All Activity

- Past hour

-

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

NeilMott replied to NeilMott's topic in Leather Machinery

Just tried to call and they're closed until Monday. Yeah, it's frustrating because it shouldn't happen on a new machine. It seems like they rushed this out the door. There's no way this worked properly when they tested it and then doesn't now. To me, it seems like air is getting into the mechanism because after I pump it a few times, it'll go down smoothly. I'm definitely not going to play mechanic on it. -

Would you by chance have a link to a place that sells Schneider's Veg-Tan? Thanks in advance. Jim

- Today

-

spring flowers and good food

AlZilla replied to chuck123wapati's topic in All About Us and Off Topic

In New England you can even start a Holy war by bringing the wrong kind of hot dog bun. This is a proper Hot Dog bun. Although a righteous Chicago Dog requires an entirely different bun. -

I have been trying to figure out how the weaver Master Tool Creaser and Embosser is able to release pressure and lift up to move belt and then put pressure back to where it was and how the gears fit into all this. I would love to see some pictures of how this is done. Thanks

-

What would your ultimate needle positioner/synchroniser do.

toxo replied to beefy's topic in Leather Sewing Machines

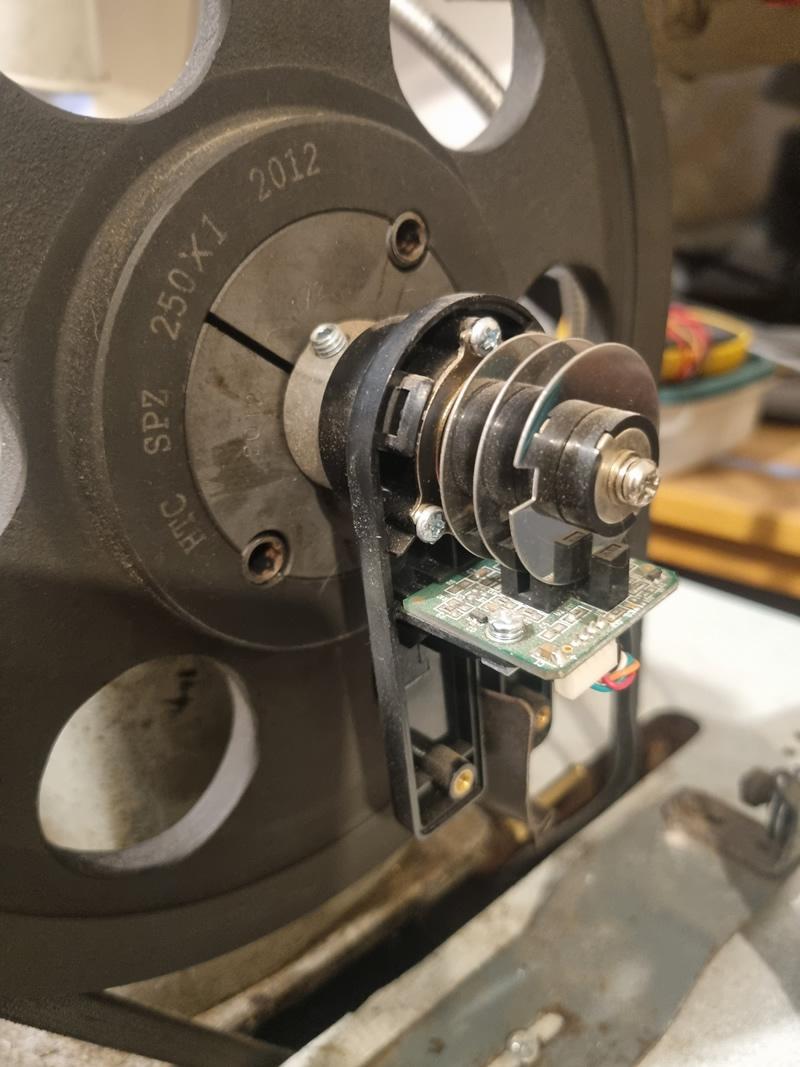

@beefyI haven't understood half of this thread so I just want to throw in my two penn'orth. Firstly the Chinese usually copy everything so I doubt that your servo won't do what all the other servos do. I still haven't got to the bottom of tuning my N/P because my machine came with a speed reducer. My China contact has asked for a video which I've sent and am awaiting a reply but Chinese holidays can be quite long. The N/P on my new machine has a N/P that I'm not familiar with so Im wondering if yours is the same. Here's a pic of what I'm gonna call "the old N/P". This is completely different from "the new one". The old one was a breeze to adjust (no speed reducer but a very big handwheel instead) As you can see, the old one can be adjusted simply by turning the relevant disc which breaks the circuit by way of a cutout. I'm thinking that you might not have seen this type. Forgive me if I'm teaching granny how to suck eggs. -

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

AlZilla replied to NeilMott's topic in Leather Machinery

I know nothing about that machine but I know a little about mechanical things. From your video, it just looks like a rough spot or a piece of metallic debris need to be cleaned up. I would definitely get LMC or whoever you bought it from to bless you taking it apart beforehand. It shouldn't be like that on a new machine but it doesn't seem like a fatal flaw. I'll be interested to find out what it ends up being. -

What would your ultimate needle positioner/synchroniser do.

AlZilla replied to beefy's topic in Leather Sewing Machines

Yes. The thicker threads we use for leather create a lot of unsightly bulk when you start forward, back up and come forward again. And the hole created by the needle isn't really big enough to have 3 stitches run thru. I use V138 and up. I start, needle up, where the 3rd hole would be and drop the needle 3 times, backwards. That gives me 2 complete stitches, with my needle all the way down and at the beginning of my intended stitch line. Now I can stitch the "right way" (forward) and I get 2 locked stitches when I hit the 3rd hole again. With domestic sizes of thread and needles on fabric it's not so obvious. On my machines without reverse, I do the same thing by turning the material around. Simple to do, but apparently takes a lot of words to explain... 😃 -

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

NeilMott replied to NeilMott's topic in Leather Machinery

My friend who's been advising me on fixes also has a Techsew SK4. He said that his feet didn't need any polishing. He has another machine from LMC and also thought they'd be very helpful. At least I kept the box in case I need to send it back. -

lunabambi joined the community

-

Bunker85Hu joined the community

-

That is a beautiful sheath. How does such soft leather hold its shape? And do you use a hard leather welt? I'm sure a knife like that is razor sharp. In any case, that is a setup fit for a chief - well done!

-

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

TomE replied to NeilMott's topic in Leather Machinery

Hard to know what's wrong with the foot lifting mechanism without taking it apart. LMC is generally very helpful with advising, sending parts, etc. In my limited experience skiver feet typically need polishing for best results. I have a Techsew SK4 and some additional FAV feet that I polished on a buffing wheel. -

What would your ultimate needle positioner/synchroniser do.

beefy replied to beefy's topic in Leather Sewing Machines

Cheers AIZilla, interesting suggestion. I'm just a beginner at this sewing gig and all the videos I've watched start of sewing forward then backstitch then forward again and continue. Would you only start off backstitching with leather but not fabrics, vinyl, etc. -

What would your ultimate needle positioner/synchroniser do.

beefy replied to beefy's topic in Leather Sewing Machines

Thanks for the suggestions Nejcek74, yes, using an Arduino Uno or Nano for this one. I normally use these boards but program in straight C using Atmel Studio, but for this simpler project will just use the Arduino IDE and "Arduino C". Also adding an external mix of operational amplifier circuits basically because I'm unsure of how the "analogue" output from the microcontroller would affect the servo. Op-amps will give nice smooth variable DC signals. The basic principle is my system will simply "go between" the foot pedal output and the servo speed command input, and "take over". It will monitor the foot pedal output as well as the heel switch, monitor the outputs from the needle positioner, and command the servo to do things accordingly. So basically the servo is nothing but a driver for the motor and it's not even aware a needle positioner is installed. The servo simply does what it's told by my controller, pretty simple really. The most difficult bit is getting the programming correct and foreseeing all the situations that COULD happen. It's so easy to find things afterwards where you say, "Oh yeah, I didn't think of that condition existing at some point" LOL. I've pondered the idea of a DIY needle positioner disk, where I can have more than 2 sensors IF there's any benefit to having more than just a needle UP and a needle DOWN position. The rotating disk itself would have just one magnet glued in a hole in the edge. Hall sensors around this disk can be moved to any position to have the needle stop in exactly the desired position. For now though I just want to get the basic design working with an off the shelf positioner. Got one arriving mid January. Never thought of the idea of automatic back stitch control, good suggestion. I like that one and it could be my next quest. Will have to work out an electrical way to operate the reverse mechanism. -

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

LOL now that's funny, I think hot dog ettequete is everywhere, but then its not lol. It is quality dependent, except that the dog always goes on the bun first, no matter what topping. Because there is no such thing as a bottoming for a dog to go on top of. The lowest form of American weinie on a piece of bread, "weinie bread" can have about anything on it, especially ketchup. While a choice German brat for example simmered in beer then browned, calls for only a good kraut on top with some spicy mustard and nothing else. I have put ketchup on the lower forms of American dogs, especially as a kid, but not ever on good dogs or sausages. Some of our worst dogs are made from chicken and pork scraps that are basically turned into the same mush as bologna, then shaped like a dog lol. They are the cheapest and cost about a buck a pound and are fair game for anything that makes them taste better lol. The higher end type All beef hot dog can have any type of specialty toppings like chili dogs or kraut dogs, but no ketchup IMO thats just crazy talk. -

What would your ultimate needle positioner/synchroniser do.

AlZilla replied to beefy's topic in Leather Sewing Machines

If I had this on a leather machine, I'd want it to backtack 3 holes first, then go forward from there. This way I only get the beginning stitches run over 2 times instead of 3. That's how I do it anyway. This way my first 2 stitches are doubled up as I get when hand stitching. -

Beautiful work. Any chance you have more pictures of that knife?

-

What would your ultimate needle positioner/synchroniser do.

nejcek74 replied to beefy's topic in Leather Sewing Machines

Great project, Beefy! I really like elevated DIY projects, and I hope you succeed. I find the needle positioner extremely useful. What are your plans for the controller — will you use an Arduino or something else that can be programmed? In my opinion, you describe the basic functions well. What I would find useful is: - the ability to check and auto-apply signals from different types of needle positioner, as you already described. - the ability to easily define the up and down positions by turning the wheel by hand and pressing a button. Currently, on my controller, I can do this either by typing numbers into the controller or by moving the three metal discs inside the positioner mechanically. I always spend too much time fiddling with that. A more advanced function would be to perform automatic backtacking ((three forwards, three backwards, three forwards, or something programmable) as you are describing, that would be great.!!!!! -

What would your ultimate needle positioner/synchroniser do.

beefy replied to beefy's topic in Leather Sewing Machines

Thanks Dikman, yes this design will be specific to my setup, but my setup is a typical Chinese servo drive, so any time I get a new cheapy servo, if the connections are not identical, I will be able to easily modify them to suit. You are right, I don't need this so much for very slow sewing but it will be great for other things when I'm going faster. I'm also finding as I'm learning to handle say tarp material or a canvas cover, not having to concentrate on the needle position will make life much easier. I'm also going to make my backstitch foot control so my hands will be completely free nearly all the time. To be honest this is more a labour of interest rather than a huge necessity. I get very engrossed in the design and programming and the hours tick away quite quickly. And when the design is completed (and works LOL) I enjoy it every time I use it. -

What would your ultimate needle positioner/synchroniser do.

beefy replied to beefy's topic in Leather Sewing Machines

Thanks Fibresport, the servo IS what normally does the control when it receives the signals from the synchroniser, but my design will command the servo drive based on the needles position. I've already paid for 2 motors and drives so don't want to buy 2 more LOL. Plus I enjoy this design work and it will be very cheap. -

What would your ultimate needle positioner/synchroniser do.

dikman replied to beefy's topic in Leather Sewing Machines

Beefy, it will be an interesting project for you and while you may be able to design/build something to do what you want it is likely to be specific to your setup. On a personal level my first servo had a needle positioner, I bought it because it sounded like a good idea and I had no idea what I was doing! I tried it and didn't like it. I find for sewing leather a slow, controllable speed is all I need and an NP is of little value. -

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

@chuck123wapati Food : Just watched sudden impact, Dirty Harry for the umpteenth time . (it's 45 degs outside and I'm hibernating with a few beers ) One line had me intrigued : DH: : " nobody , I mean nobody puts ketchup on a hot dog " Is there an etiquette to what goes on a hot dog over there? There is here. Here in Oz, a hardware chain doing a sausage sizzle, made a major faux paz. Here , we put the sausage in the roll first,followed by onions on top with whatever sauce, tomato, bbq etc. but they did the opposite, put the onions in first. OMG ! It blew up in the media A lot of fuss over piece of processed meat in a piece of bread . HS -

What would your ultimate needle positioner/synchroniser do.

fibersport replied to beefy's topic in Leather Sewing Machines

Get yourself a Kinedyne needle synchronizer for accuracy but I'm pretty sure the servo motor controller is what really controls the functions, the synchronizer is just a switch to indicate where the timing of the machine is. The Kinedyne is an optical synchronizer and is super accurate. http://kinedyne-motor.com/products/HM-750SH/234.html You could just get the Kinedyne motor and synchronizer and be done with it. Just sayin - Talk to Ryna at http://www.neelsaddlery.com/ I have no affiliation with Kinedyne or Neels Saddlery, just a very satisifed customer. -

In keeping with my growing love of my newly acquired industrial sewing machines, I'm now getting myself absorbed in designing an electronic circuit and programming a microcontroller to make my own needle positioner. I've given up trying to get any sensible instructions for my cheap Chinese servo from the seller. I know it also doesn't have any heel press functionality. So far this is the functionality I'm programming for it: Single revolution/stitch from EITHER the needle UP position or needle DOWN position. This is done by a quick tap on the pedal, either forward (for needle DOWN) or heel tap (needle UP). Stop in needle DOWN position when foot pedal released. Go to needle UP position when heel tapped. Adjustable "coasting" speed when searching for either needle UP or needle down position. This is to have control over overshoot if servo cannot stop motor fast enough. Search for needle position is cancelled if operator presses foot pedal while motor is coasting and waiting for needle UP or DOWN signal. Safety feature - adjustable timeout for motor coasting and looking for needle UP or DOWN position. Coasting stops if signal not received within timeframe. This prevents the machine going on forever if some fault occurs like a broken wire, or faulty needle positioner. Are there any other useful features a needle positioner could have ?

-

Need recommendations for steel bar plate for work bench

Tom T replied to desullivan's topic in How Do I Do That?

Just use Carnauba wax on it occasionally after polished, it will keep it from rusting. -

Source for 12-14 oz quality belt blanks

wizard of tragacanth replied to wizard of tragacanth's topic in Suppliers