Search the Community

Showing results for tags 'pfaff 145'.

-

I am looking for recommendations for grease for the gears under the 3 gearboxes on my Pfaff 145 that I am restoring. What I have found under the bottom two was probably the original, very petrified. I just took off the top gearbox, as I move through the machine. It wasn't as petrified, but it defiantly must be cleaned out and replaced. And yes I have a gallon of Lilly White Sewing Machine Oil for the oil ports. I saw where Uwe recommended tri-flow for the gears, but they make 2 kinds, and I watched the Consew 206 RB video. I would like to know why you use it, which version if the manufacturer makes several different greases, and where you have found it. I live in Central Indiana for reference. Thank you. I really appreciate all the time and effort so many of you put into answering questions and sharing your experiences and knowledge.

- 28 replies

-

- grease

- industrial sewing machine

-

(and 1 more)

Tagged with:

-

Im wondering if anyone is aware of what the minimum and maximum thread sizes are for the Pfaff 145 Model H3? I saw another post on here mentioning that #207 was the highest the top could take, and #138 was the highest the bobbin could take, though Im seeing needles available for the H3 (size 134-135) on threadexchange that go up 200/25, which I believe can handle #277 thread as well. I also see needles that go as low as 65/9, which would be relative to #15 thread? Any help is appreciated as the Pfaff manual is a bit difficult for me to understand.

-

hi folks! First time posting here, hopefully I'm not stepping on anyone's toes...Last weekend I brought home "Pfaff 145-1B H2L" leather sewing material and been googling info on it. Found this forum and theres PRICELESS information here. However I learnt its basically spread on different messages / threads so I started this "All things Pfaff 145" thread to collect everything I've found on one place. To help newbies like myself and also collect all the important data on one place. Pfaff 145 Manual in english: http://www.pfaff.com/SiteMedia/PFAFF/Products/Machines/Support-manuals/pfaff_145-manual-EN.PDF Pfaff 145 & 545 Parts book http://www.industrialsewingmachineparts.co.uk/pfaff_145_545_partslist.pdf Here's what I've learnt from classification so far: H1 & H2 7mm under foot H3 11mm under foot H4 14mm under foot Needles: 134 (H1&H2), 134-35 (H3) and 190 (H4) A: light materials, B: medium, C: medium heavy D: heavy L: leather N: 6 mm stitch length

-

Hey there! I am looking into purchasing a Pfaff 145 H3 from a local seller and have ran into an issue with the machine. When manually turning the wheel in either direction, we hear a squeaking noise. The machine seems to work fine and produces beautiful stitches so it is very odd. A friend of the seller who is more knowledgable about machines believes it may be an issue with a bearing, as the noise is much less obvious when sewing, and also went away a little after oiling the areas near the handwwheel. Any ideas on resolving this issue?

-

Pfaff 145 – 545 and Cowboy Questions These two Pfaffs are for sale semi locally 150 miles away. The asking price for the 145 is $750 and $850 for the 545. Naturally they have crappy pictures of the machines. As do all Craigs list pictures. The 145 The 545 What are the differences in the two models? Are these prices reasonable? What should I be aware of as possible problems with these Pfaffs? There is also a Cowboy cylinder arm machine with an asking price of $2100. Claims to be essentially brand new. Naturally they don’t list a model number. To me, it doesn't seem to match any of the current Cowboy machines exactly. But I’m guessing it’s an older version of the 3200(?) Thoughts on this one? Of course a question or two to the seller would clear that up. Just wanted to take advantage of all the helpful folk here to see if any of these were worth perusing. Thank You, All the Best, Jeff

-

I need to replace the needle bar on my Pfaff 545. The integral thread guide broke, so I ordered a new needle bar, and I have the new part. I removed the hook, and loosened the needle bar, but when I try to slide it down and out it hits other parts. It seems to contact the mechanism that drives the feed dogs. Do I continue disassembly of the feed dog mechanism, or is there an easier way? Remove the needle bar holder and slide it to the left? Thanks for any input you can offer.

- 6 replies

-

- needle bar

- pfaff 145

-

(and 1 more)

Tagged with:

-

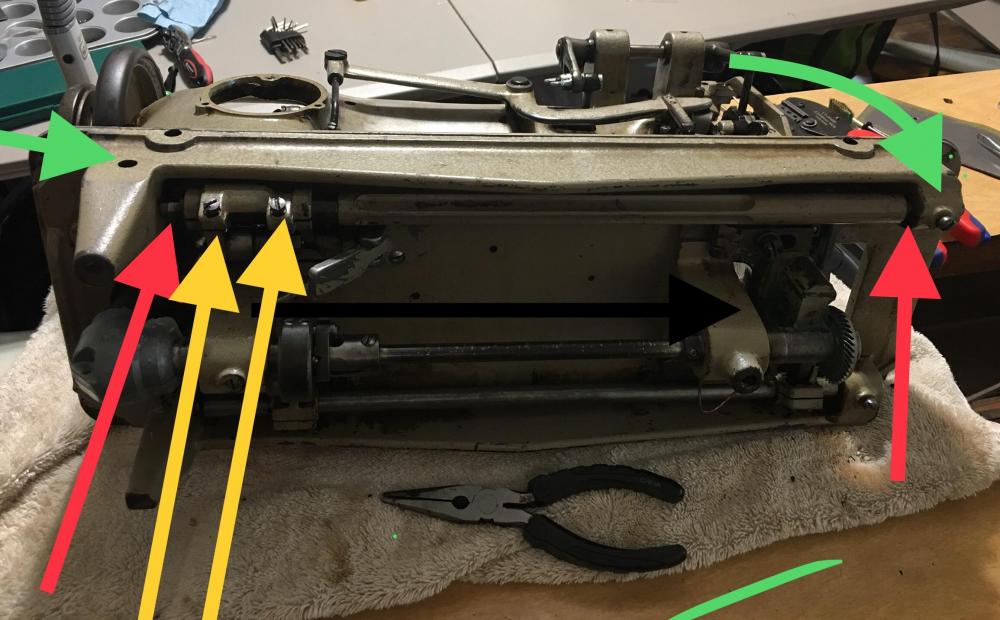

When I get the feed dog side gaps corrected between needle plate, tighten top screws (green) to hold position. (Had to move shaft/bar to the left to correct) Then loosen screws (yellow) to adjust the feed dog moving front to back evenly. (Had to move the hinge unit to the right), it reverses the gap fixed by moving bar to the left to fix needle plate gap. I tried putting shim between the edge of shaft/bar and foot (right red arrow) and completely freeing the left bolt (left red arrow) but still no success. Although instructions indicate there is no connection between the two corrections (side gap versus front to back), I’m now wondering if there is. I.e., I should be able to set them independent of each other. Also wondering if I should be moving hinges differently Any suggestions appreciated. (Using instructions for 1245 as no service Manual for 145).

-

Can anyone could help me to understand how the safety clutch in pfaff works? I described an issue in the file below. Regards, Bert HOW THE SAFETY CLUTCH WORKS IN PFAFFS.pdf

- 10 replies

-

Hey Everybody, I've been a 'lurker' in the shadows here for a few years and have learned a ton of stuff. The openness & generosity of you folks is amazing. I have a Pfaff 145 (high lift version) flat bed sewing machine I got from my Dad. Try as I might I just could not master the clutch motor when sewing thicker leather. I would try to feather the clutch to slow things down and it wouldn't punch through the leather, or I'd engage the clutch enough to punch through & it'd be a runaway train. I changed pulleys on the motor (3.5" to 1.5") and on the head unit (3.5" to 5.5") to try to slow things down & increase torque but the change was negligible to me. This was probably more of an operator issue than a machine issue but the result was still a machine I could only use on thin materials. What prompted me out of the shadows was my experience with Bob & Toledo Industrial Sewing Machines.After searching threads here about Pfaff & servo motors, I called Bob at Toledo Industrial Sewing Machines. He talked me through all of the features & benefits of servo motors, installation tips, etc. He answered all of my questions and took quite a bit of time with me. I ended up ordering the Family Sew FL-550 motor and received it in Atlanta in 2 days! Man, what a difference! Power to spare and I can now sew 3/8" thick leather with complete control! I can stitch sooooo slow too! I keep finding myself sewing stuff just to sew stuff (I have burned through a good share of my scraps). Major props to Bob & Toledo Industrial Sewing Machines!!

- 4 replies

-

- pfaff 145

- servo motor

-

(and 1 more)

Tagged with:

-

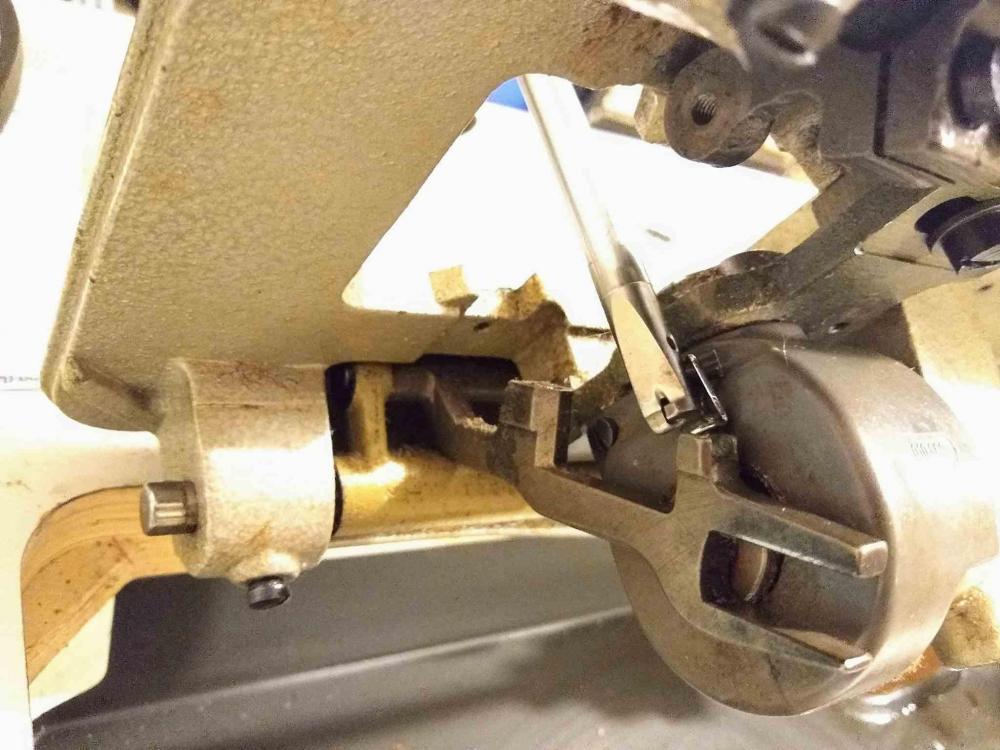

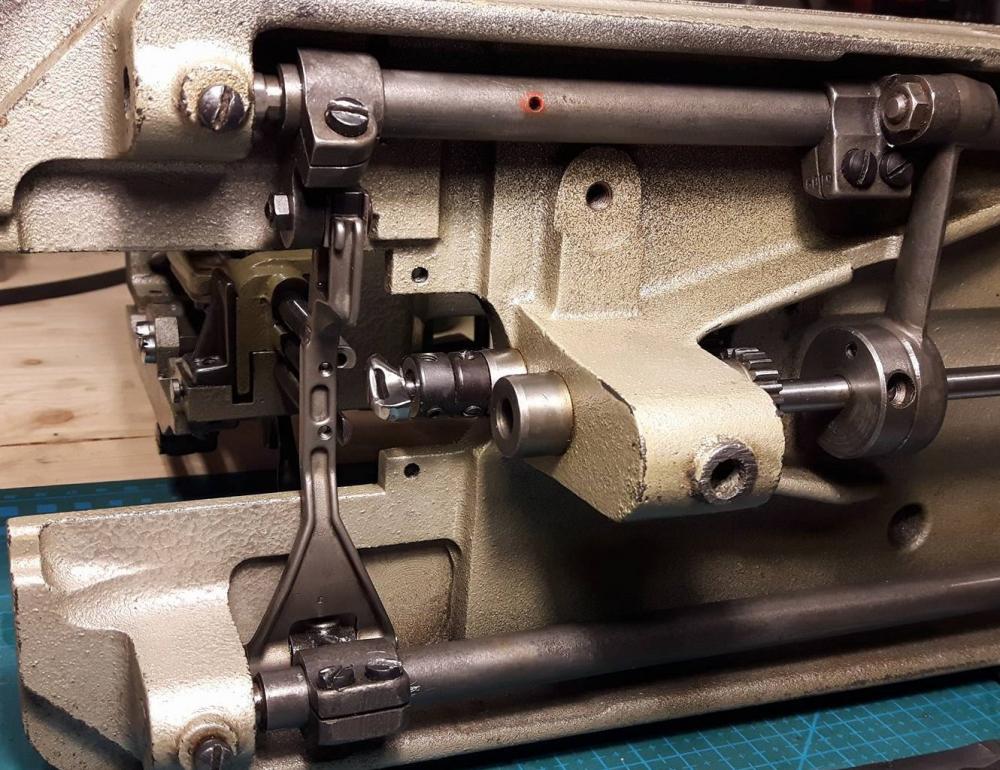

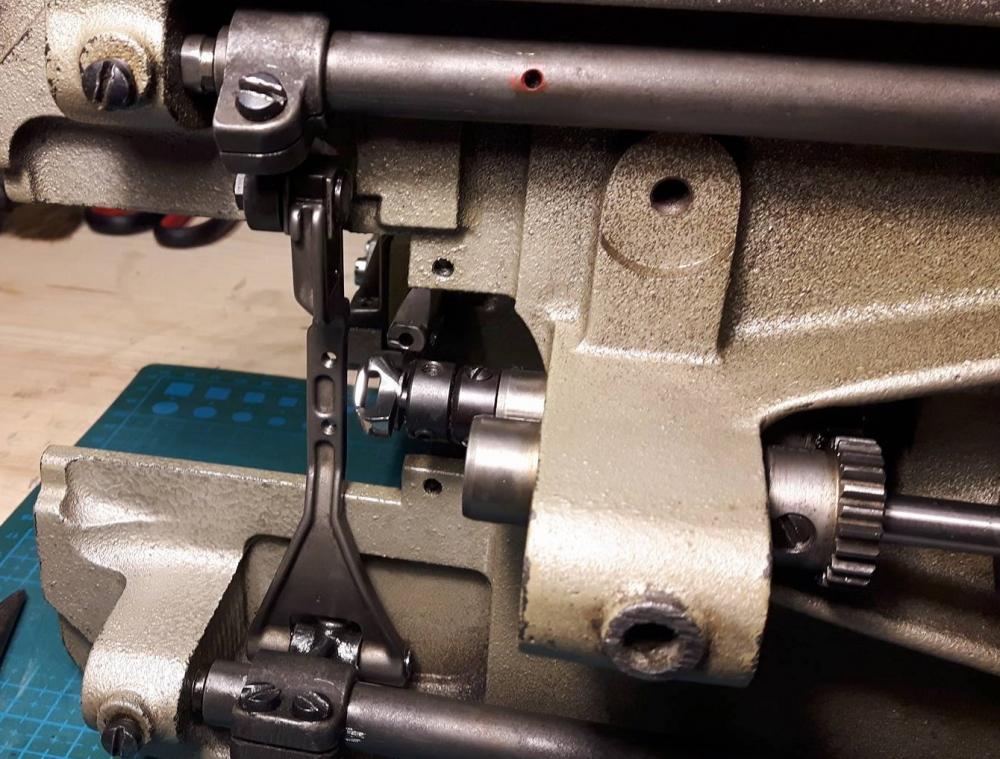

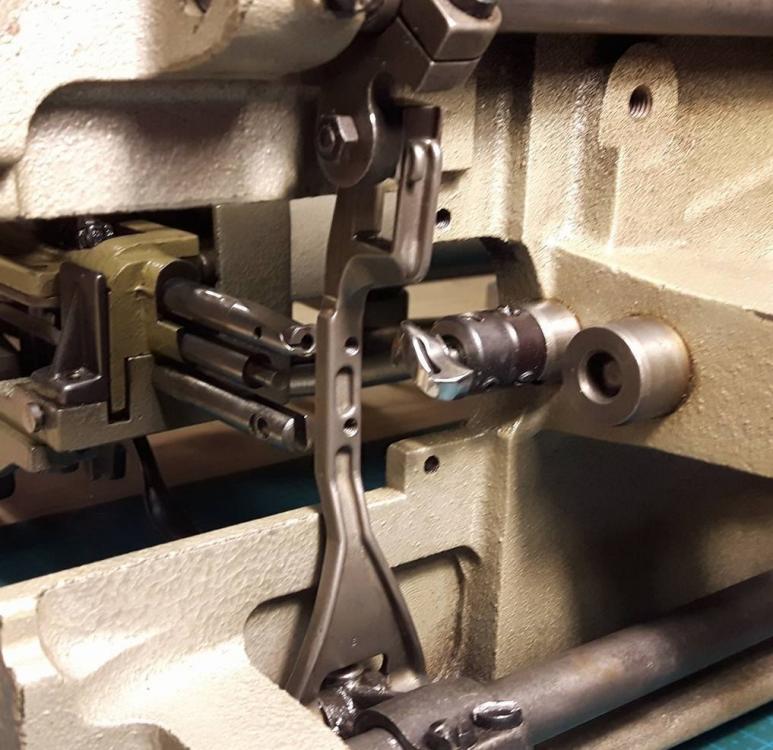

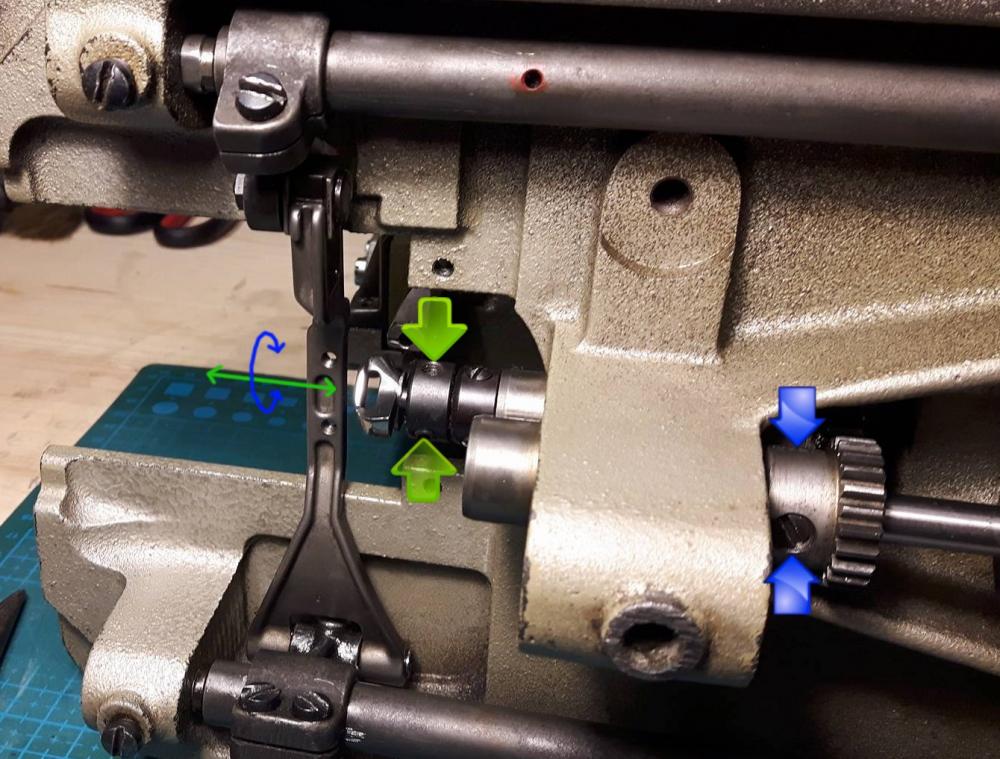

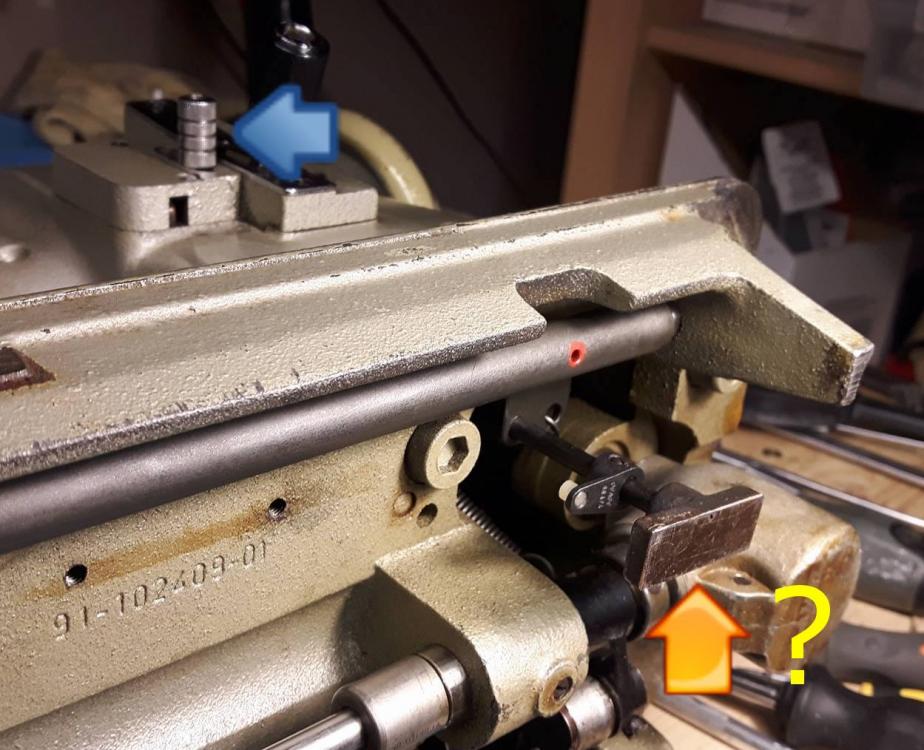

As we are going into details of my Pfaff mentioned in the previous post (link below) I created a new topic dedicated especially to this machine. So the bottom of the machine also has been cleaned up. Here are some photos including the looper Uwe asked for. The previous user forced the machine to work with 190 system needles, so knowing from the manual that this machnie is using 134 system needles I had to lower the needle bar to make the eye of the needle in the looper's range and also correct a looper timing. The looper has a flat sided shaft so losening the allen screws marked with green arrows allows to move the loper only left or right (closer or further to the needle scarf). Having no idea how to change the rotation of the looper I decided to loose both screws on the bottom gear marked with green arrows. Turning the lower gear turns the upper gear opposite and the looper as well. Turning the gear on its shaft also allowed to make no changes in the feed dog eccentric position. I am not sure if I did it properly - but have no service manual and no easier idea how to do this. The looper catches the thread properly and now I have to figure out the thread tension issue - explain later. I have a problem recognizing the unknown function of the brass foot I found on the right bottom of the machine (orange arrow). This is a block of brass fixed on the end of the vertical pushing rod. This rod can be pushed up and down. I can block this mechanism by changing the silver lever (blue arrow) position. Up position of this lever allows pushing the rod up or down and down position of this lever disangage (blocks) this function. The rod on its upper side is connected by the system of four arms with the kind of slider fixed to the lower horizontal shaft of the machine. Pushing this rod up changes the needle and presser bar position but only in their extreme forward or backward position. When both needle bar and presser bar are in their extreme forward position pushing the rod moves both bars 3-4 mm further to forward. The same situation is in extreme backward position of those bars; pushing the rod moves both them 3-4mm further to backward. I pressumed it would be a kind of 'afterburner' of the stitch lenght - but there is no possibility to pass the whole cycle of sewing while needle bar and presser bar are hitting one another and stucking in mid-position when the rod is pushed up. Does anybody have an idea of what this rod might be for? Bert

- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Hi, I'm Bert from Poland, age 50, I'm interested in sewing machines. Now I just wanted to say hello and thank you for accepting me in the group. A few words about myself: About 3 years ago I became interested in the sewing machines and technical aspects of their functioning, later bought an old damaged sewing machine and the overlock and even managed to fix them. Recently I bought very cheap Pfaff 145 industrial machine . Actually it is a rare 4145 model, which I could see as a specific combination between the Pfaff 145 and the 4143. The machine is sewing but it is grossly neglected and requires general cleaning and adjustment. Therefore, I am now looking at posts in this group regarding the Pfaff 145 with interest. Later on surely I will have some questions, but first I want to check existing posts. And here are some photos of my machine. Regards. Bert

-

I am going out this evening to pick up a Pfaff 145 H4 that has some damage but the price is an absolute steal at $50. It looks like the main shaft that attaches to the pulley (arm shaft) was snapped when the owner dropped the machine. From the pictures it looks like a fairly clean break, must be a cast shaft. This appears to be the only damage and I know replacement shafts are available. If I am reading the parts books right, it looks like part# 9-010 002-05. Could one of our resident Pfaff experts chime in to let me know how much a new shaft would be? Maybe one of you have a parts machine sitting around? Also, I'm mechanically inclined so not scared of doing the work but what am I getting myself into? I'm sure I'll need to have a shop look it over afterwards too. I just can't pass up this deal, the table and motor alone are worth more than the asking price! Thanks in advance, Ed

-

I just got a Pfaff 145 which takes G bobbins.. Does anyone know if/where I can purchase empty G bobbins that I can wind myself to match thread? Or, does anyone know of a an online retailer where I can buy #69 nylon or poly thread with matching prewound G bobbins? Thanks for any advice!

-

Need some advice please... My Pfaff 145-P-6C sews beautiful until it skips random stitches. Usually in prominent locations! Leather material used is 3 - 5 oz in weight, thread 69 top & bottom, needle 190LR - 125/20. Tried a larger needle with same results. Machine was recently serviced, no issues noted. It has been around a while used hard in a canvas factory. Any suggestions on what to try as I am very frustrated. Thanks!!!