All Activity

- Today

-

-

Is it possible that between the slightly larger needle and the fabric point punching thru the sewn material that there isn't enough friction between the needle and vinyl to hold the thread down, so the loop can form consistently? @JukiFan, does the speed of sewing have any effect on how often it skips stitches?

-

LOL, Fred! My father's mother kept a pair of geese in the fenced in front yard of her farmhouse. You had to walk through the yard to get to the door. They were definitely her 'watch geese'. My mom would take me by the hand, and admonish me to 'watch out for the geese' as we hurried to get through the yard to the front door. One of my aunts kept guinea hens. They wouldn't attack, but they certainly made a lot of noise, alerting the people in the house that someone was outside. Edit: my late husband's name was Roger. Other kids teased him by calling him Roger the dodger, and Roger the lodger. Thought that might help you remember the rhyme. Apparently, both of those rhymes have some not very nice meanings, though he never explained them to me. But Rodger the dodger might fit with this guy not being able to dodge the goose...

-

Fascinating bit of history! The gloves were made from the skin of unborn calves. The stitching was extremely fine - 32 stitches to the inch! https://limerickslife.com/limerick-gloves/?fbclid=IwY2xjawPffeJleHRuA2FlbQIxMABicmlkETFpWGNPdkZadGxEMDUxQUJNc3J0YwZhcHBfaWQQMjIyMDM5MTc4ODIwMDg5MgABHpjhkY4VkujaZbZBxHD_F-wk-QmRrvpSSdjtY6mlOLb_SbQgXo4CkygvN7Me_aem_p9tNbWgEBS2Yl2smZs-1MQ

-

Unknown Chinese servo motor controller manual needed

friquant replied to Einherj's topic in Leather Sewing Machines

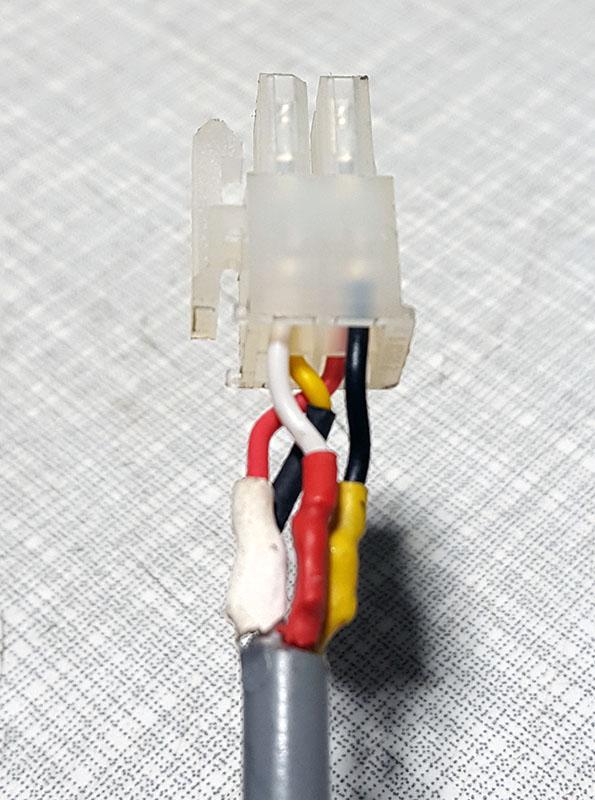

The synchronizer that came with the stitchman controller has only three wires. Here is a photo of the plug -

Completed this notebook a few days ago, see what u think. IMG_0959.mov

-

In that case you're smarter than me.

-

Unknown Chinese servo motor controller manual needed

friquant replied to Einherj's topic in Leather Sewing Machines

I've updated my original post on the stitchman motor to include error codes from the manual I was given. -

there are many options out there. sadly many people who sell industrial sewing machines automaticly label it as a machine for heavy materials and leather. and many just arent. they are high speed machines for clothing or household needs. you would like to have a walking foot machine it holds all the layers nicely together as you sew and keep your stitches exactly the same even when you go thru multiple layers of fabric foam and vinyl. like the pfaff 545 or the singer 111w series machines. the k6 models would also do but they are pretty vintage. what ever machine you find google it and see what the options are on it. servo motors are really handy for beginners. reverse is very handy especially in car upholstery work. there are many good models out there. some are better known as others. it al depends on whats for sale locally. also see whats available online in parts. doing car upholstery work or boats and such. zipper feet and welting feet are handy if you wanna add zippers or piping. when testing out a machine especially with clutch motor check how slow you can make it go. wich is handy for corners and going round edges. the slower it goes the more control you have and the better your results wil be

-

I would say that the "right" people are going to be looking in the same place that everyone else is looking. Advertise here for a targeted audience, any leather guilds you happen to have in your area and then blanket your big classifieds. Craigslist, facebook marketplace and whatever else you have. In my rural area, the fb marketplace seems to be the hot place, then craigslist and then local publishers. In short, advertise everywhere and let the people find you.

-

When I wuz a postie I delivered to a house which had about 6 guard geese. They were really vicious. More than any dog. Here posties bring the mail right to your door. I had to climb the 5 ft high gate and sprint to the door, put mail through, then sprint back to the gate and leap over it before the geese spotted me One week a new driver was on as my relief, I warned him about the geese, as did the supervisor. His attitude was 'yeah, right, I believe you, you're winding me up'. Later the office got a call to come and rescue this driver. I had to take him to the emergency dept at the hospital as he lay in the back of a small post van. A goose got him and had taken a lump the size of your hand out of his ass. The doc asked what had happened, at first he didn't believe me then he burst out laughing as he stitched the flap of ass skin back in place. That driver came back to work at the P.O.* As a note; the Post Office can invoke a law for people to keep their animals under control so not endangering posties. But we looked at the list of animals and geese weren't on it! * I just remembered that driver's name, It was Rodger. And some wit in work made up wee ditty about this incident. Wish I could remember it now

-

Start by using a Schmetz Serv 7 system 135x17 needle. I don't recommend #69 thread for this thick seam job. Move up to either #92 or #138 thread, top and bottom (or maybe 138 top and 92 bottom). If you go with #92 thread, use a #19 needle for a tight stitch, or a #20 needle for a bigger hole and easier knot pull-up. If you go with #138 thread on both sides, use a #23 needle. For 138/92, use a #22 needle. No matter which thread and needle you choose, crank down the presser foot screw to squish the material and get any wrinkles or fluff smoothed out. You might have to lengthen the stroke of the check spring and add some more slack thread via the check spring adjuster. Finally, the timing my be borderline for this thickness and density.It's a good idea to open the bobbin cover plate and watch where the hook is in relation to the top of the needle's eye on the upstroke. Also, look at the loop and make sure it isn't dissolving before the hook can pick it off.. Normally, the point of the hook intersects the needle in the scarf about 1/8 inch above the eye. It should have a big enough loop to easily grab it and carry it around the bobbin and shuttle. Maybe your timing is retarded and advancing it will both resolve the skipped stitches and any snapping sound as the top thread goes around the bobbin case/shuttle.

-

yeah i know farm Geese arent any friendlier, I sure wasn't waiting around to see which way they were going lol.

-

Oh yeah, geese can be pretty vicious! We make lots of jokes about the aggressiveness of Canada geese here in Canada! We've nick-named them 'cobra chickens'!

-

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Made a mistake, won't use Watco, that's my woodworking finish. I'll pretreat with neatsfoot oil, then stain. -

Unknown Chinese servo motor controller manual needed

Einherj replied to Einherj's topic in Leather Sewing Machines

Thank you very much for this. It helped a lot. Seems like my controller has the same parameters. I found out, though, that P-15 on my controller actually is correctly defined: 1 = needle detection, 0 = no needle detection. Then I ran into an issue with the synchronizer I bought from eBay: The wiring is different from my controller. The synchro red LED was very dim and on at all times no matter the synchro position. I measured the voltage from the controller pins, and it seems the pins layout is rotated 180 degrees on my controlled compared to the synchro. Looking at the back of the controller, the measured socket pinout is: Top left = 5v Top right = signal 1 Bottom left = ground Bottom right = signal 2 The synchro plug pinout is: Top left = signal 2 (white wire) Top right = ground (black wire) Bottom left = signal 1 (yellow wire) Bottom right = 5v (red wire) I rewired the synchro to match the controller, and now the red LED on the synchro is bright at a certain point on the rotation, which I guess is the intended result. I had no idea which way the signal wires were supposed to be, but I tried both ways, and the other way the red LED on the synchro never came on. Now, I have another problem: When I press the pedal, the machine runs maybe a half a rotation and then the controller gives an error: Er01 After letting go of the pedal, sometimes it still tries to get to the needle up position, and sometimes it just stops. Any idea what Er01 might be? -

To get it moving freely, you can oil all the moving parts, remove the bobbin and the needle, and put a brick on the foot pedal to hold it down. Let it run for 5-10 minutes at full speed. Monitor to make sure it's getting freer (faster) with time, not slower. If it gets slower with time, see if there's an oil spot you missed, and see if there are any warm spots on the machine.

-

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Not my choice. I'm making the new fenders as a favor for my daughter for her friend. The original fenders are in pretty bad shape however. Dry and brittle in some areas, and tearing easily in others. Had not been well cared for it seems. I'll return the original pieces and the new constructs to the owner when complete. I don't usually do saddle work, and my holster, sheath, and belt work are all done for personal use or as gifts... Or for pleasure. I admire the work of the pros here, who know more than I, and try to learn from it... It's interesting. -

I am in Saskatchewan. I think it is time to sell my machines and tools, age and health are helping in making this decision. I am wondering where would be a good place to advertise so the RIGHT people will see the ad. I realize nobody from a 2000 plus Kms. is likely to come for these things. Thank you in advance for any suggestions. Mods. If this violates rules delete this post.

-

Fender repair...

catskin replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Not sure why you choose to waste so much good original leather. I have fixed lots of those exact problems. Just oil the original fenders to restore them like they should have been taken care of. Then glue and sew with thin thread a thin patch on the outside and sew a piece of seatbelt from a car on the inside. NO stitching across, only along the direction of pull. Seatbelt is so thin you never notice it and can only be seen when looking on the inside. Patch on outside is barely noticeable. -

Simple answer, No. The difference of going from a fabric needle (135 x 17 ) to a leather point needle (135 x 16 ) is the tip of the needle. The fabric needle (135 x 17 ) will attempt to push a hole through rather then slice a hole in the material. You will have to check the top thread tension, bobbin tension and presser foot tension. Also a bonded polyester thread would probably provide better UV protection then Bonded Nylon thread. kgg

-

Juki LS-1341 Needle size/ range confusion?

kgg replied to RFRLEATHER's topic in Leather Sewing Machines

Here is a link to the actual Juki LS-1341 brochure which will give you the definitive comparison on all specs for the 1340 series machines. ( https://www.juki.co.jp/industrial_e/admin/pdata/filedata/332/ls1340.pdf ). If the machine was new yes. With used machines it could be iffy on the smaller thread sizes which will be an individual machine ability depending wear of internal parts typically whether it was a hobbyist machine or a machine that was used in a commercial environment. No, but I don't use threads less then V92. The only then is you have to change your top thread tension and bobbin thread tension when going from thread size to another, when you change to a different spool of thread, thread type and even color. Not going to happen that is why a lot of use have more then one machine. Machines for the most part setup to basically do one function. My thoughts: i) The Juki LS-1341 is basically a functional Juki DNU-1541S in cylinder arm form. The main concern I would have with the LS-1341 in thin material is the material being sucked down into the feed dog as the hole is fairly large. This may not be the best machine for your needs and maybe a Pfaff 335 or clone or a post bed machine would be better options as they are inclined towards smaller thread sizes. ii) How thick is the thickness material including folded over seams that you want / need to sew with what size of thread?? You really need to ask what was overhauled internally and externally for the machine, like timing belt, bushings, thread tensioner, thread guides, etc. What is the asking price for the machine. kgg -

So, the Juki has been in my possession for 10 years. I have used it probably 40 hours in making covers for gym equipment. Normally, I would use the 69# Nylon with a 135x17x18 needle. It never skipped stitches with my previous material which was thinner. With the newer 1/16" material, it happens. I switched to a 20 size needle before I came onto this forum. It could be that I am not pulling both sides of the seam tight enough before trying to apply the top stitch??? Like I mentioned before, the shop who sold me the vinyl told me that another upholstery professional told them the material was impossible to top stitch. I asked for more info and they had little to say. My O.C.D. tells me that I am missing an adjustment or something. So, if I switched to the 135x16x18 needle, would I need to adjust the timing? Vinyl is the only material that I will ever sew with this machine.

-

@Bobby B I know of Tandy Leather who sell tiger thread in 100 meter spools here in Canada. Also OA Leather supply sells tiger thread in 500 and 1000 meter spools also in Canada. OA is much more economical, but you have to buy a lot more, so spending more up front. I’ve ordered product from both these suppliers. Tandy has faster shipping. Hope this helps. Luke.

-

Has anyone seen this thread on the forum? Every time I see it i get this mental picture of Family Guy ( cartoon character) lying on a beach in Florida in a speedo with the butt of a tiny derringer sticking out from under his massive man boob. "Springbreak shoulder holster building "

.jpg.d60258221c476480a6e073a8805645bb.jpg)