Search the Community

Showing results for tags 'bevel'.

-

I’m hoping there is a beginning leatherworker who hopes to get some tools, because I have 4 old and not so old, edge bevelers to send to you for free by USPS Priority mail. I bought them used long ago on eBay, they need sharpening now which is easy to learn online how to do that. The Sizes are: 2, 2, 4, 5. (yes, two of size 2) Photo of edge bevelers Thanks! Ilene

-

Hi i am working on making leather fire helmet shields and had a few questions. Made my first one the other day but having a hard time with the beveling with it leaving alot of uneven marks. Any suggestions on how much to wet down the leather or how to start so that its more even? not sure if im wetting the leather to much or possible not cutting my lines deep enough before i bevel? Any suggestions/ tips would be great thanks!

- 10 replies

-

I purchased this Doldokki 1.0 mm edge beveler from http://www.fineleatherworking.com/doldokki-edge-beveler/ It is a duplicative size to edge bevelers I already have so I am selling it. It is brand new. I tested it on one belt strap and have not used it since. Really sharp, great steel. A huge upgrade from Tandy edge bevelers. Asking $105 USD includes shipping in continental US. This item is currently out of stock at fine leatherworking. Description from fine leatherworking: These small and sharp tools remove the corners from your leather edges to help create a round shape. They are normally used with medium to thick leather and reduce the overall burnishing and shaping time. The award winning tool company, Doldokki has been innovating and modernizing tool designs in Korea since 2007. Founded by an automotive designer, they quickly established a reputation for high quality, beautiful tools. These sleek, ergonomic tools use a variety of exotic hardwoods include ebony, rosewood, cocobolo and Lignum Vitae. The range of woods used helps to give each hand made tool more unique characteristics. They are made from SKD11 (D2) steel that is masterfully hardened to 60 Rc and shaped to its final dimensions. The semi-stainless finish and greater hardness ensures better wear and retention of sharp edges. Each tool is hand-made in short production runs and comes ready to use immediately for your leather crafting needs.

-

- edger

- edge beveler

-

(and 3 more)

Tagged with:

-

I'm making a document folder for a friend, with her initials (GW) carved in. I've found the script and can cut out fairly nicely with the swivel knife. Question is, how to bevel? The lettering is a single cut (ie not a raised letter), essentially using the swivel knife as a pen. So do I double bevel or just pick a side and bevel that?

-

I am looking for contact information for "South Coast" tool maker (see attached pics), I think they are out of Taiwan. With these two tools you can produce a basket stamp weave pattern by beveling the swivel knife cut pattern. Thank you for your assistance.

- 2 replies

-

- leathertools

- stamp

-

(and 3 more)

Tagged with:

-

Hi! I really like the way this company does the edges on their products (keeping the bevel) and I'm wondering how to achieve the same edge finish without burnishing to a round edge like most other leather products? (https://alstadgoods.com/products/slim-jim-whiskey)

-

Hi all, Question about skivving leather. If I were making something like a camera strap where I wanted to fold an end over itself to put in a D ring, do I skive the entire section where the fold is happening or should I only skive the two sections that are going to mate and leave the part where the ring would rest alone? So assuming (based on the attached graphic) that sections A and C are going to be matched up and attached to each other and that section B is where the D ring would rest, would I skive sections A, B, and C or just A and C? Thanks!

-

Hi all, Question about skivving leather. If I were making something like a camera strap where I wanted to fold an end over itself to put in a D ring, do I skive the entire section where the fold is happening or should I only skive the two sections that are going to mate and leave the part where the ring would rest alone? So assuming (based on the attached graphic) that sections A and C are going to be matched up and attached to each other and that section B is where the D ring would rest, would I skive sections A, B, and C or just A and C? Thanks!

-

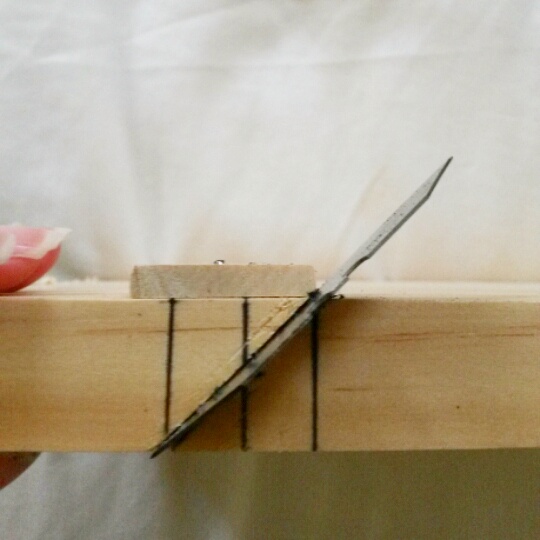

Couldn't find this mentioned elsewhere, so thought I would share this Youtube tutorial by Shane Hutchinson (from Abraided Leather) on making your own lace/thong beveller. I knocked up one quickly with things I already had in the garage (block of wood, wooden paint stirrer, utility knife blade). I found it easy to use, accurate and pleasingly fast. Have attached photos of mine below, used on 3mm Kangaroo lace. NB: Due to the depth of my block of wood rather than clamping the blade I just hammered it into the wood. This does halve the life of the blade (as the hammered side is dulled so you can't turn it over) but worth it for me as I found clamping twisted the blade to a strange angle. I used spare blades from my Stanley utility knife, AU$5.98/5 pack. These are available in Carbide which (allegedy) last 5 times longer than a regular blade. Hope someone finds this useful! Cheers, Kristy

-

Has anyone use a tool, or made a jig, for cutting leather circles but with beveled edges? I've read the existing thread about cutting circles: good info and helpful pointers to tools. But I'm making leather cup, from Stohman's "The Art of Hand..." photo attached and I'm have trouble getting accurate circular bevel cuts. Thanks.

-

Hi fellow leather-workers, I’m new to leather working and trying to figure out the best ‘order’ to do things in. Bellow is a list of steps I typically take during leather working – I would love some feedback on what you think is the correct order to do things in? 1. Cut pieces 2. Bevel Edges 3. Sand Edges & back side of leather 4. Neatsfoot Oil to soften leather 5. Gum Tragacanth to slick edges & back side of leather 6. Groover & Stitching Spacer (dampen leather for this) 7. Dye leather 8. Apply finishing coat 9. Sew leather pieces together Would you change this order at all? If so, what would you do differently?

-

I'm horrible at shading/shadowing. What tool is best to do this skull? I've been using craftool B200 to bevel but obviously don't want to use it for shading the entire thing. I thought about P206, a pear shader with no markings on it but I don't like the way it makes the skull look. Help!!

-

I completed my first belt last night. I also cut out two other belts and dyed them with fiebings oil dye (Black and Dark Brown). I have a few questions, as this is my first time doing any of this. When dying, a lot of people say not to dye the flesh side of the belt, as it may rub off over time. but what if you use gum trag on the back, over the top of the dye? Will that help with the dye not bleeding? Also, I bought edge kote (black and brown). What is the difference between the edge kote and the normal dye? If i used the edge kote, would i put it on at the same time that I dye the rest of the belt? Then afterwards, bevel and burnish? or would i bevel and burnish before dying? The belt if completed was natural, and not dyed. I noticed that when I beveled and burnished the edges, some of the water soaked onto the surface of the belt, and darkened it slightly. should I save burnishing for after i apply whatever finish/conditioner i apply? or does it matter? Sorry for all of the questions. Any help would be much appreciated. Thanks!

-

I am trying to figure out what tool I saw.... This thing looked like a rotozip or a large dremel, and hung from a pole about 3-4 feet tall. It had a cable attachment that hung down, similar to what the little asian manicure people use when they do fingernail stuff... and the guy could take a regular stamp, like a beveler or shader, and put a collet on it, and snap it into the end of the cable attachment, and when it was running, the tool would vibrate so that instead of hammering, the leatherworker just drug it along the leather.... Any ideas?

- 5 replies

-

- swivel knife

- hammer

-

(and 2 more)

Tagged with:

-

Sooo,just wondering if it would work to burnish edges of stitched double layer leather without beveling them first or no? If I don't care that the edges look rounded(which I don't) could I do it that way or is there some other purpose to beveling first?

-

Hi all I'm practicing some tooling/stamping and doing some celtic knots. I current have two lines about 2mm apart and I need to bevel in betwen them. The problem I'm having is that the bevel I have is so wide from front to back, so when I bevel down the side of line one, the back of the bevel flattens the other line, meaning I don't get a crisp bevel. I'm currently using the starting Bevel - B197 Can anyone recommend which bevel - or an alternative way I can bevel small areas? I've orderd a B935 which is about 1/2 the width, but the depth front to back is the same as the B197, so I'm going to have the same problem. A couple images of the current bookmarks I've done (first go BTW). http://www.mazdrak.c...rk/DSCF1580.JPG http://www.mazdrak.c...rk/DSCF1584.JPG Many thanks