All Activity

- Today

-

I'm the very excited new owner of my very first walking foot machine, an old Seiko STW-8B, and from what my internet searching tells me, is the exact same model as the Consew 226R-1 (please correct me if that's wrong). The first thing I always do with any new machinery is get all the manuals I can find, but I can't seem to find a service manual for this machine. Anyone got any links. Thanks, Keith

-

That is sad news. Condolences to his family.

-

I wore a cheap straw hat this summer then it got colder, tried a felt one and they are nicer than expected for comfort and protetion. You're welcome Purchased a good hhat on the Black Friday sales, sadly she is in NM, but she was able to shape the brim for me more of a flat style and a softer turned shovel size front brim. the final tweaking will be up to me, ordered a little bigger than recommended by the company and will adjust down to fit if needed. I didn't have much luck finding a shop locally carrying what was wanted. Finished the wallet back challenge that was given at the end of a class. It caused me to slow down and be more precise. Floral is an area I am intentionally trying to improve.

-

@janosaw, I moved your request to the Leather Sewing Machines forum. You will get better answers in this section.

-

A second generation of long-slide Glock holsters

badhatter1005 replied to DeWayne Hayes's topic in Show Off!!

I am in love with this holster. I cary a custom glock 34. Any chance I could purchase this pattern. Not for resale. Just for myself -

I'm trying to remove the stitch length shaft on a 112w139, seem someone dropped it on the hand wheel. The main top shaft appears to be bent. I have removed the hand wheel and can pull the shaft out about 1.5", then it stops. I have not touch anything inside of the head. I get it out enough to see the shaft appears to be split and that is where it stops dead. Must be something I am missing. Also are there any manuals that show exploded view for singer machines. Thanks Andy

-

Just saw a post on Facebook that Cobra Steve from Leather Machine Co has passed. Their website states: "It is with great sadness that we announce the passing of Steve Tayrien, lovingly known as Cobra Steve. As one of the founders of Leather Machine Company, he believed deeply in people and dedicated his life to helping others grow and succeed. His kindness, vision, and unwavering faith in those around him made a lasting impact on our community." My prayers go out to his family and friends.

-

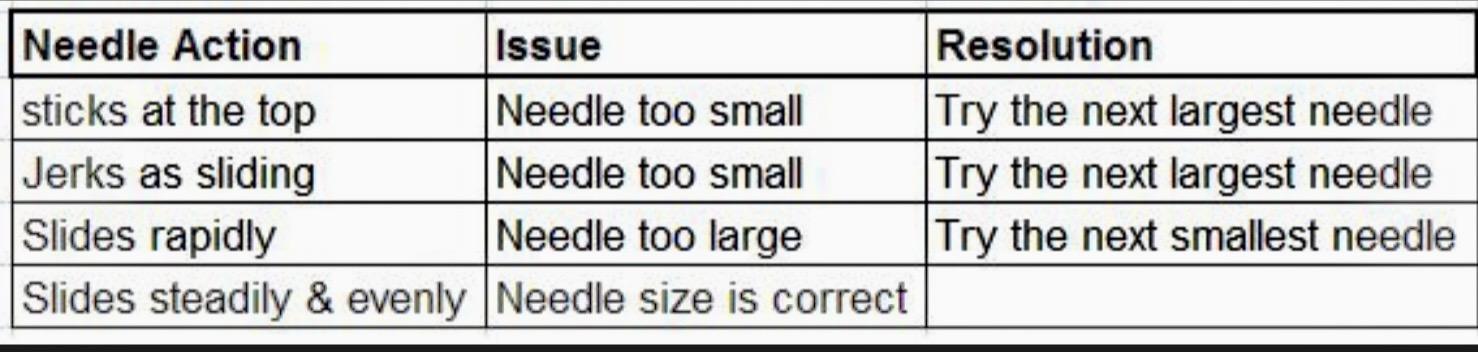

Make sure the needle has risen at least a quarter inch before turning, and don't lift the presser foot high enough to release the top tension.

-

Singer 111W103 - I am a nooby and just got my first sewing machine.

Rob R replied to a topic in Leather Sewing Machines

I have actually signed up and been approved but I see my post shows me as a “guest” hope that is a temp. thing and I can post pictures too. -

Singer 111W103 - I am a nooby and just got my first sewing machine.

Rob R replied to a topic in Leather Sewing Machines

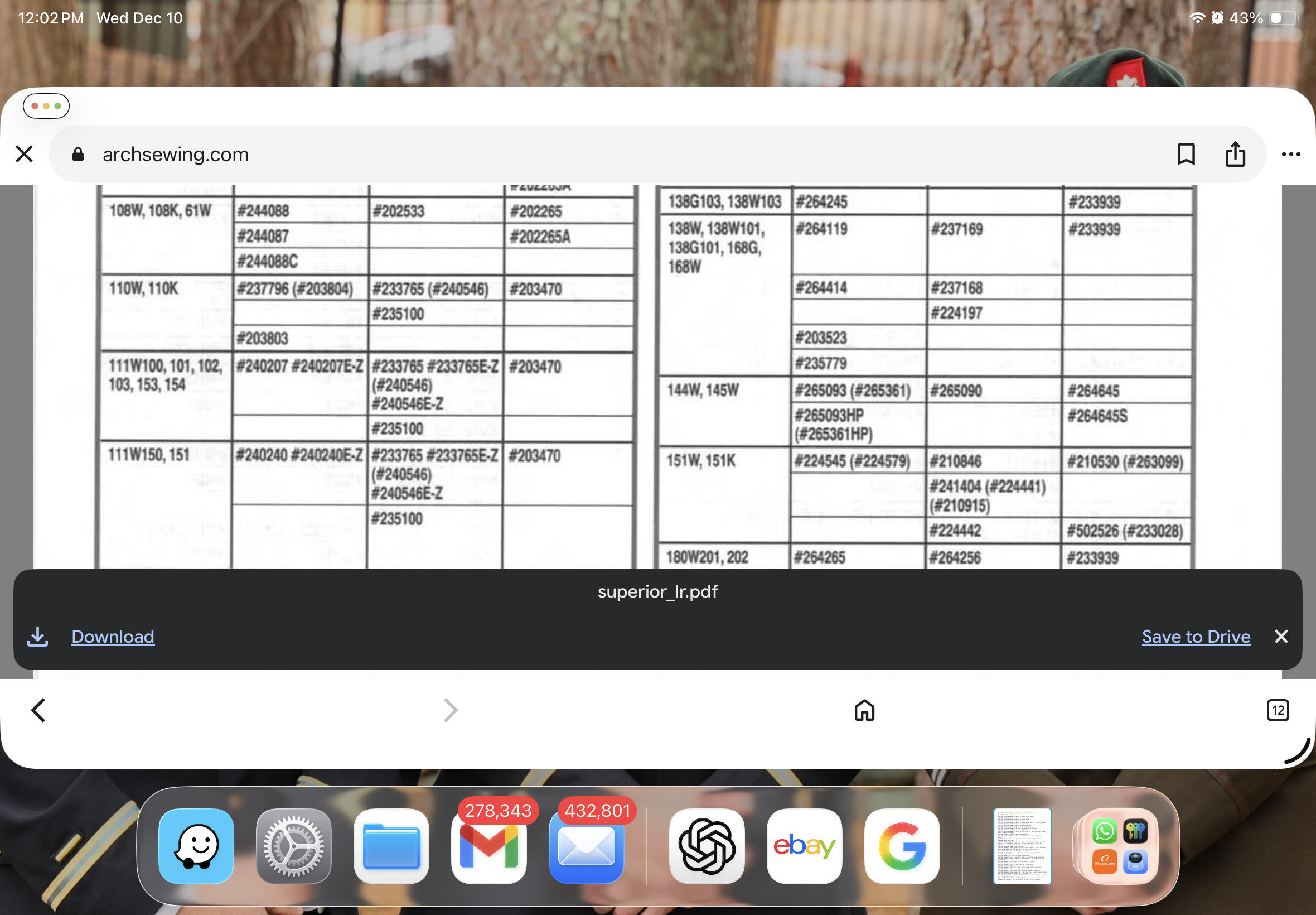

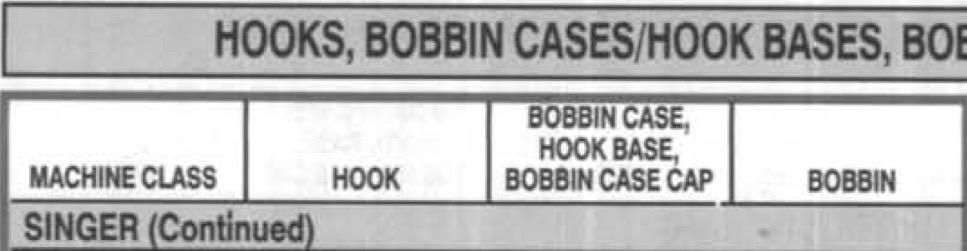

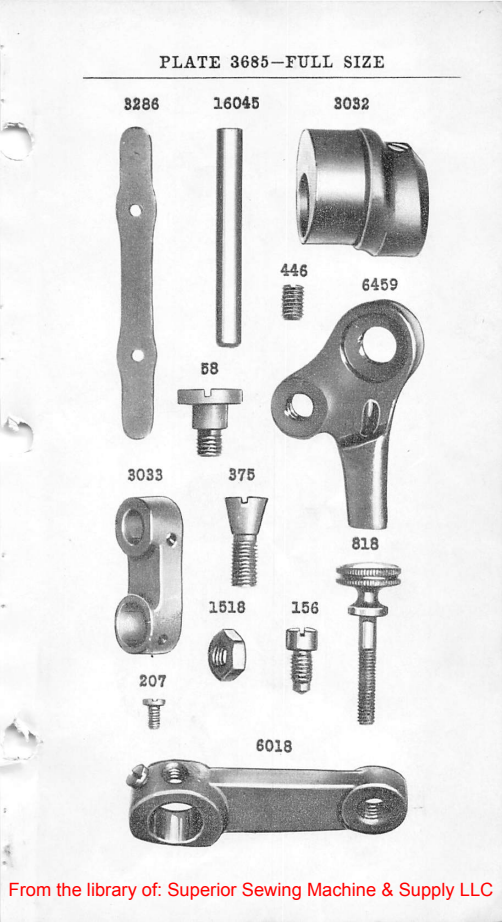

Thanks appreciate the reply - I hope to find documentation to help me order parts etc. I managed to cut and paste this together for parts I may need. Sure isn’t easy ordering parts from my local “experts” needed a 41 tooth timing belt - not happy not getting the work to install it…gives me a 55 tooth belly as the replacement…not in a month of Sundays will that go in so I returned it and ordered the OG belt from a guy on eBay it has steel teeth/staples on a cloth belt - will be here Saturday. Hope I don’t have to do the job again soon as the new belts are vinyl. -

Singer 18-2 Problem with part 3037

Constabulary replied to Ghoust6's topic in Leather Sewing Machines

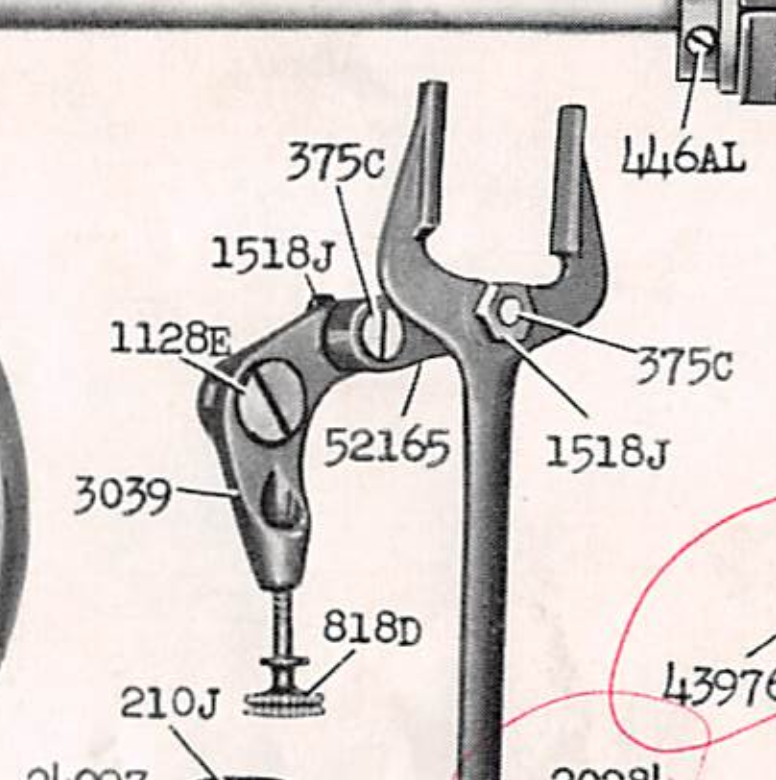

I think the fork is attached to part no 3033 (feed fork connection link) from the rear with a screw (the one which thread you see on your last picture) and the part 3033 is attached to the 6459 (feed regulator = Stitch length adjuster) and to the machine body with a screw and I think this is screw the read arrow is pointing to (see picture below). So I think you have to remove this screw first. The rest is trial and error. I recall it was similar on my Singer 45D91 back then. Look at these parts from the rear side, you should see the parts through the hole. Move the stitch length lever up and down and I think you will notice what I have described. EDIT: I just noticed the video - it shows what I mean. -

Here's a video where someone removes that fork from a Singer 31k15:

- Yesterday

-

The parts list for my Singer 31-15 shows more of these parts together as a group, which might be useful. Have you tried removing the stitch length adjustment screw (818D in this screenshot) ? With that removed maybe the whole cluster will slide out toward the camera..

-

A little pricey yes but this is the 4th motor I've bought chasing what I was looking for in a servo motor. I'm thinking I've found it. Now, if I add up all the money I've spent on the previous motors, I could have bought two of the Kinedynes and been satisfied all this time. Sometimes you just have to weigh what's important to you, a few dollars for less frustration works for me - besides I had sold some other stuff from another hobby that helped fund this.

-

Yeah, this is the challenge. That 18-2 isn't one of the common machines that everyone's seen a hundred times. I'm hoping someone will check in who's done that job. Maybe @Wizcrafts knows something?

-

upgrading to oldschool singer 132k6 and 132k7

VinnyK replied to VinnyK's topic in Leather Sewing Machines

wow thats beautifull work and a interesting machine man. i like how you fixed up the real k6 with an old table tob and some vintage legs. that would be my route aswell. but ill just have to wait and see what comes up on my path here and there. and thanks for the tips on parts. ill go take a look always good to have adresses for hard to get parts. but my main goal is fetching up parts machines. they come up around here now and again. i would like a few restored ones and set them up for a few different jobs in my upholstery work. thank you for sharing your post. it was inspiring 😇 -

I have no doubt these motors are good (they're made by Hightex) but here they're a ridiculous price. I bought "generic" servos and built speed reducers for considerably less cost and they all work fine for my needs. I guess for commercial usage the cost isn't so much a factor - but how many factories want such a slow speed machine? In most factories the speed of making something is very important (time is money) so paying extra for a slow speed you don't need is wasting money. It seems to me it's a pretty specific (and limited) market this motor is catering for? Don't get me wrong, I'd love to change my servos for these but the cost would be absurd, ain't going to happen.

-

How about diesel or other penetrating oil on the stud? How about tapping the tip of the stud with a long steel rod and a light hammer?

-

I appreciate any help and yes I was trying to push fork towards the camera and I think i did about 1-2mm and the whole mechanism start to work almost good, but almost it's not perfect. If the fork have thread then the screw should have at least cut so i can unscrew. Everything in this machine should be easy to unmounted. I can take off that fork, i was using a lot of force and even cooling it. I was looking for a hidden super small bolt in the fork holding it so tightly. As I said I was trying everything and no luck. If someone ever unmounted that fork please help. I was trying to unmounted the mechanism behind the fork and still no luck. I can/t reach bolts or they are holded by nut behind the mechanism so still no luck.

-

I purchased three of the 1000SH motors/controllers from Ryan and I run gargantuan machines (Singer 7-33, 11-20 and 11-22) with them, working heavy leather at slow speeds, no speed reducers required. (Running 230/26 needles and #346 threads.) I can't say enough good things about Ryan and his service both before and after the sale. I will say that the manual, highly technical, needs some clarification at a few points, but for most applications, it's "plug and play." In addition, because of the nature of standard rubber (or rubber composite) V belts to take a "set" while at rest, especially around the small pulley on the motor, I use an "ACCU-LINK" adjustable link V-belt (the green one) with the 3L profile. Runs without distortion or doesn't produce the black rubber dust common to rubber(ized) belts as they wear. Stupidly expensive, but easy to fit and re-adjust as necessary, and clean running.

-

upgrading to oldschool singer 132k6 and 132k7

Constabulary replied to VinnyK's topic in Leather Sewing Machines

I once owned a similar machine I stripped mine for parts back then after I found a 132K6 and I do not look back. I think they are not worth upgrading to 132K6 as parts are rare and expensive - IF the upgrade is technically possible at all. But maybe you have luck - dunu. a lot of parts (in general) can be found at College Sewing or Trojan Sewing in the UK or MARFAR in Australia. -

Yeah, took me a while to figure out that problem also. Lifting the foot causes it. Shuffling the material around while the foot is up also. Try to keep the foot down when turning and if it's a mild turn keep the needle down as well.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)