fibersport

Members-

Posts

207 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by fibersport

-

You can get complete tension assemblies for around $10 US and up on ebay. The servo motor will help but put a 40 or 45mm pulley on the motor to really make a difference. I also built a speed reducer for mine which helped slow down the start up speed even more. The post is titled Questions re: DIY box style speed reducer 1 2 .My speed reducer design is on the second page. It still isn't as slow as i want it but I think it's a limitation of my servo motor. I sent you a private message regading the manuals.

-

You figured it out. Actually I believe one of the manuals covers the exact issue, the solution is to spread the two parts apart with a screwdriver. You don't want to spread them too much or they could break, however once you spread them and the bobbin holds tight, you should be good for years. Have you been able to find an owners manual? They can be found on-line with a little searching. I have also found that downloading the manuals for the 1245 are beneficial, especially when trying to set timing and such.

-

As long as you have a little clearance between the wheel and the belt when not winding a bobbin, you're fine. I picked up a 545 a few months ago, if you need any help feel free to contact me either with a post or a private message. I'm just getting into sewing as a hobby, these are great machines, parts can be pricey though. One last thing, add a drop of oil in each hole on the bobbin winder, it will seep in and get it running even better. Be sure to give teh machine a good cleaning and lube as well. Greg

-

Does that machine have a safety clutch? When I bought my Pfaff I too thought the timing was way off, until I started ,looking deeper into it and found the safety clutch had tripped. I didn't realize that a simple jam would trip it - glad to know it works.

- 6 replies

-

- cowboy4500

- needle strike

-

(and 1 more)

Tagged with:

-

Thanks for the reply. Does yours have the long spring or is it a more self contained model?

-

Questions re: DIY box style speed reducer

fibersport replied to shelr1's topic in Leather Sewing Machines

Well even this had its issues, had to redrill the holes in the leg to get them straight using my drill press instead of my hand drill which even after measuring still didn't drill the holes lined up! Even the simple things throw you curve balls - -

Does anyone have any experience with edge guide presser feet? I've seen a couple of different designs and am wondering if one is better than the other.

-

Questions re: DIY box style speed reducer

fibersport replied to shelr1's topic in Leather Sewing Machines

Thanks for the compliments. Belt tension does take a little effort but not too much, I found setting the longer belt first since the only tension is set by the spring. The smaller belt is then adjusted using the motor adjustment as if there were only one belt. The bearings have two set screws each which prevents the shaft from going side to side. I had to drill and tap the pulleys for a set screw which I used a regualr screw for now along with small flat spots filed into the shaft and also a little Loctite retention compound. It is simple and might not hold up to 8 hours a day use but I think it will suit my needs just fine. All total I think I paid about $57. I had the angle iron laying around, I could have saved a few bucks had I used a shorter shaft but I wasn't sure how my final design was going to need. -

Questions re: DIY box style speed reducer

fibersport replied to shelr1's topic in Leather Sewing Machines

They were on my phone but I sent them to my computer via email and then resized them to around 500 kB and then saved that file to the computer - phone font size is way too small for these older eyes! I am uploading them again but have moved them to the C drive on the computer rather than my Microsoft365 drive, maybe that's the problem. It was not, I clicked on "insert other media" and they appeared. Must have been user error .... -

Questions re: DIY box style speed reducer

fibersport replied to shelr1's topic in Leather Sewing Machines

It wouldn't let me upload them even after resizing, trying it again. Doesn't seem to be working, I see them after I pick them and watched as they were uploaded, they are both around 500 kB so well under the 1.46 MB limit. Anyone have any suggestions? -

Questions re: DIY box style speed reducer

fibersport replied to shelr1's topic in Leather Sewing Machines

Here are a couple of pictures of my version of a speed reducer using information from this thread - thanks to all! Pulley sizes are 120 and 40 mm with a 15 mm bore. I welded up a U shaped frame out of 1-1/4" angle. The frame pivots on the leg of my table and is tucked in so it's out of the way. A spring keeps tension on the belts. The motor mount is used to fine tune the belt tension on the belt between the motor and large pulley on the reducer. Belt selection is kind of critical, I used a belt length calculator to pick my belts which worked well. I would like to slow it down a little further as the lowest speed of my servo motor is a little too fast for my liking although I need to do some sewing to see if I can adapt to the slowest speed. My options are a larger diameter large pulley, a larger balance pulley on the machine or a servo motor controller that has a lower intial speed. Overall I'm very satisfied with it and really like the simple design. I ran it without the spring and it worked OK until I tried to sew 4 layers of vinyl which cases the small pulley on the speed reducer to slip. Adding the spring worked great, it actually rises up a bit on startup but there is no slippage on multiple layers of vinyl. I don't have much tension on the spring, if it did start to slip all I would do is pull it down a little more. I do need to cut the shaft down and paint the frame but until I spend a little more time with it I'll call it almost done! -

I'm talking about a Pfaff, 545 for clarification. Maybe that explains the different location of the screw on the smaller forward foot between the Pfaff and the Consew? I only have a Pfaff presser foot and nothing else to physically compare it to, again just trying to wrap my head around the differences since this is a new hobby to me.

-

Kind of curious and trying to learn. Are presser feet interchangeable between Pfaff/Consew/Singer etc.? It seems that as long as they are the same shank length, they should interchange. I noticed some of the screws for the front foot are in a different location, maybe there might be a clearance issue? I realize there may be some specialized presser feet that won't work but I'm wondering if they look similar they should work?

-

Questions re: DIY box style speed reducer

fibersport replied to shelr1's topic in Leather Sewing Machines

I really like your design, it has given me some great ideas for making mine. I'll be sure to post some pictures when I get it done. Thank you (and everyone else on this thread) for your inspiration! -

Questions re: DIY box style speed reducer

fibersport replied to shelr1's topic in Leather Sewing Machines

No problem. I ordered my parts from ebay, they're coming in on a slow boat from China as they say so I'll have to be patient. One other question: is your reducer mounted on a hinge or something? It looks like there is a pivot towards the outside of your frame. -

Questions re: DIY box style speed reducer

fibersport replied to shelr1's topic in Leather Sewing Machines

Parts all on order, now to just try and be patient for them to arrive. Agreed on the belt also. -

Questions re: DIY box style speed reducer

fibersport replied to shelr1's topic in Leather Sewing Machines

Thanks Constabulary, extremely helpful! In my mind I kept trying to find a 150mm pulley without much luck, never thought to just change the size of the smaller one as well. I'll be placing my orders tonight! -

Questions re: DIY box style speed reducer

fibersport replied to shelr1's topic in Leather Sewing Machines

Sheir1 - would you mind sharing some of the details on the pulleys and pillow block bearings such as vendor and specs? Thanks -

Thanks for the additional info

-

Thank you very much, appreciate the quick reply. I'll look a little closer tonight to compare. I'm assuming that it's made that way to be gentler on the material?

-

Can someone explain the "P" code - "four-motion drop feed on top feed machines"? I picked up a 545 and just doing a quick comparison to my 145, the feed looks the same. Not really sure what the difference could be between a P and non-P machine.

-

Thank you, good to know.

-

Was wondering what experience people have with presser feet made in China? I have a Pfaff and some of the types of feet aren't available except from China. They are all over the internet for low prices and would like to know if "you get what you pay for" holds true.

-

How about the name of a good supplier of used parts?

-

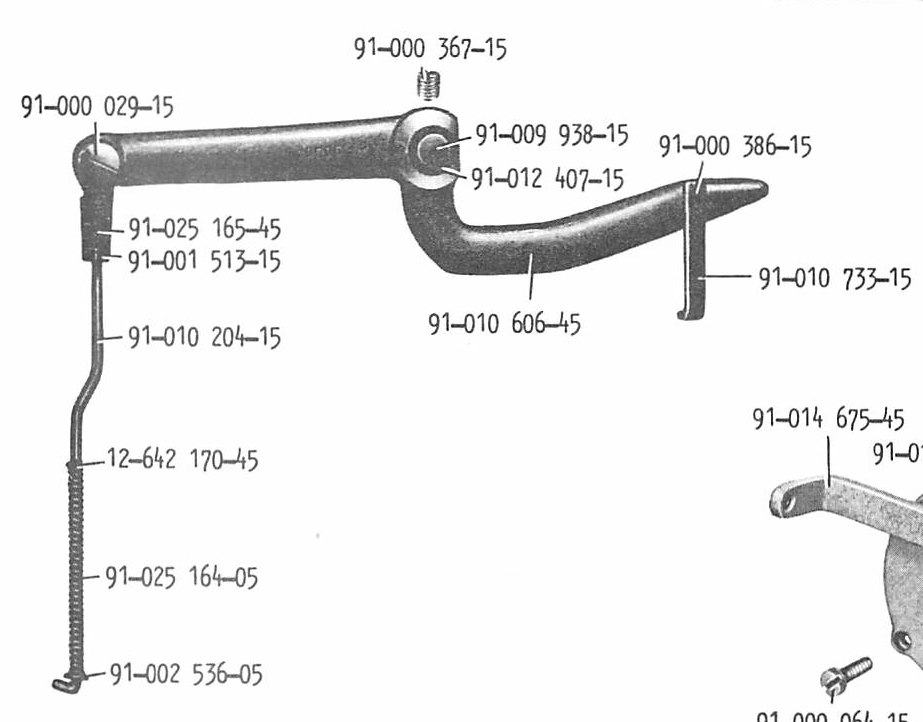

I'm looking for this part 91-010 606-45, it's called the lifting lever. My machine didn't have one when I bought it and although not necessary to sew, it would be nice to have it. Any help is greatly appreciated. Honestly a broken one or even a tracing would be helpful as I could make one if really need be.