All Activity

- Past hour

-

Fortuna Leather Splitter not turning on.

Morgan311 replied to Morgan311's topic in Leather Machinery

Thank you Bruce! -

Lovely, unusual items! Do you have these available on Etsy too? I have seen something similar there. They are in my list of things to purchase and make, the trains and the dog.

-

Yep, a slippery slope that leads into a rabbit hole!

-

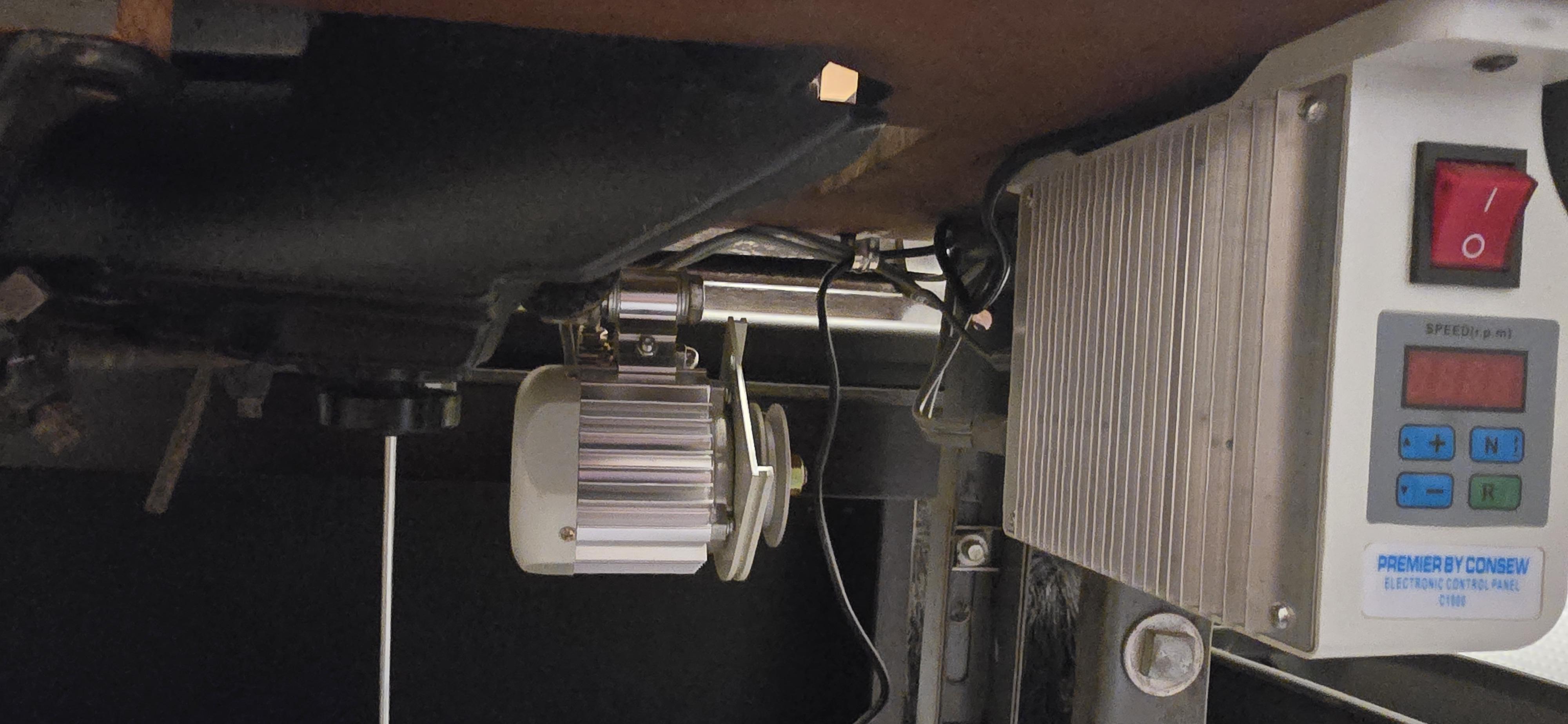

Congratulations! Can we get a good photo of the back of the machine? Specifically I'm looking for what attachment points the machine head has for a knee lift / foot lift. Having a knee or foot lift is quite convenient...worth putting in the effort to source/install one. I used to have a motor controller that said "by consew" like that. It had a minimum speed of 200rpm. If you haven't already, I suggest finding a manual for the motor controller and making sure the minimum speed is indeed set for 200. (Factory default is probably higher than that) Also, if you don't have a 45mm pulley yet, they are easy to come by, for example here: https://www.amazon.com/KKUANG-Industrial-Aluminium-Electric-Clutches/dp/B0DLGNBZFQ It will slow down your minimum speed at the hand wheel, and increase the torque at the hand wheel.

-

You did good, got a real bargain there. They are good solid machines and it should serve you well.

- Today

-

Fortuna Leather Splitter not turning on.

bruce johnson replied to Morgan311's topic in Leather Machinery

My first call would be to Campbell-Randall. They are on here as a member but you will get faster results calling them. -

I’ve found a singer 29k171 that is an offer I can’t pass up in Connecticut where I’m visiting. I live in AZ does anyone have any ideas on how I can get this monster back home with me for the most reasonable cost? Thanks!

-

I just wanted to thank everyone that responded to my other post looking for help picking a machine. Without your advice, I might have ended up with a much more expensive machine and disappointment. Instead, I spent $200 and a several hours cleaning and swapping out the motor on this beautiful Singer 211g165. I got the servo for free from a friend that had it lying around collecting dust, so I got a great deal on that! Anyway, allow me to show off DeVille #9 (the factory it once lived in, and the number on the table). If anyone has stories to tell of theirs, helpful info and links, etc. please share!

-

Hello from Ukraine – Leather Pattern Designer

Scoutmom replied to Olena TS's topic in Member Gallery

welcome and nice items -

Canter Cart joined the community

-

Beautiful work with some unique style. well done.

-

Morgan311 joined the community

-

Hello Today my skiver decided to literally scream at me and shut off. She still gets power but will not turn on. I don’t have a manual and it’s such an old machine I can’t find much info online. Has anyone had this issue? I appreciate any help you can give me. It’s a Fortuna HIGH PRECISION BAND KNIFE SPLITTING MACHINE Thank you Morgan

-

Hello from Ukraine – Leather Pattern Designer

FrankHester replied to Olena TS's topic in Member Gallery

Great work! Welcome! -

What fun stuff! I love all of it.

-

Railed sig 1911 bbq rig

Stetson912 replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks for the kind words. I'm gonna have to look for a set of maple grips now haha. -

Pictures this afternoon. From the tool marks and screw heads I think this was worked on several times for sure. I'll update. Thanks!

-

You're on a slippery slope now. Might as well start saving up for that walking foot industrial.

-

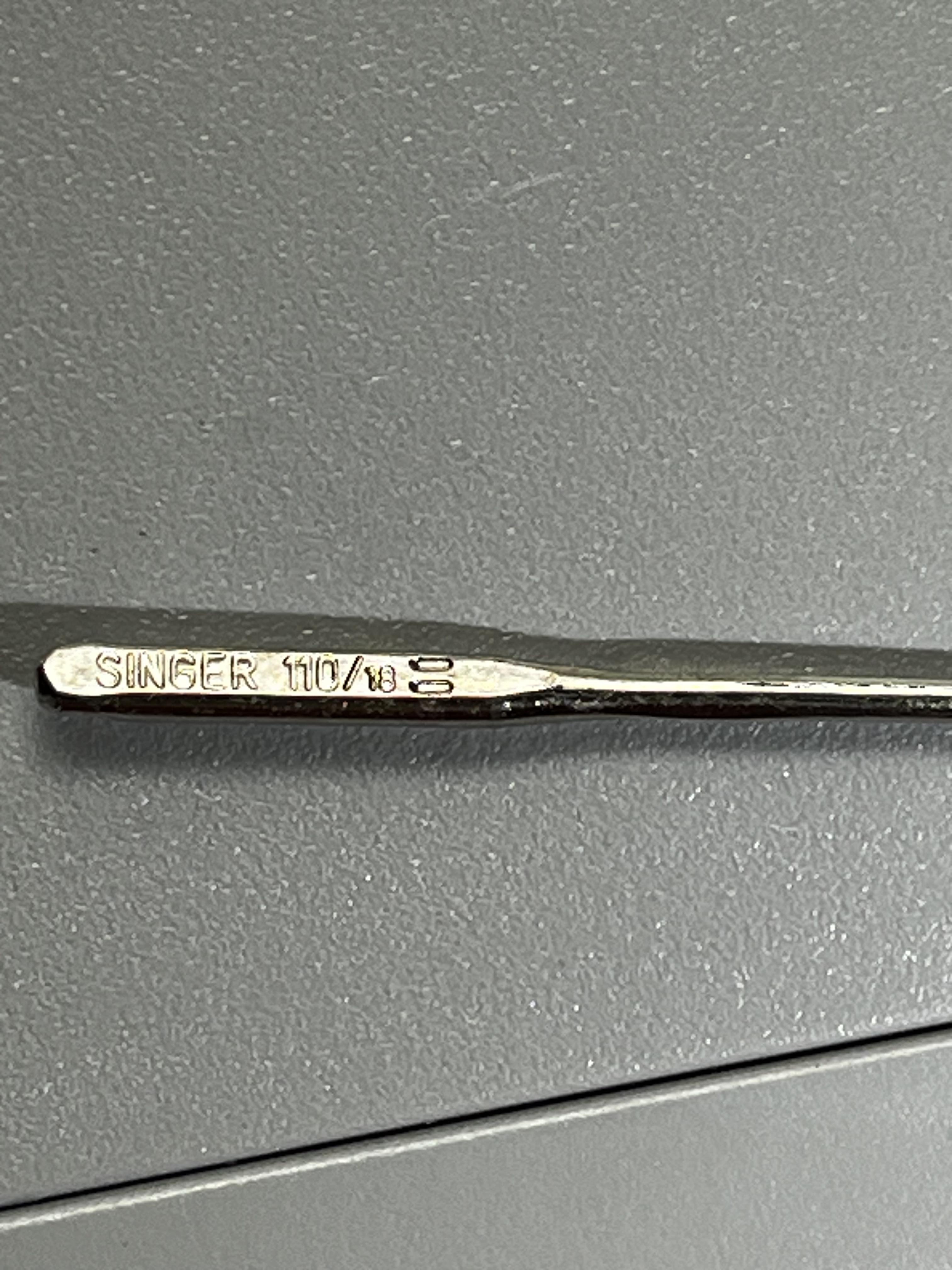

Thanks everybody! With the thread I have and a 110-18 needle it’s working good! I’m traveling slow but somewhat erratic on this practice piece. Will check the chart! Thanks! Dano

-

does not sound like a 7-34 - just from what I have in mind it sounds a bit like Singer 7-10 (or similar) thread regulator spring - but I´m just guessing... We need pictures I´d say. 😉 Barrel hooks always appear a bit sloppy cause the thread needs to slide around it.

-

The largest needle commonly available for domestic sewing machines is a #18/110. I once found some #20 needles for an old iron body Singer from yesteryear. Those machines held up much better than the plastic body machines of today. I mentioned this because most so-called Upholstery thread is #69 bonded nylon. This size is normally sewn using a #18 (Metric 110) needle. Leather point needles work best on leather, as opposed to round points. You should be able to get a decent stitch using #69 thread with a #18 needle by balancing the bobbin vs top tension and enough foot pressure to keep the leather from lifting with the ascending needle. But, if you plan to sew leather on a regular basis, buy an iron body walking foot machine that's mounted on a 20 x 48 inch industrial k-legs frame and table and powered by a 3/4 HP servo motor.

-

I did mean the marketplace here. That's why I linked to it. In fact, I'm not on fb so it never occurred to me that there might be confusion... 😄

-

To me, that shredding still looks like the needle is too small for the thread. If that thread came from a regular fabric store, I wouldn't think it's bigger than v69. According to this handy chart it wants a 16 OR 18 needle. Maybe an 18 will solve the shredding. How about trying some smaller thread with your size 16 needle on some scrap? It might prove the concept.

-

Wonderful Work Welcome to the forum.

-

Hi! I’m Olena, a leather designer who enjoys creating a bit unusual patterns. I love animals, so you’ll often see them in my work 🐾, but I also get inspired by steampunk and fantasy ideas. I share my projects on leatherpatternts.com and make video tutorials for each pattern on my YouTube channel.

-

I moved your post to Leather Sewing Machines

-

.png.e561de4c736c060e5ff3504cf2bf5fa0.png)

.png.192acdc94acf38550986ffd5eea01e66.png)

.png.f354f6df3745759296a2239b1dda66ec.png)

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)