All Activity

- Today

-

That is very nice intricate work on the sheath. Is it hand sewn? Very interesting pattern your knife blade too

-

Well done Tilda. May you have lots of happiness and few stabbed fingers in your new profession Take it as it comes. I'm a man, a bloke, and it makes me really, really mad that women have to fight to get the jobs they want or especially qualified for One of my sisters went to a posh grammar school. She got 11 'O levels' and 6 'A Levels' = that meant she was very smart. Her careers officer told her to learn to type and get a secretarial job!

-

Uhh! That sheath looks like it's going to be a show stopper at any LARP event. Nice work!

-

Internship and maybe a new start

Tove09Tilda replied to Tove09Tilda's topic in All About Us and Off Topic

Oh Sheila, that sounds really too familiar! It's a men's world, we are just allowed to exist in it as it feels. Some time ago, I used to be furious about it. Now I just shrug and say, “As long as no man kills me, it’s fine.” It’s dark humor, but honestly… it’s survival. In my field, it’s insane how you can be highly qualified and still not get the job, while a man with barely any qualifications — just a few more month of experience in any field, but yours — gets hired easily and then looks at you like you’re crazy for even daring to apply. I’ve beaten McKinsey consultants in practical exams, but none of that seems to matter anymore. Instead, people get angry that I refuse to work for free. So really, changing careers just feels healthier — especially considering how the political climate here in Germany is shifting. And thank you for sharing your story! And glad you found your place as a nurse! The Dr. Best story sounds amazing and inspiring. I can totally understand why you would have loved to do this permanently. My best story is probably working with THE family business consultant and scholar (he loves! like really loves, alpro chocolate milk and is the most chill Italian guy I've ever met! Plus had the craziest stories form sitting in family boards) and being told by an Ex-Wallstreet Broker, that he thinks I'm highly talented (best about that: A McKinnsey Consultant heard that and was sooooo goddamn mad at me, she really showed her "best" character" 😂). Since then, I can't take any McKinsey Consultant seriously for life of me. -

-

Trying to give some TLC to an Adler 30-7

Wizcrafts replied to Hellboy's topic in Leather Sewing Machines

That needle alignment is weird. It appears to be too far forward in the hole. A proper alignment is dead center front to back. The needle clamp itself can be moved sideways to get closer or farther away from the hook. Remove that clamp and check for foreign material that might be causing the needle to sit on an angle. Maybe the clamp screw is loose. Tighten it after centering it sideways.. If this doesn't solve the problem, maybe the throat plate has two different size holes. Rotate the plate if the other hole is larger. Also, that needle looks very large. Try a smaller needle. -

If the needle is splitting the top thread on the way into the material, your check spring ie either not properly set, or is accidentally bypassed, or is missing. The purpose of a check spring is to maintain some tension on the top thread as the take-up arm moves down. The assembly should have a bottom stopper bracket that can be adjusted to stop the downward movement of the spring at a position where the needle has just entered the top of the material. The spring action should be adjustable too. Set it to just hold the thread taut. This should solve the thread splitting problem.

-

Ideal and "make do" machines for newbie

Wizcrafts replied to Bry2's topic in Leather Sewing Machines

Almost any walking foot machine based on the design of the Singer 111w155 will do that work. Look in your local ads for a SInger 111w155, a Juki LU-563, a Consew 205rb-(number), or any other brand that has triple (compound) feed. They are usually found in upholstery shops and they sell them off when they buy new machines. Expect to pay between $500 and $1200 for a good condition walking foot machine. -

DIY Tooling Easy Carve Concentrate

bruce johnson replied to thecodyvance's topic in Leatherwork Conversation

Totally agree, with the different recipes out there it is a for sure that everyone makes their casing cocktail a little differently and still get results. The exact recipe I was given is 1.5 cups water, 1/2 cup Lexol conditioner (brown jug), 2 tbs baby shampoo (for surfactant to help the moisture penetrate faster and stay more even), 1 tbsp brown listerine (source of thymol to prevent mold). My real recipe evolved into making it up in a 2 liter or gallon jug by eye. three parts, one part, some shampoo and some listerine. The variable that not many consider is the tannage of the leather. Every tannery's leather is a little different. That is why I generally stuck to a single source. I figured out the amount I needed to apply based on weight of the leather, how much time in the bag or covered to penetrate and equalize, then how often I needed to reapply for large projects. I used a lot of Sadesa and understood it's behavior well. Rundi uses mostly Hermann Oak now and it takes more casing solution and I would take a longer time for the same "look". -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Ideal and "make do" machines for newbie

Northmount replied to Bry2's topic in Leather Sewing Machines

Have you looked at this thread? -

Good morning, I am looking at starting to sew leather and biothane. I have braided and done other work but have never sewn with leather. I have sewn horse blankets, and large items (not clothing etc). Can I get reccomendations for what the ideal machine would be and what a good safe starter machine is?

-

FlemingDK joined the community

-

Hi Hans My machine Adler 5-27 are breaking the thread instantly when starting to stitch even with loose thread. It looks like it is when the needle is going in. What can be the reson for this? Regards Fleming

-

I believe I fixed the problem, why the needle wasn’t picking up the tread on the bobin. I must have upset the whole timing, when i loosened two screws under the shaft of the shuttle hook, and loosened two extra screws I shouldn’t have touched. when i was moving the horizontal cog to turn the shuttle hook shaft. I also moved another part bolted to the shaft that sits against the horizontal cog, the horizontal cog turns a vertical cog at the bottom of the shaft of the shuttle hook and when I moved the horizontal cog a little bit to one side I accidentally speed up how fast the hook turns round. and after a few hundred stitches it would skip a few stitches and then wouldn’t pick up the tread from the bobbin. didn’t take me long to sort it out, luckily. I have my 236g131 working again. a fantastic lesson learned, from a great mistake. I will add photos later on this evening.

-

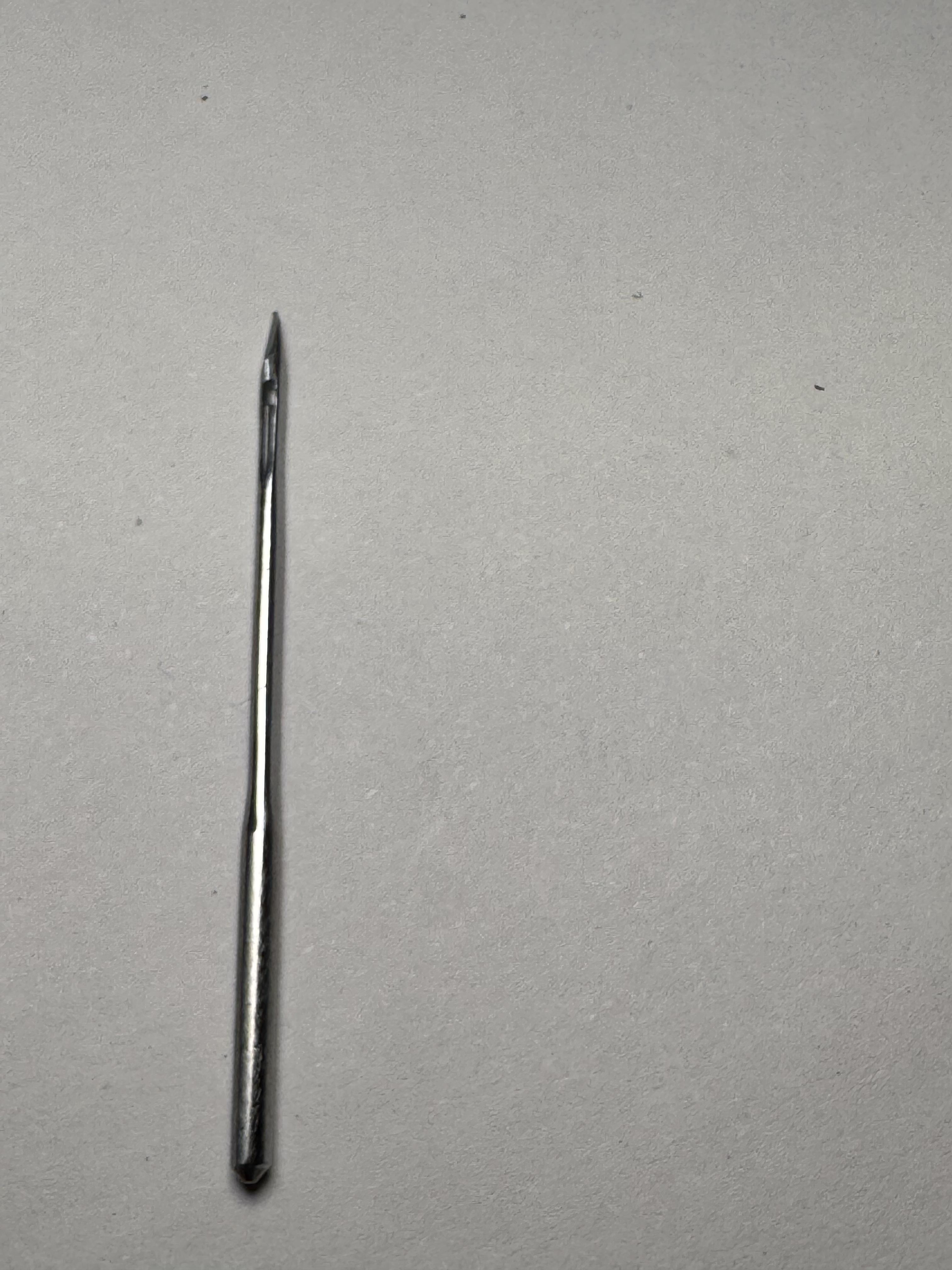

Hello RockyAussie, im was sure I had changed the 287 needle out to the 134 before I took that picture. You are correct RockyAussie, the 287 doesn’t have a scarf, or very much of a scarf at all. so that was the 287 needle in the machine before I changed it first two pictures are the 287(16x2) and the last few pictures are both the 287:right and 134:left the shaft off the 134 is very much wider in diameter.

-

Just put the antique on a Silva Fox pattern of a cowboy enjoying a coffee. This one forced me to get better at folds in fabric, seemed like 1/2 my time was doing folds. I have heard not to use "it was a bad piece of leather" to justify a poor result, This piece was done on a bellie, it tooled differently all over the piece. Bottom right was firm and uppper left was spongy. For me the cost makes up for the aggrevation.

-

Trying to give some TLC to an Adler 30-7

Hellboy replied to Hellboy's topic in Leather Sewing Machines

OK!! A little update and I'm really excited. So big thank you Mr. Wiz! I printed the documents you sent and they were very helpful! After cleaning my machine and tinkering with it, it actually works!!! My mind in blown and I'm excited. So far, I only needed to get the thread wire in order to push the thread down the pipe. So, after looking at the specs you sent, I think I'm missing a few nuts and bolts to make it perfect, I need to dissect it more and figure out the details, but, my next big question is, how do you allign the machine? I'll post pictures, but it seems that the needle coming down and slightly grazes the hole it goes into where the bobbin in. Any ideas on that?? Thanks again!! drive-download-20251021T020528Z-1-001.zipdrive-download-20251021T020528Z-1-001.zip File_003.heic File_004.heic IMG_2004.HEIC IMG_2005.HEIC IMG_2006.HEIC