Search the Community

Showing results for tags 'seams'.

-

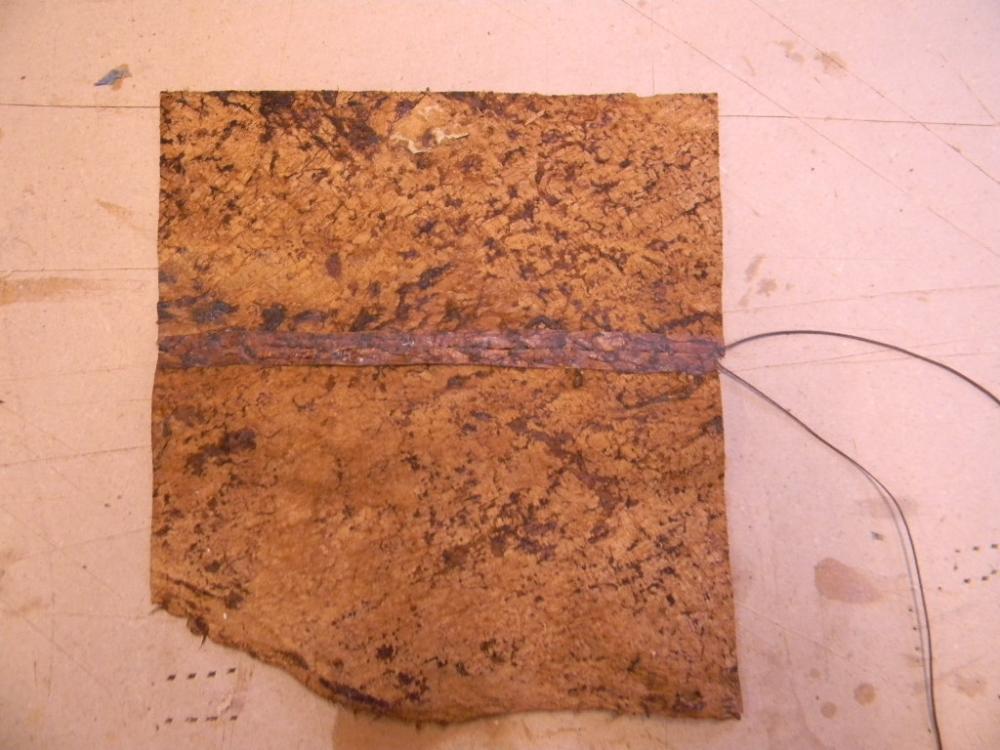

I see high end goods made with exotic leathers pieced together to make wider panels. The seams are nearly invisible. I want to learn how to achieve that look. I bought a couple carp skins from Springfield a while back. They're not quite wide enough as one piece to cover my cane handles with. They're around 3 to 3 1/2 inches wide and I need closer to 5 inches wide. I decided to experiment on one of them to see if I could make it wider. I cut it in half and trimmed the edges so I could put the bottom edge of one piece on the top of the top edge of the other in an attempt at keeping the scale direction running the same way. I lined them up face to face and stitched them together using a saddle stitch and 0.6 mm tiger thread. The leather was pretty stiff so I soaked it in some water to make it more pliable and folded the edges of the seam open on the back side. I clamped it open and flat overnight so it could dry. This is where it's at now. I'm mostly satisfied for a first attempt. Due to the scale pattern a perfect match just isn't possible. I'm ok with that. It's usable for a handle cover and wetting the fish leather made it much more pliable and easy to mold. It's pretty stiff and almost papery feeling when dry. The seam is visible, but not bad. I'll have to pad it somehow so the edges by the seam don't show under the leather. My stitching chisel is large for the thread size. There are a few small holes at the stitch line but they're not visible unless you hold it up to a light. If I do it this way again I'll use my sewing machine and regular thread for a less bulky, flatter seam and line it with wax paper. the leather wanted to stick to the wood. I'll also use wider boards. Am I on the right track with this method? I know this method can be improved. How do the pros join two or more smaller pieces together for a larger panel? What should I be doing differently? Should I try just butting the two pieces together and gluing them to a backing of some sort? I'm concerned about gaps at the seam opening up if I try that. I would like to use some exotics like these skins and ostrich legs, I'm looking at toad skins too, but many are too small to make one piece covers from them. Thanks for any advice.

- 8 replies

-

- fish leather

- seams

-

(and 3 more)

Tagged with:

-

Hey all, new member and leather hobbyist here. This may be a very dumb question, but can I use super glue to bind edges of multiple layers of leather? I don't have a leather or saddle shop near me, so resources are limited to Hobby Lobby and online. Thanks, JC

-

Hi. I am making a bag and bed to put a rivet on the side just like this bag in the picture. My brain is telling me that putting a hole through the seam will make the thread break. But dooney and Bourke does it ...so there must be a way to do this without breaking the thread and risking a weak seam that will come apart. Anyone has any advice on doing this? Also what tools makes those grooves like the one on the loop?

-

Hello! I have a Consew 227R that I use to make bags, purses, etc. When going over thicker seams, the foot gets hung up and wont move over that area. I've tried "less and more" foot regulating pressure to no avail. I've also a thicker separate piece of fabric under the back area of the foot to balance it out. I end up having to "tug" at the back of the fabric to help it move over the seam. I hope someone can help me with this issue. I can't Thank You all enough for your help and time. Happy Holidays!

-

Hi All, TL;DR: Is there a non-painful way to hand-stitch a hidden seam on an article you can't just stitch and then turn inside-out? I'm musing about making a holster for my Browning Buck Mark .22 target pistol, and there's just something about WW2-style holsters that enchants me--the big foldover flap, integral mag pouch, etc. Most holsters of this style follow this generic pattern: Notably, the mag pouch is creased and then stitched quite closely to its edge, no doubt by machine. Yesterday I came across this image for a Czech Army holster, and I notice that all of the seams are tucked under: I have done a pocket or two using Ann Stohlman's trick of poking a tiny "gopher hole" in the outer layer every 10 stitches or so, so the needles can come up and through, but you keep the hole hidden by turning around and stitching right back down through it. As you get further from the gopher hole the awl and needle must pierce at ever increasing angles, so eventually you jump ahead another 10 stitches and make a new gopher hole. Right now the only way I can think to hide all of the seams is to stitch one side open-faced, then fold it over, stitch the bottom through the open side, and then gopher-hole the last side. Is there an easier way to do this? Thanks! Dave

-

I'm currently in the beginning phases of making a corset for my wife and was looking for a bit of advice. First off, here is the pattern I plan to use: This pattern shows half a corset, from front closure to lacing. What I am concerned about are the edges to the sides meeting up cleanly. As you can see I have a curve where the front and back pannels meet the side, where most of the waist cinching will occur. I am using 5-6 oz. leather. To combine each piece I plan on using an overlap of about 1/2 inch to act like boning and I am not sure how to handle the curving part of the piece. Should I notch it? Some other method? Any oppinions/advice would be greatly appreciated.

-

Hey all.. I'm good with finishing the inside of seams on leather items, and good with finishing seams on canvas items.. But when I combine the two I run into issues.. I'm making a waxed canvas bag with a reinforced leather bottom.. and I want the seams finishing on the inside of the bag.. Does anyone have suggestions on finishing the inside seams? I could do a bound seam, but other styles that lay flat just won't work for both.. French seams, flat felled seams are great for fabric, too tough for leather.. Any thoughts? Thanks Todd