All Activity

- Past hour

-

Unfortunately I have a neck injury ( thank you US Navy lol) that has caused my hands to lose their strength. I am living in Las Vegas and need to sell all of my leather working tools and the collection of leather. Would you sell it as a bulk sale or a piece at a time? I have mostly hand tools and Veg leather from 9-0 down to thin kangaroo. What should I do?

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Found a stray bushing in my Seiko CW8-B

Northmount replied to WMages's topic in Leather Sewing Machines

I don't know where you get that idea from! At the bottom of the comment box it provides some very simple instructions. As Fredk says, reducing file size is preferred, to 800 pixels in the longest dimension. Especially helpful to members on the fringes of the internet where large files take forever to download. -

You can paste photos directly* from your computer or phone. They need sized to no more than 800 x 600 pixels, ie about 150kb * this is actually preferred

- Today

-

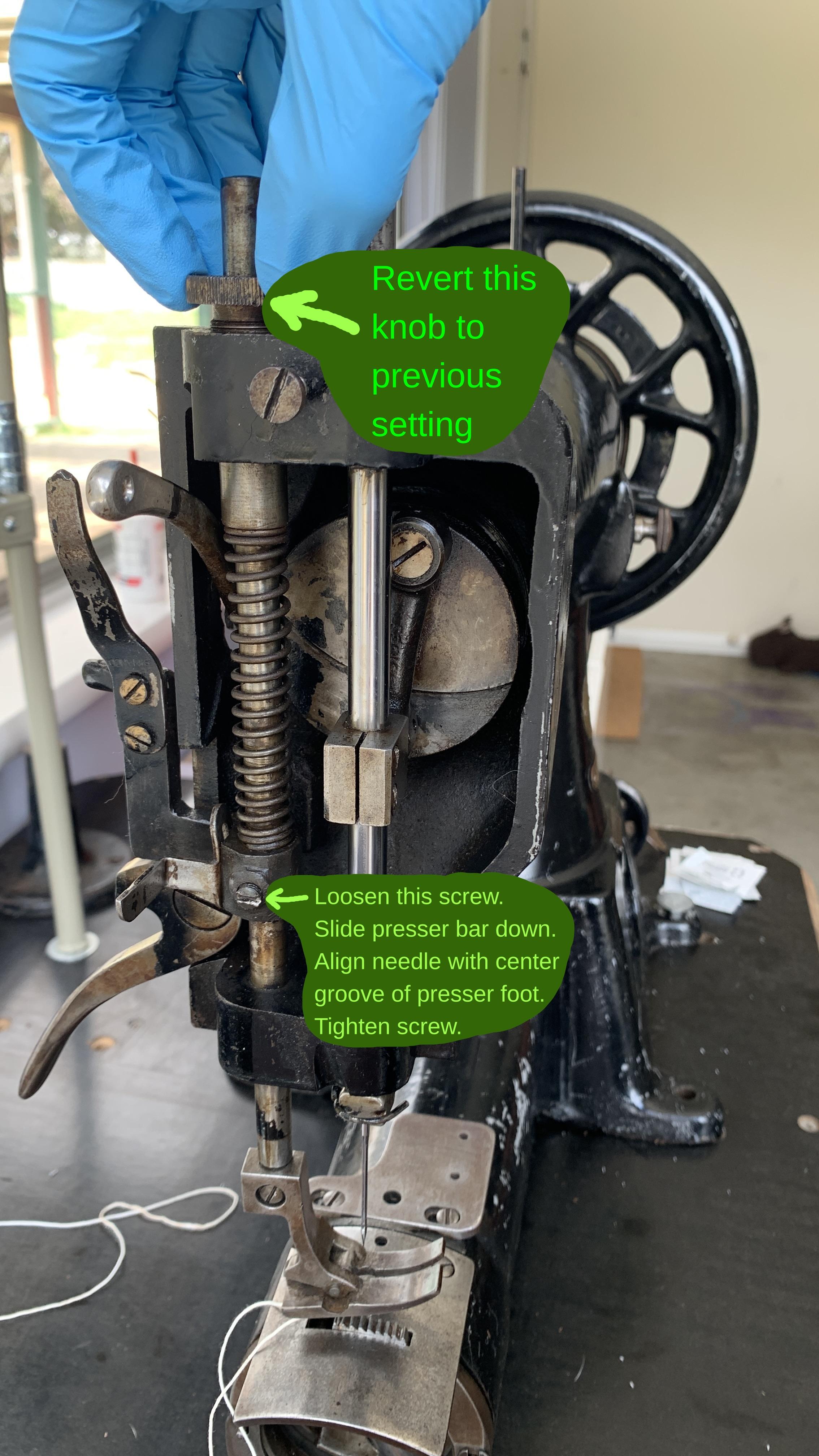

I do not have an ftp site to upload images here but the part I found wandering around in my machine is about 1/8" thick 1/4" in diameter and flat on two sides with an unthreaded hole in it. I presume it's a bushing. I can message or email images. My Seiko CW-8B started leaving the top thread (138) lay on top in tight radius turns. I tried making certain the needle had started back up before turning and didn't resolve the issue. Although there have been zero changes to bobbin tension since it sewed fine, and no major changes to top thread tension and same size needle. Yesterday, it was missing occasional stitches even in straight aways on a belt. I investigated this morning with an intention of increasing the bobbin tension by a half turn. I paused and took time to do a little cleaning and found this small bushing lying inside the chamber that houses the bobbin case. It's about an eight inch thick and in threaded. It has straight sides so I assume it's a bushing that isn't supposed to rotate. This also indicates to me there is likely a small screw somewhere yet none fell out when I slipped off the lower cup from the end of the cylinder? I'm fairly mechanically inclined but do not have experience with a sewing machine. I'm reluctant t try to remove the bobbin case for fear of getting its out of one. I'm looking for advice if anyone recognizes what part this is. I do not have a schematic for this machine.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

beautiful!! i love that dogs smile!!! Dont take a minute for granted my friend that next 20 will go by in the blink of an eye. My wife and I are at 45 years this fall and going strong. -

This item has been sold.

-

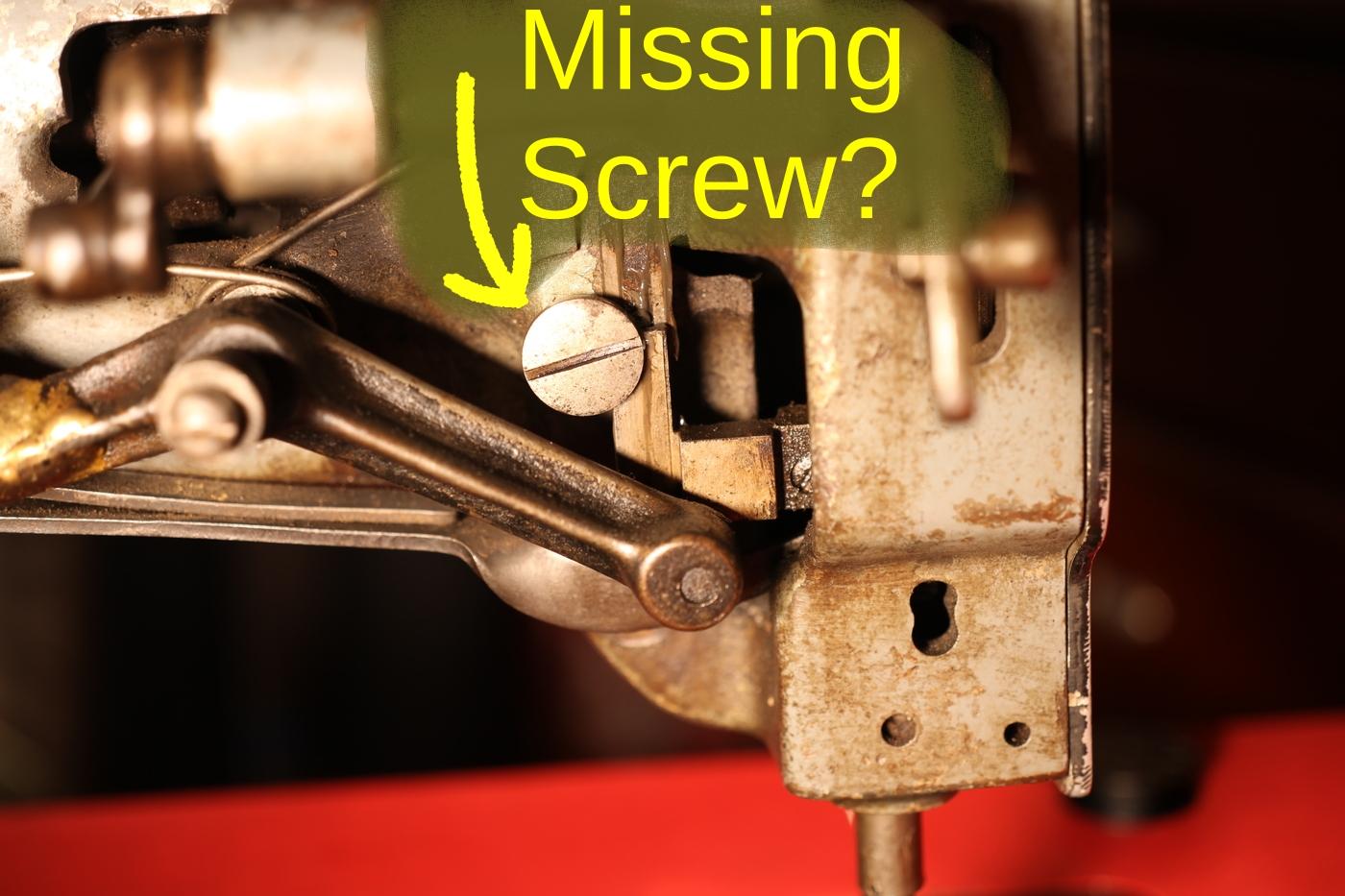

I wound this down as far as it can go (where my hand is). I took the plat off and included the entire mechanism in case there is another trick you can show me. You led me to the light, thank you so much! Everything is working perfectly now woohoo!

-

I have in the past made several different size punches like this myself. I do find a bolt slightly smaller than the hole and wrap some tape around it to keep it firmly held in place for being hit with a mallet or hammer but loose enough to remove and get out the waste occasionally. I generally make up a mild metal shape about the same as the inside hole of the punch I am making and after a bit of shaping use it to refine the end shape of the punch. I make quite a few from stainless tube which works pretty well.

-

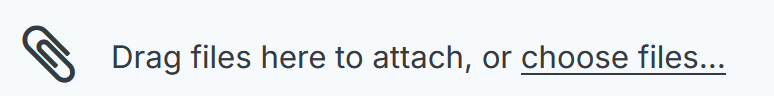

The knob that you turned increases the spring pressure. You can loosen that back up. To bring the presser foot down to a usable position, loosen the screw near the bottom of the spring.

-

I wound this down as far as it can go (where my hand is). I took the plat off and included the entire mechanism in case there is another trick you can show me.

-

Can you show a picture of what you adjusted to put the presser foot bar at its lowest setting?

-

Великолепная работа с кожей!

-

Hello everyone I have recently purchased a Singer 45K25 as I wanted to complete a leather upholstery project for my car. The machine came with a wheel instead of a foot and the alignment of the wheel was weird where it came down onto the leather. I couldn't sew the upholstery as the wheel grips further away from where I need the pressure to be. I am topstitching if that helps to clarify? So I purchased a foot for the machine and it arrived and I installed it, but now my issue is that even with the presser foot bar wound down to its lowest setting, I still have close to 1cm gap between the foot. and the feed dogs. I sat in the slough of despond for a while thinking I had bought a machine too fierce and uncouth for what I wanted to sew, when I thought perhaps I can have a foot made with a longer shank? My thinking is that it would not just be a matter of having a longer shank, but the needle hole opening would need to be calculated correctly as the foot angles out from the bar it is attached to. So if I commissioned a foot it might need a little engineering knowhow to ensure the needle hole aligned correctly. Does anyone here understand what I am talking about? better still, does anyone know someone who knows how to fabricate what I am talking about? I think a shank approximately 10mm longer would allow me to unwind some of the presser bar and give a bit of allowance back for adjusting the pressure and would allow me to sew materials thinner than 1cm thick. Attached is a photo of the machine with the foot all the way down. Am I under thinking this? Am I nuts? I really like my beastie machine a lot and am reluctant to rid myself of it.

-

Hjay joined the community

- Yesterday

-

I recently bought one of those off Temu for £12, for tool, 2 sets of dies and some snaps. Not used it yet. I have one for use with KAM snaps and it works fine so I reckon the new one will as well

-

Smiche joined the community

-

Great job beautiful work.

-

A couple of years ago . . . I was in an Amish store that sells material for sewing . . . kinda like an Amish Joann Fabric shop. They had this tool in there . . . and I knew exactly what it was as soon as I saw it . . . the tool itself was 35 bucks . . . and the set of dies was 18. Both sets fo male and female came in that kit. I went back later and bought another one just like it . . . so I didn't have to swap dies every time I wanted to do a snap. I have been just plain pleased with this tool . . . it is great . . . you have to be careful and follow directions . . . and if you do . . . great snaps every time. I believe I also saw them in Hobby Lobby . . . not certain. There is a cheaper version like this . . . sells for about 18 bucks . . . comes in a kit . . . Amish buy them for the snaps for the women's clothing . . . it is a smaller tool . . . and I don't know if it will do line 24 snaps . . . mine does every time. Nothing against Dot . . . but that's a bunch of money for a snap setter. May God bless, Dwight

-

Help! Singer 111w155 stripped / stuck screw

friquant replied to matthew123's topic in Leather Sewing Machines

-

Help! Singer 111w155 stripped / stuck screw

friquant replied to matthew123's topic in Leather Sewing Machines

This is normal. The extra work is going into compressing the presser foot spring. The effect goes away if you lift the presser feet. Mine does not lift as far when the inner toe is down. Maybe you aren't getting enough lift. Try pressing down with your hand on the far end of the foot lift bar and see if the feet will come up. -

Help! Singer 111w155 stripped / stuck screw

friquant replied to matthew123's topic in Leather Sewing Machines

-

Help! Singer 111w155 stripped / stuck screw

friquant replied to matthew123's topic in Leather Sewing Machines

Genius! -

That was good help, thanks! Found the online manuals - parts, owners, and adjusters. All I needed!

-

-

It that's not THE excuse to make a new collar, then I don't know XD Have a lot of fun with your new family member! My little setter-cross, who is a rescue from Italy, also taught my mums puppy all the nasty things and now he is teaching her how to behave like a little retard again. And I thought that phase was behind us. Thank you for your feedback and for sharing your experience! I know what you mean, I’ve also seen some cheaper leads fail at that point. That’s exactly why I used Italian dorsal leather, not skived at any point, cut from the best end, and sew everything with strong polyester thread in saddle stitch. The rope itself is made for dog leashes, so I feel good about the stability. But it’s always interesting to hear how others approach it — your rivet and shrink tube method definitely sounds very sturdy! Best, Tove