All Activity

- Past hour

- Today

-

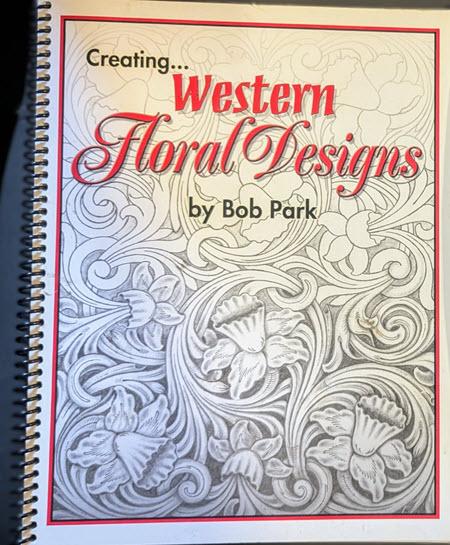

I have a spiralbound copy of Bob's book. Practically new, never did end up very good at carving. Sorry not digital though! I am actually on here because I am selling a bunch of my books and stuff. Hands no longer work the way they did, so need to lighten the load a bit. I haven't even put anything up yet, if you guys are interested, let me know Thanks, Only

-

Thanks for the feedback guys. Yes, it is a small holster, and proportion does make a difference, And yes, some people would actually really like that look. I don't hate it but I think for my next project, I will try 0.8mm or 0.85, with the 5spi irons I tried Ritza one one project in the past and seem to remember that it is essentially a hollow tube that lays very flat and that did not appeal to me. I prefer the twisted cord "rope" look. Dave... beautiful work... My next project is a holster for my Kimber K6s DASA 3", so I can relate to snubbies.

- Yesterday

-

Ah, you guys are funny. The roof isn't that high, plus the fact that under certain weather conditions I get condensation on parts of the roof so moisture could drip on anything stored there. kgg, it's a modified 650 press, I managed to get one of the last ones here in Oz before the 750 arrived. I had a Lee Loadmaster before that but I got tired of the primer problems it had so swapped to the Dillon, it's a great press. What on earth do you do that requires 3 1050's?

-

Nice old iron. Others have given good advice. My only comment is finding the boat type bobbins can at times be difficult so don't loose / damage the one you have in the machine. What is the going price roughly these days??? kgg

-

I recently found this same cooling design on an industrial motor. In this photo, the cover (far right) has been removed. So I asked my favorite AI about it, and I found this page: https://en.wikipedia.org/wiki/TEFC_motor

-

Leather Machine Company Cobra Class 26 like new

Trent Locke replied to Charles_Bandolero's topic in Used

Hello Charles, I would be interested in your Cobra 26. Can you post some info and pictures. I live in Huntington Beach, CA and would like to what would cost for shipping as part of my decision process. -

Anyone taken a cheap servo motor apart?

AlZilla replied to AlZilla's topic in Leather Sewing Machines

The executive summary at this point is that I believe the noise is in the bearings, but taking it apart and reassembling it quieted it down by more than half. My current theory is bearing damage and the case was torqued out of alignment by the beating it took in transit. I've taken it apart and examined it to the best of my ability and tools. I find nothing with excessive runout out or bent out of detectable shape. I took high res photos to look for cracks and found none. I've ordered bearings which arrive tomorrow. I need to get an appropriate puller as all mine are automotive type. The bearings are 15mm id, 9mm wide and 32mm od. 6002-rz is the part number and they're available for a few bucks each on Amazon. I'll upload pictures of the disassembly for the next hapless adventurer. Further updates when I get around to swapping the bearings. -

Anyone taken a cheap servo motor apart?

dwhacks replied to AlZilla's topic in Leather Sewing Machines

Have you gotten anywhere with this? I bought an "open box" motor from amazon that is noisy like you describe. More under more tension or load. -

I would use WD40 to cut through any grime, then a light wash with warm soapy water to wash off the WD40

-

Moved your post to Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners. It really has no connection to Hardware! You need to provide more information. It's sort of like asking "What colour should I paint my car?" You need to tell us what you want the conditioner for and what you expect it to do for you. What kind of leather, what is the item used for, what weather or work conditions is the item subject to? None of us here have a crystal ball to see what you actually want. Once you give us some details, someone will be able to help you.

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

looking to buy tooling for a J A Richards die bender

Northmount replied to Sam wurz's topic in Wanted

I split your post off an old thread about post bed sewing machines. Your post has nothing to do with the old post's title / subject. It is bad etiquette to post like you did and won't make you any friends here if you continue with such behaviour. I moved your post to the Wanted section in the Marketplace. -

I see a lot of wasted overhead space. I'm sure you could figure out how to hang stuff from the ceiling. I see you have what appears to be a Dillon RL-550C. Dillon makes really decent presses, you should get excellent results. I have 5 Dillon presses for my other addiction 1-RL 550c, 1-XL 750, 3- Super 1050. kgg

-

There's always UP.

-

Well, I for one love it. I have about 3 dozen domestics. The short answer is sewing machine oil and cotton swabs. The longer answer is at Quilting Board Forum, the 3rd post down. Especially the decals. They're not silvered like so many are, so be delicate and keep it away from direct sunlight. Also, don't carry it by that handle as it's not really meant for that. EDIT: My attitude is conservation, not restoration.

-

Looking for a replacement for discontinued Denver Side

TomE replied to mjpaisley's topic in All About Leather

Hide house has a 4 oz FOC (free of chrome) leather in pistachio, a slightly darker green. https://www.hidehouse.com/Leather/Aspen-Cow-Full-Grain-Semi-Aniline-Finish-AS15-P.asp As best I can tell, this is similar to a chrome tanned hide but using other minerals in place of chromium. -

That's a neat job of installing zippers. Looks very professional.

-

Hello peeps, Saturday i picked up a old Singer 128. Well from what I see it is a model year 1924 by serial number. Portable unit and the wood case is in great shape. My question for all you gurus is what to clean it with? Something that won't hurt the finish on machine. The mechanical underside is can use solved on. The black finish and all the gold is what I'm worried about. It is not bad just has years of built up material fuzz,oil and dirt. Lady said it was her grandmother's. Got a real good deal on it. No plans for leather sewing, maybe some light weight soft leather. Have always wanted one and been watching this one for awhile. Had a not going to sell price for awhile. Finally they came down to reality. So figured I'd ask here for something to clean it with and not hurt the finish. Thanks for the help.

-

Well mission accomplished. Had a few health issues. Heart attack tried taking me out but still kicking. Have been done for awhile and did achieve my goals. Can get my bad foot in now without a lot of trouble or pain. I put the zippers in the back, makes it easier for me to slip my foot in. I do appreciate all the help. Used the YKK zippers glued and sewn in by hand. Was actually pretty easy job. I was a little nervous ok alot nervous. Cutting in to a pair of expensive boots is nerve wrecking. My feet have a lot of nerve damage pain and neuropathy. On top of the drop foot. Will try posting a Pic for anyone who may be looking for help. I cut about 1/2 in wide seam basically the stich line. Everything else i cut and pulled out the thread. Then hand sewing everything back. Take your time and let the glue set up.

-

Singer 132k6 capabilitues and upgrades

Constabulary replied to Ed Neil's topic in Leather Sewing Machines

I´d try this by hand cranking the machine but again the needle hole has to be wide enough for 2 thread strands + needle. 214x1 / 328 needles have the same dimensions as 216x1 and I´m using the 214x1 in my machine w/o problems. 216x1 has a slightly different needle tip they have some kind of channel in the tip - not sure why. In case the hook tip hits the needle you have to move the hook a bit to the right and probably the bushing of hook driving shaft too. But it depends on how the machine is set up. Back in 2015 when set up my long gone 133K I started this topic: -

-

Yeah Chuck, gotta watch for invading Abalones!! Nasty buggers!

-

Straight from the web-site "These customizable baby booties are sized for 3-month-old newborns, featuring genuine white deerskin sides and veg-tanned cowhide soles."

-

New to me Pfaff 145 H3 BSN, set up and other questions

dwhacks replied to dwhacks's topic in Leather Sewing Machines

Finally getting back on this. @fibersport I found used parts on ebay, although I haven't tried installing them yet, it seems like a pretty big job. I adjusted the needle bar to use the correct needles. I also adjusted the bobbin case opener as per an @Uwe video. It seems to sew well, although there is a bit more noise in reverse, maybe this is normal. One thing is I don't find it particularly "easy" to turn over the machine. Its not hard, but its not like it would keep spinning like a top if I were to give it a spin (without the belt on). Instead it would instantly stop. I'm not really sure how "free" it should be though either, but I feel like its a bit tight or sticky. It does not have a tight spot, it is throughout the entire rotation and stroke, so its not binding in one spot. Any ideas what to look at? or should I completely disassemble and hope I can get it back together. -

Singer 132k6 capabilitues and upgrades

friquant replied to Ed Neil's topic in Leather Sewing Machines

Re: Clutch motor It's a 110V motor. It's normal/fine for switches and capacitors to be rated for higher voltage that the actual use case. But even if you did want to use a clutch motor, this is not the one to use because it's a 2-pole motor (3500rpm) instead of the 4-pole variety which are only 1750rpm. Good move on the digital servo. Is it a cylindrical shaft 15mm diameter? If so, you can get a 45mm pulley for that here: https://www.ebay.com/itm/376135081840 which will slow it down considerably. Re: Belt slipping I would buy a new belt. The belt looks all dried out (less grip) and looks to be too narrow for that pulley. V-belts need to be pressing against the walls of the pulley to get the best grip. I've been buying belts like this one: https://www.amazon.com/dp/B0BK1FQHRR but I suspect that a 3/8" automotive (rubber on the outside) belt would be the grippiest.