All Activity

- Today

-

Help! Singer 111w155 stripped / stuck screw

matthew123 replied to matthew123's topic in Leather Sewing Machines

Thanks Friquant! You are totally right...I am missing that lock nut and that screw and I didn't realize it. Uh oh. Any idea what that screw does? -

Like @Dwight and @AlZilla have said break it up into various pieces. Check and see what the items can be purchased for new and ask fair reduced price. I think you would have to take a lot less selling them as one big lot. Someone maybe interested in leather while others may want needles and thread or tools. I have in the past bought bulk lots but got them for a real cheap price and then sold off the items that I didn't want for a profit. kgg

-

I missed this when you posted it. Most ingenious. How about the hitting end, they appear to stand up to the impact pretty well? I'm almost certainly going to copycat this idea. Maybe fill the hollow end with molten lead.

-

Spent some quality time with my patcher sewing these purses back together. The leather was dry, the cotton (?) thread was deteriorating, and the plastic piping was cracking. It was a learning experience. I replaced the zipper on both purses and made new rolled leather handles for one of them. I'm thinking it's easier to make bags than repair them. Maybe I will test that idea.

-

Piece it out, if you're not in a hurry. It'll be a lot more work and time for you but you get a higher return. The most likely buyer for the lot will be a dealer or reseller who will need to make a profit. You could always price everything out individually and then mention that you'd consider an offer on the lot. Maybe someone will come along who wants exactly the collection of things you have.

-

Found a stray bushing in my Seiko CW8-B

friquant replied to WMages's topic in Leather Sewing Machines

I would check if the machine is in time. And if it has a safety clutch, make sure it is engaged. If you can, make a slow, closeup video like Karbo's here to show the timing of your machine: https://leatherworker.net/forum/topic/131845-pfaff-345-issues/#findComment-784860 and post it for us to review -

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

Of all you've written about, this may be the most impressive. Congrats to both of you. -

I finally have some adapters for this press. I decided against modifying the press and chose to modify the attachments. I bought a Little Wonder 104 rivet set and anvils. I had an adapter made for the anvils. I had the rivet set turned down to fit the press. I also had a Tandy mini punch set that I never use. I had the handle modified to the press. Overall it works pretty good, but the stroke seems a little short. Randy

-

Here in Ohio . . . our best bet for selling stuff is Facebook marketplace . . . I bought a truck . . . milling machine . . . I've seen whole shops on there . . . and I've sold a brass bed headboard . . . portable air tank . . . it's just good. I'd try there first . . . doesn't cost anything unless you want to pay for some special treatment of your ad . . . just make sure you put a good list of what you want to sell . . . if the information doesn't spark an interest . . . no sale. Do you have any machinery? You can list it here . . . or if you want . . . you might break it up into machinery . . . hand tools . . . leather (size & sq footage) . . . you might sell it all on here. May God bless, Dwight

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

CREALTY 40W LAZER AND CUSTOM ENCLOSURE

Northmount replied to ferrissteve's topic in New and Refurbished to Like New

Some photos and manufacturer's specs would be very helpful. -

Unfortunately I have a neck injury ( thank you US Navy lol) that has caused my hands to lose their strength. I am living in Las Vegas and need to sell all of my leather working tools and the collection of leather. Would you sell it as a bulk sale or a piece at a time? I have mostly hand tools and Veg leather from 9-0 down to thin kangaroo. What should I do?

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Found a stray bushing in my Seiko CW8-B

Northmount replied to WMages's topic in Leather Sewing Machines

I don't know where you get that idea from! At the bottom of the comment box it provides some very simple instructions. As Fredk says, reducing file size is preferred, to 800 pixels in the longest dimension. Especially helpful to members on the fringes of the internet where large files take forever to download. -

You can paste photos directly* from your computer or phone. They need sized to no more than 800 x 600 pixels, ie about 150kb * this is actually preferred

-

I do not have an ftp site to upload images here but the part I found wandering around in my machine is about 1/8" thick 1/4" in diameter and flat on two sides with an unthreaded hole in it. I presume it's a bushing. I can message or email images. My Seiko CW-8B started leaving the top thread (138) lay on top in tight radius turns. I tried making certain the needle had started back up before turning and didn't resolve the issue. Although there have been zero changes to bobbin tension since it sewed fine, and no major changes to top thread tension and same size needle. Yesterday, it was missing occasional stitches even in straight aways on a belt. I investigated this morning with an intention of increasing the bobbin tension by a half turn. I paused and took time to do a little cleaning and found this small bushing lying inside the chamber that houses the bobbin case. It's about an eight inch thick and in threaded. It has straight sides so I assume it's a bushing that isn't supposed to rotate. This also indicates to me there is likely a small screw somewhere yet none fell out when I slipped off the lower cup from the end of the cylinder? I'm fairly mechanically inclined but do not have experience with a sewing machine. I'm reluctant t try to remove the bobbin case for fear of getting its out of one. I'm looking for advice if anyone recognizes what part this is. I do not have a schematic for this machine.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

beautiful!! i love that dogs smile!!! Dont take a minute for granted my friend that next 20 will go by in the blink of an eye. My wife and I are at 45 years this fall and going strong. -

This item has been sold.

-

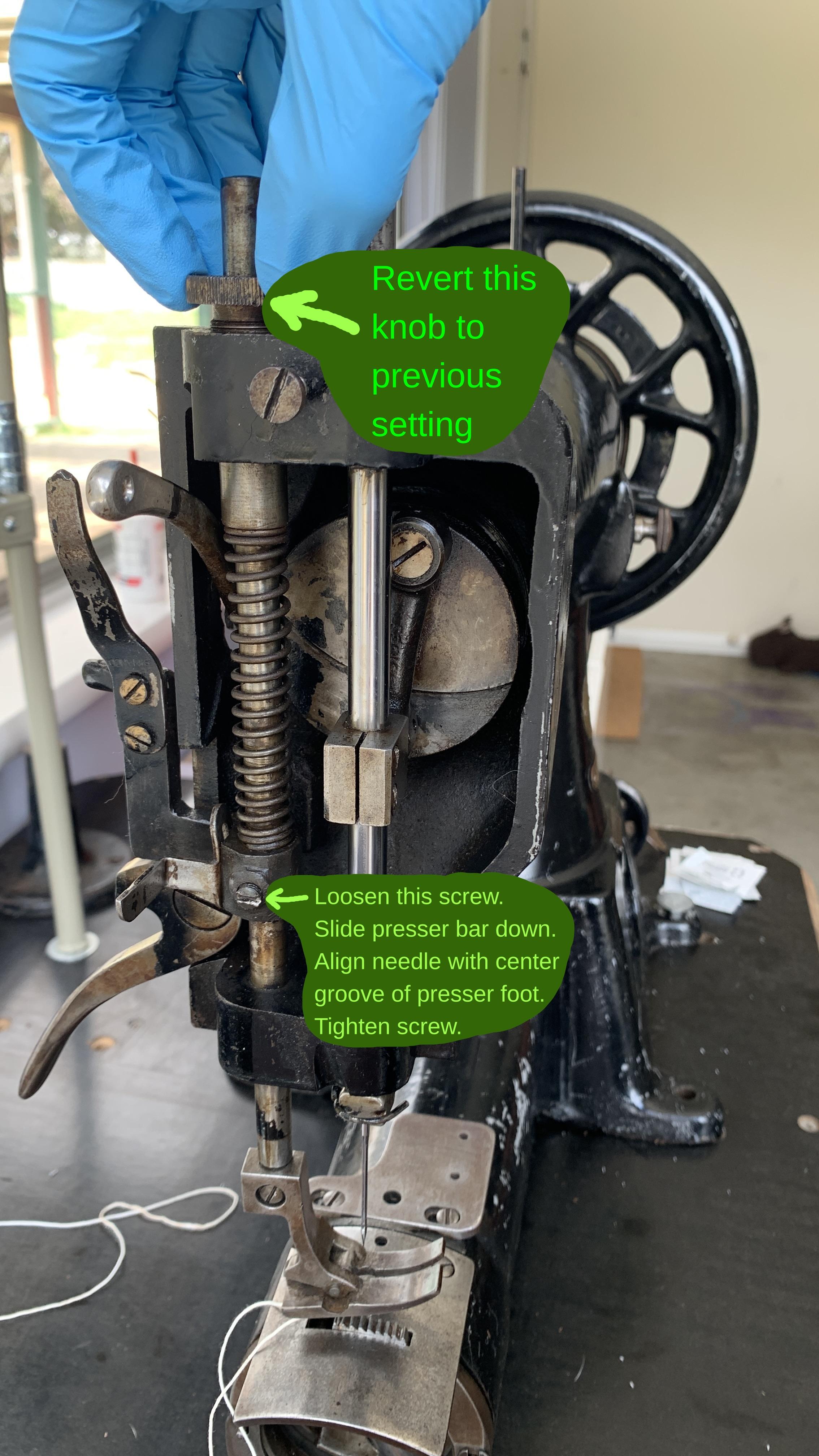

I wound this down as far as it can go (where my hand is). I took the plat off and included the entire mechanism in case there is another trick you can show me. You led me to the light, thank you so much! Everything is working perfectly now woohoo!

-

I have in the past made several different size punches like this myself. I do find a bolt slightly smaller than the hole and wrap some tape around it to keep it firmly held in place for being hit with a mallet or hammer but loose enough to remove and get out the waste occasionally. I generally make up a mild metal shape about the same as the inside hole of the punch I am making and after a bit of shaping use it to refine the end shape of the punch. I make quite a few from stainless tube which works pretty well.

-

The knob that you turned increases the spring pressure. You can loosen that back up. To bring the presser foot down to a usable position, loosen the screw near the bottom of the spring.

-

I wound this down as far as it can go (where my hand is). I took the plat off and included the entire mechanism in case there is another trick you can show me.

-

Can you show a picture of what you adjusted to put the presser foot bar at its lowest setting?

-

Великолепная работа с кожей!

-

Hello everyone I have recently purchased a Singer 45K25 as I wanted to complete a leather upholstery project for my car. The machine came with a wheel instead of a foot and the alignment of the wheel was weird where it came down onto the leather. I couldn't sew the upholstery as the wheel grips further away from where I need the pressure to be. I am topstitching if that helps to clarify? So I purchased a foot for the machine and it arrived and I installed it, but now my issue is that even with the presser foot bar wound down to its lowest setting, I still have close to 1cm gap between the foot. and the feed dogs. I sat in the slough of despond for a while thinking I had bought a machine too fierce and uncouth for what I wanted to sew, when I thought perhaps I can have a foot made with a longer shank? My thinking is that it would not just be a matter of having a longer shank, but the needle hole opening would need to be calculated correctly as the foot angles out from the bar it is attached to. So if I commissioned a foot it might need a little engineering knowhow to ensure the needle hole aligned correctly. Does anyone here understand what I am talking about? better still, does anyone know someone who knows how to fabricate what I am talking about? I think a shank approximately 10mm longer would allow me to unwind some of the presser bar and give a bit of allowance back for adjusting the pressure and would allow me to sew materials thinner than 1cm thick. Attached is a photo of the machine with the foot all the way down. Am I under thinking this? Am I nuts? I really like my beastie machine a lot and am reluctant to rid myself of it.