All Activity

- Past hour

-

Right then, Hand-sewing in zips. This really does get under my skin. I do them, but it brings me no pleasure. The problem surrounds the gluing in. I have tried contact glue as well as PVA. Neither of these adhere to the zip material. Ok, a wee bit. But I found the zip moves, which creates an non-straight zip. I have been using a double sided tape for the past couple of years. This does work well keeping the zip in place; however, the adhesive is all over my awl and needles. Urgh! Now I have to wipe the residue from the tape off my awl and needles about every five holes. The residue and tape also do not allow the awl or needles to move smoothly through the leather. There has to be a better method. Some type of adhesive that will keep the bleedin zip still and won't smear adhesive all over the tools. Ideas? Cheers!

- Today

-

I use 100% of Fiebings products for dying, staining and finishing leather, I don't use any other - although it's more expensive than others that I've tried, but it's the only one I'm satisfied with so far. This is not a commercial for Fiebing's, I'm just explaining myself. I use Fiebing's Pro Dye to dye the leatherwork (then applying acrylic resolene with airbrush. I dip-dye belts and for everything else I use airbrush. But after dying (mostly after dip-dying) belts are very stiff - so I would consider using Fiebing's Neatsfoot Oil and then Resolene - would it work? Would it even be reasonable to use Resolene after Neatsfoot oil? And another question: After tooling leather and dying it with Pro Dye - is okay to use Antique Finish? And after that, I would use Neatsfoot oil and then Resolene for the finish - would it work or am I using too much preparations for leather? Thanks for any help!

-

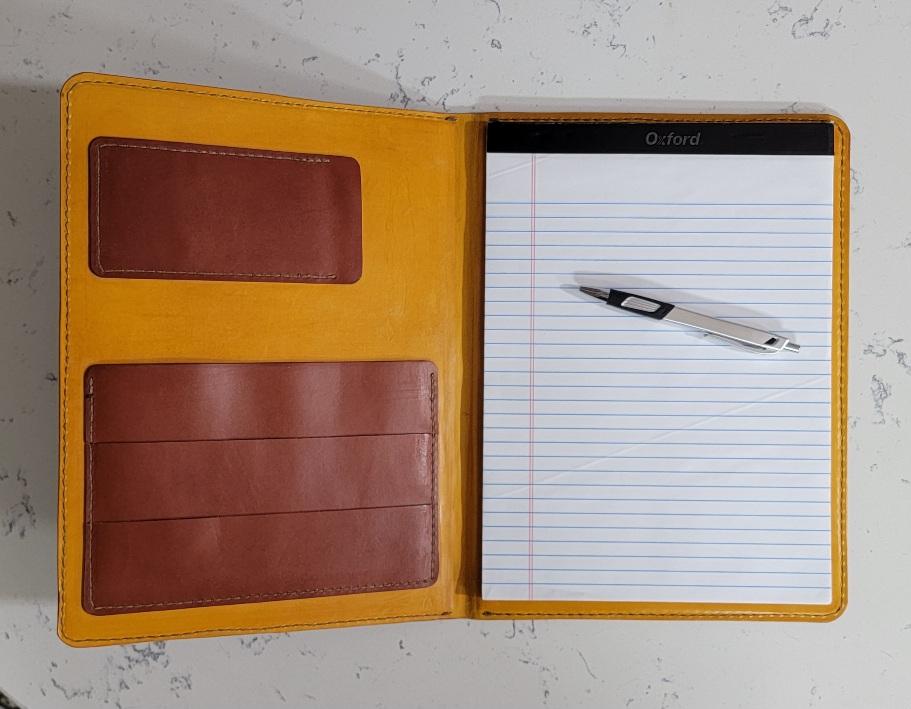

Very nice. I've not seen using binder's board as a core on the insert. Did you tool around the edge before sewing?

-

My response was a bit short I guess. Well, we have not seen the machines but I would assume that the 211´s are old factory machines that probably have been stored for maybe decades (we do not know, do you?). You for sure will need a new motor (Servo motor + maybe a speed reducer for better speed control) and depending on the wear you may need a new hook and maybe a new timing belt. Replacing a timing belt on a 211 is no fun work IMO due to the shaft bearing on the hand wheels end. So if you are able to replace the parts by your self. And since we have not seen the machine it may need some more bits too. You may need $100+ for the motor + maybe $150 for the speed reducer (if needed) and maybe $50+ for additional parts (all guessing) and your time for repair and adjustment work. So a lot of guessing here. Pictures of the actual machine(s) may help. The machine it self could probably sew what you what (as AlZilla already said) but it is meant for flat work and not really for sewing over thicknesses. There are for sure better machines for leather work. Triple feed machines are a lot more versatile than needle + drop feed machines, especially when it comes to accessories like presser feet and so forth. My 2 cents.

-

Introduction Are you struggling with hot foil stamping problems like patchy impressions, foil peeling, or burnt leather? You're not alone – over 65% of leathercrafters face leather foil stamping errors in their first year. This guide systematically diagnoses foil stamping failures and provides actionable fixes, whether you're using manual brass molds or hot foil stamping machines. Leather Foil Stamping Problems & Solutions Cheat Sheet Problem Possible Causes Tested Solutions Pro Tips Blurry/Faded Impression (Leather foil not clear) • Low temperature • Insufficient pressure • Dirty mold/leather • Increase temp by 5°C increments • Add silicone cushion under leather • Clean with isopropyl alcohol Use harder brass molds (≥3mm) for sharp details Foil Peeling Off (Hot foil not sticking) • Wrong foil type • Dwell time too short • Moisture on surface • Match foil to leather (see table below) • Press for 3+ seconds • Pre-heat leather at 60°C for 10min Peel test: Wait until foil cools to room temp Burnt Marks/Holes (Foil stamping overheat) • Excessive temperature • Pressure too high • Thin leather • Reduce temp to 120-150°C • Decrease pressure to ≤3Bar • Use thermal barrier paper For burns: Sand + leather dye blend Misaligned Stamping (Foil stamping misalignment) • Manual positioning error • Loose mold fixture • Install laser guide ($25-50) • Use magnetic positioning jigs • Overstamp with metallic paste Design with 5% bleed area to hide minor offsets Partial Transfer (Uneven foil adhesion) • Uneven surface • Worn silicone pad • Foil tension issues • Level leather with glass plate • Replace silicone pad every 500 impressions • Adjust foil roll tension Quick fix: Use spot-heating pen for missed areas Foil & Leather Compatibility Guide Leather Type Ideal Temp Range Vegetable-Tanned 140-160°C (285-320°F) Chrome-Tanned 130-150°C (265-300°F) Suede/Nubuck 110-130°C (230-265°F) Oily/Waxed Leather 150-170°C (300-340°F) Synthetic Leather 120-140°C (250-285°F) Exotic Leathers 125-145°C (255-295°F) Common Foil Stamping Failures and Solutions 1. Blurry or Faded Foil Impression Problem: The stamped text or design appears blurry or lacks sharp edges. Possible Causes: Temperature too low to properly transfer foil Dirty or oily stamping die surface Insufficient stamping time Uneven or unprepared leather surface How to Fix: Adjust the temperature to the recommended range (110–130°C) and test accordingly Clean the die surface with alcohol or a soft cloth before stamping Increase stamping time to 1–2 seconds depending on leather type Use a flat backing plate or prepare the leather surface for even contact 2. Foil Peeling or Not Sticking Properly Problem: The foil flakes off easily after stamping. Possible Causes: Using foil not suitable for leather materials Insufficient temperature or pressure settings Stamping time too short for proper adhesion How to Fix: Switch to leather-specific foil with proper adhesive coating Increase pressure settings as per machine specifications Extend stamping time to 2–3 seconds for better adhesion 3. Burnt Edges or Leather Damage Problem: The edges of the stamped design show burn marks or the leather surface is scorched or even punctured. Possible Causes: Temperature set too high Sharp edges on the stamping die concentrate heat Using thin or soft leather without adjusting settings How to Fix: Lower temperature settings to between 100–120°C Smooth and round off sharp die edges to distribute heat evenly Shorten stamping time and reduce pressure for delicate materials 4. Misaligned or Double Impressions Problem: The stamped pattern is shifted, duplicated, or misaligned. Possible Causes: Lack of proper positioning tools during manual operation Leather or work surface not fixed securely Loose stamping die or machine vibration How to Fix: Use positioning aids like clamps or laser guides Employ jigs or templates for consistent placement Ensure die and worktable are securely fastened; control machine operation carefully 5. Excessive Indentation or Leather Damage Problem: The stamping leaves deep impressions or damages the leather surface. Possible Causes: Excessive pressure applied Using dies with deep engravings unsuitable for the leather thickness No cushioning layer between die and leather How to Fix: Reduce pressure gradually and test for optimal depth Use shallower engraving dies for softer leather Add silicone or leather padding beneath the die as a buffer How to Prevent Foil Stamping Failures Always perform test stamping before production to find the optimal temperature, pressure, and time for your leather type. Regularly clean dies and stamping plates to ensure even heat transfer. Choose foil specifically designed for leather materials. Store leather in a dry, stable environment to maintain surface quality and adhesion. Frequently Asked Questions (FAQ) Q1: Why does foil stamping effect vary between foil batches? A: Foils have different adhesive bases depending on material and manufacturer. It’s best to test and use foils from the same batch and brand for consistency. Q2: What if my machine’s pressure setting is inaccurate? A: Use pressure test paper to calibrate or rely on trial impressions to find the right pressure. Consult your machine’s manual or supplier for recommended settings. Q3: How long do stamping dies last? A: Brass dies can last a long time if properly maintained. Replace dies when details wear down or affect the stamping clarity. Conclusion Foil stamping failures are common but manageable with proper analysis and adjustments. Using high-quality equipment and materials combined with standardized procedures will greatly improve your product’s finish and consistency. If you encounter challenges you cannot resolve, feel free to contact our technical support team for personalized assistance. Welcome to Share Your Stamping Details! More Guides & Tutorials Which Maxita Hot-Foil Machine Actually Fits Your Bench?,2025, Jinglin. The Ultimate Guide to Maxita Hot Foil Stamping: Master Your EC-27 & EC-17, 2025, Jinglin. Maxita EC-17 vs. EC-27: Which Leathercraft Machine Is Right for You?, 2025, Jinglin. Maxita Hot Foil Stamping Machines Comparison: EC-17 vs. EC-27 and Holder Types, 2025, Jinglin. 3-Line Foil Stamping Guide: Maxita EC-27 & EC-17 Tutorial, 2025, Jinglin. Detailed Causes & Solutions for Gold Stamping Failure: Guide for Leather Hot Stamping Users, 2025, Jinglin. Hot Foil Stamping Machine FAQ: Common Issues and Practical Solutions, 2025, Jinglin. Maxita Hot Stamping Machine: Leather Craft Embossing Guide, 2024, Jinglin.

-

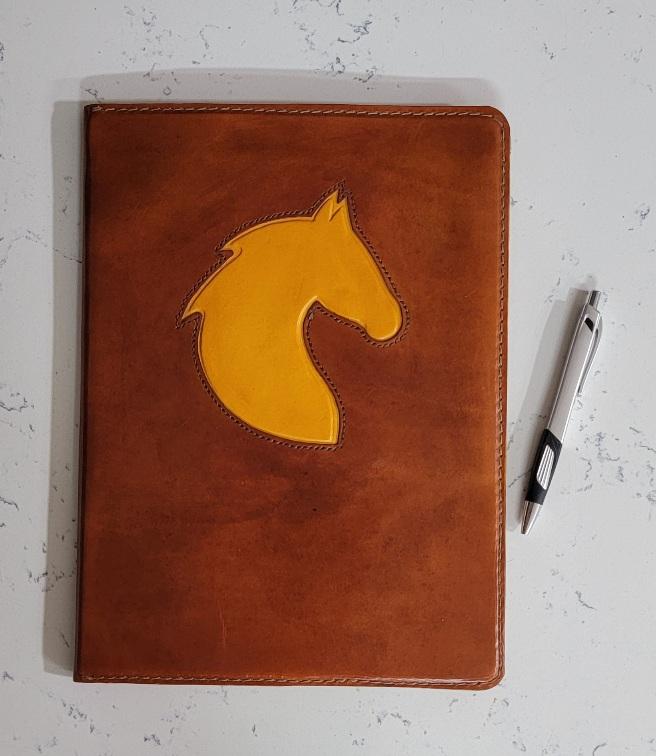

Looks real nice. Great work. Simple but elegant.

-

-

Based on what Constabulary says, it's like my 111W151 and I agree with his assessment. I like my 151 and it might work for what you want (I've done small leather goods w/o trouble). The lack of reverse is not a big deal until you get to small leather goods. The backstitch with larger thread becomes important from a visual perspective. There are a couple ways to do the back stitch but they take a little learning curve and practice and you'll still fluff it once in a while. For not much more money you should be able to find something with reverse and *know* that it actually works. Besisde, 300 bucks for a run of the mill machine that might work? Even if you know what you're looking at, it's still too much.

-

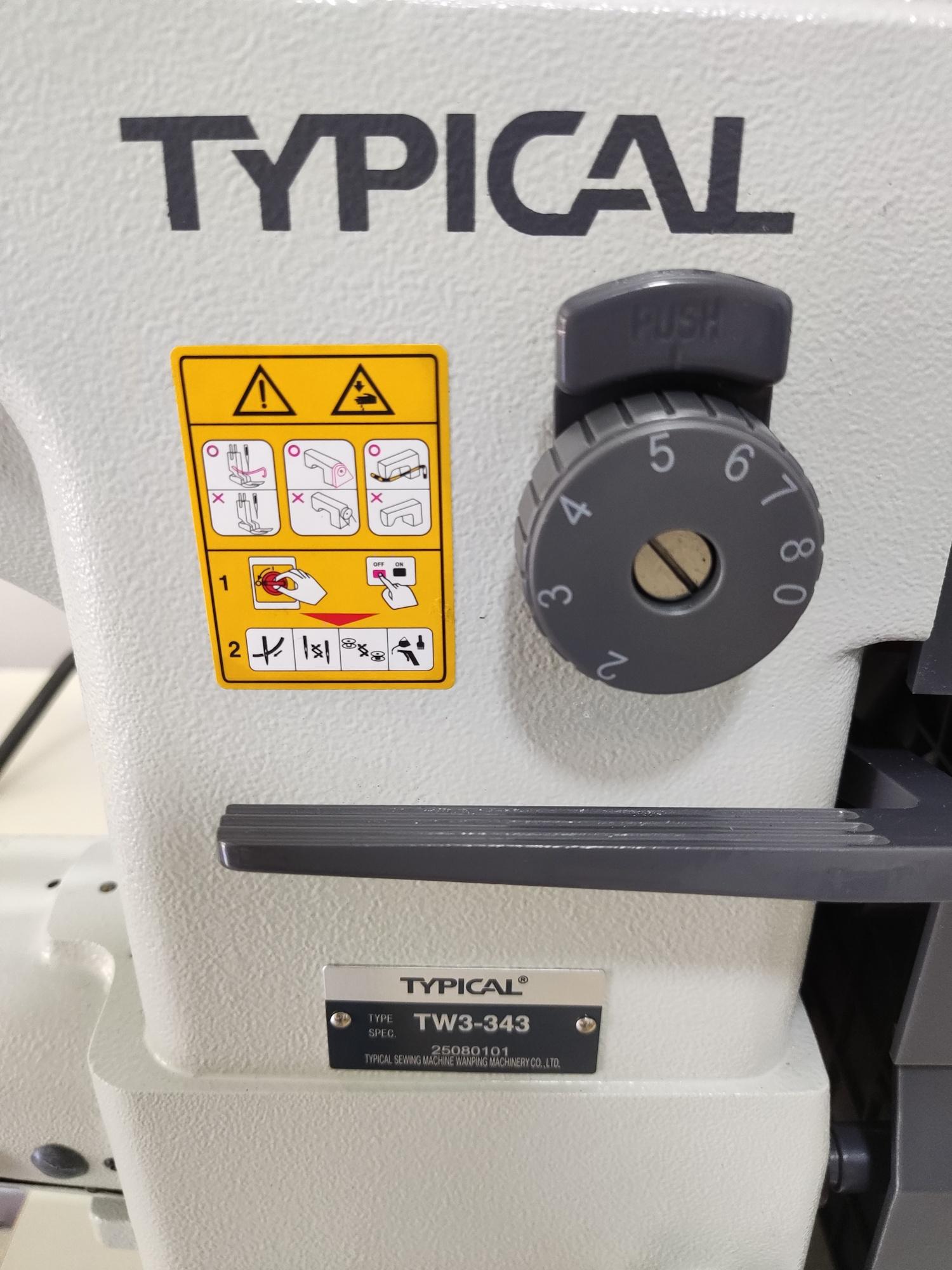

will juki 1341 accessories fit this Typical tw3-343?

friquant replied to TakashiOkada's topic in Leather Sewing Machines

You can stand behind the machine and press down on the lever with your hand to check how smooth it moves without the pedal being in the way. You may need to grease the part that slides up and down near the presser foot. Cool! The bobbins on my jianglong 341 are 20mm. -

its a needle feed + drop feed machine w/o reverse. you find some main information in the service manual (1st google hit on my end) I would not buy it. Singer 211W151.pdf

- Yesterday

-

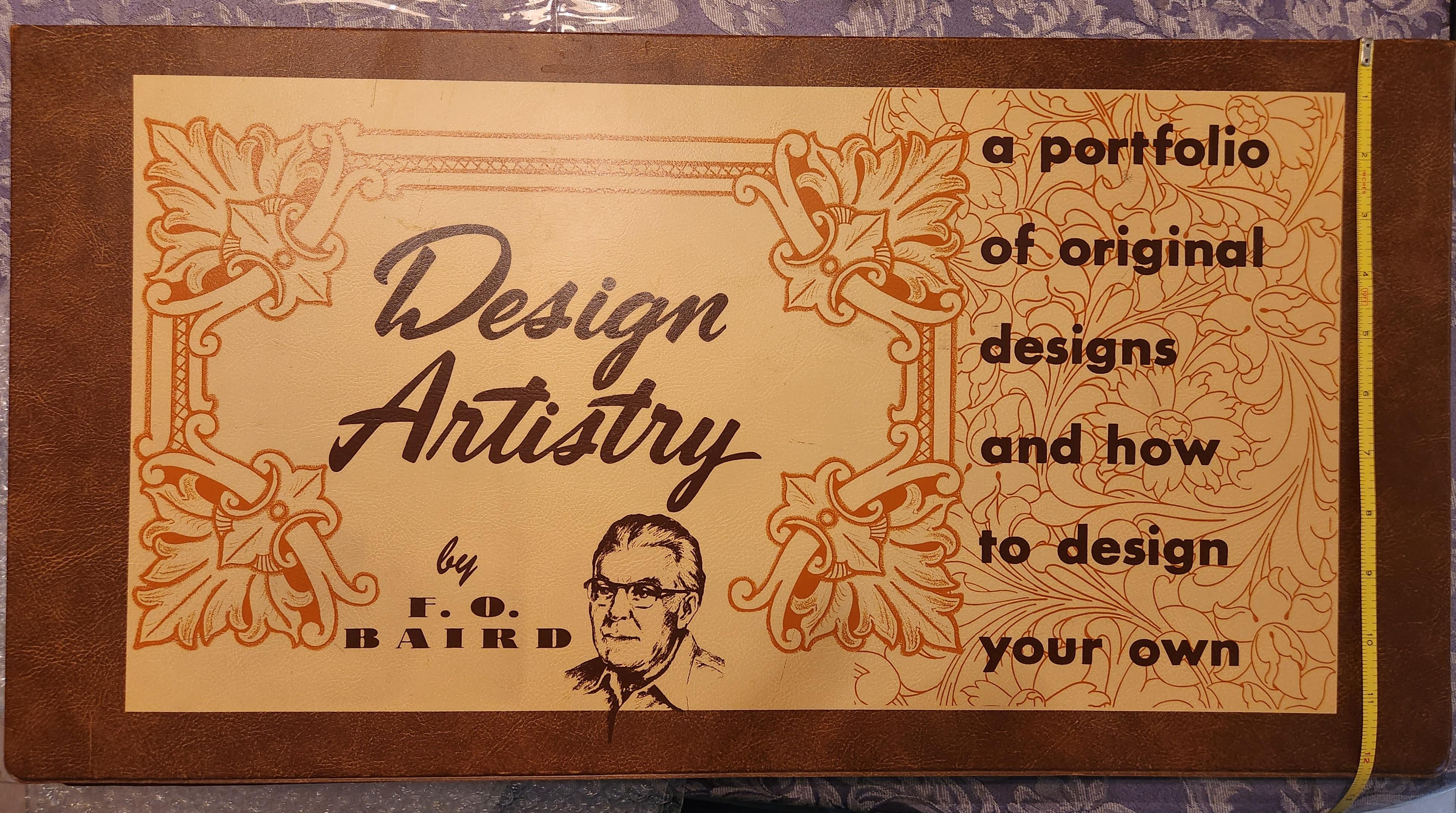

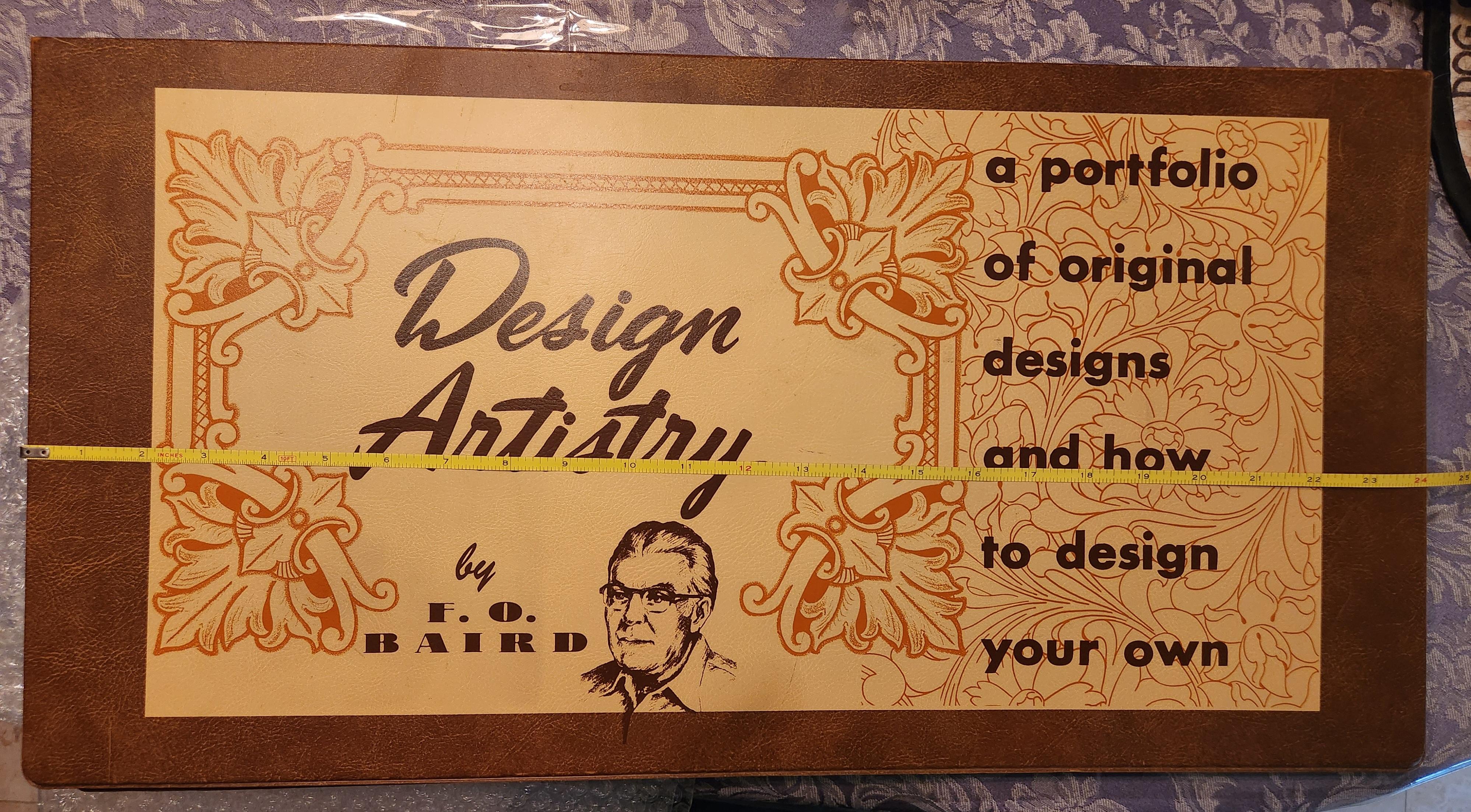

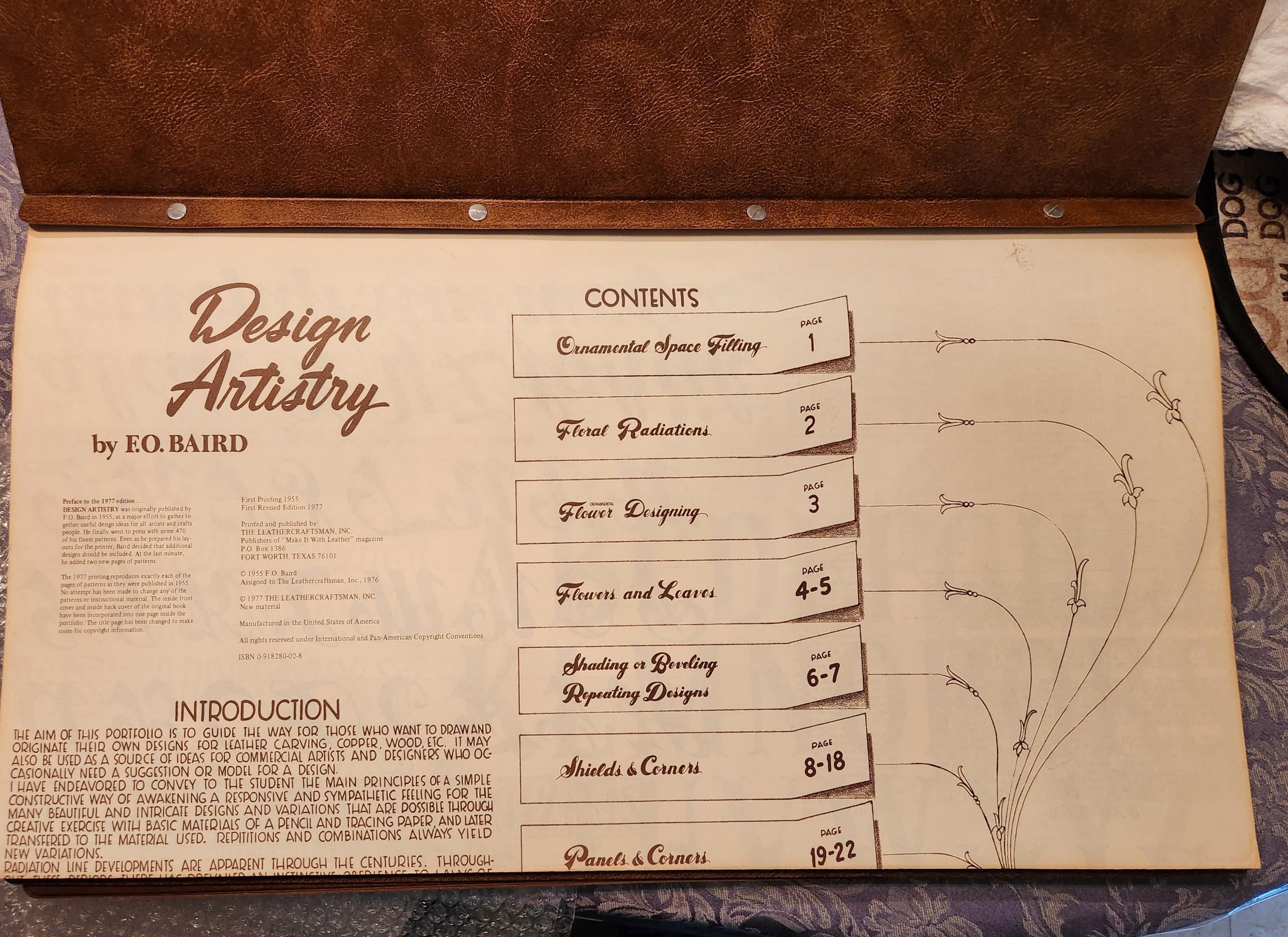

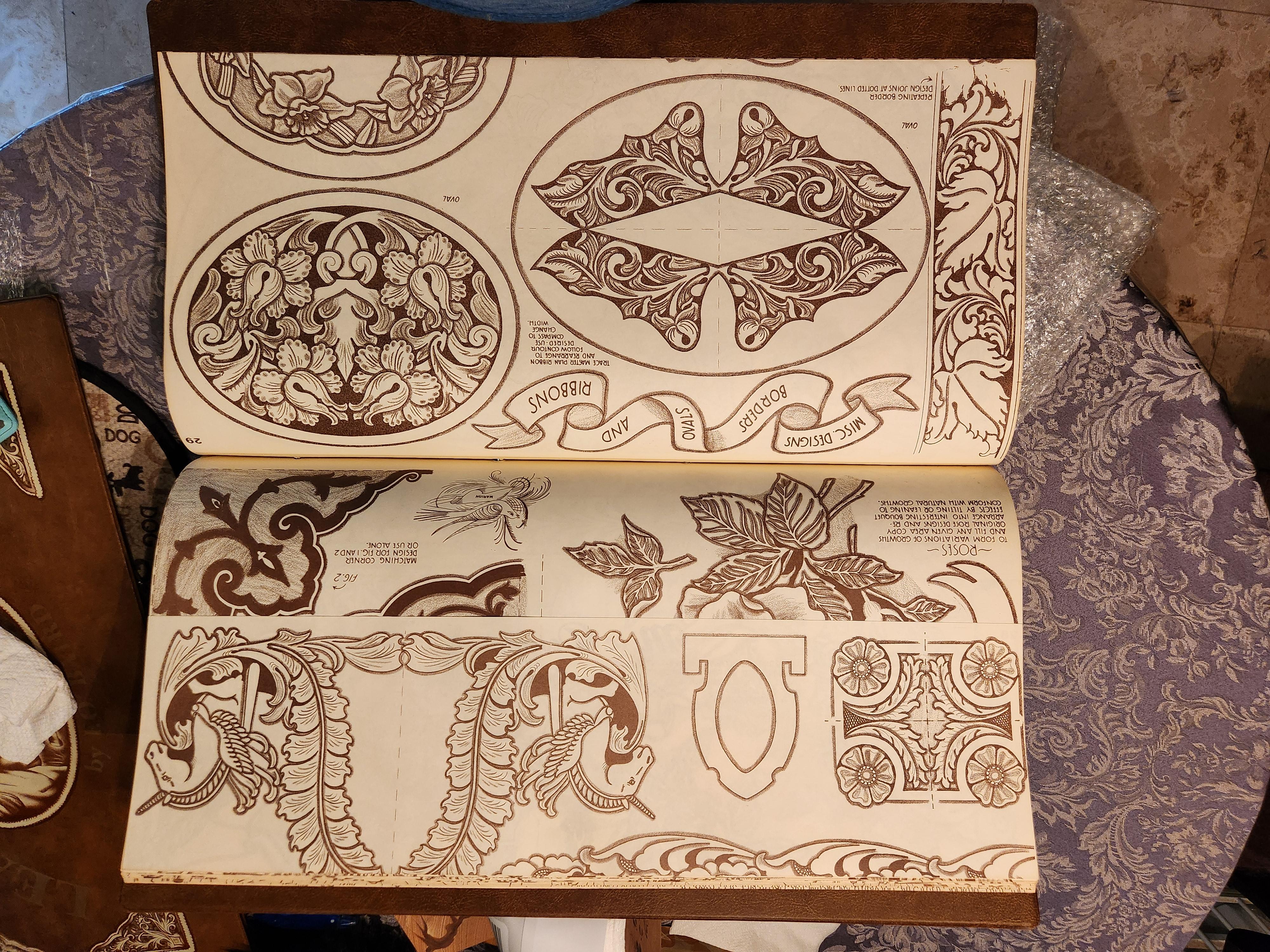

I have a very good copy of the large Design Artistry book by F.O. Baird. All pages are in excellent condition. There are a couple of hardly noticeable scratches on the front. The book has pages that can be removed to be used as patterns. Will ship to US only. $300 plus shipping to be calculated at sale.

-

C.KRAMPUS joined the community

-

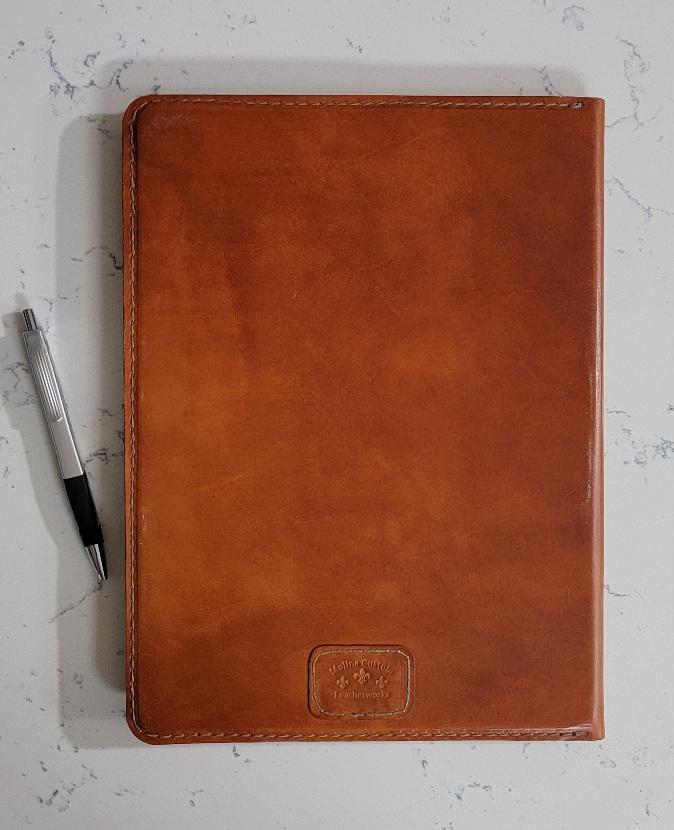

For my sister's birthday I put together a notepad portfolio. She's a counselor for the VA and also involved in horse therapy so I figured inlaying a horse profile would be fitting. I used 3oz vegtan with 1.8mm binder's boards as a core, the pockets are 3oz English bridle, the inset is also 3oz vegtan and also has a binder's board core. If anyone knows of Veteran or 1st Responder that can use counseling they can reach out to her https://www.adonairanchcounseling.org/

-

I'm considering getting a used 211w151, but I'm having difficultly finding much information about this exact model. Owner has 10 available, doesn't know if they work, and is asking 300$ each. I make kink gear, collars, cuffs, harnesses, etc, plus the occasional small items like wallets. I am using chrome tan leather in the 2-5oz range, max 4 layers, normal 1-2 layers. Unfortunately not a lot of options in my area (Northern VT), but would this machine even be capable of what I need it to do or would I be better off biding my time and hoping something better comes up? (Or just try and save up for a new compound/triple feed walking foot machine)

-

will juki 1341 accessories fit this Typical tw3-343?

TakashiOkada replied to TakashiOkada's topic in Leather Sewing Machines

Oops you're right. This is the link. https://www.etsy.com/listing/1628261312/folded-edge-cylinder-arm-table-read-the It's for juki 341/1341 and clones but this is not exactly a Clone so I'll have to ask the manufacturer. Thanks Thank you @friquant . Apparently the problem is not the chain rubbing, I held onto the chain to prevent it from rubbing and there was no difference. Something in the mechanism feels clunky, I'm going to try the pedal and presser foot tension suggestions. Diameter of the bobbin is 25mm. -

I don't have a source for patent leather, unfortunately, sorry about

-

will juki 1341 accessories fit this Typical tw3-343?

friquant replied to TakashiOkada's topic in Leather Sewing Machines

Looks very sturdy. What is the diameter of the bobbins? Your chain is rubbing on the table. If willing, you can drill a hole closer to the machine that will be a straighter shot to the pedal. Also, if the chain still rubs, replace it with a cable, and make a slide for the cable out of some vinyl and grease the vinyl. Also at the foot pedal end, the chain is installed in the default (but unfortunate) position of out at the tip of the pedal. You probably don't need that much lift. Mine I drilled a new hole a couple inches down from the tip and it gives me enough travel will less force. Another help is to reduce your presser foot pressure. For very low pressure, I remove the presser foot spring, but on very thin fabrics I need to keep the spring installed. -

will juki 1341 accessories fit this Typical tw3-343?

Wizcrafts replied to TakashiOkada's topic in Leather Sewing Machines

This is a question that you should ask the manufacturer, if you can find their website, and if they have a contact form. If you can't find the manufacturer, contact the company that sold you the machine. Maybe they know how to reach the builder. You attempted to link to a flat bed attachment, but neglected to include the URL. Please try again. -

Neston joined the community

-

its a western purse made to look like a saddle. Very popular back in the day. Tandy sold a pattern kit at one time.

-

switchi10 joined the community

-

When you say "saddle purse" what exactly are you looking for? A purse or a saddle bag? a purse that looks like a saddle or a purse made in the style of saddle bags? If you have a picture of what you want people can help you better. Doing a web search of "the vintage saddle purse pattern" brings a lot of different results.

-

Use the search function; there are several threads that may help you.

-

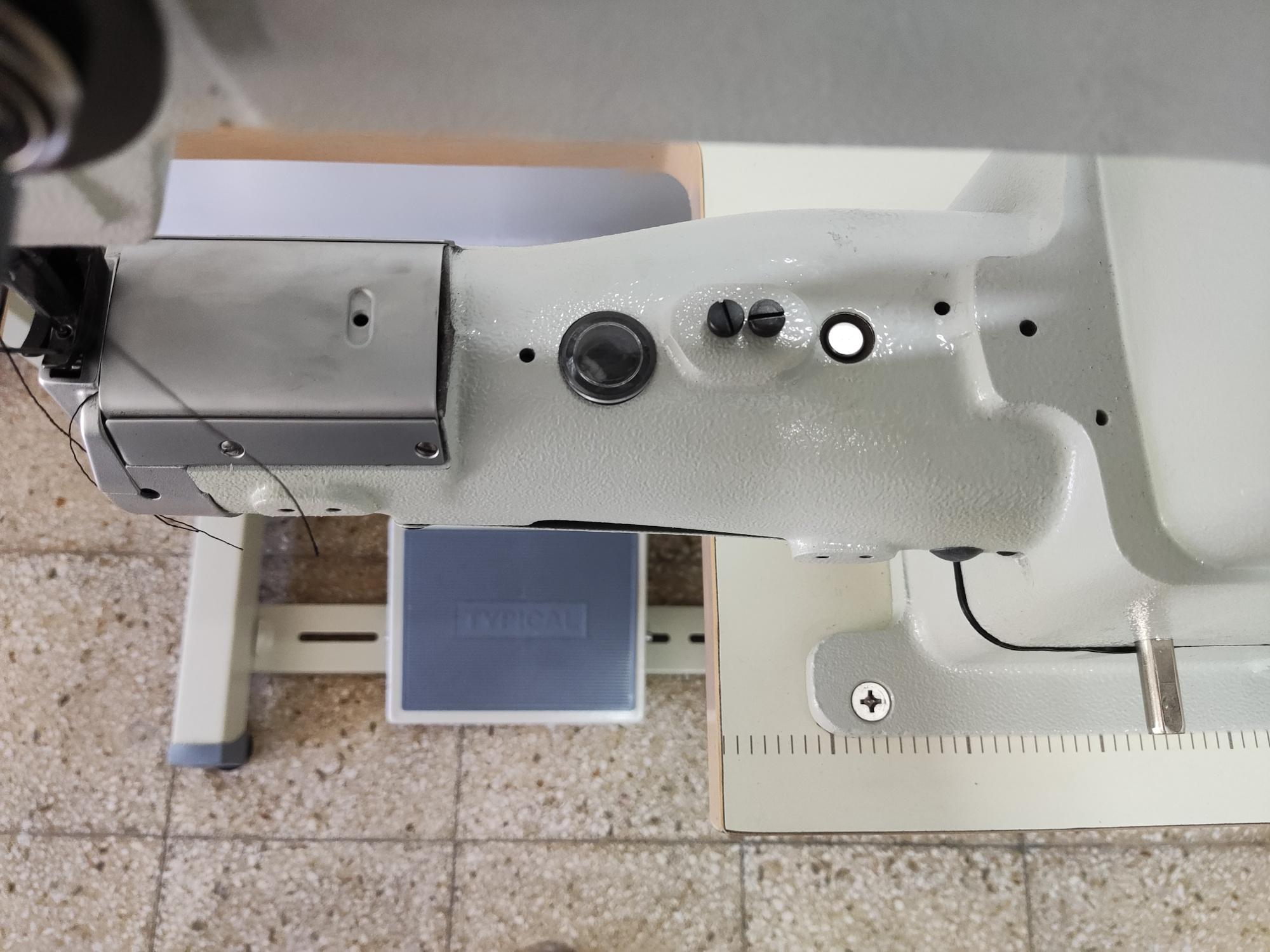

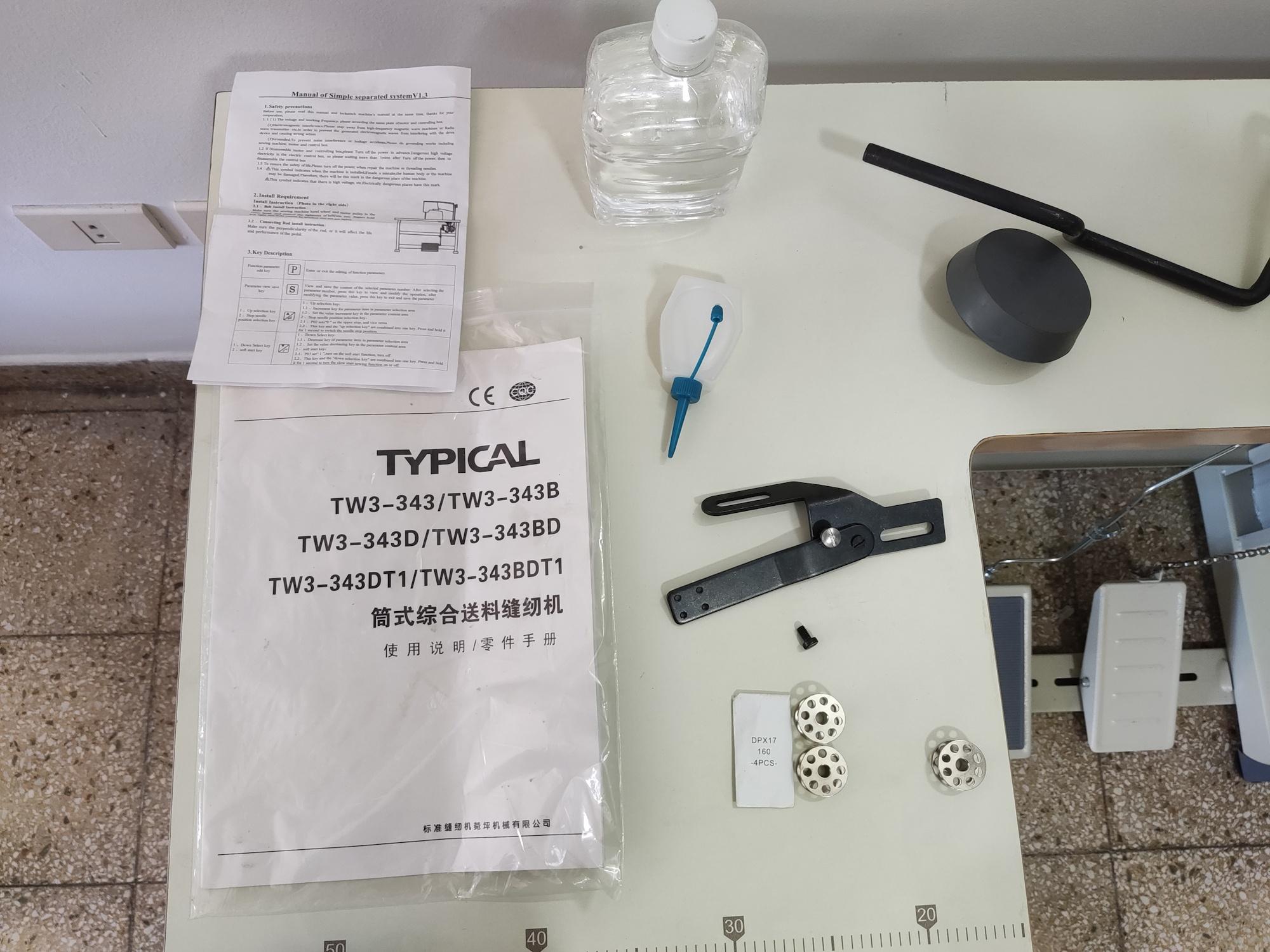

Hello. my machine just arrived! I promised I'd post some pics so here they are. thank you so much for your advice! it ended up costing 2,016 US$ Sadly the smaller table you guys recommended to me has to be imported and it's gonna be prohibitively expensive so I'll pass on that one. This is a typical TW3-343. I was planning on buying a typical 341 which is a direct clone of the Juki 341 but the seller told me there's a new version, that's why I went with this. It resembles a Juki 1341 but the bobbin winder is in a different place and it has full self lubrication, not only at the bottom like the 1341 AFAIK. it came with a 550w brushless servo motor. if you guys know which clone this machine is from I'd love to know. I have also want to know if this flat bed attachment will fit. the bobbins are HUGE, bigger than bobbins on my Seiko tf-5/6 and post bed. It also came with a binding attachment which I appreciate. I don't know if this is normal but the pedal that lifts the presser foot is not smooth at all and I have to press significantly harder than the motor pedal, it's uncomfortable to use with an office chair with casters, is this normal? I'm asking because I've never used anything other than a knee lift so I don't know if this is something I have to get used to or if it's something that needs to be addressed. I have a small speed reducer I bought from aliexpress couple years ago that I could Install but I'm hesitating since I've read some threads saying it doesn't work well with needle positioners.

-

Hello all. I am trying to locate the vintage saddle purse pattern. I have looked everywhere.. I am wondering if anyone in this group has the pattern?.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)