All Activity

- Today

-

I use my CO2 laser to make all kinds of acrylic stamps and templates for rifle slings, holsters, guitar straps, and belt templates. I have also done some for folding knife sheaths. Occasionally, i am asked to laser engrave knife handles, holsters, and sheaths which I can do on my CO2 laser. I recently got a Fiber / Diode laser which allows me to engrave metal. So now I have added the ability to laser engrave the blades as well as other metallic items.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

What an honor my friend, it sounds like a great time indeed. Is anyone videoing it? It would be nice to see the work. It will also be a nice change of pace for you I'll bet. I had to laugh at myself, my tim the tool man brain said hey you have a treadmill motor it would make a great pottery wheel motor. So I get it out and get it wired back up, and I'm sitting there watching it turn slowly on setting 1 whicjh would be a good speed i imagine, i really have no idea lol, But it looks like i could keep up anyway i turn it up a notch still not bad so i kicks it into high 10 on the setting man that thing took off a good 1800 rpm and i got this image of clay flying around the room at lightning speed, kids and dogs runnign for cover, the wife yelling . LOL It was then i realizesd i have gotten to the point and age that i can kind of think through my decisions and see a bad outcome before it happens. So now i'm making a simple kickwheel with no motor... i still dont know what to do with the motor??? Life is good!! -

Learning to do Portraits of People

chuck123wapati replied to RidgebackCustoms's topic in Figure Carving

lol Trial and error, and a book was all we had when I was first learning this stuff. But nowadays I do peruse YouTube just like everyone else. I've always studied art and creating things so this is just a part of that. If that makes sense?- 3 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

buongcuaxit28 joined the community

-

heeulewno77 joined the community

-

About £/$200. Its not hard to learn to use it. I think the resin gives a better print, less noticeable print lines, which don't matter at all for stamp making but I wanted it for printing DnD figures as well so a better sharpness was needed than I could get with the filament printers. Plus there are environment friendly resins, ie water based. Resin printers are safer than filament types. The filament type heats a coil of plastic and lays it down. If the plastic gets stuck it can overheat and start burning giving off toxic fumes and potentially setting fire to your building - it has happened. The resin does not need heating at all Takes the same time to print as a filament printer. But it prints your subject upside down by dipping in & out of a vat of resin. You don't know if the print is a success or has failed until the end when it finally raises the print clear of the vat The printing is very temperature sensitive. The printer, the resin and the room has to be at a constant 22* or more One thing more, Ppl are put off 3D printing because it 'takes 3 hours 45 minutes' (as an example) to print. Bu you are not sitting there very minute. You set it to print and go for lunch/make a belt/get a coffee hth

-

There is a break in period with them , I am sure the binding is in the upper pulley wheel .On the machine side of the upper pulley wheel you will notice an elliptical groove . the needle lifting arm ( the see-saw bit across the top) has a little bearing that sits in side the elliptical groove and this is what give the see-saw its motion thus lifting the needle . This usually needs a bit of time to bed in. You will probably notice the tightness occurs when the bearing is in a tighter radius in the groove . Some older singers still have that tight spot even after 30 years . Technically the machine is a singer clone in every way and should perform as one . They have not been around for that long so no one really knows how long they will last . My bet is at least a lifetime, where a singer might last 3 life times . I have 3 singers and one clone . the singers are well over 100 years and work perfectly 99% of the time . The clone is 3 years old and still a little tight but prefers a thicker thread than the singer . i ended up putting an original singer shuttle and bobbin in it and works better . I think the clone bobbin shuttles are not that good especially the tension spring on them . I think oil and putting it to work should sort it out

-

I thought that hole was a necessary part of it.

-

hathihiien26 joined the community

-

By all means. It works great. The saw blade center hole didn't do much for it, though, unless you want to hang it up on a hook.

-

I am literally reading through the manual now well trying to. But it says specifically where to oil and stuff! one thing read said, it may just need a break in period? Like to run consistently for a while. Could it just be that ya think? This one has never really been used at all. It’s essential brand new, no one one just had time to mess with it. my biggest issue is I don’t know how it’s “supposed” to run. I’ve never used one in good working order haha

-

To find out what is binding up, you can turn the handwheel very slowly and pay attention to which part of the circle it binds at. Binding typically means something is trying to move farther than there is space to move. You can start taking inspection covers off to see the linkages that are at work. I've had a machine bind when it tried to lift the needle bar too high, and the needle bar ran into the head unit. Or when the latch opener tried to open wider than there was room for. Not sure what you'll find on this machine, but if you start exploring hopefully you can find some clues. While you're at it, you can oil the linkages 😀

-

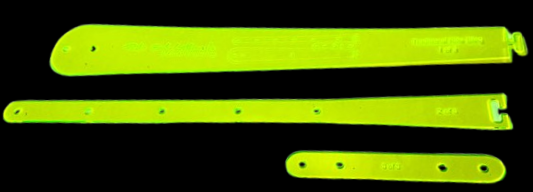

Maybe. this is the one I bought that is "too long". The arm from center of screw to center of screw is 1.5 in. The shank length on the machine is 1" Here's a pic of what I bought (that doesn't fit): I think a 1/4 in shorter would work

-

@SUP To misquote Julius Caesar, venerunt, viderunt, laboraverunt, They arrived at 07.30 and away by 14.50, Very much quicker than I thought, By several days! I might get things sorted by Tuesday and get back to this properly. But in the meantime I've got to knock-up a new belt for #1 son

-

First time posting! Today I met a cool guy through a Facebook purchase. Owns a Shoe Repair shop about an hour an away. I went to buy an old Landis 5 in 1, but left with alot more. He gifted me a shoe patcher machine, he said it was a singer or Adler clone. It’s not the green one that around $100, it’s the white one that’s around $400. It’s brand new, he just said the wants to lock up. I don’t have it threaded or anything. But the wheel cranks fine just meets a little resistance at first. But after a full rotation it seems fine. I’m so new, I don’t even know where to start. I’m really looking forward to for help trying to find some decent videos on them and such. I’m not sure on how to add a photo but here is a link to and identical one on Amazon. https://a.co/d/1q9SAgj and and all advice would be appreciated. Just remember this was a gift, and I want to get this specific machine to work. I know I want a better machine in the long run! Haha

- Yesterday

-

-

Yes I use my 3D printer ( Bambu Lab x 1 Carbon ) for belt hole guides, stamps, table top attachments for Juki LS-341 and Juki TSC-441 clones, binding attachments, templates, hand press guides, molds for wet forming to name a few and on various other prototype items before turning it into a piece of equipment. I find 3D design and printing opens up avenues where something isn't available, it's more cost effective to 3D print or both. Stamps why pay $50 for a stamp when you can do it for 50 cents or less. kgg

-

I'm trying to find a roller foot for a Singer 44-10. I bought one on Amazon but the arm the roller is attached to is too long and I'm not able to move it into position. Any help is appreciated. Thanks!

-

I can see where the one on the right could work well, the curving edge should allow for an easier/smoother slicing action. I might have to pinch the idea.

(1).jpg.d107e79a81dd7a2d11f165752ac22f74.jpg)