someone was visiting this thread so here is what I found earlier this year on evilbay in Jan 2025. They are for 1/4" piping. This set is not a plug and play set as I needed to adjust the height of the bars to which they mount as the length of this set is shorter than the "standard" 441 feet set. They do work when the machine is adjusted but I have as of yet have had no need for these.

-

Agreed, the last line is too true, it took a while for the eureka moment where it came together. I’ll add to this, the presser feet that came with my 801 were unfinished and took smoothing and buffing to work well without damaging the finish. Also, there are specialized feet that have their niche, such as roller feet and some that create a groove that allows easy folded edges. Similarly to sewing machines the 801’s can benefit from appropriate presser feet.

-

Cobblers often use a heater prior to placing the pieces together, this activates the contact adhesive to create a good bond. I use a heat gun to activate the dried contact adhesive when laminating vegtan for belts and holsters, similar to what TomE does. The edges are easier to finish as there is less of a visible line where the laminate comes together. YMMV

-

On screw top glue containers it is useful to smear a light coat of Vaseline on the threads, this prevents needing to use a tool to unscrew.

-

Yes, many things going on at the same time. I remember my learning curve and finally getting the balance of needle, thread and settings right was very satisfactory. This all takes time to build experience and confidence, like when learning the guitar, don't rush and try to force things.

-

Yes, that is probably a tapered pin. Be sure to drive it out from the small end. I would measure the ends with a vernier to determine the small end. Support the shaft end well and drive it out with a drift punch. As others pointed out, proceed with caution as not done correctly could end poorly.

-

Looking a photo 1 again I see what appears to be a pin on the left, notice the circular dissimilar coloration on the shaft.

-

@friquant In the first picture there appears to be screw slots inside the holes, maybe screws in there?

-

@KloverI found the thread where this was discussed. This link should take you to the page where the hammers are shown:

-

Those are quite heavy duty, nice work!

-

@RockyAussie << @Klovermade some tests and posted images/video where he tested the tension for both the top and bottom thread when his machine was in balance. I seem to recall that the bottom was 1lb and the top 3lb. That being said, the thread path plays an important role as well. My preference, based on my experience, is to make sure that the top thread is wound 1 1/2 to 2 1/2 times around the tensioner on the left side of the machine. Thread slippage needs to be minimal here, wheel needs to rotate, or I get inconsistent stitch tension. There is no standard or correct one side fits all on these machines. Thread types and thickness change how you set up as well. Good luck with your new machine.

-

@Cumberland Highpower I had not yet considered the table surface yet but what you mention makes sense. I will probably use HDPE or such as I have that on hand and should be quite suitable I think. I'm thinking that the table top be circular so I can get into openings etc like when I do when doing tote bags with circular cut-outs for the handle. Similar to what some spindle sanders are but without oscillation and variable speed control using a foot pedal.

-

@Cumberland HighpowerDid not know about the Galli Burnishing wheels and did a search and came across this beast: https://youtu.be/-hXaNNV9wGo?si=_7ke0kzdVgUQQ9iv Fascinating what machines are out there. I'm actually considering making/building a horizontal burnisher for doing the edges on larger items such as bags and briefcases. I saw such machines being used in some of the videos that I saw on utube and my interest was piqued. I have 2x 750W servo motors that came off sewing machines on hand and considering using 1 of these as I could control the speed with a pedal. Thoughts? @LomaeArts I like your thought process, many ways to accomplish what you are going for.

-

Exactly, do what method is appropriate for the task at hand and do it correctly else it is a failure.

-

Same difference, I remember my late maternal grandfather, a blacksmith, rant on about the inferior electrical arc welding replacing hot rivets in rail car manufacture and that they were "weak". I dared point out to him that the liberty ships were welded together, once... That being said, I have seen many ugly leather pieces with large holes punched and overly thick and garishly colored threads used. These makers also tend to be vocal about how inferior machine stitching is. YMMV

-

Acrylic Template for J Frame Cross Draw Holster.

CdK replied to PastorBob's topic in 3D Printers and Lasers

Use your laser and mark the flesh side of the leather, easy peasy, no need for a template.