All Activity

- Past hour

-

Not uncommon. What I would do is: i) remove the pulley BUT mark it's position on the shaft as it is easy to put it back wrong and you will be out 180 degrees. ii) check and see if there is a high spot in the groove. Depending on findings you may have to lightly grid it. But this could be as simple as reinstalling the pulley not as far in on the shaft as it's original position. It could have been installed to far in at the factory or by the guy you got it from. Don't forget to lightly oil the shaft or the groove in the pulley. kgg

-

Singer 132k6 capabilitues and upgrades

friquant replied to Ed Neil's topic in Leather Sewing Machines

Can you send us pictures of your current setup? (Motor, pulley, belt, machine) Also photos of your old motor, control box, and nameplate if it has one? (If you want help diagnosing the old motor, that is) New leather belt? Old leather belt? I like having my belt tension set just high enough to go through my thickest material, that way I'm less likely to break things. My belt is not very grippy, but I'm considering getting a regular rubber automotive belt instead of these cloth-covered belts I've been using. Not sure what other folks are using for belts. - Today

-

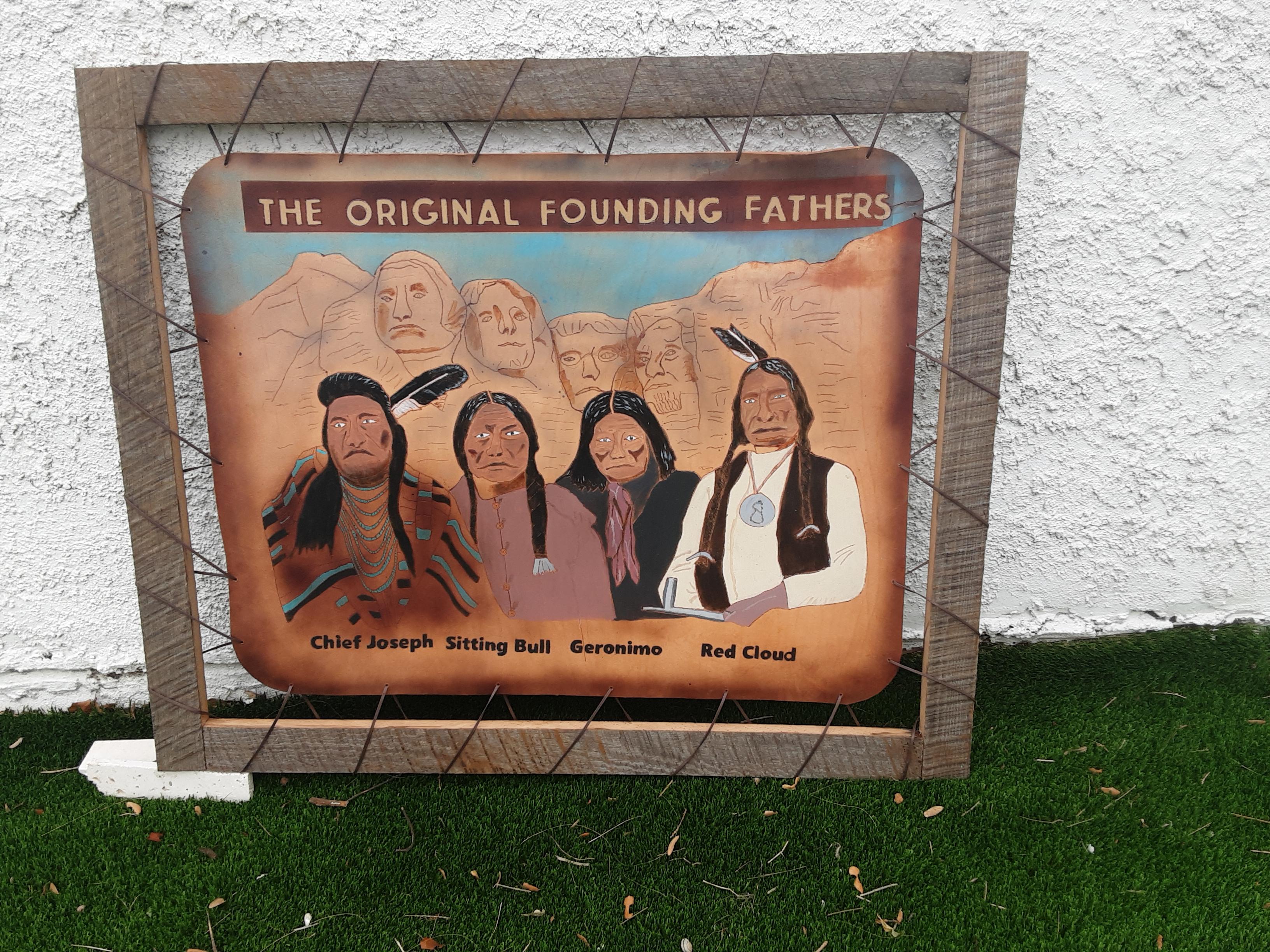

After my first and only attempt, which I primarily used pyrography, I really appreciate your work. I struggled with the texture. It was all trial and error with the intention for a bit rustic. I made this for my friend who is native american.

- 4 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

I just tried Googling if there was any information in Danish, but sadly nothing came up. My best guess would be to contact Sieck in Germany and see if they have any information on the machine. Good luck Brgds Jonas

-

Welcome :-) Nice looking bag. Brgds Jonas

-

Ed Neil joined the community

-

I thought I sent the following reply from my phone but, I don’t see it here so I’ll write it again: I found a video online of a gentleman (in the UK I believe) that was doing the same thing as I am on a similar machine. What I learned was there is a way to change the height of the shaft that the foot mounts to, that then allows the user to properly position the roller foot. Thanks for replying but, I think I’m all set. Regards…..

-

I just got a singer 132k6 what would be the heaviest tread and needle it can use i set it up wit a 750 w servo mottor since thw one ii had eather capasitor may be bad or the hile mottor its a bit confusing since the mottor is 120v the capacitor is 330v and the box where the on and capacitor and of on and off swich is is calling for 250v. (Transmiter mottor and swich+capacitor). The leather belts slips from time to time.

-

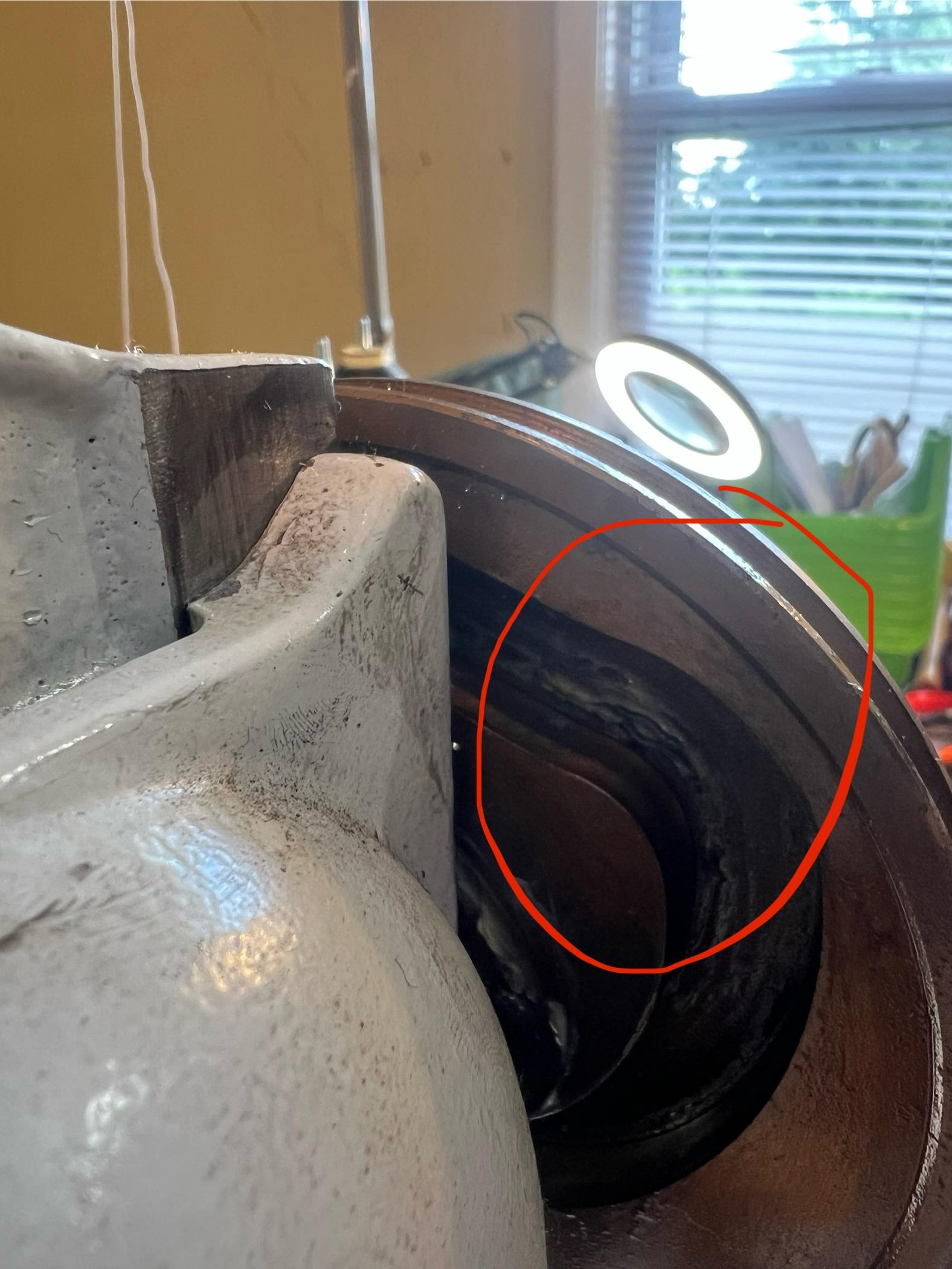

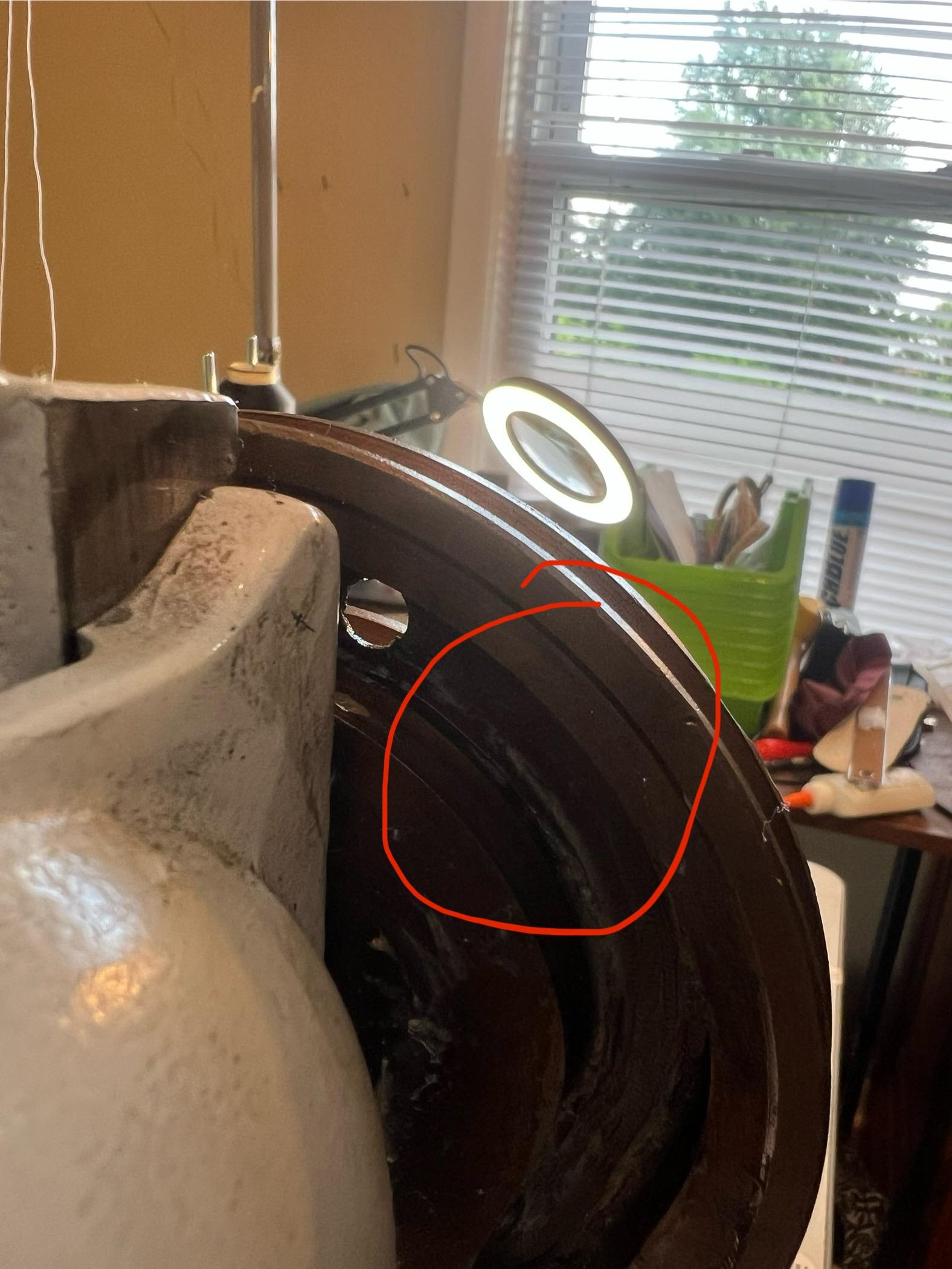

Ok so this is where it catches or meets resistance, however I should say that. Where that inner groove starts to change direction. In the picture the red is where the resistance starts and then where it ends. It’s hard to show the position is in when it’s actually resisting. So the photos are the spots where the bearing is at when it’ is resisting(im horrible at these kind of descriptions haha) I think that’s hardest part of all this. Every step of the process has so many elements to learn! Like every day there’s something g to research added to the list haha thank you!

-

Chances are what oil came with the Consew was Sewing Machine Oil like Lilly White. Sewing machine oil is not 3 in 1 oil. I know I am the odd man out on this point but I never use sewing machine oil in any of my new or used sewing machines. I use a combination of synthetic motor oil and synthetic transmission oil. The amount of each varies depending on whether I am flushing a machine or just normal oiling. kgg Good one. I like that. kgg

-

3 in 1 and other hardware store oil contains additives that oxidize and form a gummy substance that turns into a hard shellac. When this happens, your machine will seize up. Use sewing machine oil. It is clear, Lily White is one brand. It generally doesn't stain items you are sewing, but can. Others here are using transmission oil, hydraulic oil, synthetic oils, etc. There are lots of posts and a fair amount of debate as to which is best.

-

That so cool to me. There are few machines in this world that last like well built sewing machines. Mr James, the man who gifted me this machine(and unknowingly had now adopted me haha) has some that his parents bought used when their leather shop opened before he was born and he’s 77!!! You hit so many good points thank you! I’m 100% a newbie to sewing machines. I have a brother I bought from Walmart and a Consew CN2053R-1 I bought last month. I thought it was perfect and it is a great machine, but won’t sew through some of the leather seems I need it to. Anyways… so when I’m looking for videos on how these are supposed to work and such, what do I call this machine? A Singer Clone? Better yet if I need to buy parts for it or whatever, what machine should reference to make sure the parts compatible? thank you so much for sharing!

-

I can definitely see the advantage of laser engraving letters on leather instead of trying to keep stamped letters straight, uniform, etc. Usually laser engraved leather that I've seen is burned/blackened on the bottom and I just don't like the look. Is the fact that yours isn't blackened just advancing technology and/or technique? I could see a laser in my work room if I can avoid Cajun blackened cow hide

-

RobK87 joined the community

-

I would forget about what the manual says about oiling locations until you are sure that everything is oiled properly. I would give it a good bath in synthetic oil to get oil in those bearings and all the places where metal rubs against metal and get any manufacturing debris out of the machine. I usually flood a new or new to me machine just to make sure there is oil everywhere and any garbage is gone. It can be messy but it is worth it in the end. kgg

-

Yes and no. It comes down to your particular situation. However I do agree with the cheaper 3D filament printers the filament can get clogged when the nozzle size is to small for the speed or the filament type or using cheap filament can be a problem particularly with printers that don't have monitoring or give you notification of problems. I rarely do overnight prints as I still don't like leaving 3D printers unattended just in case. In my case I just didn't want to deal with fluid. Very doubtful. This comes down to what type of 3D printer is being used and it's speed capabilities. That is the beauty of all 3D printers do your design, ship file to printer and go do something else. If you are using .stl you have to do another software step but if your printer is capable of accepting .step then it is just a straight export. I do totally agree when doing certain items like DnD figures a resin will give better print quality / detail but the gap is closing. kgg

-

RestlessHands joined the community

-

I have two types: A) with a large wheel: the dimension according to my mic. Large Wheel: a) Center of screw to center of screw on arm is 1.435" ( 1 - 53/128", 35.9mm). b) Wheel Diameter is 1.236" ( 1 - 15/64", 31.4mm) Small Wheel: a) Center of screw to center of screw on arm is 1.435" ( 1 - 53/128", 35.9mm). b) Wheel Diameter is .8745" ( 7/8", 22.21mm) Body is the same, length is the same just the wheels are different diameters. kgg

-

I use my CO2 laser to make all kinds of acrylic stamps and templates for rifle slings, holsters, guitar straps, and belt templates. I have also done some for folding knife sheaths. Occasionally, i am asked to laser engrave knife handles, holsters, and sheaths which I can do on my CO2 laser. I recently got a Fiber / Diode laser which allows me to engrave metal. So now I have added the ability to laser engrave the blades as well as other metallic items.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

What an honor my friend, it sounds like a great time indeed. Is anyone videoing it? It would be nice to see the work. It will also be a nice change of pace for you I'll bet. I had to laugh at myself, my tim the tool man brain said hey you have a treadmill motor it would make a great pottery wheel motor. So I get it out and get it wired back up, and I'm sitting there watching it turn slowly on setting 1 whicjh would be a good speed i imagine, i really have no idea lol, But it looks like i could keep up anyway i turn it up a notch still not bad so i kicks it into high 10 on the setting man that thing took off a good 1800 rpm and i got this image of clay flying around the room at lightning speed, kids and dogs runnign for cover, the wife yelling . LOL It was then i realizesd i have gotten to the point and age that i can kind of think through my decisions and see a bad outcome before it happens. So now i'm making a simple kickwheel with no motor... i still dont know what to do with the motor??? Life is good!! -

Learning to do Portraits of People

chuck123wapati replied to RidgebackCustoms's topic in Figure Carving

lol Trial and error, and a book was all we had when I was first learning this stuff. But nowadays I do peruse YouTube just like everyone else. I've always studied art and creating things so this is just a part of that. If that makes sense?- 4 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

buongcuaxit28 joined the community

-

heeulewno77 joined the community

-

About £/$200. Its not hard to learn to use it. I think the resin gives a better print, less noticeable print lines, which don't matter at all for stamp making but I wanted it for printing DnD figures as well so a better sharpness was needed than I could get with the filament printers. Plus there are environment friendly resins, ie water based. Resin printers are safer than filament types. The filament type heats a coil of plastic and lays it down. If the plastic gets stuck it can overheat and start burning giving off toxic fumes and potentially setting fire to your building - it has happened. The resin does not need heating at all Takes the same time to print as a filament printer. But it prints your subject upside down by dipping in & out of a vat of resin. You don't know if the print is a success or has failed until the end when it finally raises the print clear of the vat The printing is very temperature sensitive. The printer, the resin and the room has to be at a constant 22* or more One thing more, Ppl are put off 3D printing because it 'takes 3 hours 45 minutes' (as an example) to print. Bu you are not sitting there very minute. You set it to print and go for lunch/make a belt/get a coffee hth

-

There is a break in period with them , I am sure the binding is in the upper pulley wheel .On the machine side of the upper pulley wheel you will notice an elliptical groove . the needle lifting arm ( the see-saw bit across the top) has a little bearing that sits in side the elliptical groove and this is what give the see-saw its motion thus lifting the needle . This usually needs a bit of time to bed in. You will probably notice the tightness occurs when the bearing is in a tighter radius in the groove . Some older singers still have that tight spot even after 30 years . Technically the machine is a singer clone in every way and should perform as one . They have not been around for that long so no one really knows how long they will last . My bet is at least a lifetime, where a singer might last 3 life times . I have 3 singers and one clone . the singers are well over 100 years and work perfectly 99% of the time . The clone is 3 years old and still a little tight but prefers a thicker thread than the singer . i ended up putting an original singer shuttle and bobbin in it and works better . I think the clone bobbin shuttles are not that good especially the tension spring on them . I think oil and putting it to work should sort it out

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)