All Activity

- Past hour

-

Thanks for gently keeping me from the edge. This certainly is making me crazy. I'm really only steering towards flatbed because of budget reasons. That one Singer came up because it's in the range I'm able to spend right now. And for my most pressing concern being the boat seats, the cylinder arm isn't really necessary. I think I'm trying to just maximize my spend since both space and money are restrictive for getting endless machines. It also seems that to get any machine at all, I'm going to need to drive an hour and a hall or more in almost any direction. I'm getting worn down by the idea of so much travel to see machines that maybe need work or won't actually do my boat seats. Additionally, there is no one nearby that works on industrial machines. I did find a guy that's willing to travel to me, but I don't know anything of his reputation. All that is to say that if something on the list looks more reliable than the next, I'd like to just go that direction. I looked for the other models recommended, but came up short (presumably I live in a machine void, which is odd since there are so many creative people here) and time is running out to finish my project. I think I'm just afraid to make the wrong choice. If anything happens with whichever machine I choose, I'm likely going to have to learn to repair it myself, so good documentation and parts availability would be helpful. And you can bet I'll come back here for advice on that. Thanks to everyone for your help!

-

Learning to do Portraits of People

RidgebackCustoms replied to RidgebackCustoms's topic in Figure Carving

Finished another one. Used a sub-standard piece of leather because it's what I had. There are a couple of fat wrinkles running horizontal through the center of the portrait. I don't think I nailed the likeness, but this is why we practice.- 6 replies

-

- portrait carving

- figure carving

-

(and 1 more)

Tagged with:

-

I've been happy with the chrome tanned billet bends from Naudin and Booth. https://boothandco.com/products/booth-saddle-strap-leather-rawhide-cow-billet The leather is stiff with little stretch. I believe it is tanned by Thomas Ware and Sons in Bristol. Perhaps it is available from UK suppliers? It seems that dressage saddles have a wide range of billet lengths and hole patterns that I like to match. My personal record is 33" billets on a Hermes saddle.

-

I just got a hide in from Wicked & Craig Natural Skirting 8 to 10oz. I made these similar to my gun belts a little thinner. One piece is 8 to 10 oz and I skived down one about 5oz. They are a little under a 1/4". The old Landis 16 is sewing really nice. Thanks'

-

Hello from near Nairobi, Kenya – New Member Intro

PastorBob replied to Origibelts's topic in Member Gallery

Welcome from SW Missouri USA. That's pretty cool. -

Rings Blue Guns available $7.00 each + usps shipping

PastorBob replied to Rick Jorgenson's topic in Miscellaneous/Other

Let me know what you find out on the Judge blue guns. May be interested. -

Those are really nice! I have never tried one of those slings. You may have inspired me to take a crack at one. Thanks.

-

For me the type of strap cutter I use depends on the thickness and width of the strap. I use an inexpensive wooden strap cutter for thin leather (<7 oz) and narrow straps (3/8"-1"). The wooden strap cutter is also handy for cutting straps from small pieces of leather. Abbey England sells one that is as good as any I've purchased in the USA. I do sharpen and strop the blade, holding it with a surgical needle holder (heavy duty hemostat). For 6-12 oz straps that are 1/2"- 1" wide I use a draw gauge. @bruce johnson has some nice draw gauges that are ready to use, and a tutorial on his website about how to hold the draw gauge. For heavy and wide straps (> 3/4") I use a plough gauge that I bought from Vergez Blanchard. I did spend some time reworking the angle of the knife blade (~15 deg) and I put a small bevel on the back side of the knife to keep it from pinching the strap excessively against the gauge. It is my go-to tool for cutting lots of straps from a side of 9-10 oz leather.

- Today

-

Tips/advice for 1st craft market tent?

Handstitched replied to ThisIsMyFirstRodeo's topic in Marketing and Advertising

There's a heap of great advice here. A few more bits to add to that list: good music:, my most recent market at the weekend, the muso was good, but he needed to expand his ' repertoire ' , it was a bit repetitive. The type of music being played can make a difference at a market, the overall atmosphere, the way people browse and buy, and so on. Crap or too loud music can drive them away. The music at one market I went to made it sound like a funeral. At another, the 'singer' couldn't sing, the only thing missing was a howling dog and the vendors had their hands over their ears 👂 🙉 Food stalls near by : Depending on the food, ( aromas) can either invite people to a market or drive them away. Location Location location 🎶 I have some ' goth boots ' with spikes all over them ( they are on here somewhere), and wow , they sure attract people IN to my stall. They ask questions, take photos etc. I then, talk leather, show them pics of everything I have made in my folders, my machines, a few ' how to ' pics and so on, keep them interested, i at least sell one or two items😀 HS -

As a note the higher the number at the end means the more recent the machine was made with the Consew 206rb-5 being the most recent. Base on my own experience of owning a couple of Consews with the last one being a Consew 206RB-5 I can not recommend them. From your list it appears you have decided on a flatbed so the next thing is decide on a budget otherwise you are going to drive yourself nuts. Is this machine going to be your main machine and your first machine? kgg

-

You didn't mention if it was a motorized strap cutter or a mechanical one that you are looking for. ????? kgg

-

Hi all,I have owned a strap cutter for about 20 years with good service but has now sadly given up on life.i recently bought a cheap one which unfortunately proved to be false economy.i wonder if anyone can recommend a reasonable model in the UK please?thanking you in anticipation, mark

-

I found a couple machines on marketplace that weren't mentioned in this thread, but seem like they'll work. Thoughts on these? Singer 211g-155 for $200, looks to be on good shape in the pictures Singer 211g165 for $700 Cutline C225 for $350 Singer 153K103 cylinder bed for $1000 And then these various Consew 206RB's: Consew 206RB-1 for $1250 Consew 206RB-2 for $750 Consew 206RB-5 for $1195 Sorry for the continuous questions!

-

Help! Singer 111w155 stripped / stuck screw

friquant replied to matthew123's topic in Leather Sewing Machines

The easy way to get even lift between the inner vs outer toe: Release the foot lifter Turn the handwheel forward until the needle point comes down and meets the plane of the throat plate Loosen the screw I pointed to in the photo. (If either presser was airborn, it will now drop to the throat plate) Tighten the screw -

Help! Singer 111w155 stripped / stuck screw

matthew123 replied to matthew123's topic in Leather Sewing Machines

You guys rock! Thank you so much for all the amazing advice. Friquant, thanks for the heads up about adjusting that clamp screw in back. I did try that one first, but I ended up with the machine binding before I could get enough lift out of it, so I figured the next step was the stripped screw "C" in question for the eccentric. Great point about extending the filing to the edges of the screw...I think that should help a lot. I will try a flat sided carbide burr! I posted a pic of the screwdriver in the screw groove. As you can see, it's not quite tall enough and definitely not thick enough. I will either search for one or work on filing down a piece of metal to serve as the new driver. Dikman, I love the idea of drilling out the center of the screw with a small bit but still keeping the flathead groove on and use that to loosen it. I never thought of "coring" out the inside of the screw to relieve the pressure like that, but it totally makes sense and sounds like it will work! I think laying the machine down on its front is a great idea and will be very helpful. Alzilla and Friquant, do you think the impact driver is too much force against the shaft that this all rests on? I have one of those things but hesitated to use it. Thank you all again!! -

True. They show up pretty well with the macro camera lens, or through a jeweler's loupe. A tiny bit of progress..

-

Help! Singer 111w155 stripped / stuck screw

AlZilla replied to matthew123's topic in Leather Sewing Machines

I wouldn't heat those parts. I don't know what that would do to the hardness. But I would lay it down and build on what looks like a pretty good dimple almost dead center. I'd get a punch and make that bigger and deeper. Then I'd start with an 1/8" drill bit and work up. You'll need to determine how long that screw is so you don't drill through it. -

Help! Singer 111w155 stripped / stuck screw

AlZilla replied to matthew123's topic in Leather Sewing Machines

Mine is a more rationally sized, smaller one, but yes. They work especially well on these screws we deal with that haven't moved in a hundred years. - Yesterday

-

I think so, mouths can be tricky too sometimes

-

Help! Singer 111w155 stripped / stuck screw

dikman replied to matthew123's topic in Leather Sewing Machines

A straight-sided carbide burr to try and get a deep slot with a flat bottom and parallel sides. Try heating the screw again and then hit it with a freezing spray. Drill through the screw, sometimes this can relieve pressure on the threads and allow it to move. Doing this first and then heating should allow better heat penetration to the threads and then a screw remover tool. Just a few ideas, of course the screw will need to be replaced and if you can't get a replacement then re-tap for an allen-head grubscrew. -

Help! Singer 111w155 stripped / stuck screw

friquant replied to matthew123's topic in Leather Sewing Machines

When dremeling the slot, I would go all the way to the edge of the screw head. If you overrun and go into the eccentric a little bit that's okay too. Make the sides of the slot as vertical as possible. Do you have a flat-ended burr? You may be able to scrape the sides into better shape (with a flatter bottom) using a smaller flat screwdriver or the pointy end of a file. Can you post a photo of the screwdriver bit that you are using, next to the screw you are trying to remove? Ideally the bit would be the full width of the screw head, and the full thickness of the screw slot minus just enough to get in there. I would lay the machine on its front (make sure it's supported well, not resting on any delicate parts) so you can press down from above using your body weight. I've started using a drop of diesel instead of PB blaster. When removing stuck screws, I go one way then the other. Add more heat. We're talking kitchen-sized torch, not cigar lighter. And consider the manual impact driver. -

That's true. And the eyes are the most difficult to do, especially with any expression, is it not?

-

Check out the link below to make your own Sheridan Style Custom Patterns! $49.95 https://circleccustomleather.net/quick-and-ez-pattern-system

-

Help! Singer 111w155 stripped / stuck screw

friquant replied to matthew123's topic in Leather Sewing Machines

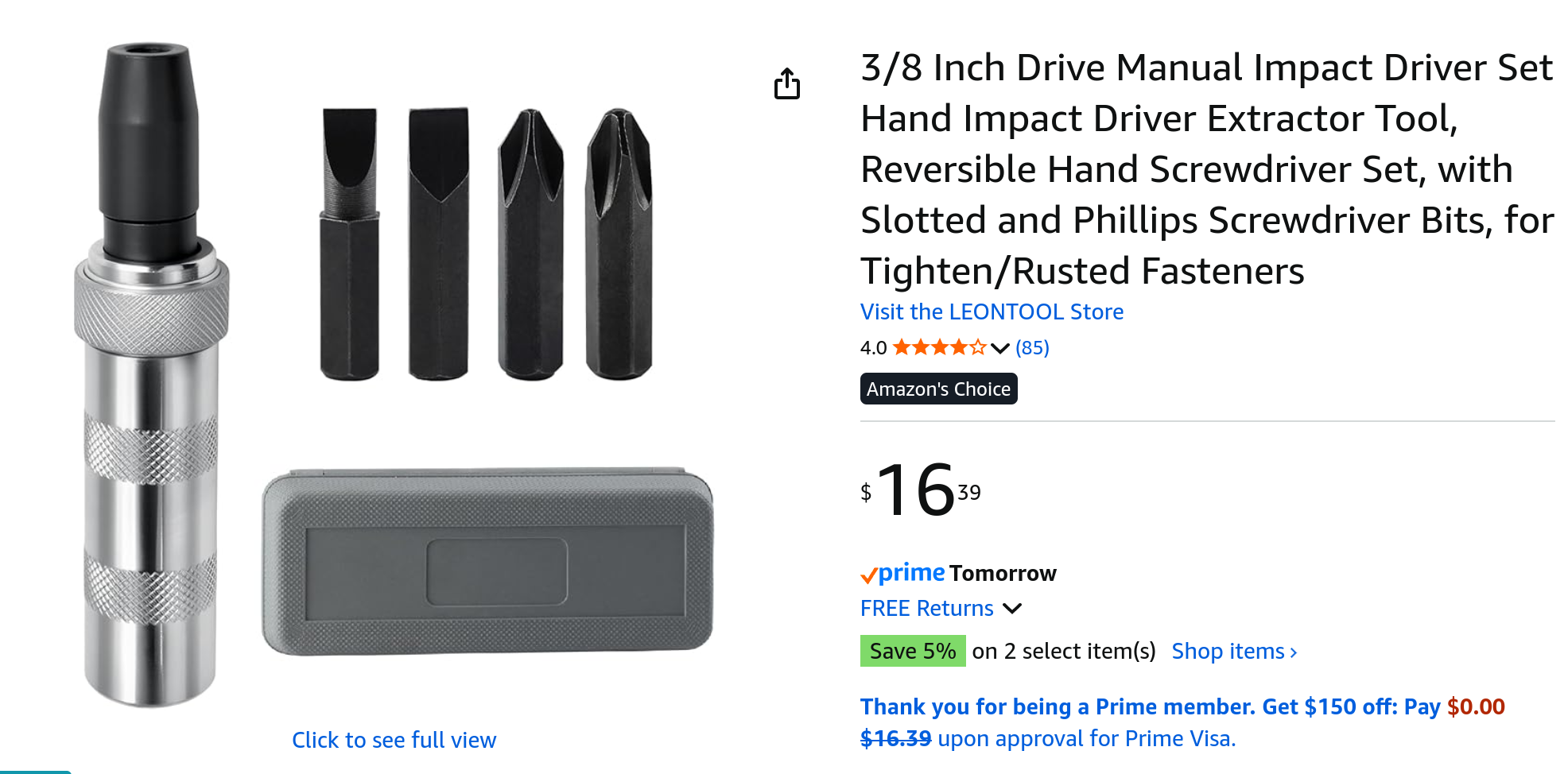

As for removing the screw with the mangled head, has anybody tried a manual impact driver on their sewing machines? https://www.amazon.com/LEONTOOL-Extractor-Reversible-Screwdriver-Fasteners/dp/B0CTXD91YW

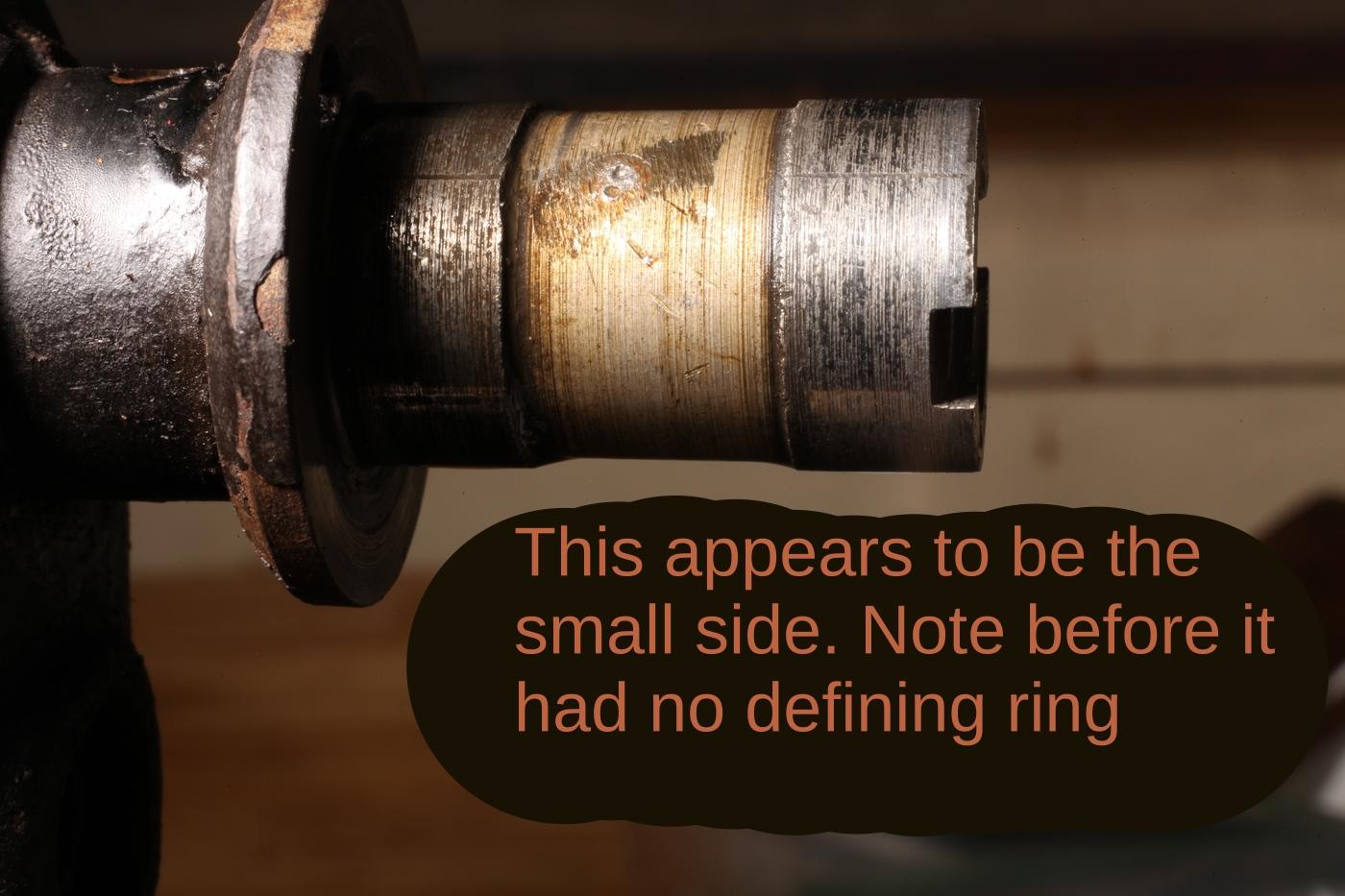

.thumb.jpg.44df3c23d48a352dbe4966e2afca38cc.thumb.jpg.3eb6eaa33af224aa1c4f82d0ab00d322.jpg)

.jpg.bf9bf0db77a102498b1ad5632295ab7e.jpg)