Search the Community

Showing results for tags 'sewing machine'.

-

Option A: Digital Servo Motor See the parent article: Choosing a Motor While lots of motors are sold under the moniker “Servo motor”, the most obvious way to recognize a digital servo motor is that it has an LCD on the front of the panel. Note on this forum you will hear people talking about “brushless” servo motors. In theory, a digital servo can be brushed or brushless, but all the digital servos I’ve seen are brushless. So you can assume when folks are talking about a “brushless” motor on the forum, they mean a digital servo. 1. What does “servo” really imply A true servo motor is one that has a feedback loop. You ask it to go 500rpm, and it has an encoder or some other feedback mechanism that it uses to go exactly 500rpm. Whether stitching through thick leather or thin fabric, it keeps going exactly the speed you asked for. 2. Is a Digital Servo the Right Motor for Me? Choose a digital servo if: - you want to use a needle position sensor - you’re OK with doing some basic setup in the LCD menu, - If you want the consistency of the needle always penetrating the fabric, without need to “get a run at it” - you want a motor that does exactly what you tell it - you don’t mind the surprise of instant start. (digital servos have a minimum speed) - you can find one with a minimum speed of 100rpm or lower 3. What is a Needle Position Sensor? A needle position sensor allows a digital servo to stop at the same position every time you let off the gas. I like my needle position sensor configured to stop in the needle-down position. That is the position I use most often, since it allows me to turn corners while stopped in needle-down. So when I let off the gas, instead of stopping immediately, the motor actually proceeds to the needle down position and stops there. 3.1 Positioner: Heel Tap When you have a needle position sensor, it will typically have heel-tap functionality. That is, when configured to always stop in the needle-down position, after it comes to a stop in the needle-down position, you can press the other end of the treadle (the end close to you) and the machine will move approximately a little more than half a rotation and stop in needle-up position. Now you don’t have to do nearly as much hankerin' with the handwheel, because the needle already knows how to stop in your two most desirable positions. 3.2 Positioner: One Stitch Stopped prematurely? A little tap on the pedal and it will give you one more stitch and stop again in your preferred stop position. 3.3 Positioner: Reverse Magic Reverse is convenient with needle positioners too, since you typically want to start reverse from the needle down position. Just allow the machine to stop before you move the stitch lever, and you’ll automatically be starting your reverse stitches in that “reverse magic” position (needle down) where moving the stitch lever does not move the feed dog at all. 4. What’s the Big Deal about Minimum Speed? When looking for a servo motor, the most important feature you should be looking for is a slow minimum speed. When the digital servo motor starts turning, it immediately goes from 0 to whatever the minimum speed is. Meanwhile you’ll be be holding the threads down so your seam locks, and trying to steer at the same time The lower the minimum speed, the less jarring this all will be when the motor starts. 4.1 Examples with 100rpm minimum speed As of August 2025, the lowest minimum speed I’m aware of in a Currently Available Inexpensive Digital Servo Motor (CAIDSM) is 100rpm, and it costs a little more than a hundred dollars. You will need to buy the needle positioner separately, which will cost you another 30. (Will post link as soon as mine arrives and I’ve tested it) 4.2 Examples with 200rpm minimum speed Previously I used these two models which have 200rpm minimum speed. I’ll put air quotes around the brands, since these are just labels and you can buy the same motor with a variety of labels on it. “Stitchman”: https://www.alibaba.com/product-detail/Energy-Saving-Servo-Motor-Industrial-Thick_60477748373.html “Consew C1000”: https://www.amazon.com/dp/B01N6IYMCZ 4.3 Gear Reduction You can lessen the minimum speed that your digital servo offers by gearing it down. The simplest way to gear it down is to buy the smallest motor pulley (the pulley that goes on the end of the motor) that you can. Ideally your digital servo will use a 15mm cylindrical-shaped shaft (no taper), because aftermarket pulleys are readily available in 45mm O.D. for about ten dollars. 3:1 belt reduction is commonly available and costs about $110. You may or may not decide you need that much. There are also examples here on the forum of custom built gear reducers using pulleys and pillow blocks. 6. What’s already Working Well Since this article does set out to name certain deficiencies in the CAIDSMs, I thought I would also give praise to the things that have already been ironed out, and are much appreciated! 6.1. The maximum speed can be set to something approachable instead of the default 3500rpm. 6.1. Setting the maximum and minimum speeds is a repeatable process. That is, if you want max speed for one project to be 1200 rpm (at the motor) and for another project you only want 700 rpm, you can select exactly those values in the menu. 6.1. The digital servo already runs well at consistent speed with great penetration power. 6.1. Needle position sensor has basic functionality. 6.1. The power switch is usually in easy reach of the operator. 6.1. The power switch lights up so we can see it’s powered on. 6.1. Digital servo motors are quiet! You won’t know it’s on if you’re not on the gas. 6.1. Digital servo motors come with an adjustable bracket for setting belt tension. 6.1. Digital servo motors come with a V-pulley. (I can’t believe I’m listing this as a feature!) It’s just a larger-than-ideal diameter. 6.1. Electric braking: When you let off the gas, the digital servo motor applies electric braking until the motor comes to a stop. (After coming to a stop, the brake is released so you can easily move the handwheel) 7. The Ideal Digital Servo Motor For those whose ambition it is to built better Digital Servo Motors, here are several categories that could use improvement. 7.1 Ideal Needle Positioner 7.1.1. When you tap the gas pedal to ask for one stitch, you should ALWAYS get exactly one stitch. If you give two stitches instead of one now there’s an extra hole in the leather that I hadn’t planned on. Also, giving more stitches than asked seems like a safety issue. 7.1.2. When you heel-tap to ask for the needle to come up, the needle should come up. It must not do a full turn and then come up. A full turn would put unwanted holes in the leather and is a safety issue. 7.1.3. Distance in degrees between needle-down and needle-up should be configurable. (My preference would be to set the needle-down position using the set screws on the needle positioner, and then have a single setting “distance from needle-down to needle-up” in the menu that has a range from 1 degree to 359 degrees (degrees of handwheel, not motor pulley), with a default of about 200 degrees. 7.1.4. If the belt slips such that the motor has to turn farther than it expected for the needle position sensor to register one complete cycle, the motor should stay in needle detection mode. 7.1.5. Ideally, the needle position sensor should have an LED that lights up when the positioner is in the needle-down position. (Makes for easier setup) One of my CAIDSMs has this, one does not. 7.1.6. Assuming this unit comes with a needle position sensor, the controller should have needle positioning enabled by default. 7.1.7. Needle positioner should work even if using considerable gear reduction, such as 3:1, 4:1, or 5:1. 7.1.8. Ideally, allow the user to easily toggle between stopping at needle-up, stopping at needle-down, or disabling the needle positioner. (One of my systems has this option, the other does not) 7.1.9. Ideally, after letting off of the treadle as the motor continues to turn to come into the desired position, this speed of this motion would be configurable. Some users will want this motion to happen at the minimum speed. Some users may want it to be somewhat faster than the minimum speed. (Of my two digital servos, both of which have 200rpm minimum speed, one comes to final position at 200rpm and the other comes to final position at about 250rpm. I did not see any way to adjust either.) 7.2 Ideal Included Pulley 7.2.1. Motor should come stock with a small motor pulley (35mm-45mm) to lessen the effects of the minimum speed. 7.2.2. If motor does not already come with a small motor pulley, motor should use standard 15mm cylindrical shafts with a key hole. After market pulleys are available for these shafts down to 45mm for about ten dollars. (In a pinch you can 3D print a small pulley for any style shaft, but it may not grip as well as the metal ones.) 7.3 Ideal Minimum Speed 7.3.1. Ideally, the minimum speed would be 30rpm. This would alleviate the need for a gear reducer for many people. If you’re going to tell me that you can’t keep the motor cool at 30rpm, then put a temperature sensor on the motor and let us run at 30rpm until the motor gets too hot, and then make us take a break. When I’m sewing, most of my time is spent getting the next seam ready, and not that much time actually stitching. So there’s little chance of me overheating a motor. 7.3.2. If you can’t offer a minimum speed of 30rpm, perhaps you can build in true soft-start functionality. By this I mean when you first press the treadle the motor would start at something very slow (like 10rpm) and would ramp up to the minimum speed over the course of say one second. This would give us more reaction time during that first stitch when we are both holding down the top thread and guiding the material and keeping our fingers out of the way. (By the way, the only feature similar to soft-start I have actually seen on CAIDSMs would be better described as “how long to wait before full speed is allowed” and was not a soft start the way I am imagining it.) 7.4 Ideal Gas Pedal 7.4.1. There should be a long range of travel in the foot pedal between slow and fast. CAIDSMs have a range of travel of less than one inch. If you can only offer one inch of travel, then how about providing instructions for drilling alternate holes in the treadle so that the amount of treadle rotation required for full actuation is still large (30-40 degrees). 7.4.2. When the maximum speed is set to something slow such as “900 rpm”, the range of pedal travel should be spread across the entire usable range. Meaning you should have to push the pedal all the way to get to 900rpm if 900 rpm is your max. 7.4.3. If the gas pedal is pressed down while the power button is turned on, the motor should not start. (Safety) Rather, the motor should wait until the gas pedal is released and then pressed anew before motor starting. 7.5 Ideal Physical Layout 7.5.1. The menu should be accessible from the standard seated user position. (Some CAIDSMs have the menu hard-mounted with the motor, which is hard to reach, hard to see.) 7.6 Ideal Safety 7.6.1. Pressing the gas pedal after the power switch has been turned off should have no effect. CAIDSMs do not have this yet. Rather, it takes about 12 seconds after turning off the power switch before the LCD goes blank. And until the LCD goes blank, the motor has full power. This is a safety issue because it takes patience to turn off the motor and then wait for the LCD to go blank before performing maintenance issues like threading the needle, replacing the bobbin, replacing the needle, etc. And we want to make sure users can perform maintenance without the risk of accidentally engaging the motor. 7.6.2. When the power switch is turned off, the motor should immediately stop. CAIDSMs currently keep running after power is switched off, until they bleed off the internal capacitors. 7.6.3. Ideally one could limit the amount of torque through the control settings. Another way to limit torque is to run your belt on the loose side. One of my CAIDSMs shows an option to limit torque, but the option doesn’t actually work. 7.7 Ideal Menu Design and Factory Defaults 7.7.1. There should be no settings visible in the menus that don’t do anything. 7.7.2. The settings in the menu should be numbered incrementally. No skipping numbers, as this is confusing. 7.7.3. Instructions for operating the manual should be provided in clear language. 7.7.4. The factory default maximum speed should be something medium slow like 1000rpm. Let the user increase it through the menu if they need it faster. 7.7.5. Ideally the documentation would include an email address or website where users can ask questions and get clarifications about features. (CAIDSMs don’t even say who the actual manufacturer is.)

- 2 comments

-

- servo motor settings

- servo motor

-

(and 2 more)

Tagged with:

-

I need some help distinguishing the main differences of the 2 juki cylinder arm machines. i prefer the bobbin arrangement of the 246. I sew backpacks, so need this machine for sewing in bottoms, doing some repairs, binging round bottoms and items with tight corners, sewing collars ect. I used a 246-7 earlier this year and was impressed, and the swing away binder attachment worked well, though i have no need for -7 version. i do not want a dedicated binder for this machine. Advanced sewing has both models available used and trying to make the most informed decision i can. on the pictured 246-6 they offered to set it up as a manual machine, new motoor with needle positioning. my work is at alpineluddites.com if you want to see exactly what i build. i did buy a Pfaff 355 a few years ago and it didn't have pull i needed and kept breaking needles. i sold it to a leather worker. thank you

-

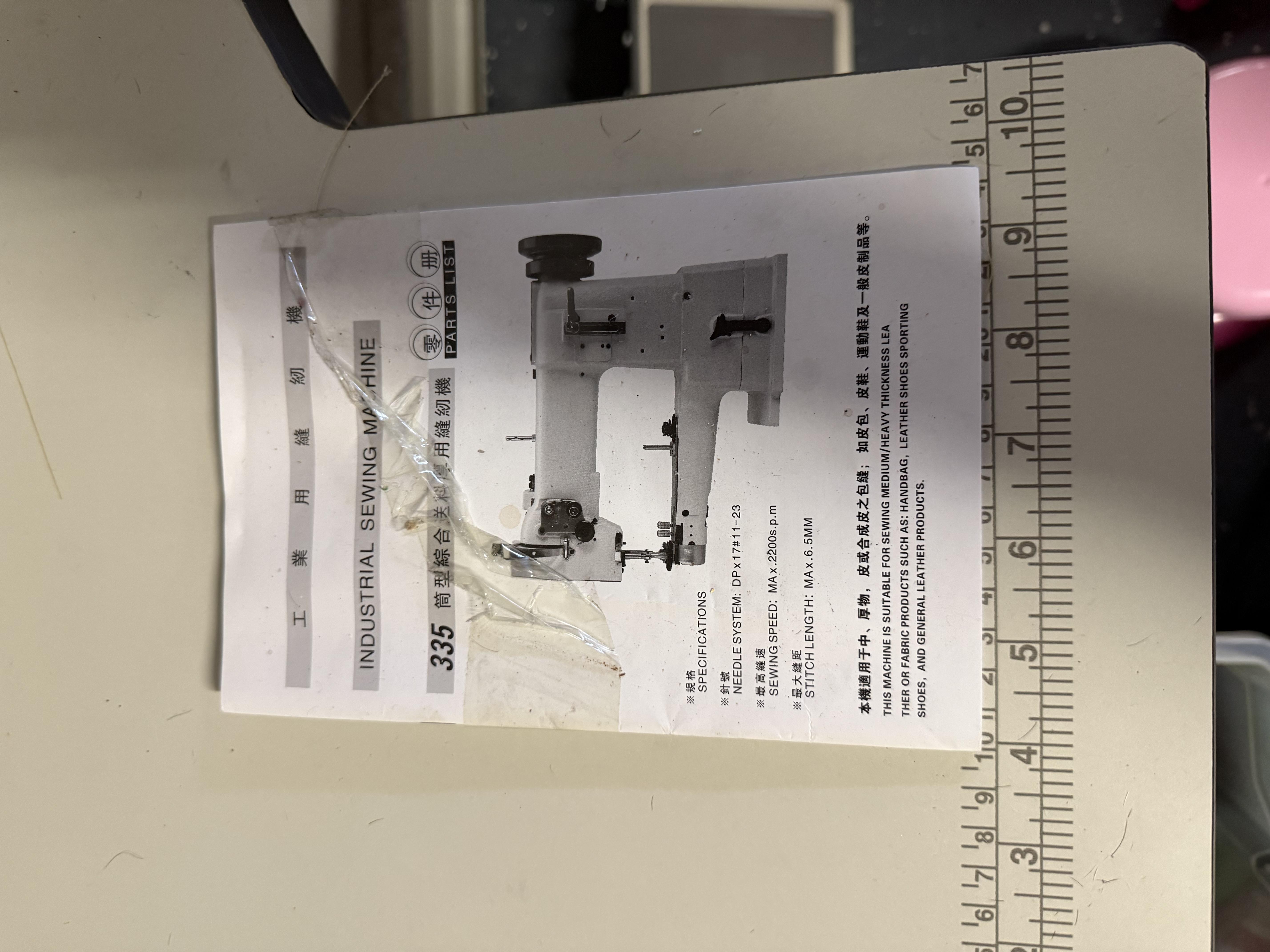

$1200 OBO located in Orange County, CA less than a year old. Runs great and has only been used a handful of times. I upgraded to a Servo motor. It also has a table. We are moving and I unfortunately can’t take it with us. The FY335A is a Medium to Heavy Duty Walking Foot Cylinder Bed with Compound Needle Feed or (Unison Feed) Lockstitch Sewing Machine with an “M” size Big Bobbin and end of the cylinder Big Size Rotating Hook mechanism. The FY335A machine includes a lever-operated stitch length mechanism with a reverse feed regulator for back tacking and stitching in reverse. Some additional features of the FY335A include a semi-automatic lubrication system. The machine sews thread from size z-46 up to size z-207 in the needle with up to z-138 in the bobbin. SPECS Sew up to: 7/16" Thread Size: Up to 207 / Reverse feed Speed, Max (SPM): 2500 Presser Foot Lift by Hand: 5/16" (8mm) Presser Foot Lift by Foot: 1/2" (13mm) Needle: 135x17, DPx17 Needles System Stitch Length Max: @4.2 SPI (6mm) Cylinder Diameter: 1-31/32" (50mm) Work Space: 10-5/32" x 4-11/32" (258mm x 110mm)

- 2 replies

-

- sewing machine

- industrial machine

- (and 7 more)

-

"The Classic Custom Leather Stitcher by Luberto’s Sewing Machines is in excellent condition. This candy apple red machine includes an owner's manual, setup instructions, stand, and eight spools of leather thread. Dimensions: 22” wide, 19” deep, and 38” to work surface." Price $4,000 or OBO. Must pick up in Estes Park, Colorado.

-

Buongiorno, ho acquistato da poco una Durkopp Adler 69 e studiandone il funzionamento mi sono imbattuto nella regolazione della pressione dei piedini; so che la parte filettata più grande serve per regolare la pressione dei piedini ma, nonostante i miei tentativi, non riesco a capire a cosa serva la piccola vite in alto (cerchiata in rosso), quindi chiedo a voi. grazie a chiunque mi risponderà

- 3 replies

-

- sewing machine

- adler

-

(and 3 more)

Tagged with:

-

$400 obo In great working order! Located in Monterey Park, California 91754 May be able to deliver locally for a fee

-

I bought this Consew 255RB-3 sewing machine brand new in 2017, but I've only used it three times because I prefer sewing by hand. The sewing machine has been sitting in the corner unused. In addition, earlier this year, due to health reasons, it was determined by my doctor to select another craft. I will no longer be able to do leather work. Therefore, I have decided to sell my supplies and equipment. About the Consew 255RB-3: This Consew 255RB-3 is a heavy-duty, single-needle, lockstitch sewing machine designed for industrial use. It features a walking foot mechanism, ensuring uniform stitching on a variety of materials, from light fabrics to heavy leather and vinyl. The machine is equipped with a large bobbin, vertical axis hook, and a Centra-Lube® semi-automatic lubrication system for smooth operation. Key Features: Walking Foot Mechanism: Ensures consistent stitching on multiple layers and thick materials. Triple Feed: Drop feed, needle feed, and alternating (walking) presser feet. Large Bobbin & Vertical Axis Hook: Reduces the frequency of bobbin changes. Centra-Lube® System: Semi-automatic lubrication for reduced maintenance. Stitch Length: Up to 10mm (2 1/2 SPI) with reverse feed. Safety Clutch: Prevents damage to the hook. High Lift: Allows for sewing thicker materials with ease. Applications: Ideal for sewing a wide range of products including auto, boat, and furniture upholstery, tarpaulins, covers, awnings, tents, handbags, luggage, sports equipment, outdoor clothing, and more. Included: Consew 255RB-3 Sewing Machine Walking Foot Complete Taglo Table K-Stand with Drawer for tools Instruction and parts manuals Thread Bobbins Lamp This machine is perfect for professional leathercrafters looking to upgrade their equipment or for businesses needing a reliable, high-performance sewing machine. Don’t miss out on this great deal! $1900.00! (K-stand and lamp are usually sold separately; both are included).

- 6 replies

-

- sewing machine

- gently used consew sewing machine

- (and 2 more)

-

Hi guys. First post. I've just acquired an old singer 411u 967aa sewing machine with the goal of doing a bit of upholstery work. It's in running condition and while it could use a bit of a clean and some tension adjustments it was a reasonable deal, and local. The machine didn't come with any manuals and while I've found a parts list and part of a service manual online, I haven't been able to find a user manual. I'm keen to get hold of as much information on the machine as I can to give myself the best chance! II've emailed singer, checked the ismac website, singer website, manualslib etc etc. If anyone happens to have th3 user manual or complete service manual on this machine, that they can share I would be very grateful. My machine is a bit worse for wear than this picture but it's the same model

-

I'm just getting started and do not plan on this being a business, only a hobby. I am very confused as to what type of sewing machine I need. I'm looking at the Tandy Outlaw but have thought of electric models. I would like to do belts, guitar straps, wallets, knife sheaths, and possibly holster. Any ideas would be greatly appreciated. I would like to stay in the price range of the Outlaw if possible. I purchased one of the Chinese machines for about $125 but have given up on it. If anyone wants a fishing weight, they can have it. Thanks in advance.

-

Hello, a couple days ago I asked whether I should get a post bed or a cylinder arm sewing machine. Thanks to the input from this community I have decided to purchase a post bed for shoemaking. I am wondering what post bed would you recommend? I plan to sew work boots around 16 oz leather combined and want to use bison leather rarely, but would be in the vicinity of 18 oz of leather combined. I have seen the techsew 830 which from what I have seen is the only post bed capable of sewing 3/8 of an inch. Compared to other post beds they are rated for a maximum of 5/16 inch leather. I was wondering what other post beds would you recommend or should I get the techsew 830? Also will the techsew 830 sew 3/8 veg tan leather or is the 3/8 a maximum for like denim and the maximum for leather is something else?

-

So, I bought a Consew 206RB-5, and I'm excited to get started. Table showed up preassembled, servo motor looks cool, whole thing seems neat...but, hey, anyone know how to set this thing up? I've read a ton of posts here, and elsewhere, watched near endless videos on Youtube, so, of course, now I know how to assemble the table that came preassembled, and how to thread the machine 80 different ways. Thing is, none of that is how to take the machine from cool parts in a box to actual, working machine. How do I install the bobbin winder? I need to drill new holes? There's a sheet metal housing that, I think, covers the belt, is that so? What are these curved springs with copper wire in them for? Or this wee metal piece lined with cork? Generally, what is all this unexplained crap, and what do I do with it all? And, of course, why is the instruction manual slightly less useful than a screen door on a submarine? I'll take my answers off the air, thank you!

- 9 replies

-

- 206rb5

- sewing machine

-

(and 3 more)

Tagged with:

-

Hello everyone I am new in the leather work industry and I am making dog collars and leashes and sewing them by hand. But now I am interested in buying a sewing machine to speed up the process and be even more precise. I am doing some research online but it's very difficult to understand what machine will be the one perfect for me. I am working with natural leather that is 3/3.5 oz thick and/or natural leather 3oz plus a padding made with soft leather (0.8/1oz) and some foam. What would you suggest I could buy? My budget is 500/600 CAD. I found two Omega machines on e-bay that seem interesting but I read good and bad things about them at the same time (model Omega 307 and Omega walking foot WF22ZZ). Thank you a lot for your help!

- 23 replies

-

- sewing

- sewing machine

-

(and 4 more)

Tagged with:

-

Hello! I recently bought an industrial Juki that came with this servo motor. I was under the impression that the dial in the front would adjust the speed, however nothing changes when I turn it. Does anyone have this motor? Is there a way to change the speed? Photos of the motor are attached. Thank you!

- 5 replies

-

- sewing machine

- servo motor

-

(and 1 more)

Tagged with:

-

Hi folks and good morning from Australia I have a slight problem with my Cowboy CB4500 and servo motor The machine is 10yr old but has done very little work and most of that is 8/9oz.Today I have gone to sew and switch the power on everything lights up as per normal the LED on the front has these little [ ] things that just revolve around the screen as per normal no noise at all, have pulled all power connections (plugs) out put them back in switched power off for a while switched it back on again I am at a loss as I only used it a month ago and it was perfect. The only thing I have put it down to is we did loose power for about 2 days due to flooding in the north of the country and I did hook up a generator for that time and the machine was plugged in to the wall maybe a power spike from the generator, but then it should not switch the LED screen on.I DON’T KNOW

- 3 replies

-

- servo motor

- cowboy cb4500

-

(and 2 more)

Tagged with:

-

Hey All, New to the forum, but not quite new to leather working. Wanted to pick the brains of experts around here and get some suggestions as to the best machine and attachment for our needs. We're looking to produce our current leather bag line in-house along with a few additional styles in the coming months, but don't have the correct machine to sew leather edge binding on our bags....or even the bags for that matter. I've been sewing our smaller items with a Brother LS2-B837 walking foot honed in exactly where I like it, but it does not suit the purpose of sewing duffel bags due to the flat bed design. I've prototyped a few duffels in the past on this machine, but it's definitely not ideal for production use! I really have 2 questions. One is about machine selection and the second is about sewing leather binding. Question 1. What machine recommendation do y'all have for sewing our style bags. We use #138 polyester thread on 5-5.5oz veg tan, edge skived, 2 layers minimum, more where pull tabs, handles, etc attach. We're not sewing through anything crazy like 1" of thickness, but we do have a few spots like handle sewing where its close to 20oz of leather. Picture of duffel bag attached for reference..... Question 2. When sewing a leather edge binding, do most manufacturers prefer to glue then sew or use a binding attachment to feed it through? Also, is the binding sewn on the same time as the seam, or is the bag sewn, then the binding attached after? We're low volume at the moment (15-20 bag runs) so not vitally important we're the most efficient at this time, but still need to be able to grow into our machine. Thanks all for the help in advance and excited to see what else I can learn in the meantime! Regards, Joe www.blvd-east.com

- 34 replies

-

- sewing machine

- binding

-

(and 1 more)

Tagged with:

-

I have a lightly used Cobra Class 26 for sale. Not used much because I also have a Class 4 and we use the class 4 mainly everyday. Looking to purchase another class 4, so we're looking to get rid of the class 26. Runs smoothly. Never had any issues with it. Comes with: Work platform Owners manual Schmetz needles in sizes 18, 20, and 22 2 spools of thread (black and white, size 69 nylon from Leather Machine Co) Local Pick Up In Southern California Only

- 10 replies

-

- used

- sewing machine

-

(and 1 more)

Tagged with:

-

Good day everyone! Many moons ago, my wife and I were avid Cowboy Action Shooters while we still resided in Southern California. We used to shoot/compete fairly regularly with The Cowboys in Norco, CA - even occasionally traveling to Arizona etc. for larger competitions. As I became more involved in the sport, I took up leatherworking to make us custom gun belts, holsters etc. and when I was good enough my wife treated me to an Artisan Toro 3200 leather sewing machine. Unfortunately, after the birth of our daughter and a move back to Canada I'm no longer involved in the sport and no longer make use of this incredibly powerful sewing machine. Sadly, during the near 2500 mile journey, the moving company we contracted was less than gentle with my machine and the castors on the stand were broken and the spool holder damaged. Nothing a competent spot of weld couldn't fix for the spool holder and I am sure someone handier than I could put new castors on the base but it is what it is. Additional images and a short video can be accessed at the link below; https://drive.google.com/drive/folders/19FVdLbwEQMJcbShvRpPS_vfISToiZDPL?usp=sharing I have only worked on a small handful of projects with this machine before I stepped away from leather working and cowboy shooting. Outside of the above mentioned issue with the castors and spool holder, the sewing machine itself is in excellent condition. I have regularly oiled it to ensure the internals stay lubricated. I'm asking $1500 for the sewing machine. As I am moving soon and because I live in the Toronto area, my preference would be for the buyer to pick up the sewing machine being as it weighs a not inconsiderable amount. However I am willing to entertain discussions about possibly shipping the sewing machine if the buyer is willing to pay and help with coordination (as I have a lot on my plate right now with my move as it is). I'll do my utmost to check in on the listing as often as I can in case there is any interest. Thank you for your time and consideration folks!

-

I'm wanting to get my bf a good sewing machine for Christmas. What's a good decent priced sewing machine I can get for basic leather/fur work? What do the prices usually go?

- 8 replies

-

- sewing tips

- sewing leather

-

(and 3 more)

Tagged with:

-

We have an Adler 30-15 treadle sewing machine for sale. Asking $2,000 OBO. Our friend who owned a leather and saddle shop recently passed and we purchased the entire contents of the shop from his estate. We have never used the machine but seen it being used while spending time at his shop. My wife is the leather worker in the house and her bad knees precludes the use of a treadle machine. We are keeping the other modern electric machines that came with the estate. We are located in central Wisconsin so pickup at our location is preferred but I am willing to discuss other possibilities. I know this is my first post so if anyone is concerned I am a scammer, but interested, please message me. I am willing to do whatever to help alleviate those concerns. I have many more photos and higher quality photos I can send interested parties, I wasn’t able to post them here due to the data limit. If there are specific photos of certain parts of the machine you would like, message me, I am more than willing to take more and send them.

-

Please assist. My bobbin hook is not spinning at some points. I will move it around and sometimes it will spin and others it won't. I'm hoping there's just something stuck down there. https://www.reddit.com/u/verniyah/s/4jdO9hBg9K

-

I've decided to bite the bullet and get a sewing machine, but I need some guidance. I don't picture getting into bags very often so a cylinder arm isn't needed...yet. I was looking at sailrite for a bit, but keep getting directed to Cobra. My question is can a class 20 cleanly stitch thin pieces of veg tan, say 3-4oz? And same question for the 18. Also if you have any recommendations on other models to look at please let me know. Thank you.

-

Hi y’all I am an Arizonan now living in Namibia Africa and I just pulled the trigger in buying my first industrial sewing machine to up my leatherwork game. I imported a new Oryx 341 (same machines as the cowboys in the US, just re named the oryx as its more relevant for Africa) from South Africa and have it all dialed in with a recently added speed speed reducer. It was quite expensive and a pain in the ass to get it sent over but well worth it. Its a solid machine! Namibia is one of the most remote countries in the world in terms of population and logistics. Its no easy feat getting leather supplies here with (luckily) only one overpriced leather supply shop and absolutely no online shopping options whatsoever with lack of online payment systems and reliable shipping. As well as I literally live in the middle of nowhere in the desert with the nearest grocery store being 4 hours away. My brother is visiting from the US soon so naturally I plan on loading him up like a pack mule with stuff from the US lol. I would like to get a drop down edge guide and a few different presser feet styles for the machine. I am trying to spend as least amount of money as possible so was hoping to find some deals on parts from other bigger brands or generic label that will fit on the machine. Anyone have any info on what might be compatible? Also any recommendations for time saving leather tools/gear you can’t live without? Bonus points if they are small and not extremely heavy!

-

- Leather Machine Co. Cobra Class 4 w/stand Asking $2,750 - Master tool self centering belt punch w/ dies Asking 1400 with dies - Master tool little wonder with staple dies Asking $300 with dies $4,000 FOR ALL THREE MACHINES (save $450) Located at Goliger leather in Ventura Ca

-

I need to change the hand wheel to a larger one, I’m starting to get a blister from cranking it for the right needle position :), it’s just too small. Can someone point me in the right direction to get a new larger wheel or one with a handle? Thanks.

-

Cobra Class 26. Runs perfect, nothing wrong with it. Have stitch guide, and flat top attachment. 4 bobbins, several spools of thread, needles etc. Ready to go to work. I built my business off this machine and recommend for anyone upscaling from handsewing. Its a very smooth and even machine and it will sew faster than most people are capable of. Programable servo motor to set maximum speed to your comfort. Reversable for easy lock stiching. If you have any questions feel free to ask. Willing to give a lesson for those who may not know how to run a sewing machine. Located in Fischer, TX $1500.00