All Activity

- Past hour

-

This is awesome news now is this for anybody shopping blades will you do it thank you this is great News Wow can you do this for anybody at those prices that's a great deal wow this is awesome news Thank you for posting such great information much appreciated

-

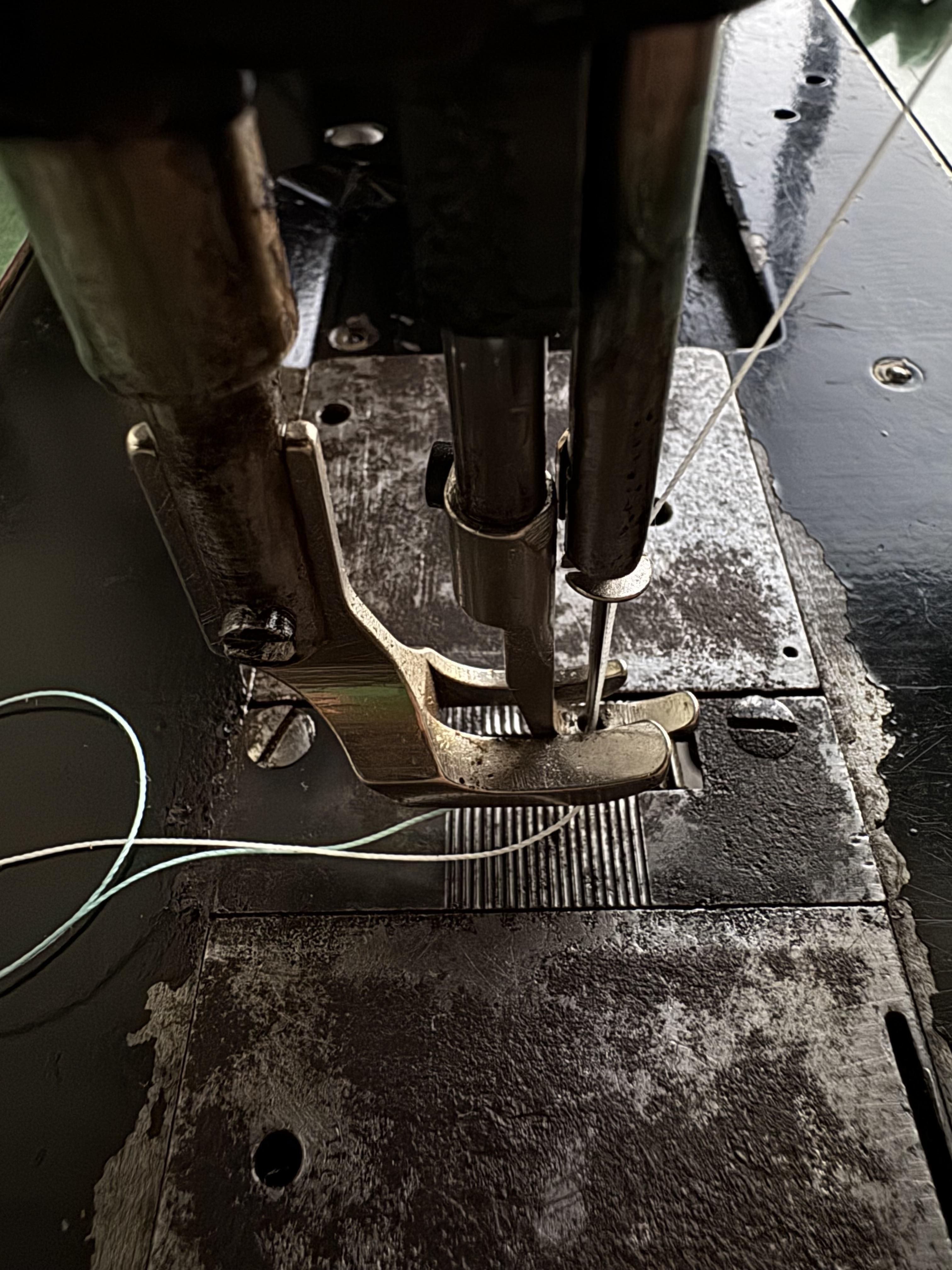

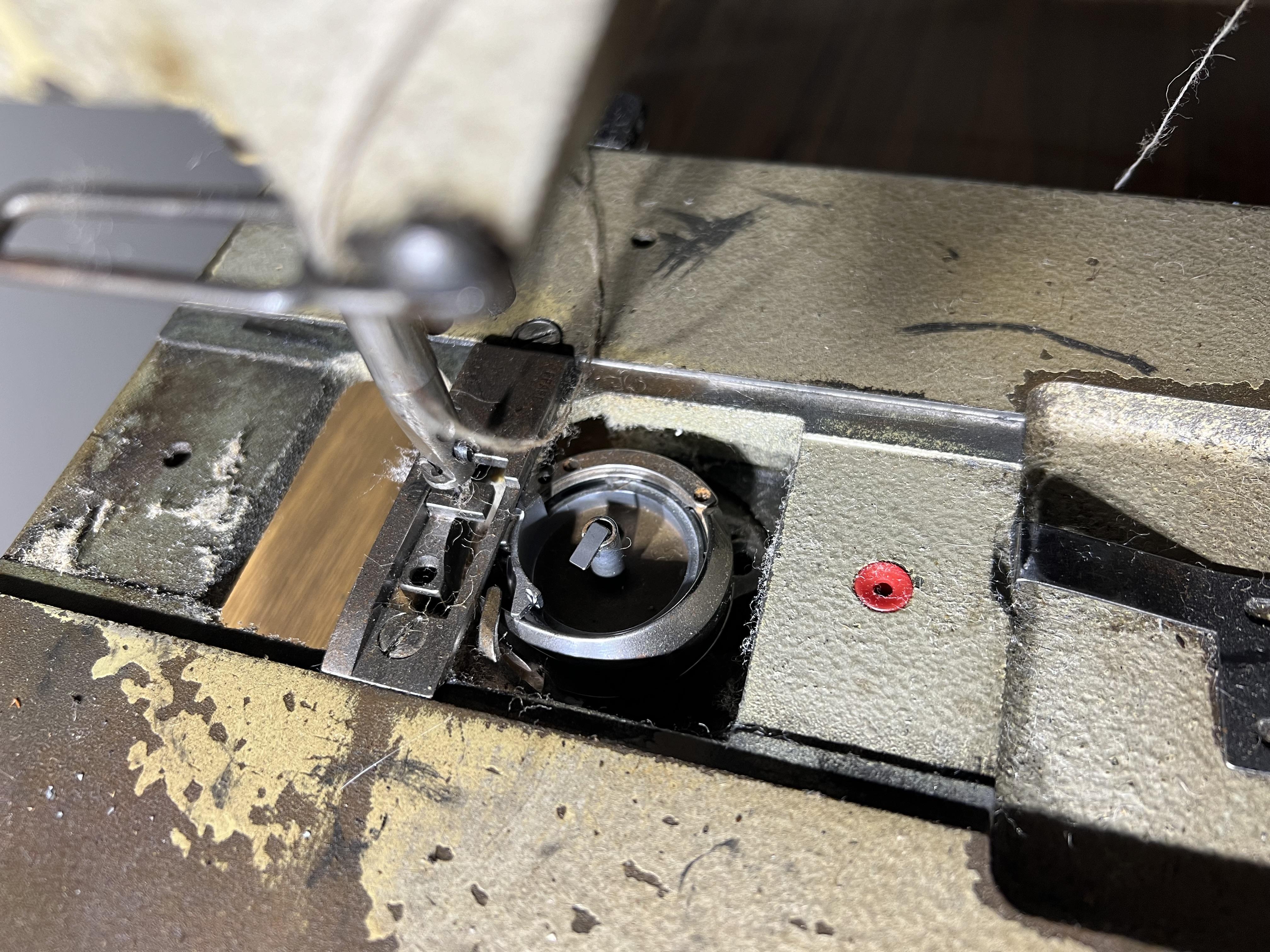

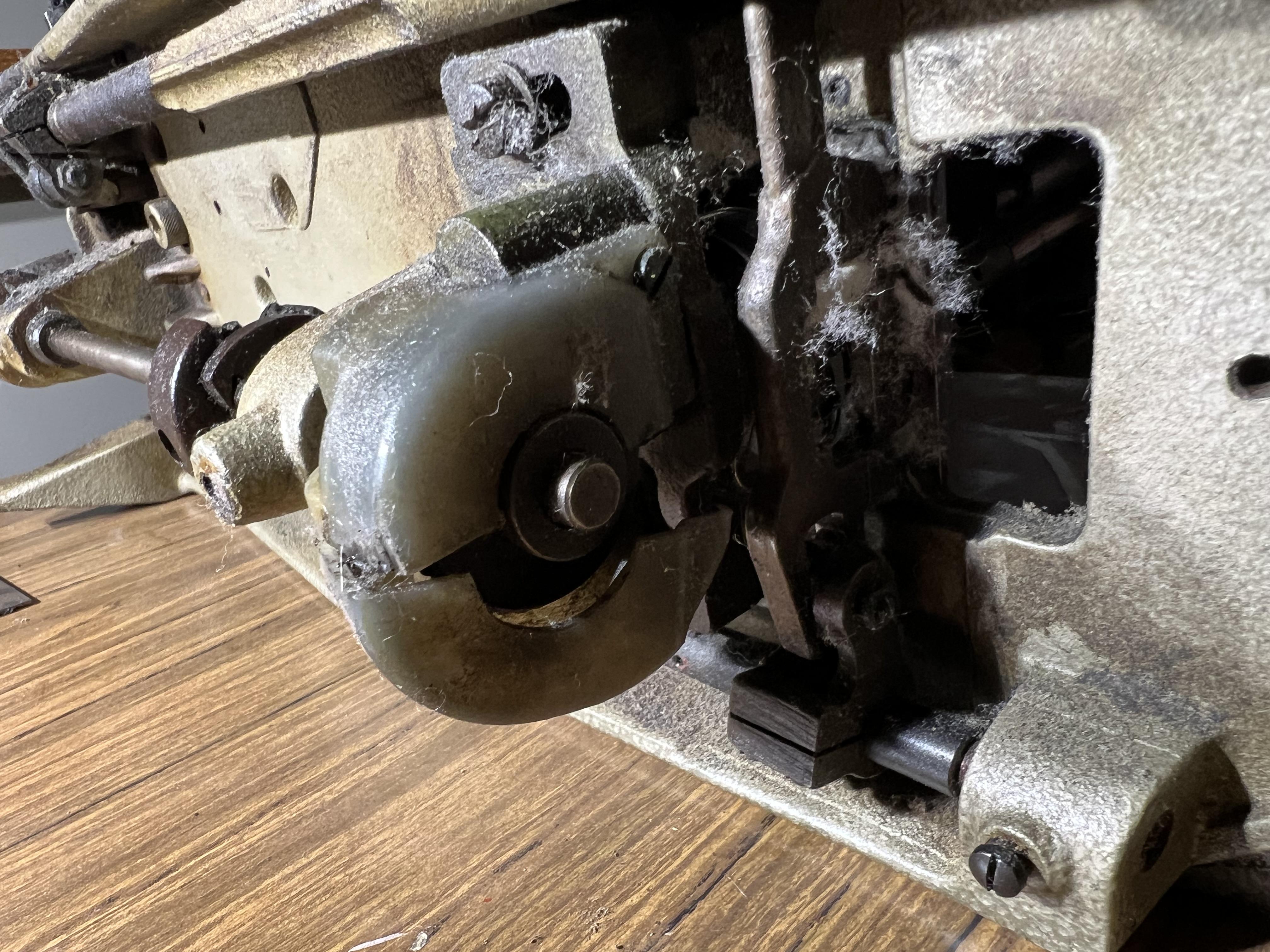

I would suggest a couple more photo's with no thread in the needle, the needle plate removed showing the position of the needle as the hook enters the Scarf ( indentation / cutout ) of the needle to catch the top thread. If the hook to needle timing is off you will get skipped stitches. kgg

-

Repair of leather edge on Louis Vuitton bag

Mulesaw replied to Mulesaw's topic in Satchels, Luggage and Briefcases

@PrePro One day late (I hope you don't consider me a complete untrustworthy fraud) :-) I was so tired when I finally made it home, that I fell asleep on after eating supper. But here's some information on the thread: I used Gütermann extra stark M782, colour 327 Over here in Denmark it is available in most regular sewing machine/fabric/embroidery shops. So I guess it should also be available in the USA. If it is possible, I would bring the bag that you want to repair into a physical shop to check if the colour is a good match. I have no idea of the age of the bag that I repaired, so in theory the colour could be faded a bit. But if you don't have a Gütermann shop near you, the colour I used was 327. I have used the same line of thread (the extra stark M782) for other projects as well. Occasionally I get a pair of riding boots in light brown or dark brown. And instead of buying a large spool of 2000 m in a cpecial colour, the M782 gives me 100 m of any imaginable colour for around 5$. Good luck with the project, and please let me know if you need any more help :-) Brgds Jonas - Today

-

I guess I’ll just need to fine tune then. The hook seems sharp and I’m letting machine do its thing.

-

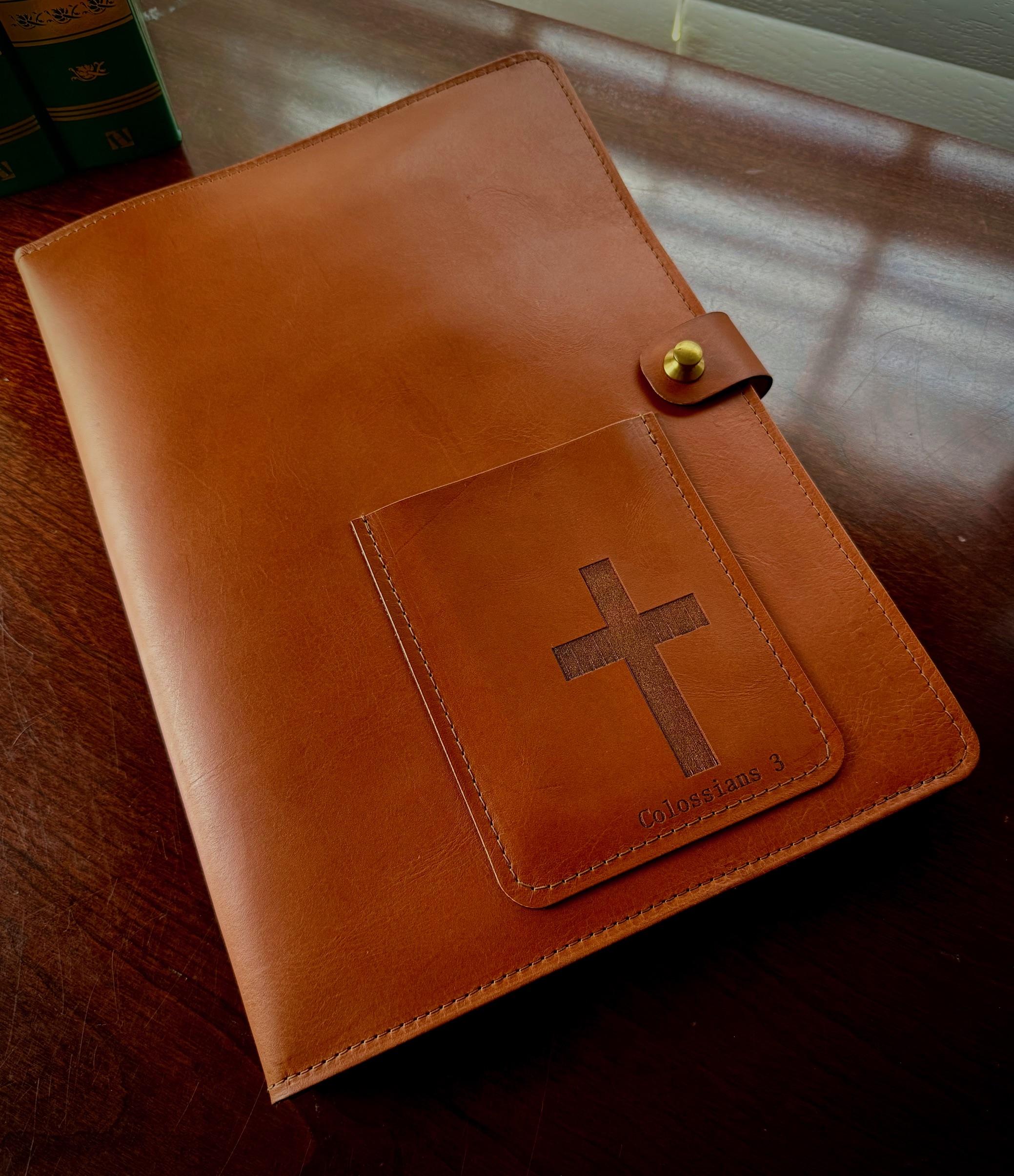

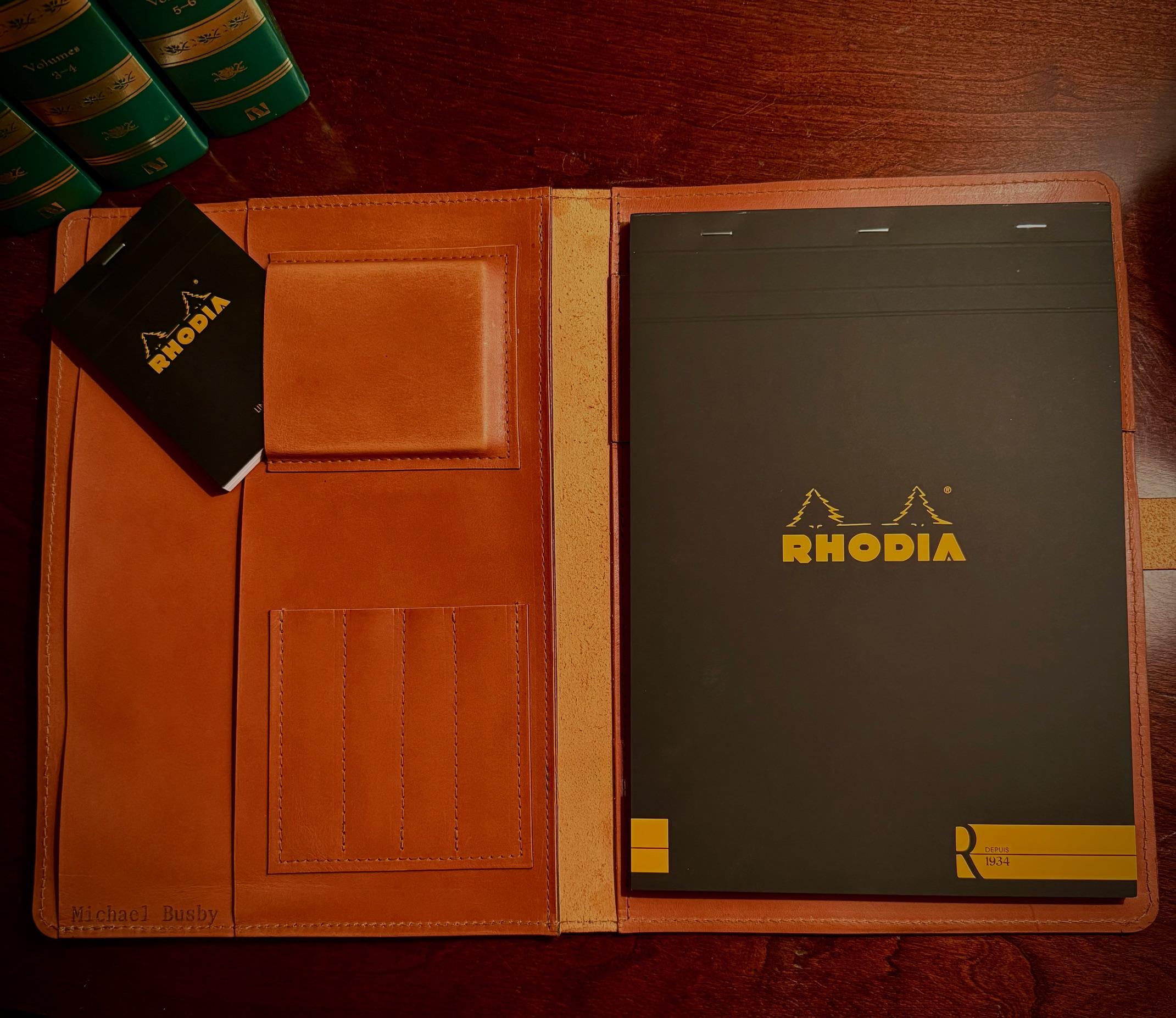

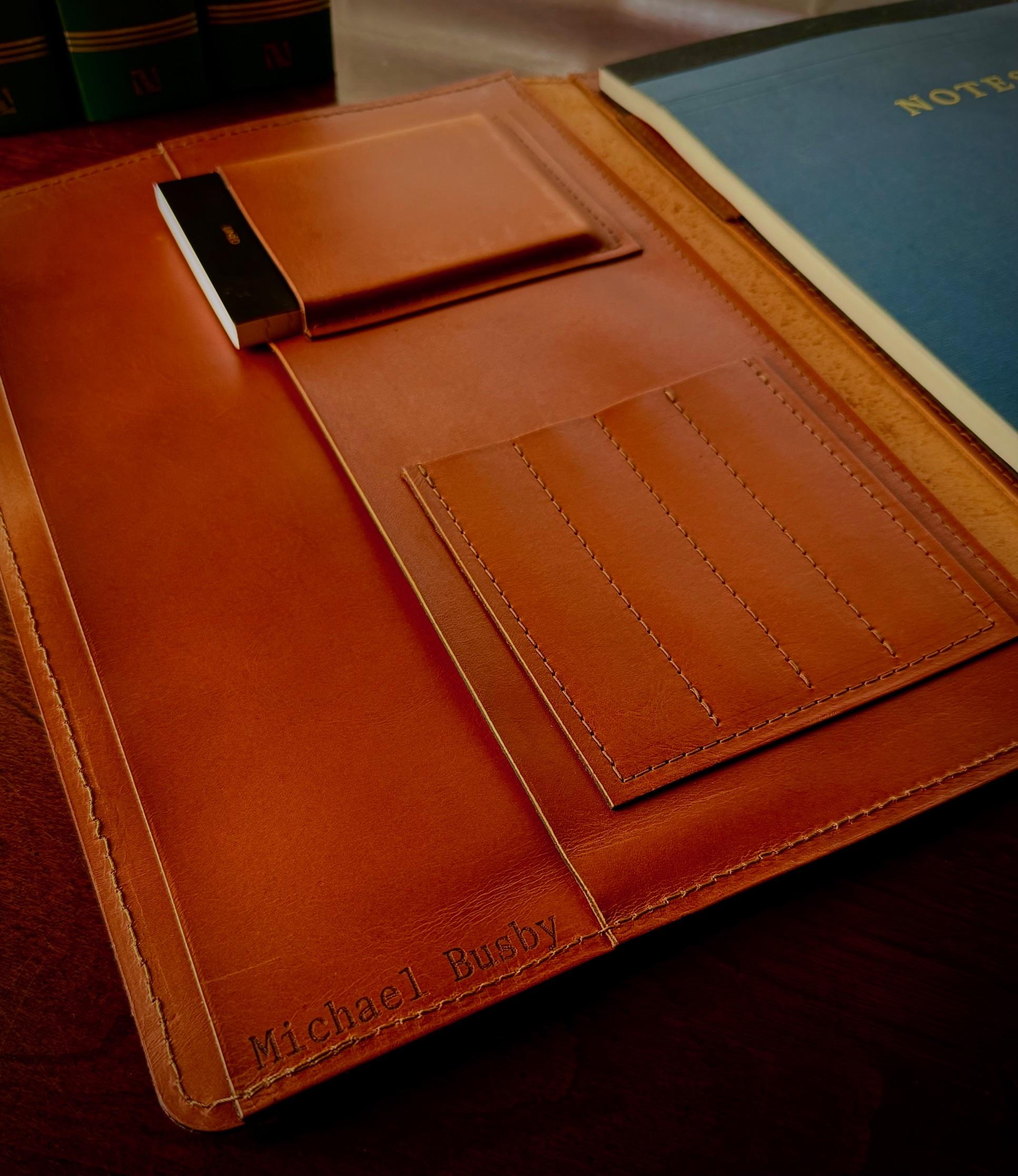

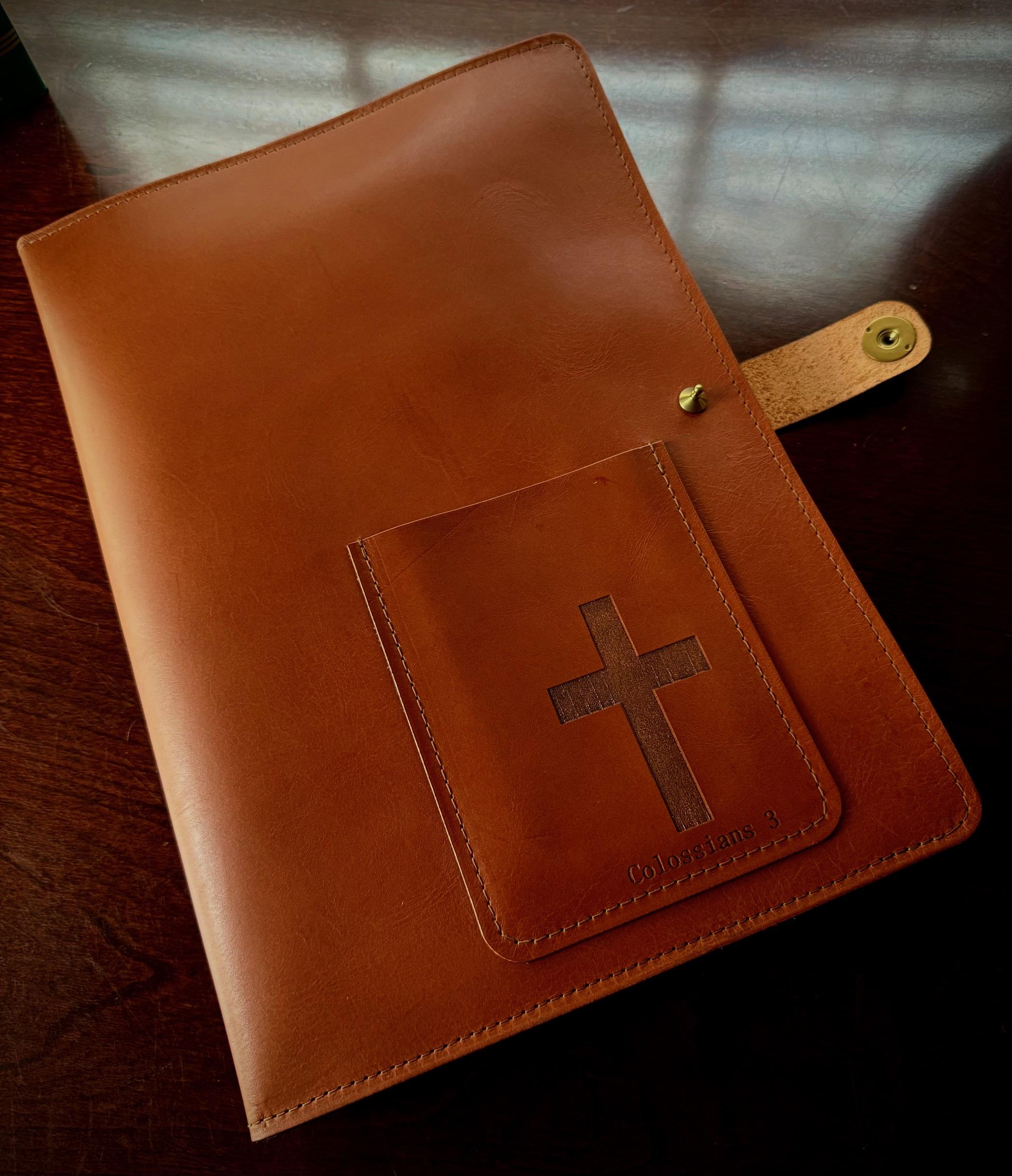

Hey everybody! This is my first post in a while. I just got this portfolio finished up for a customer and felt like it was worth sharing. This may be my favorite thing I've ever made! What do y'all think?

-

IP address shows Valenciennes, Hauts-de-France, 59300, France @el_pipou You should put your general location in your profile. It helps get info relative to your location.

-

Looks like you've got the corners down. I wonder why the stitch length is varying and the occasional skip. Probably the hook, needle, needle bar height and timing need to be fine tuned. Are you letting the machine feed the material without tugging on it? That can mess with the feed and thus the stitch length.

-

Easy fix: Loosen the screw at the top rear of the inner presser foot, rotate the foot till the needle is centered in the hole, tighten the screw. Would you mind taking some close-up shots of your hook point from above? My Singer 144W103 (built in 1943) had a dull hook point: https://leatherworker.net/forum/topic/131846-best-angle-to-sharpen-a-hook/#findComment-784869

-

Pfaff 545-H3 missing parts!!! Help please 🙏

friquant replied to darkhornsleather's topic in Leather Sewing Machines

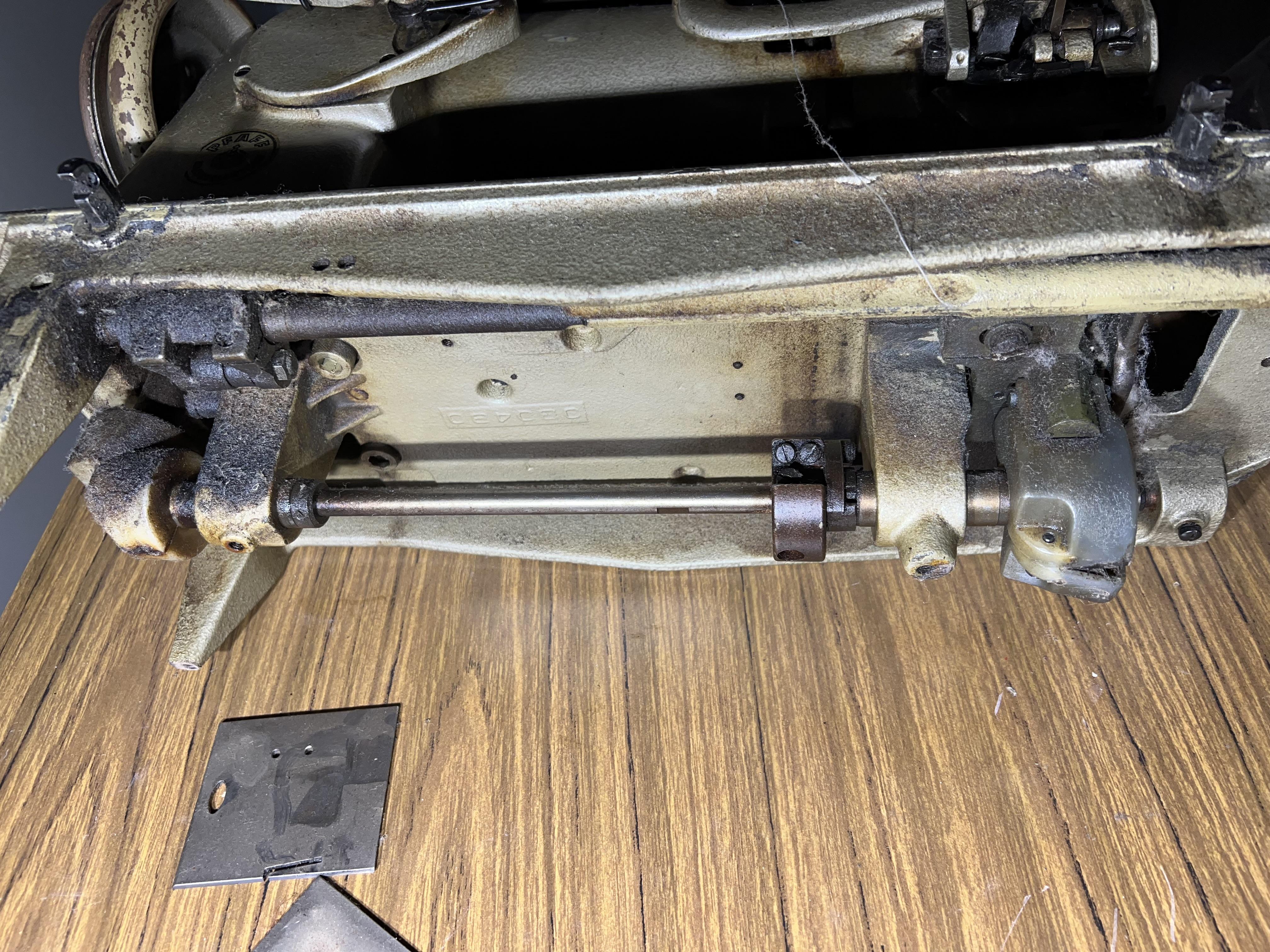

As soon as you get some presser feet on it, I would suggest oiling the machine and then turn it over slowly by hand to see what is functioning vs not. Go easy on it just in case something binds from being disconnected. Do the presser feet walk Does the needle bar go up and down Does the feed dog move Does the hook pick up the top thread Does the bar in the back (for a knee lift) pick up the presser feet Does the stitch length regulator effect more / less feed dog movement Anything anomalous, take a close-up video and post on here to get some ideas 📹 -

If it has stench I'd not use it at all, Something in it is 'off' and could affect the leather. Just dispose of it properly and write off its cost to experience

-

@AlZilla @kgg Thank you both so much for the advice. I followed all of it. Switched to 135x16. using a size 20 needle with Tex 90 nylon. Made the needle face the correct orientation. Repaired the small thread guide at the bottom. I still feel like my needle is a little too close to the inner wall of the foot but worried to crank on it too hard. It’s sewing like a dream only have a small issue with it skipping every so often or another. Will post new practice pieces after. Again thank you so much for all of your help!

-

What country are you in?? A link to where you bought it would be helpful so someone else doesn't buy it by mistake. kgg

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

There is a guy here who has two of the wagoneers, both in perfect shape. man i would love to get my hands on one of them. I built this little 68 cj5 years ago, before i adopted my grandkids. I had to get a bigger truck lol. It had the Buick Odd Fire V6, and i added lockers in the front and rear end so all four wheels had traction. 4" lift and 35" monster mudder tires./ This little sucker was bad ass!!!! I even painted it lol. -

Pfaff 545-H3 missing parts!!! Help please 🙏

darkhornsleather replied to darkhornsleather's topic in Leather Sewing Machines

Thanks heaps for your reply. I will google the manuals and start from there. -

Pfaff 545-H3 missing parts!!! Help please 🙏

nejcek74 replied to darkhornsleather's topic in Leather Sewing Machines

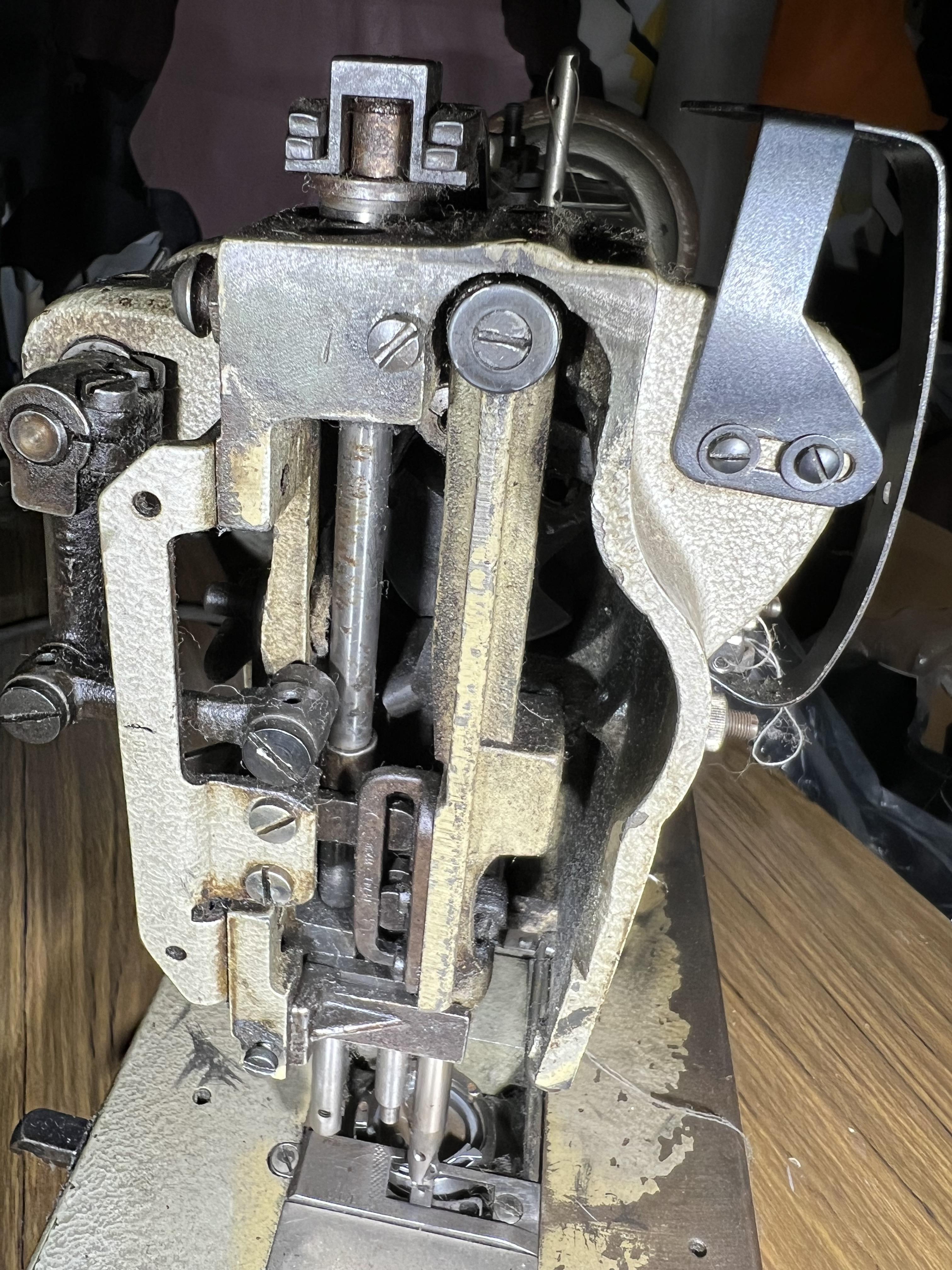

Google for parts diagram of the pfaff 545. Find the other post here for pfaff 545 and also 1245. Others, including me we already wrote and linked a lot of info how to time it. Feet will be the same as for 1245. Same is for hook and bobbin case, but you need to choose the right one according to your subclass (H3). 0) check this forum, 99% is already here 1) get parts diagram and find missing parts 2) compare it to 1245 to find some equivalents. 3) go to ebay/amazon /Aliexpress and get what you can 4) if something is still missing you will have to do more research 5) use pfaff 1245 engineering manual for timing it 6) ask here for what is missing -

Pfaff 545-H3 missing parts!!! Help please 🙏

darkhornsleather replied to darkhornsleather's topic in Leather Sewing Machines

Thanks for your suggestion. I managed to delete some of the images, successfully. I downloaded the parts list and I find it very puzzling to know what are the missing parts 😳 -

thank you for your anwser, Ill probably try to resell it or give it away regardless of what it is because I simply dont want my shoes smelling like this 😂 it was cheaper than most neatsfoot oil... (30 bucks a liter whereas other oils were between 40 and 55), so I guess it was adultered with something... it does WORK very well though, perhaps a little bit better than the other oils, but the stench overcomes that fact. I tried it on my meast favourite pair of boots and the stench didnt go away (yet anyway) I guess Ill try to use another strong scented product to mask the smell like some shoe-wax or something

-

Ha, ha! I guess it lives up to the name in the hands of some riders. Thanks for your kind words, Ron. Thank you, @JDFred. Already planning the next one in my head.

-

Pfaff 545-H3 missing parts!!! Help please 🙏

AlZilla replied to darkhornsleather's topic in Leather Sewing Machines

Well, you've got multiples of the same pictures, it would help if you cleaned that up while the edit window is open. This post is quite a bear on mobile. Then a list of what parts you're looking for would help. I'm sure there's a parts diagram somewhere you could work from. Australia is really going to complicate it, but who knows ... ? -

Hello everyone, I bought this machine to salvage and bring it back to sew again. I have multiple industrial sewing machines that are working well for me. I never attempted to fix a machine before. The maximum I have done was change motors from clutch to servo. So I am very excited about learning how to do it and get to expand my knowledge with your help guys. I stumbled upon this one on marketplace and I went to check it out. It was used at some point to sew in a mattress factory. As far as the person that sold it to me, he’s not sure what happened to it before it stopped working. It doesn’t have any feet or anything apart from the side plate. Unfortunately, it’s missing some parts, as per our discussion. I would like to be able to get the missing parts, preferably from Australia. It would be greatly appreciated, if you can help me to bring it back to life.

-

Diego5.7 joined the community

-

Sounds like it might be compounded neatsfoot oil, this is pure NF mixed with petroleum-based oils. It can be made cheaper because it's effectively diluting the NF with (relatively) cheap mineral oils. It will still work on leather but most leatherworkers prefer the pure stuff. If it's compounded it should mention it on the labei. A google search for P Paulin doesn't come up with anything.

-

meatrhit joined the community

-

How to add needle positioner on adler 669

HarrySingh replied to HarrySingh's topic in Leather Sewing Machines

@shoepatcher Do i needle to drill hole and thread with tap for screw to hold it or just it has tight fit , please advise....

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)