Search the Community

Showing results for tags 'resolene'.

-

I have been making veg tan notebook covers and antiquing them with Tandy's Eco-Flo Gel Antique. I can get a very nice look with lots of color variation. However I have found that the water-based antique is extremely susceptible to damage from water, even days after it is made. I looked on the board to find recommendations for a non-shiny top coat sealer, and couldn't find a good comparison of different products, so I went ahead and did my own testing on raw grain-side veg tan. I compared Fiebings Acrylic Resolene, Fiebings Leather Balm with Atom Wax, Fiebings Leather Sheen Acrylic Finish, and Angelus Matte Acrylic Finish. I used all at 100%, lightly shakened, with a small wool dauber dipped into the finish and wiped back and forth across a 3" x 3" square, starting wet and ending up dry, in a single coat. After drying for 20 minutes I spritzed water over them to check water resistance. Here are my findings: Resolene was the shiniest and the least absorbent of water. For my purpose it is too shiny. Angelus Matte was the second shiniest and tied with least absorbent of water. Leather Balm was the third shiniest, and the second most absorbent. Leather Sheen was least shiny, and most absorbent. There is an obvious direct correlation between shiny and water absorbency. I suspect that if I used the Leather Sheen in two or three coats it would perform better in water resistance and also become shinier, but I just did the single coat for comparison. Since I'd prefer to apply only one coat of finish I am going to use the Angelus Matte. It has the additional quality of being thin enough to easily airbrush.

- 1 reply

-

- leather sheen

- resolene

-

(and 3 more)

Tagged with:

-

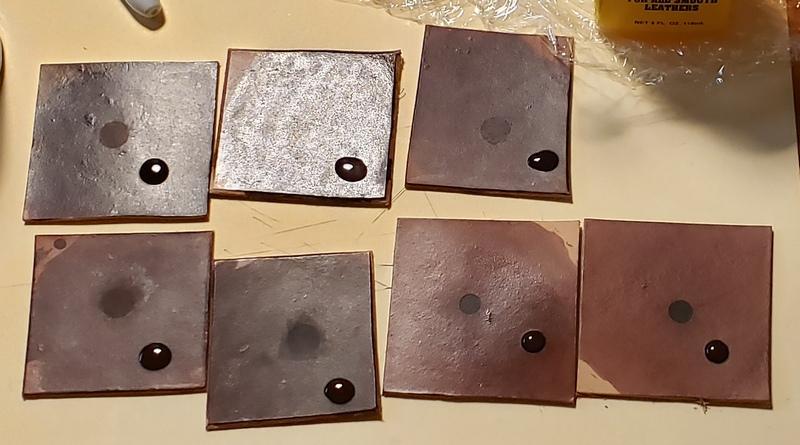

Yesterday, I tested seven different finishes. These were applied over Fiebing’s Pro Mahogany. I was looking for: color change, level of gloss, flesh burnishing and waterproofing qualities. This report is not super organized and may contain errors but I think it conveys the basic results of my tests. I do not wish to spend more time to perfect it because it was a casual test anyway. I put two drops of water on each sample. After one minute, I wiped off one drop of water and let the other sit until it was completely absorbed (over an hour or two). I wanted to know the short term and long term water resistance of these products. When the samples were completely dry, I buffed them in attempt to “repair” them as much as possible, without re-treating them. Buffing did slightly improve their appearance. The damage actually came in the form of cratering. It appeared that the solution had evaporated completely off of the sample. The edge was easy to see and feel. The crater was approximately 1/20 of a millimeter deep. Resolene won the water test. It was completely waterproof. I had a thick coat on there. The color change was quite dramatic but Tan Kote was even more so. Tan Kote was second best. The one minute test showed damage only if the light was reflected off of it in just the right angle. The long term test was a little bit easier to detect but not too bad. Tan Kote resulted in the deepest color change. Shocking, actually. Very dark brown. Satin Shene was a surprising third. The short test did show a very slight discoloration and some loss in gloss. You could tell there was some damage but it was minimal. Color change was very significant. Gum Tragacanth and Tokonole were tied. More damage on both areas than Satin Shene. Sno Seal and Shoe Polish were by far the worst. I must qualify this by saying that I did not warm the leather, nor use multiple coats. I smeared on one coat, rubbed it in and buffed it off. The water damage on these looked like they had burned with a cigarette or like acid had eaten into them. Satin Shene, Tokonole and Gum Tragacanth were the easiest to work with and they all resulted in a very similar semi-gloss finish. Resolene and Tan Kote were sticky and impossible to apply smoothly with a dauber. An air brush would be a much better method of application for these two products. BTW, I did not thin them for this test. I know that is protocol but I am lazy. Both have superior water resistance to the other products tested. Tan Kote can be applied with a dauber and then quickly spread with a finger to smooth it out. This actually resulted in a nice smooth finish that was second in gloss to Resolene, and significantly glossier than the others. If for some odd reason, I could only have one product for flesh burnishing and top coat, Satin Shene, Tokonole and Gum Tragacanth would all work but I would go with Satin Shene, because it had slightly better short term water resistance and it was the best of all the products for burnishing the flesh side. I do not consider this testing to be definitive in any way as it was not scientific and I may get different results if done on different leather on a different day. nick Top row: Tan Kote, Resolene, Tokonole Bottom row: Gum Tragacanth, Satin Shene, Neutral Shoe Polish, Sno Seal

-

Materials used: Fiebing's Resolene Fiebing's dark brown leather dye Acetone in the form of nail polish remover Mink oil Basically the problem I have comes from every time I need to apply resolene to my project; they keep turning yellow. They started off as white, lambskin loafers. I used acetone to deglaze, and after used a wool dauber to apply the dye. I let it sit overnight for 10+ hours, buffed it with mink oil to remove any sitting dye, and then proceeded to apply resolene as lightly as possible with a clean wool dauber. At first, it went on like it always does when applying it to a project. It would turn a bit yellow, but it never affected the underlying dye. Then after maybe 5 or so seconds, the dye underneath started turning a sick yellow/green color. This process has been repeated with the same results maybe 5+ times. I understand that airbrushing would give a better result, but even putting a drop of resolene on top of the shoe seems to pull out the dye and turn it yellow. So even if I avoid any "rubbing" motion on the leather, the resolene still reacts poorly. At one point I applied two coats of dye, and let sit for 24 hours. Still bad results. Is this a leather problem or a product problem? I have since purchased Angelus sealant and will try that today, but I don't want to keep trying if the leather requires a different type of dye. Right now the dyes I am using are alcohol-based. Would labskin take oil based better? I will try to take some pictures later today when I get home. Edit: I added an example of a picture I had taken already of the resolene applied to a small part of the shoe

-

I am making a harness/blouse and I have a 1/4" strip of leather between two grooves as a border on the pieces. I wish to retain the pale look of the veg tan on this strip and dye the rest to a dark brown. What is the best way of doing this. If I need to post a picture or two to clarify please just ask.

-

Hello I'm wondering if anyone has successfully used Acrylic Resolene on top of Tan Kote. The reason I'm asking is that, after I apply a 50/50(resolene water) coat on top of my tooled and dyed test project (dyed using fiebings spirit dyes), and then apply fiebings antique paste, allow to dry thoroughly, buff, and add a sealing layer of 50/50 resolene, it lifts quite a bit of the antique. I've done some research and have found that to be common, and many suggest using neatlac and tan kote combinations etc. But I'm a creature of habit and acrylic resolene has treated me well over the years with spirit dyes, I know how it ages, it's limits etc, and I'm hesitant to change my top finish, thus I'm wondering if anyone has used tan kote to seal the antique(recommended in many topics regarding antiquing here) in combination with resolene. Of course I will be experimenting, but it can be hard to know if something works well down the road, like the finish lifting or cracking, it may look good now and for a few months but I worry about such a combination failing Cheers! -Cheyenne

-

I want to know how much Resolene I should apply. I'm using Fiebieng's Neutral Resolene finish and I've read that a thick layer will show bend-spots or cracks. Need advice on this ASAP

-

Hi everyone, as a hobby I've decided to take on my (natuzzi) leather sofa which had some cracking and some worn patches especially on 2 of the cushions, applied chamberlains milk balm which hid a bit of cracking it had, but those patches were still rough rest of the sofa had this kind of glossy (or so I thought) finish, but 2 of the cushions were feeling rough... so I thought maybe sanding it down to smooth out a bit would help... which kind of did smooth out the leather in those patches, but did nothing to restore that shiny finish, neither did any of the conditioning/buffing... so I thought it needs some finish (which it did, cause some dye was getting transferred to the buffing pad). So I have applied Fiebing's resolene on the sofa and it looked a bit shiny, and on one cushion I felt some roughness so I though, I sand it down and reapply resolene again (since those are the most worn 2 coats would protect them better) and here I am with a blinding sofa... After reading a bit here I saw that people mix it with 50% of water to do less shine, but I think that only would work if you didn't have dried shiny resolene underneath... don't think it would become matte just because I'd add diluted resolene on top... I googled extensively and saw various suggestions for getting less shiny finish using different kind of finish, though I didn't see much for the correction steps... what to do when it's already in that shiny state... sand it down (what grits 800/1500/3000)? Get Fiebing's deglazer and start from scratch (remove/redye/reapply resolene with 50/50 mix)? Acetone? What's my best option (preferably cost effective, not something like get a new sofa)... Thanks!

-

I am doing a project on veg tan leather with small lettering. I am dying it red and then painting the letters white. I was told you could just dye the whole thing red. Apply a coat of resolene which should seal in the dye and then paint over the red dye. But the red keeps bleeding through the white. Am I not letting the dye dry long enough or maybe not letting the resolene dry long enough. I'm letting the dye dry about 3 hours under a fan. Buffing then applying resolene with cloth letting dry for 2 hours and buffing then applying the paint. Any suggestions?

- 14 replies

-

- dying

- acrylic paint

-

(and 1 more)

Tagged with:

-

Hey people~! I use vegi tan leather which bought from local shop in los angeles. I think the leather quality is not good enough. and need to make it more stronger from scratch and sun light. i use neetfoot oil and carat essence for finish.but i don't think it's enough. I like the leather quality of http://www.thepremoworkshop.com/ . Could you recommend any finishes or the method [or leather which i can buy from Online]?? Thank you~!!

-

Hi, everyone! I recently purchased a couple of 4 Oz bottles of Resolene and Leather Balm with Atom Wax to add to my extensive portfolio of finishing options... that only include Tan Kote, besides the message mentioned earlier. My question is: can these products be used together, in different stages on the finishing of one piece of leather? or are they incompatible with each other? I will be dyeing my leather with Fiebing's Pro Oil Dye Dark brown, in case that makes a difference. I remember reading somewhere here that Resolene can be used as a resist before dyeing. if that's the case, what are the benefits of resisting vs not resisting? With just common sense as my ally, the term "resist" tells me that it's intended to affect the degree to which the rest of the products applied afterwards are absorbed into the leather. I know that mileage may vary depending on the type of leather used, the conditions under which the products are applied, etc., but it would be nice to know some of the experiences of other members since the combinations for trial and error are just a step away from endless. Thanks, Everyone!! Efraín.

- 4 replies

-

- resolene

- leather balm with atom wax

-

(and 1 more)

Tagged with:

-

I have some questions regarding acrylic resolene and neatsfoot oil that I am hoping someone can answer: 1. How long will acrylic resolene last? If it is on a mask that is worn once or twice a year what is the expected life? 2. Will neatsfoot oil penetrate a piece that has been covered with acrylic resolene, let's say the piece has seen moderate use for a few to several years.

-

Hi Guys, I'm very new to this, but I found some great stuff here about the ability to topcoat with Resolene after conditioning w/ Lexol, so it seemed like the perfect place to ask. I have an AGVSport Tracer jacket where the manufacturer chooses to leave webs crossing the zip-openings on the wrists unlined on the inside for some reason. (also seen this on 1 or 2 others, btw) I've already topcoated the finish-face with Resolene, but to save the long-sleeve white shirts from constantly turning bluish-black, would it be OK to coat that rougher inside-face with Resolene also? -Or would that lead to something like a "Dry-Rot" situation that people describe when you accidentally coat a jacket in something that doesn't let the leather breathe? Thanks very much for any help and expertise!!! -My shirts thank you too!

-

Hi guys, I've been having some issues with my Fiebing's Edge Kote and Eco-Flo dye leaking if the leather gets damp. What products or techniques do you use to prevent that? Normally the amount of leaking from the Edge Kote isn't terrible, but I worry about it for bag straps. Again, it's only an issue if it gets wet, but still, I'd love to find a solution! I have tried Tan-Kote, Bag-Kote, and the Eco-Flo Satin Shene without much success. I've been doing several coats and letting it have plenty of time to set. The leaking is significantly worse if I treat the leather with saddle soap before or after, which is a pity because I love its effect. I really want a fail safe way to finish edges at the least, and if possible dye my own leather without having to worry about ruining people's clothing! Thanks!

- 2 replies

-

- finish

- seal leather

-

(and 3 more)

Tagged with:

-

After a few prototypes and studies I finally finished a complete, full-sized mask. Not completely satisfied with how poorly eco-flo super sheene performed blocking the brown hi-lite color stain in the white areas despite having applied 5 coats. Next time I'll try resolene.

-

Can someone explain how to apply Clear-Lac and Acrylic Relolene? I am working on a Bible Cover. I painted the flowers with Tandy's Cova Color and Highlighter Stain. The cross & Cover background started out with beige stain, but was too orange for me. I made the mistake of finishing the edges of the cross with gum tragacanth stuff before staining, so anyway this is what I came up with and am pleased with it. I would like to have a very good seal on it, but I am afraid of running the colors together. I think one more mistake may be one too many...lol I have sprayed a light coat of Fiebings Leather Sheen on it. Would I be better off to use Acrylic Resolene or Clear-Lac? Should I just brush it on? Will it cause the colors to mix together? Will it darken the flowers?

-

I'm almost finished with a knife sheath that I'm not really happy with, but the knifemaker likes it. It's got an iguana skin insert and I made the window a little too big; it's in the curve of front to back. I padded it before I put the liner in but I don't like how that worked either. Still -- I'll do another and it'll be better, right? My question is -- how do I finish the iguana skin? The top layer of the sheath is 9-10oz vegtan, lined with 2-3oz. I've dyed the leather black and put a light coat of neatsfoot on it this morning. I put a little on the iguana skin too -- it's old and looked a bit dull. Don't know if I shoulda done that or not. I'm going to put some Resolene thinned half with water on the leather -- does that go on the iguana skin too? Thanks.

- 4 replies

-

- finishes

- neatsfoot oil

- (and 4 more)

-

I left a message on the forum in the dyes, finishes thread but didn't get an answer yet.... Sorry for the re-post but this is for a wallet/money clip that I need to be done with because it is sold... I have been using Resolene and decided to try Tan-Kote... I tested this on piece of scrap but I guess my scrap was too small to see streaks in the Tan-Kote. I have managed to go back over the piece with just a damp wool swab, so now I have kind of a satin sheen to it but I want it to be shiny or at least more shiny. How do you apply Tan-Kote without it being streaky? Can I dilute it with water like Resolene? HELP! Please! Terry

-

I have a problem and am at my wits’ end, so I figured I’d come ask you intelligent and experienced people for advice. :-) I apologize if this is long-winded. I have designed a cuff bracelet that fits various wrist sizes because it is slotted rather than clasped. I made a prototype that I have worn for months and months to “test drive” it, and it’s holding up great and gets a lot of compliments. But now that I’m trying to make it in other colors to sell, black in particular is giving me trouble. (By the way, I am using 7-oz. natural veg-tanned leather from Wickett & Craig.) Mine is dyed Fiebing’s “LIght Brown” (which is actually a lovely mottled dark brown) sealed with full-strength Resolene, and it’s doing fine. I’ve had a couple since then crack beside one of the slots — that could be due to overcutting the slot and/or not conditioning the leather. So I’ve started using leather conditioner after dyeing, and also using a punch tool to cut the slots instead of a hole punch and utility knife, and I haven't seen the cracking problem again so far. So here is the current problem… The several black ones that I’ve made recently have not held up to a stress test — the finish appears to rub off at the contact points. (See the picture for an example.) I haven’t made many colors, but my brown one doesn’t do this. (Of course, it’s possible that it DOES do this but I just can’t tell because the color behaves differently.) I have a dark blue one that has a similar issue to the black (though not quite as bad). It didn’t get conditioner, so I doubt it’s the conditioner causing the problem. I have tried different dyes (Fiebing’s Pro Oil Dye, and Angelus Jet Black). I have tried Black Resolene (which has had the WORST results for this), as well as clear Resolene (both at full strength). I have tried with and without additional finish after the Resolene (Eco-Flo Satin Shene, or Fiebing’s Leather Balm with Atom Wax). I have tried PRAYER. :-) I have used up a lot of time and leather. I need a durable and flexible finish that will prevent dye bleed when the person wearing the bracelet sweats, and that will not rub off at contact points. I suspect this is possible, as belt-makers seem to do okay… What finish do they use (or is it a certain kind of pre-dyed leather)? Should I be cutting the Resolene with water 50/50 (as I have seen suggested elsewhere in the forums), and would it solve the problem? Any help will be greatly appreciated!

- 15 replies

-

- finish

- rubbing off

-

(and 3 more)

Tagged with:

-

I've been dabbling with leather working here and there recently as a means to add pieces into my chainmail work. I'm at the point now where I'm dyeing leather and having some issues. I started out using Tandy Leather's Eco-Flo All in One dyes which seemed to work great. However they're listed as a sealer, and they certainly do not seal in the dye. Get a bit of water and it'll start to bleed color. Moved over to Fiebing's dye with the intention of doing a 50/50 Resolene/water mixture over top as a sealer. However the Fiebings dye came out looking a metallic golden as opposed to the black is was supposed to. Is it alright to use a resolene mixture over top Tandy's Eco-Flo? The Eco-flo gave me the color I was going for, a very nice solid black but its just not sealed in and its likely the pieces I'm making are going to get a bit of rain on them at some point or another. I'm using Vegetable tanned leather, its not tooled or treated other than being tanned. I'll try and get pictures of the pieces for clarification if needed.

- 6 replies

-

- fiebing

- tandy eco-flo

-

(and 1 more)

Tagged with:

-

So here's the playing card suit coasters in all their wobbly glory! I think it's pretty easy to tell which one I started with and which one I ended on, my stamping made progress as I developed a bit of technique. I loathe the number four, so I made a fifth coaster with all the suits on it, and managed to make a horrible looking club, but meh. The big version of the club turned out nicely so I'll take it. These were all carved/stamped on pre-dyed chestnut veg tanned scraps, it took some doing to get five coasters somewhat close to the same thickness. Several coats of watered down resolene went on them, and the edges were burnished (badly) with a felt wheel with my dremel knock-off. Looks better than when I started in any case.

- 1 reply

-

- coasters

- playing card suits

-

(and 3 more)

Tagged with:

-

Hi All, I know this topic had been covered a lot previously, and I've tried looking for the answers without posting a new topic, but I'd still like to get some input from you. I've recently started making leather watch straps. I like the results, and have no big problems with any of the techniques, except from dying and finishing. I am using veg tan leather for this. The challenge with watch straps is that the leather is in direct contact with skin, so perspiration causes some dye to bleed out of the leather. Going forward I will probably avoid dying the side that is in contact with skin (this is not the flesh side, as I am folding the leather when making straps), but even for the top side, I would like to lock in the color as much as possible, to avoid damaging the sleeves from the color bleed and rub off. Here are some of the questions I have regarding this: 1. If I use acrylic resolene for waterproofing, to prevent the water from penetrating the leather (to a certain degree), it should work the other way around as well, preventing the dye to bleed out. Is this correct? 2. Does using acrylic resolene or leather sheen provide permanent protection from dye bleed/rub off, or is it a treatment that needs to be repeated after certain periods of time? I am not too worried about waterproofing or leather conditioning, as this will be the concern for the person who purchases the product going forward. I am more concerned with locking in the dye. 3. Right now I am using Eco-Flo water based dye. Now that I am reading the posts I see that most people recommend using spirit dyes instead. I am happy with the visual results of water based color, just concerned with locking in the color. Does spirit/oil based dye provide better results when it comes to this? Will I get similar results when using resolene or sheen on water based dyes? 4. Any additional advice/comments regarding the subject are more than welcome. Thanks everyone! Dejan

- 3 replies

-

- top finish

- top coat

-

(and 5 more)

Tagged with:

-

Hi everyone I thought I would share some results in light fastness of dyes and finishes. First let me say I was not making these test pieces to test light fastness but was testing for waterproof finishes with zero dye bleed on thin flexible veg tan. So far no luck on that one. When flexed all the finishes caused water spotting which often spotted the dye. So I ended up with all these tests cut from the same leather and thought heck lets hang em in the window and see what happens. Here is the result after about three weeks or so. I kept reading about resolene having UV protector in it well sorry folks I contacted Fiebings and there is no UV protector in resolene. That said although the difference is slight it was the most protective. However I was using it 50/50 with water and where the coverage was not completely even the sun faded and marked the dye. I hate using resolene and plan to order some angelus 600 to try at some point. I get a nicer more water resistant finish with folk art satin varnish but it is shiny and not UV protective either according to my test. So I tried ceramcoat matte varnish (interior /exterior) as it gives a nice finish but didn't pass the water test on thin leather when flexed and is it also does not have UV protection. Just like resolene, people on line say it has UV protector in it (Amazon sellers for example). So I contacted the manufactures and no it does not have added UV protection. I forgot to enquire about the folk art satin made by the same company. As an aside ceramcoat was my bullet proof go to varnish but it seems to me the formula has changed and I am out of my old supply :-( While all the dyes faded the areas with a finish of some sort had significantly less sun darkening of the leather under the dye thus there is obviously some UV protection but not enough to protect the fugitive dyes. Where there was just kiwi shoe polish or bees wax the leather sun darkened a lot. The red dye changed the least. I am planning to make a folding green man camp chair so I really need to solve this puzzle of both water protection, UV protection, dye bleed and flexibility. Some things I am going to try in the future (money and time withstanding) is angelus acrylic finish, silicon for shoes and car products to stop fading. Anyhow I will keep ya posted on the eventual results. Hope this is of some help to someone. Cheers, Toolingaround PS sorry for being so long winded

-

Okay, I have quite a few questions in regards to sealants/finishes for acrylic paint! What would you consider to be the most durable sealant/finish to go over acrylic paint on an item that will be used outdoors and must withstand a lot use? Is there a certain sealant you put on the paint prior to using the finish? I've heard that Resolene is the best to use, is that true? If so, how many 50/50 coats do you put on the item? How many coats of sealant prior to Resolene? Thank you for your time!

-

When would I apply Resolene ? After I burnish with saddle soap and before I burnish edges with wax, or after the wax? The wax wouldn't let the Resolene penetrate would it, and vice versa. It's an item the may get wet, should I just use neat lac instead, as the last step?

-

Hey all, I have a little problem on my hands. I just finished this little project and after I added the finishing touches and sealed my leather with resolene, I then realized i forgot to add my stamp. So my question is it possible to still case the leather, maybe from the backside so it gets it damp near the core and then add my logo? I'm sure if i were to try to add water to the front it would just bead up and never soak in. Also the flesh side is lined with fabric that has been attached to the leather with some 3M 77 spray adhesive. Just hope someone had a few tips before I start this. Thanks! P.S. Its a little christmas gift for my girlfriend so I can't mess this up