All Activity

- Past hour

-

Toxo . . . go to the other thread about clicker dies and no press . . . find my post on page two . . . lots of good ideas for you there. Long and short . . . you can make something much better than a clicker die on your computer . . . which will do a better job as well. I have done both. May God bless, Dwight

-

Answers in no particular order (), a fellow member of my shooting club also dabbles in leatherwork (I think I got him started!) and has found a source of die rule, although only in 1 metre lengths - but it aint cheap! Nor will the postage be! You are right, by the way, about getting things here, it's not like the US!! The banding steel I've got is high tensile and if I use the method of making the shape out of wood (backing block) and screwing the steel band to it I'm pretty sure it will stand up to the pressure of the press. Case hardening, an interesting idea but the steel band is factory coated to resist corrosion and it could be difficult to remove, also heating the thin steel to the necessary temperature is likely to deform the shape once made. Forges, I have a coke and a gas forge so heating it is no problem and I have several different size anvils, rather the problem is how thin it is (0.7 mm), I've managed to burn/melt much thicker stuff in the coke forge!! If the info I found is correct (and I think it is) the banding steel has 0.2% carbon, 1.2% manganese and a small amount of sulphur. So tough, ductile but can't be hardened, and it's very springy. Anyhow, I appreciate you taking the time to think of possible solutions.

-

Let me ride this rodeo out of town . . . and start a new one. You obviously have a computer . . . and if you have ANY photo program . . . you can take a photo of ANY SHAPE you want . . . fill in the shape with black . . . and go to your 300 dollar 10 watt laser engraver. It may take two 30 second passes to cut out your shape . . . but it will cut up to 8 oz in two passes. The neat part is you never EVER have to get another clicker die. They are a thing of the past with a laser engraver. I use mine to cut small stuff any time I want an EXACT shape . . . the engraver and Adobe Photoshop Elements 2.0 (5 dollar program on Ebay) . . . are all I need. My bed is about 14 inches by 14 inches . . . so I can cut anything that size . . . and as many exact copies I want providing I have the leather. You do have to rig up a fan to take the burnt leather stink away . . . but that is the worst . . . and it is not hard at all. AND THE BEST PART . . . When you get done with cutting stuff out with the laser engraver . . . you can then waste a couple days . . . and as much corrugated brown cardboard as you can scrounge up . . . learning how to do roses . . . buildings . . . automobiles . . . horses . . . any shape you want . . . for any drawing you want . . . on your laser engraver. The cardboard mimics leather fairly well . . . so you can get a good idea of your settings needed . . . then do a small check piece of leather . . . then do a large picture or drawing or whatever your heart desires. If you really take your time . . . you can do photographs . . . army patches . . . custom book marks . . . billfolds . . . purses . . . and if you let your daughter play with it for a while . . . she might teach your wife how to use it . . . they can make the decorated front of the purses . . . you can do the rest . . . and you have a whole brand new product line. Or you can just put names on the key fobs . . . that'll work too. May God bless, Dwight

-

How to Lift a Sewing Machine Safely

MyOldHyde replied to friquant's topic in Leather Sewing Machines

You bet! Hoyer is a big manufacturer of medical transport devices and I think first made the patient lift, hence the name. Now this is showing off... how I got in and out of my truck! Hey, when you're 70, 250lbs feels like 500! - Today

-

That had to take a long time to post and I’m sure everyone here appreciates it! I wish I could get a copy of that book, wow!😃

-

I second the notion that the best water repellency you can get is with Resolene (or Mop & Glo cut 50/50 with water). This is an acrylic film layered on your leather. It can be damaged and it is not 100% water proof forever but it is far better than any other top coat for this purpose.

-

Tobby joined the community

-

Hi Judo, I am interested in the Landis 5 in 1 (item 19), do you have a price in mind for that item? Also, would need to ship it to Charlotte, NC. Thanks! Tobby

-

TriciaT joined the community

-

Fitting a Paso Fino

TriciaT replied to firephil's topic in Choosing the Right Saddle for the horse(s)

Hi there, i have a Pasofino and use the Imus 4 beat gaited saddle that works quite well. My horse is about 15 hands. Be sure to watch directions on where to put the saddle because it’s much more forward. Good luck! -

Wot he said It must have taken you ages Thanks for doing it and sharing it I'll peruse it all properly later when I have some more time spare

-

I get 'lift-the-dot' fasteners from a sailing supplier. I don't need no special tool. They have wee tabs which go through the leather and a backing support plate which I bend over by pushing on them with a screwdriver than lightly finish by tapping them down

-

Was going to suggest "Pull-the-Dot" brand snaps but just discovered that they require a special tool to set them. $124.

-

The perfect oval punch.

wizard of tragacanth replied to bsshog40's topic in Leatherwork Conversation

Did you find a punch? If not, here is my recommendation. Most belts are 1 3/4" wide, so add a little and make your punch 1 13/16". Most belts will fit 1/4" slot but give it an extra 1/16", so 5/16" wide is good. So, final answer is, minimum... 1 13/16" by 5/16". BTW, I use a 4lb. hammer for this punch. You are in Texas, so I would recommend Texas Custom Dies... good people. http://www.usacuttingdie.com This is the style that I have. If you have a clicker, that's different. -

Fully agreed. Leather work takes me to a different place.

-

WOW!! That is an impressive task you have done here. Thanks for sharing 🙂 Brgds Jonas

-

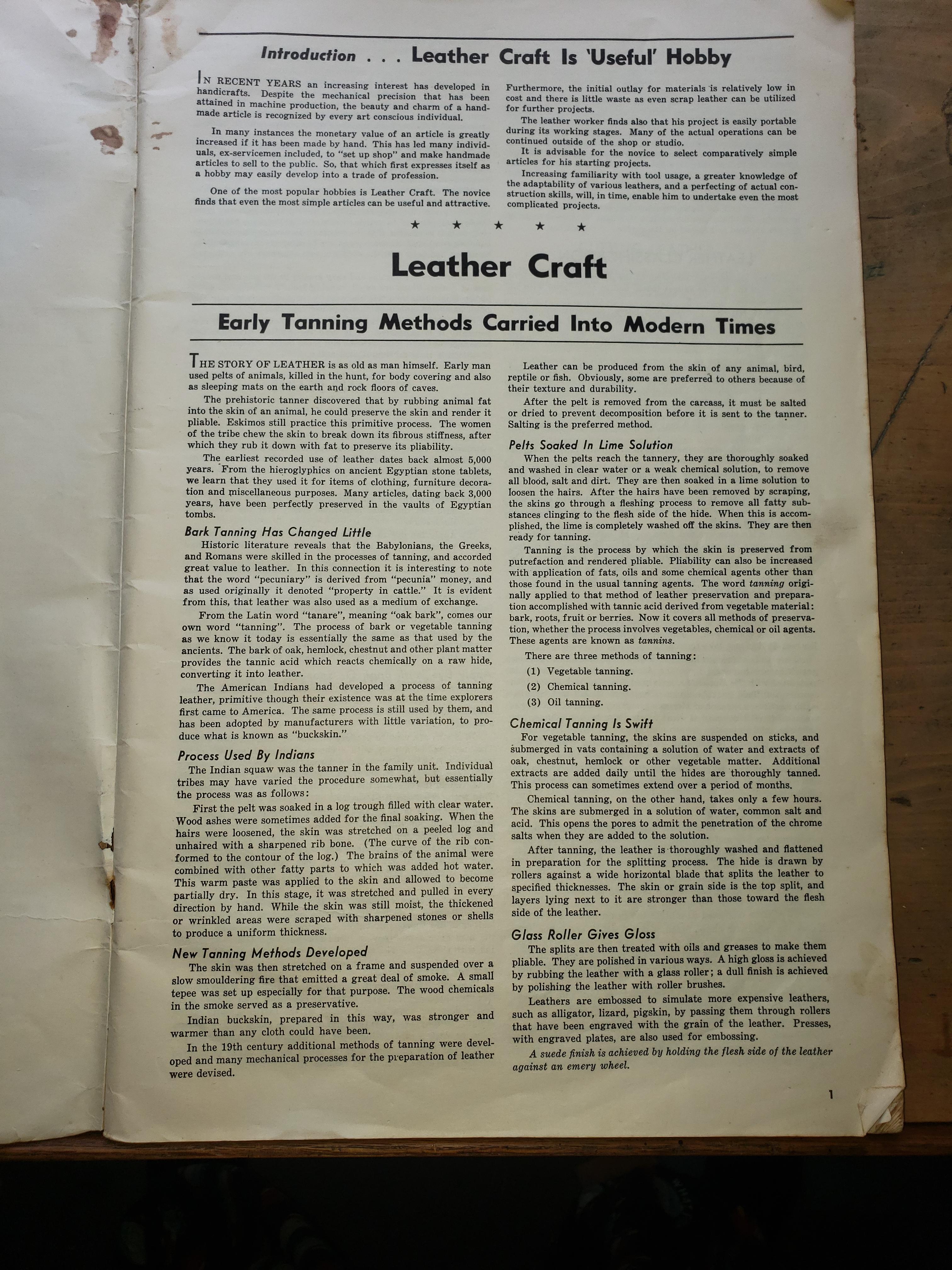

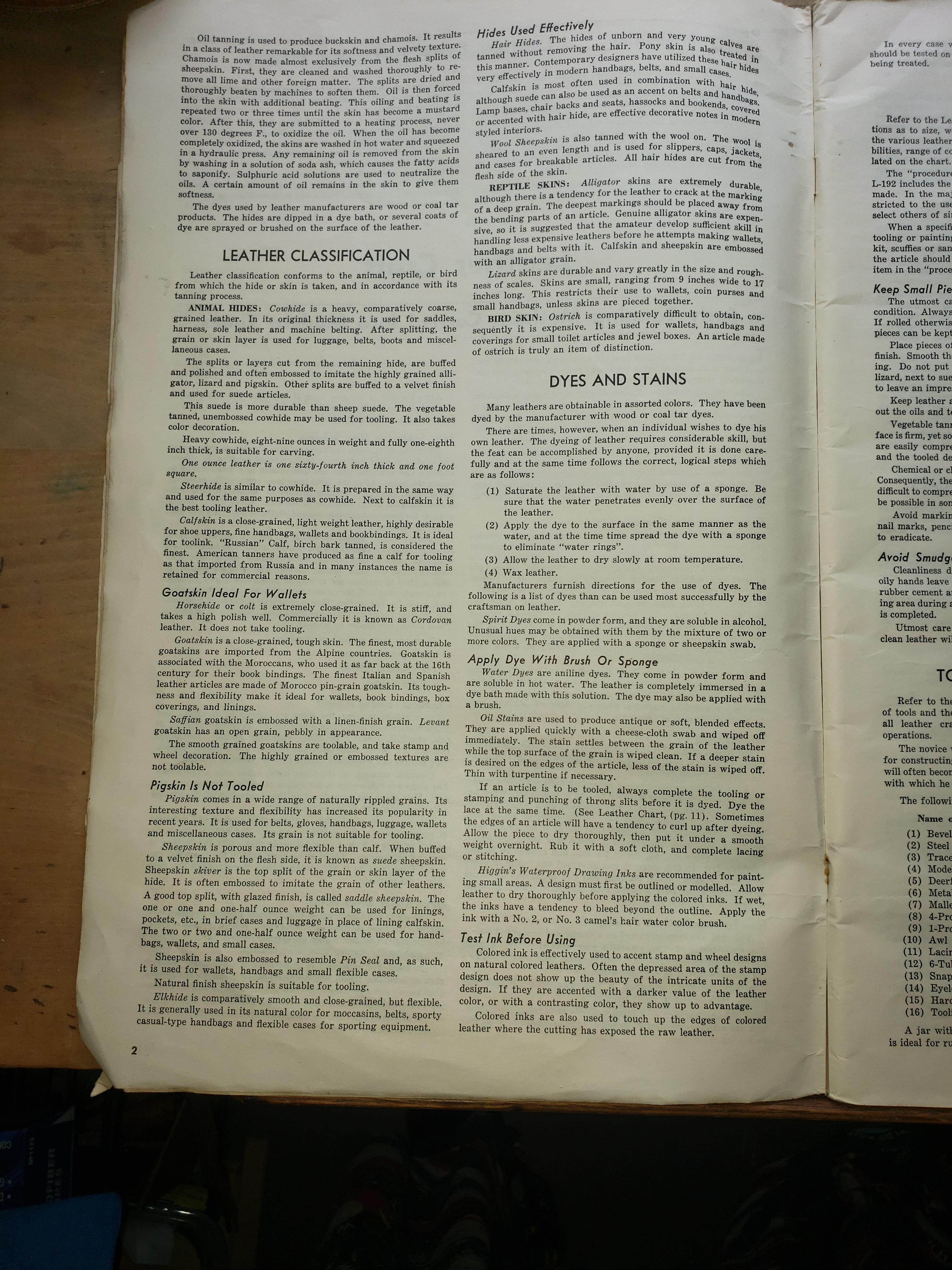

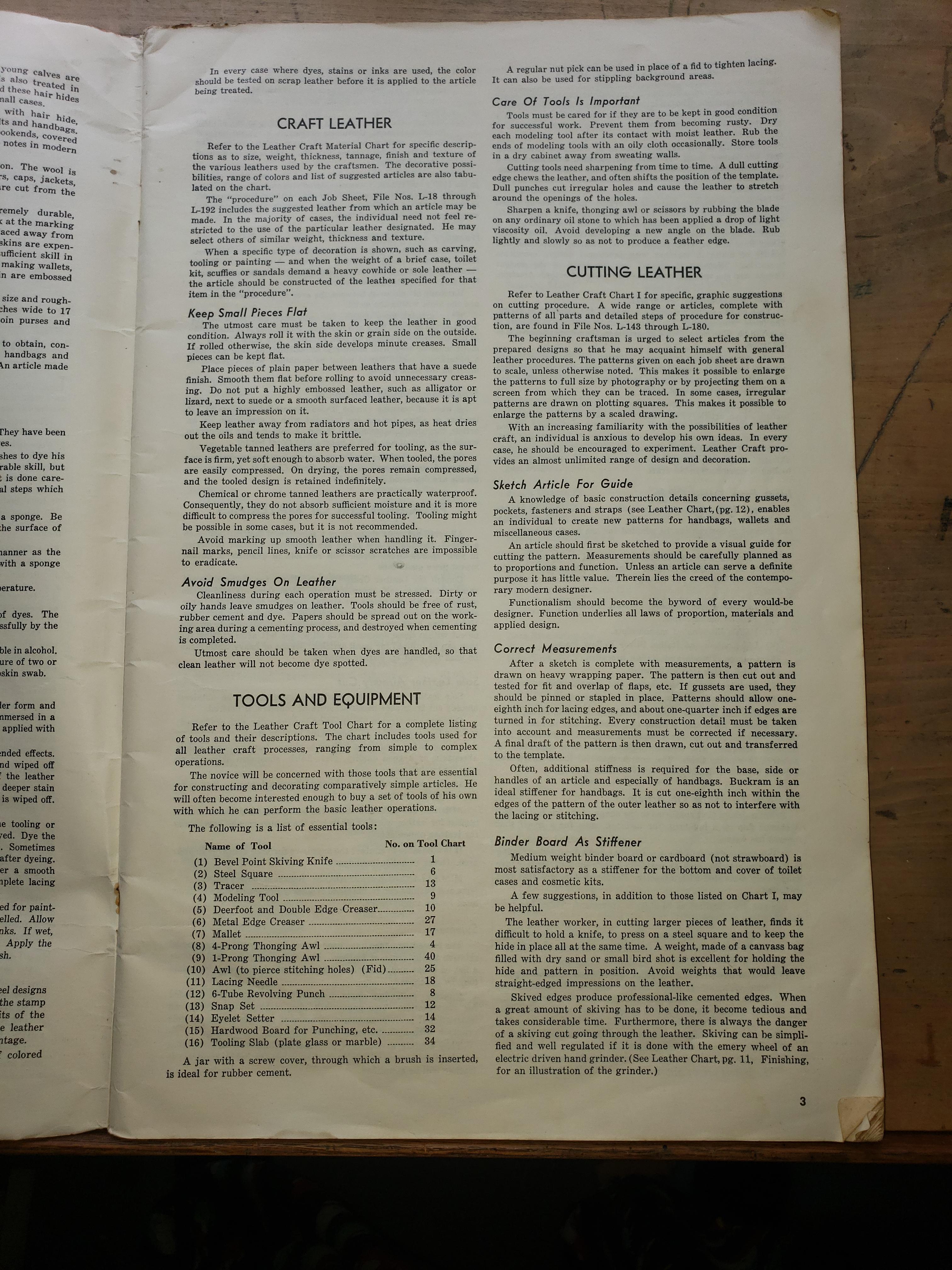

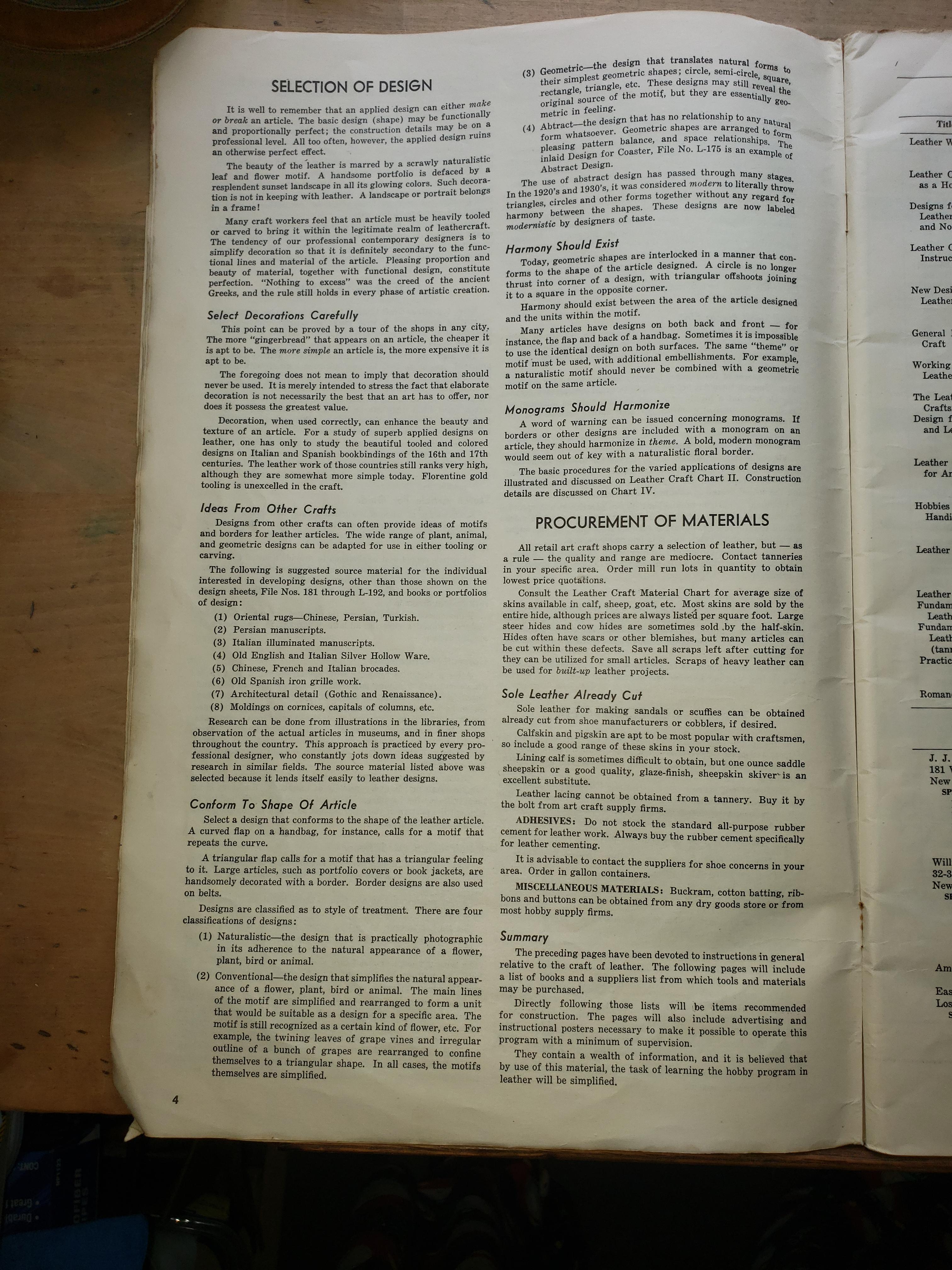

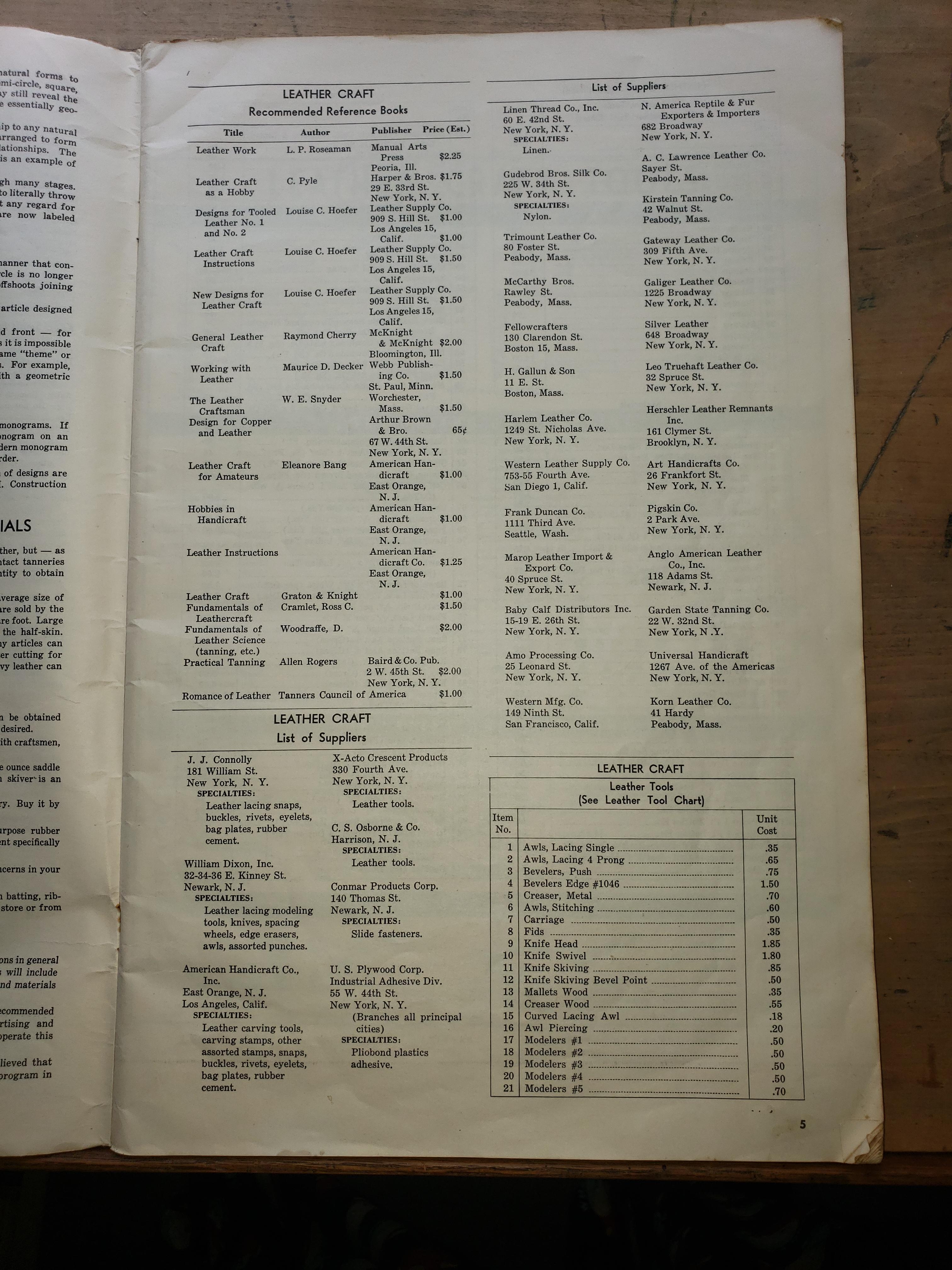

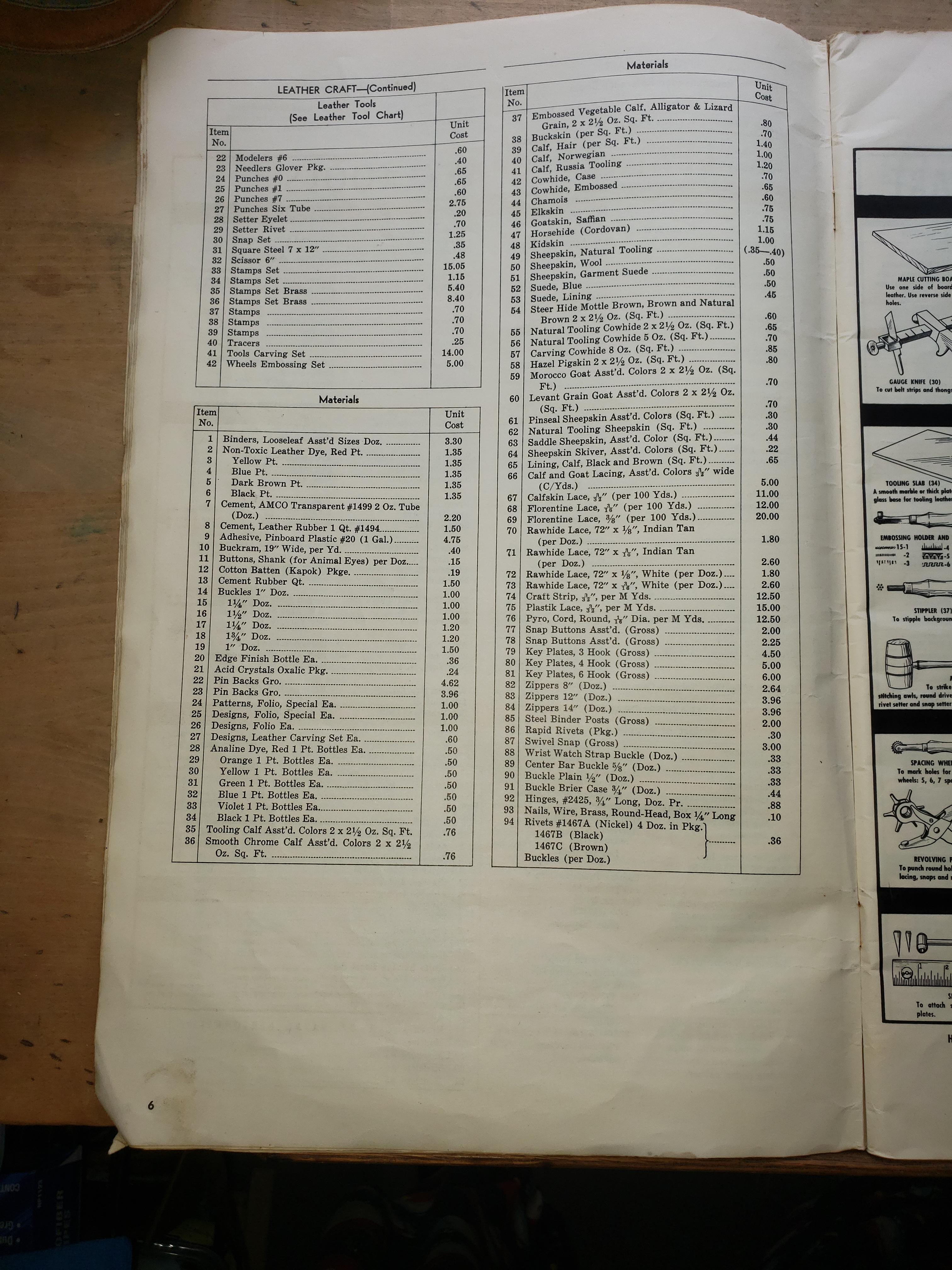

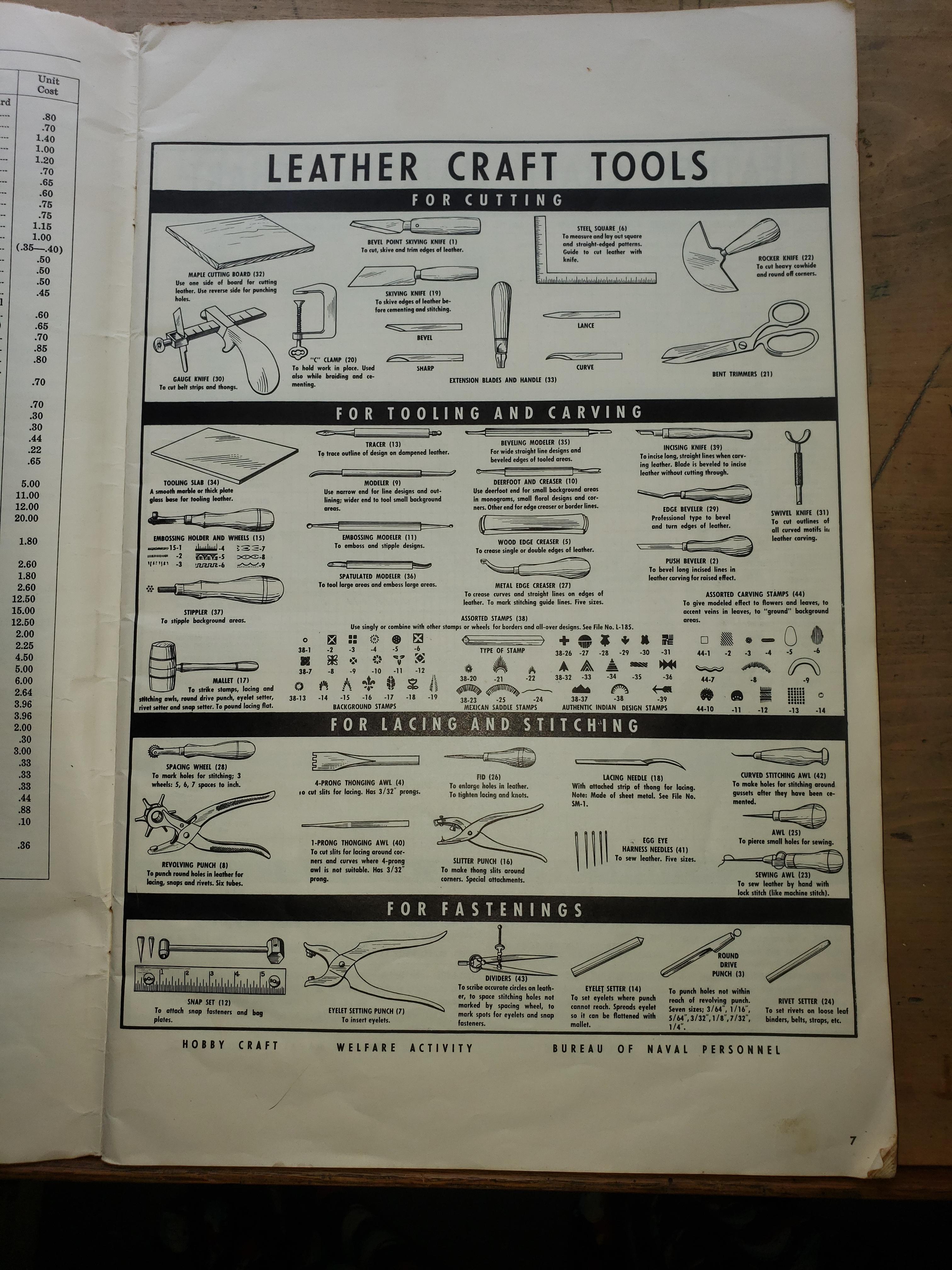

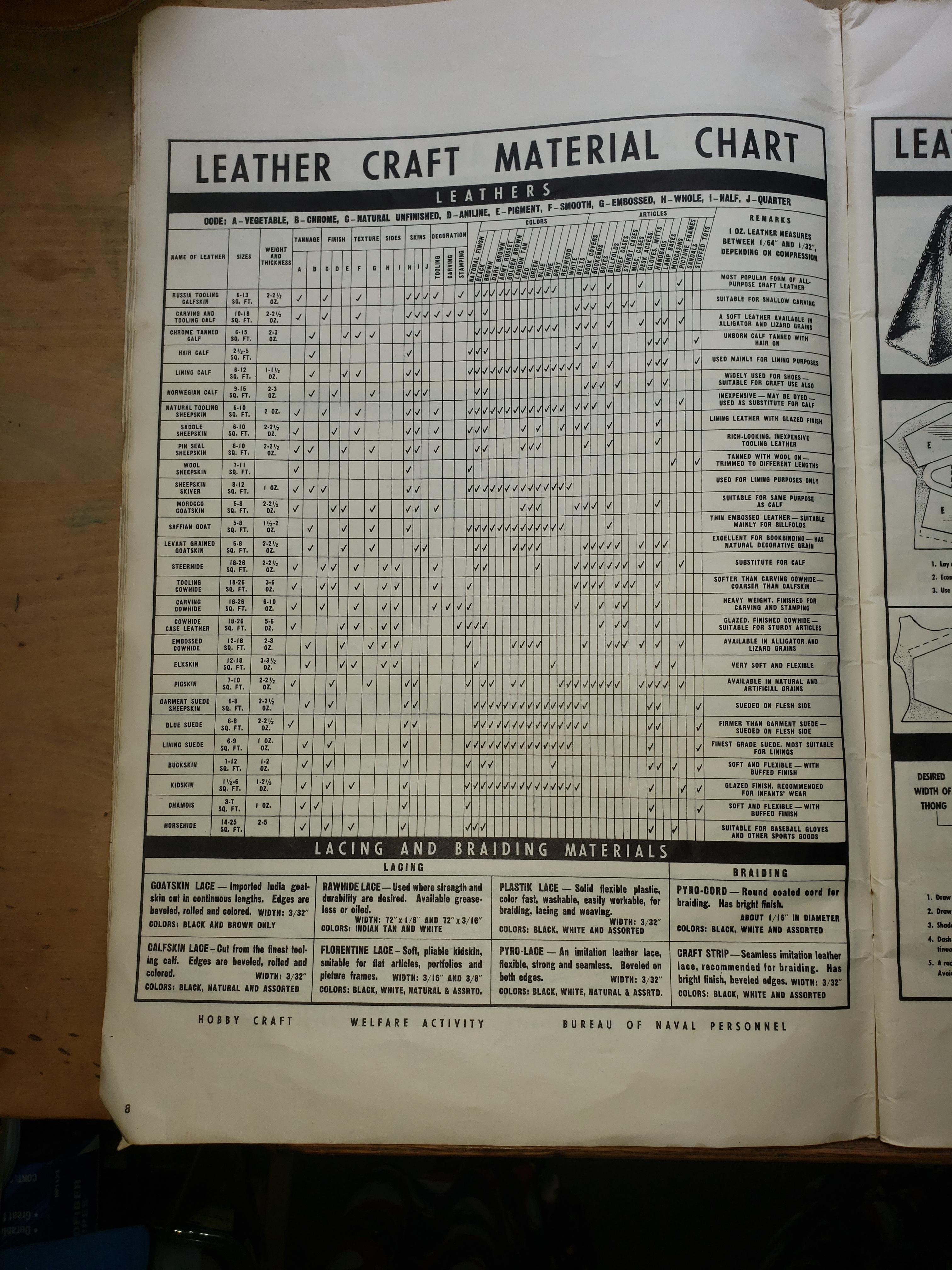

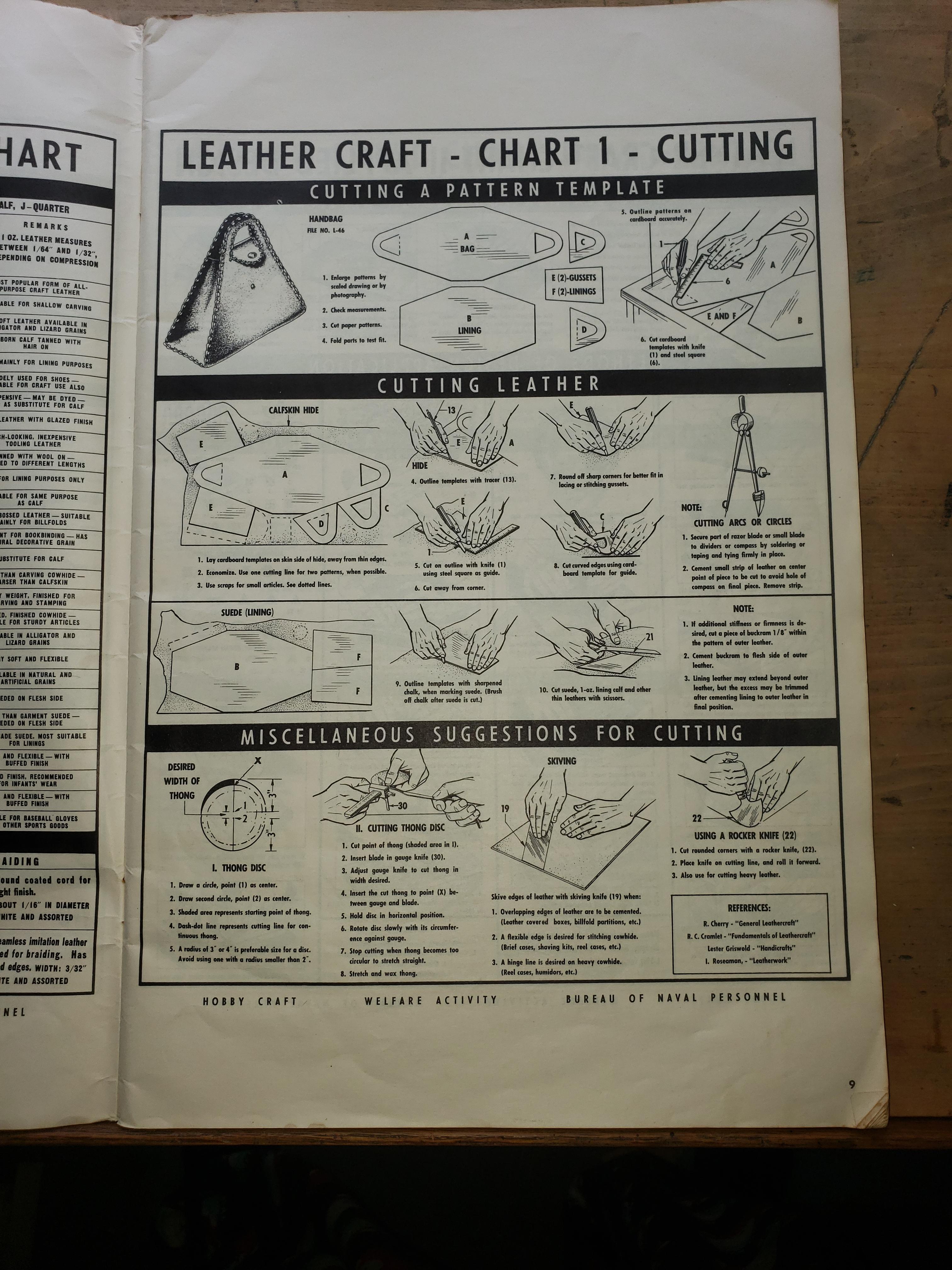

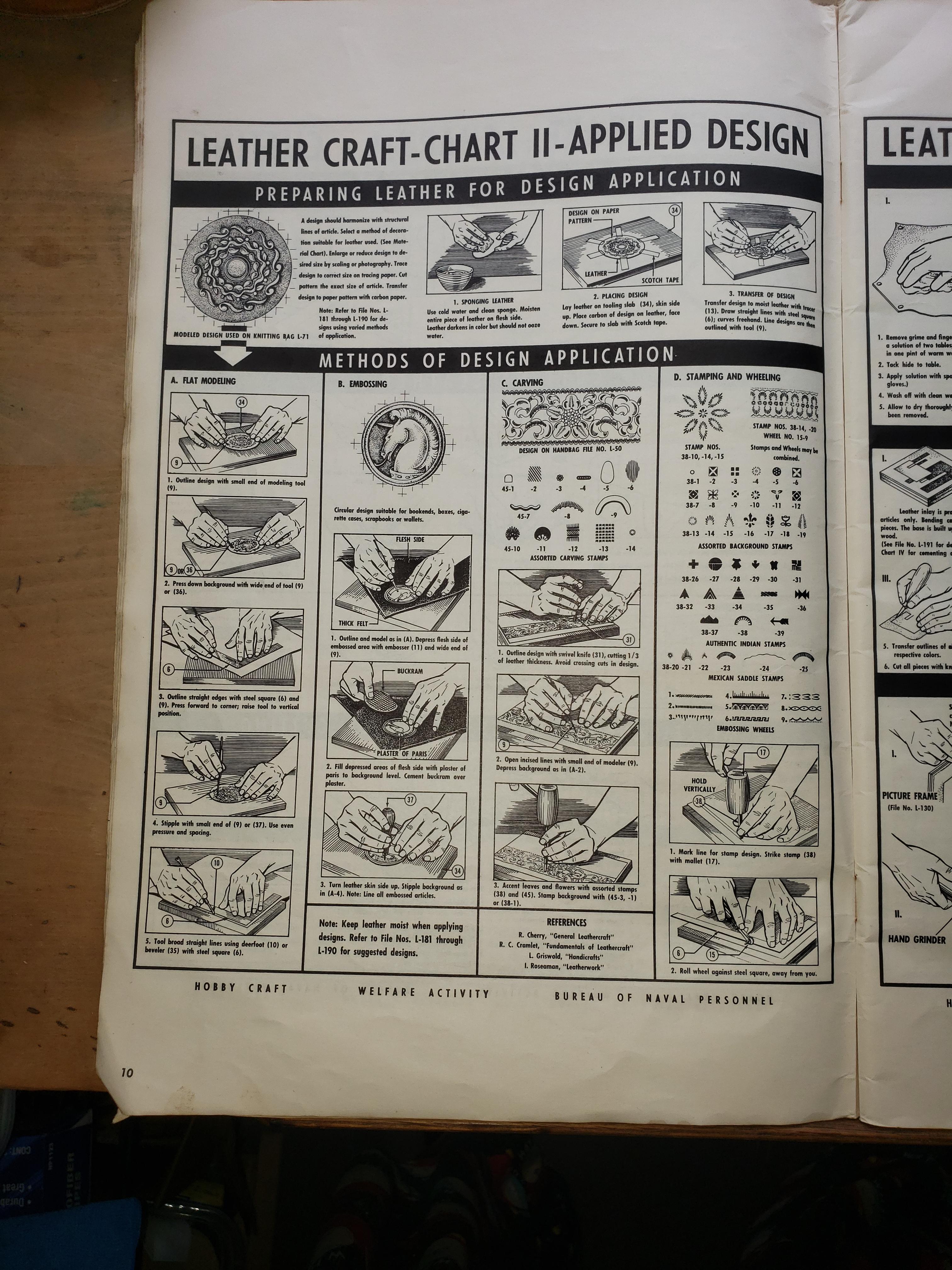

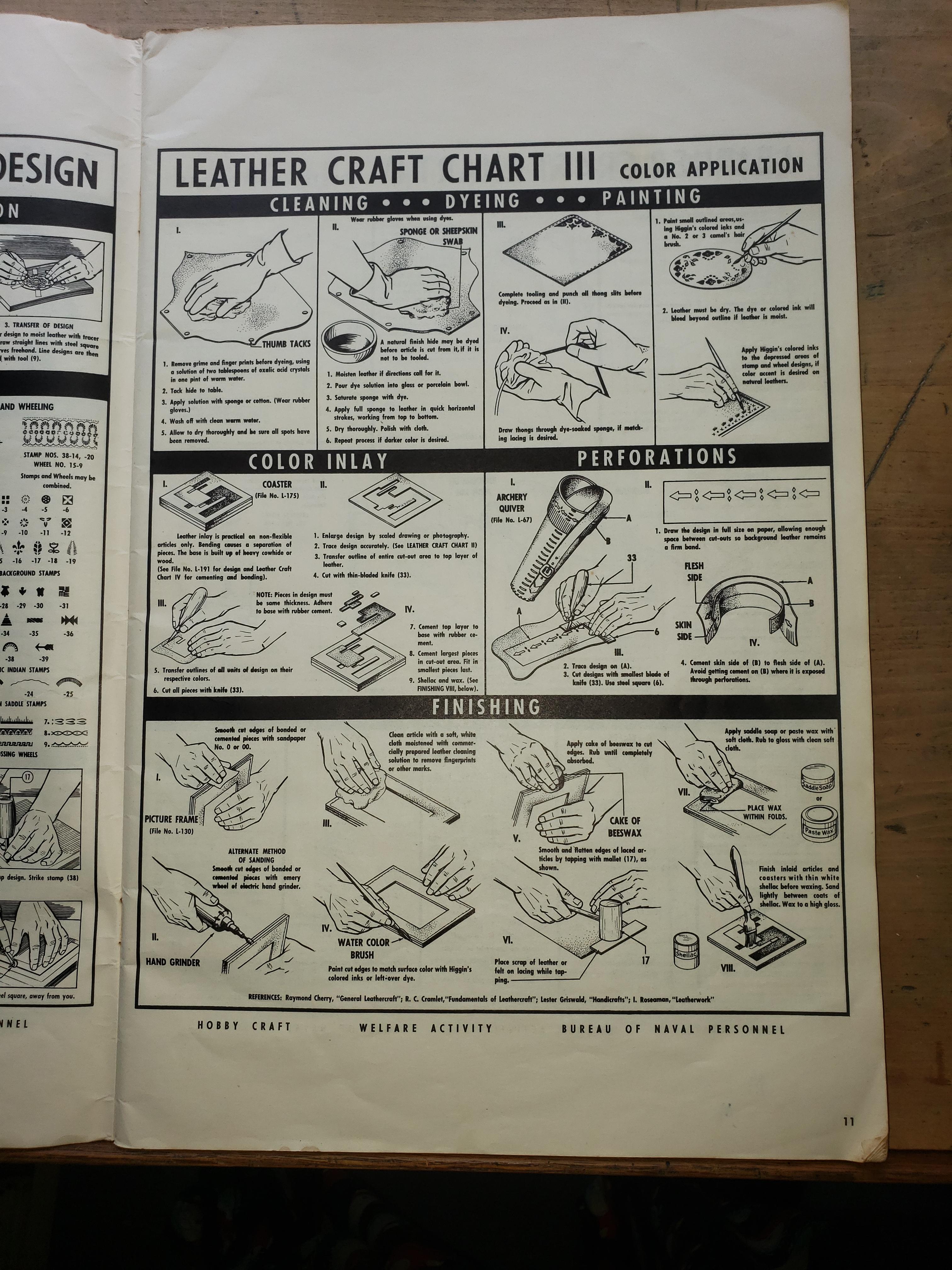

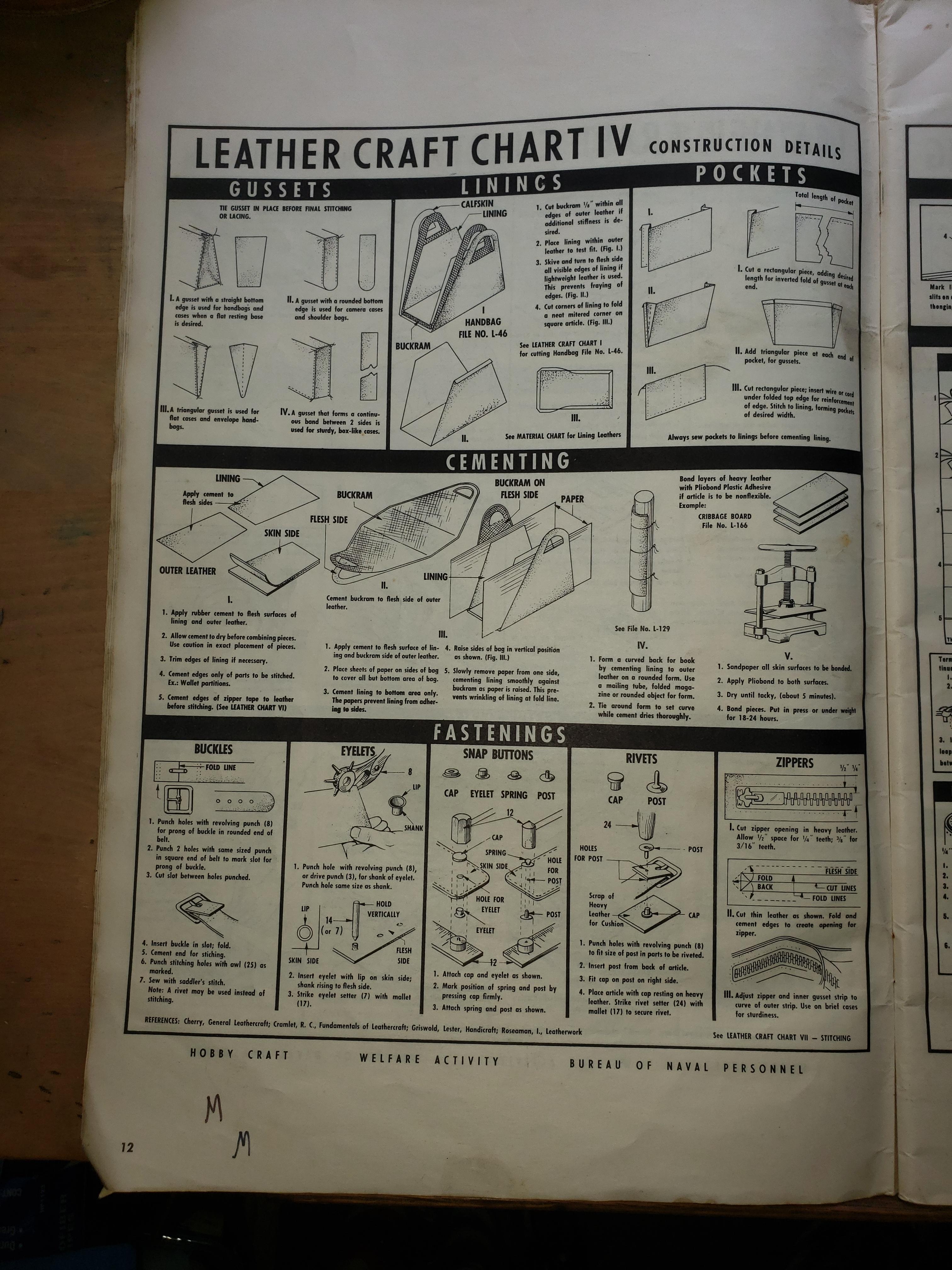

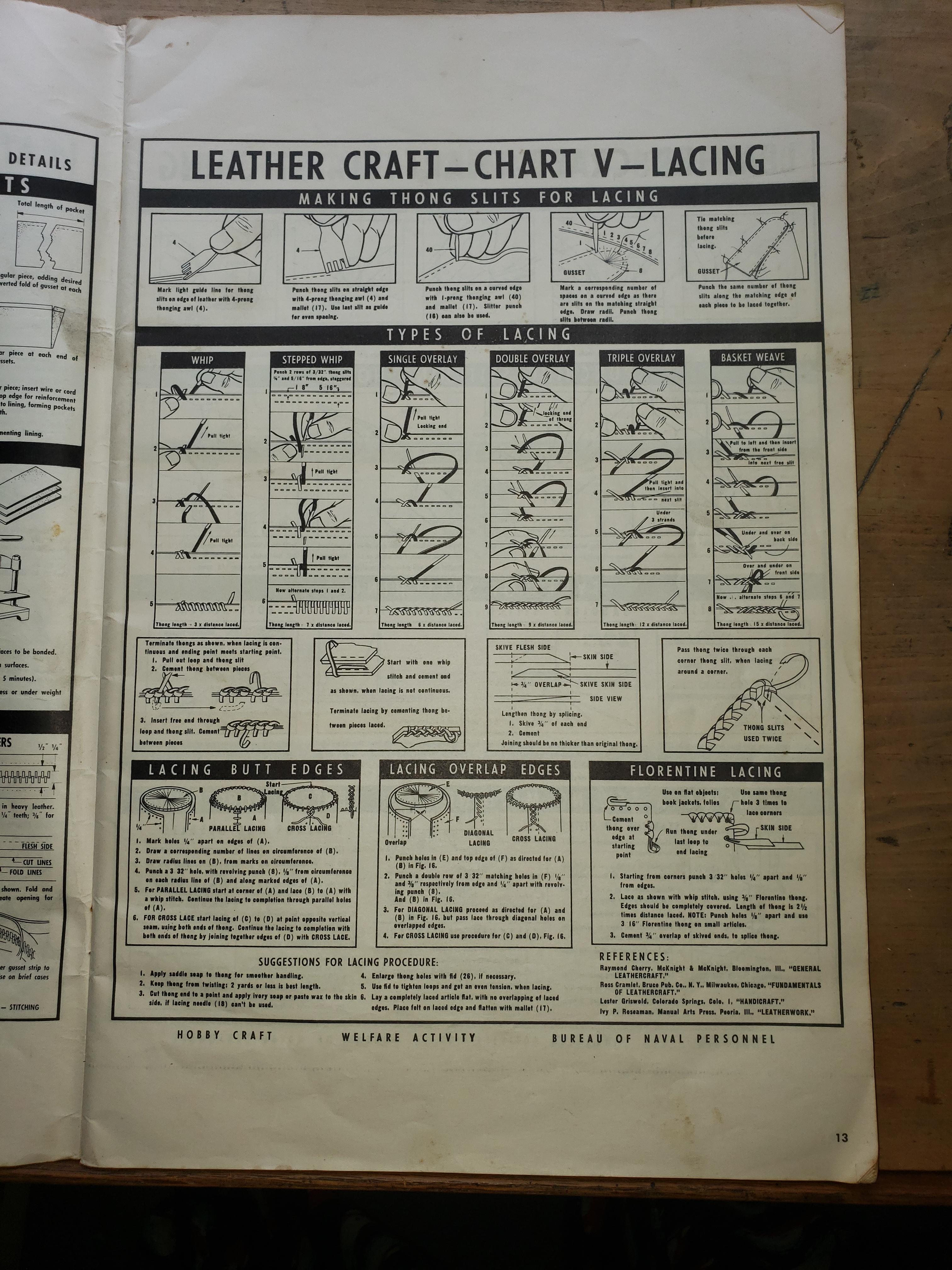

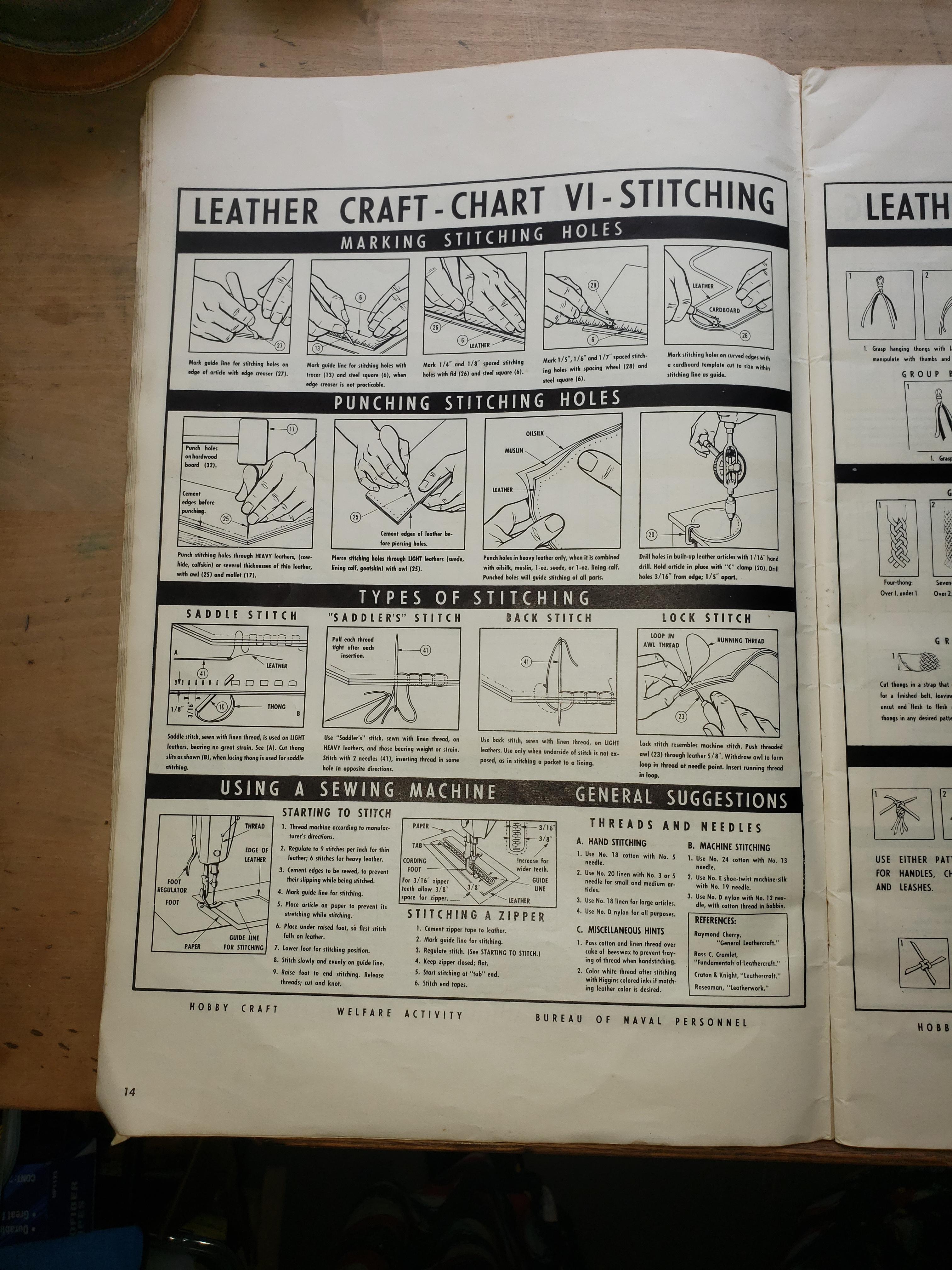

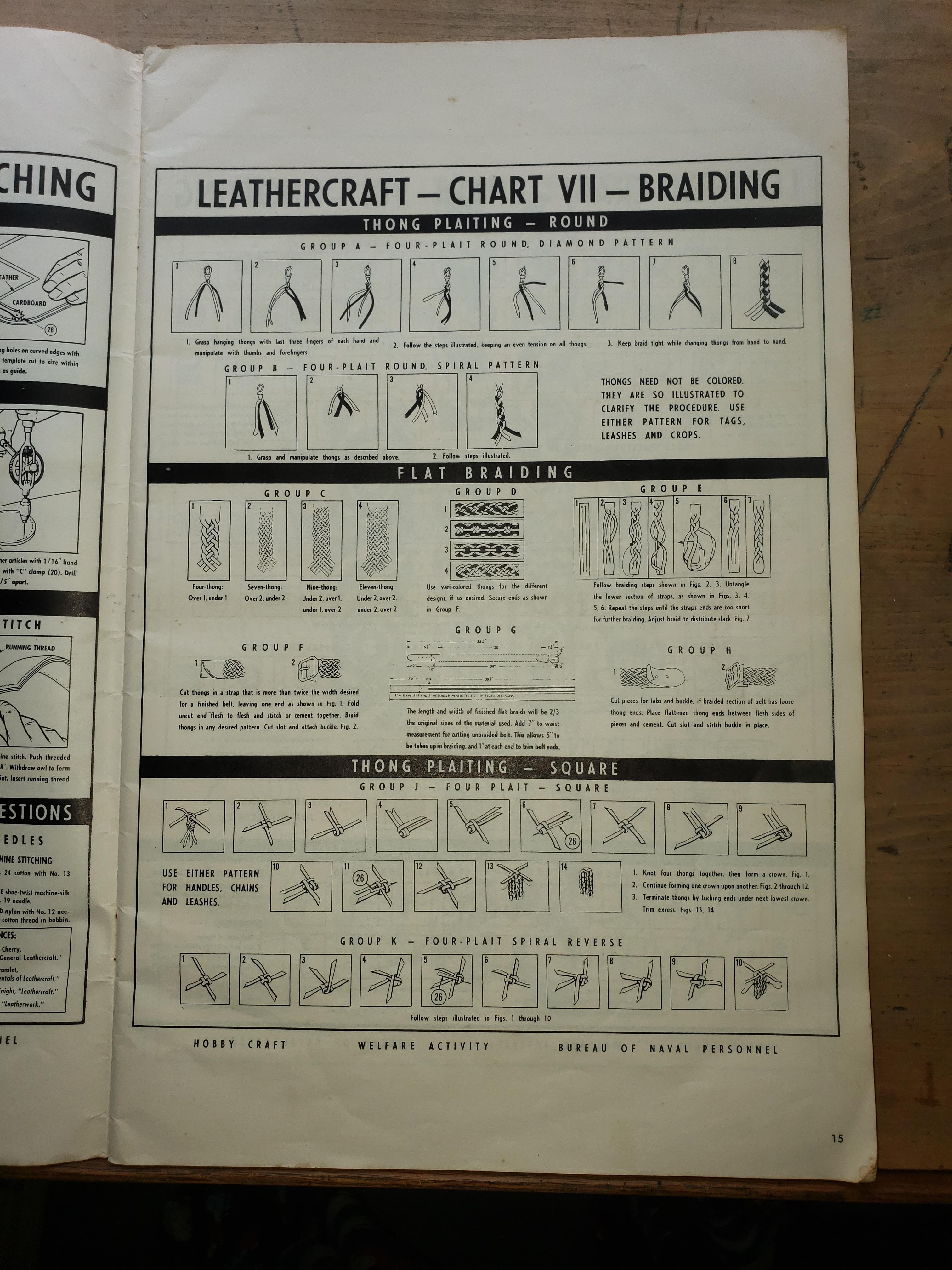

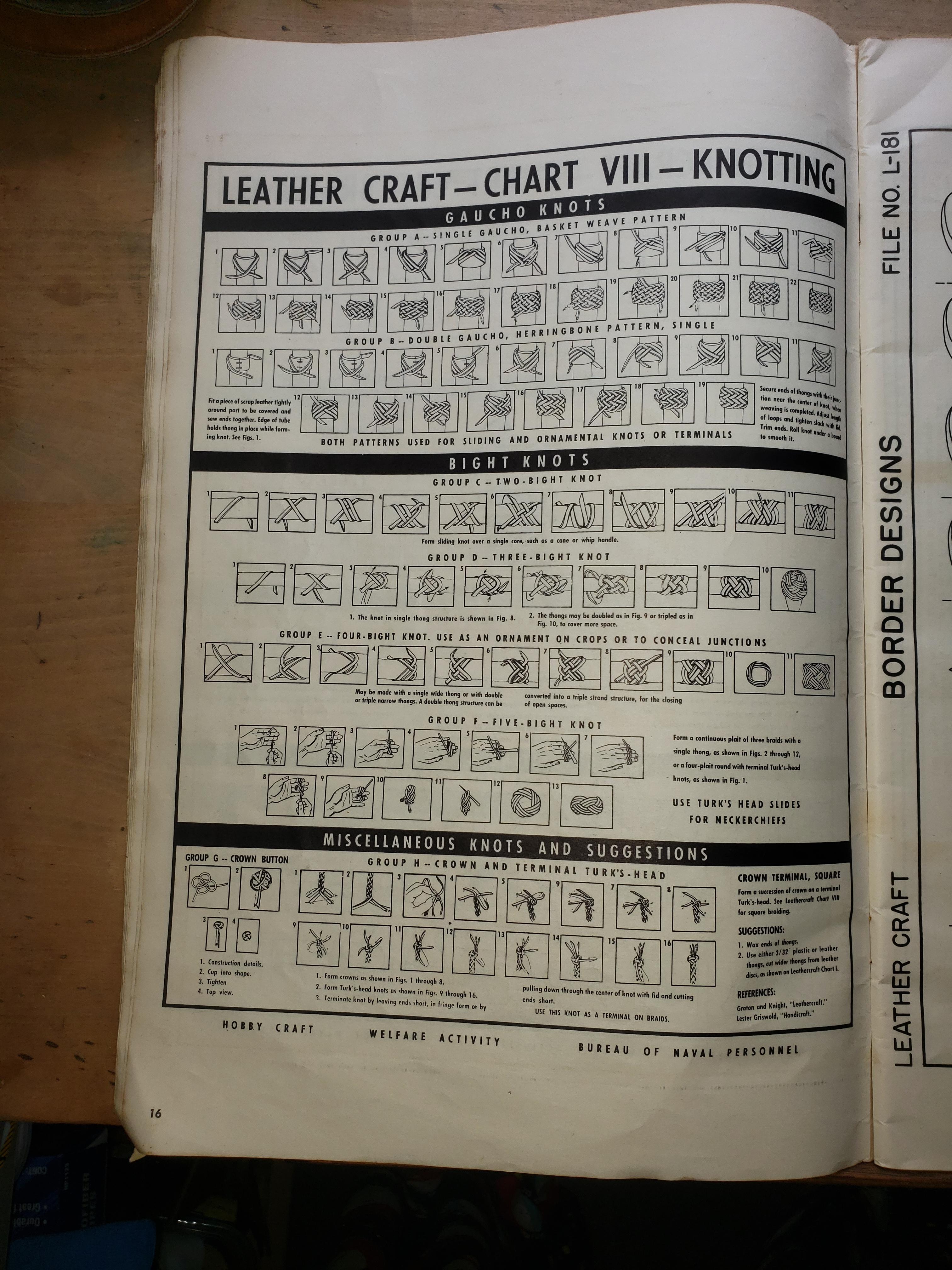

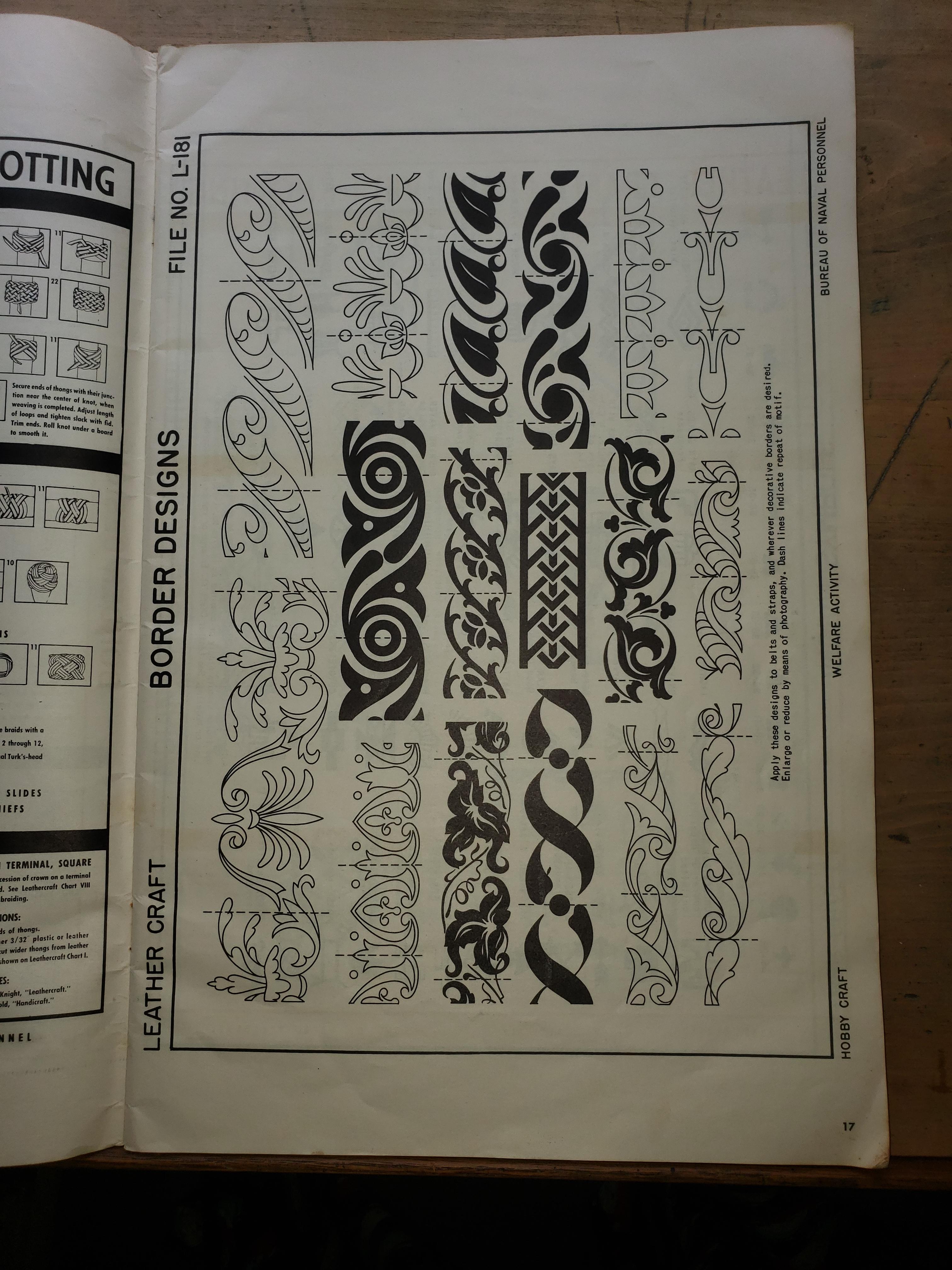

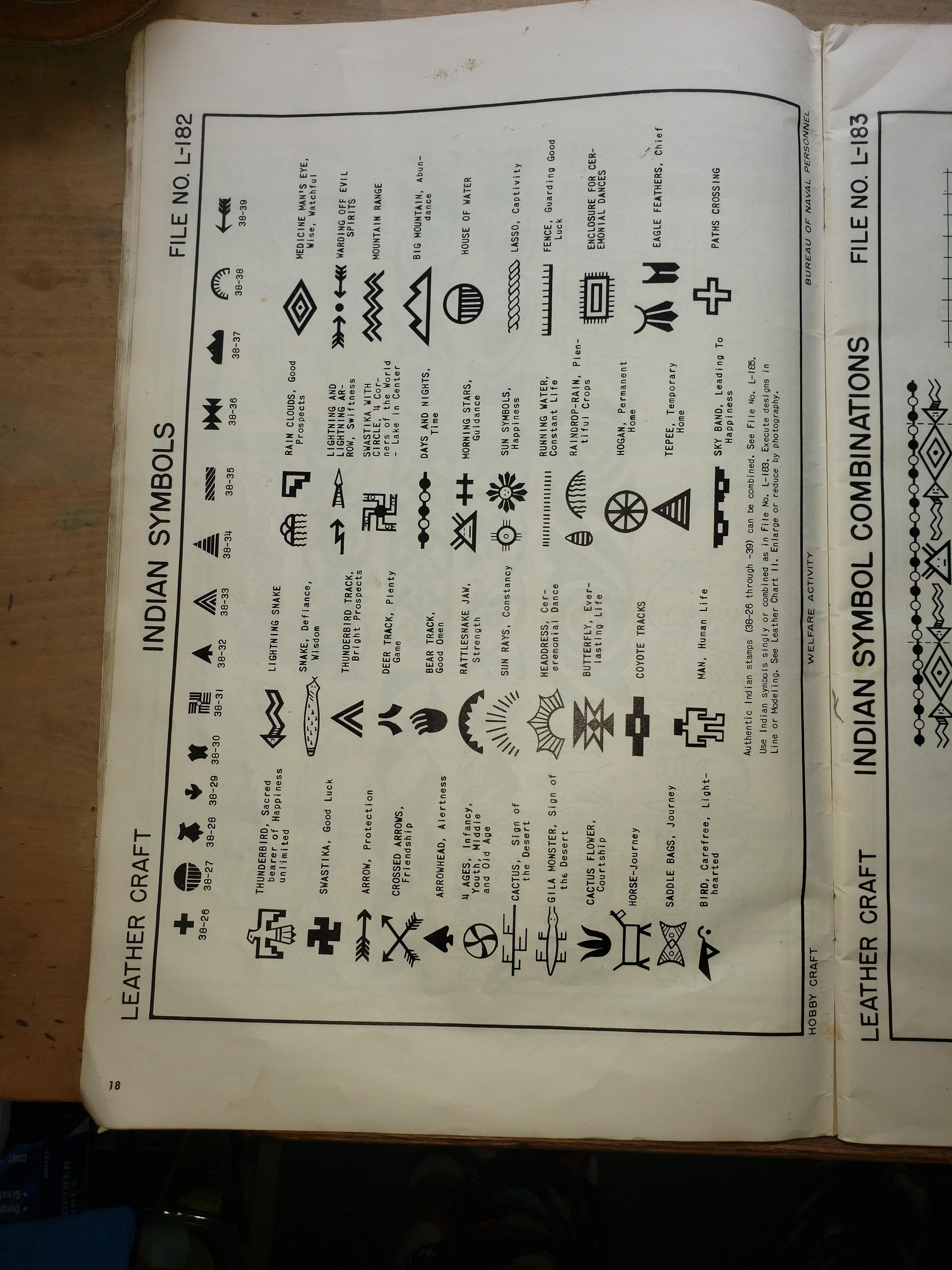

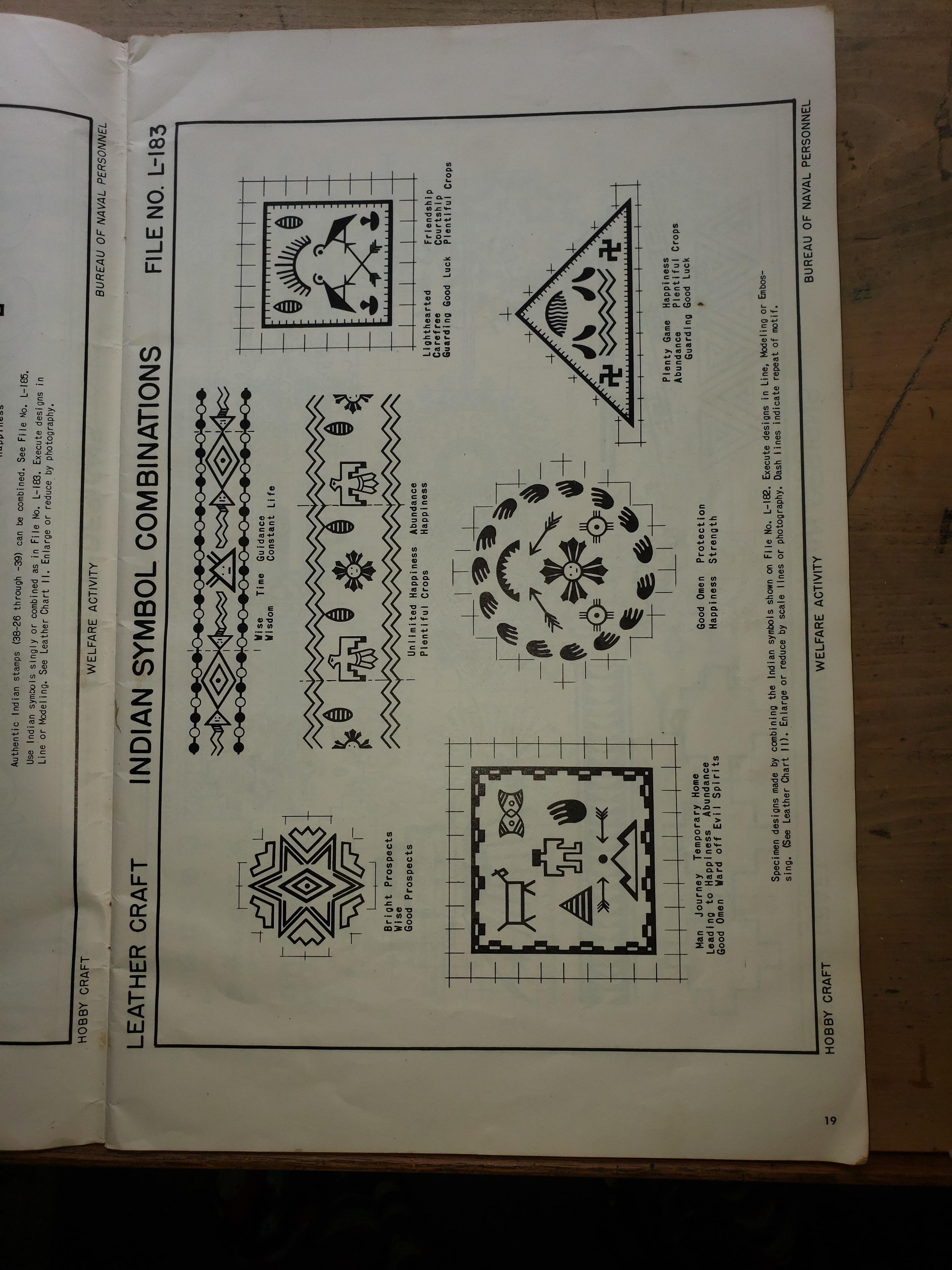

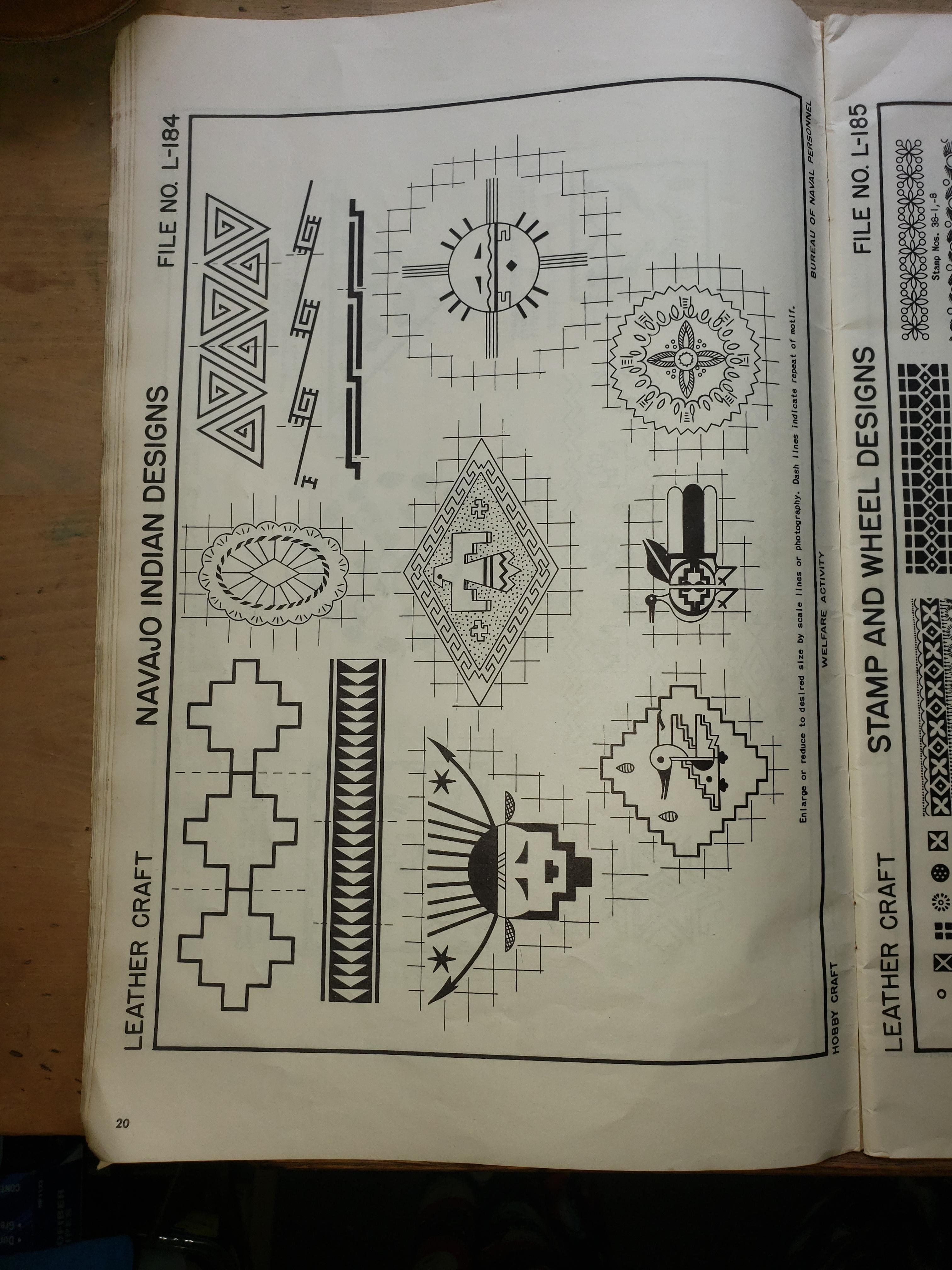

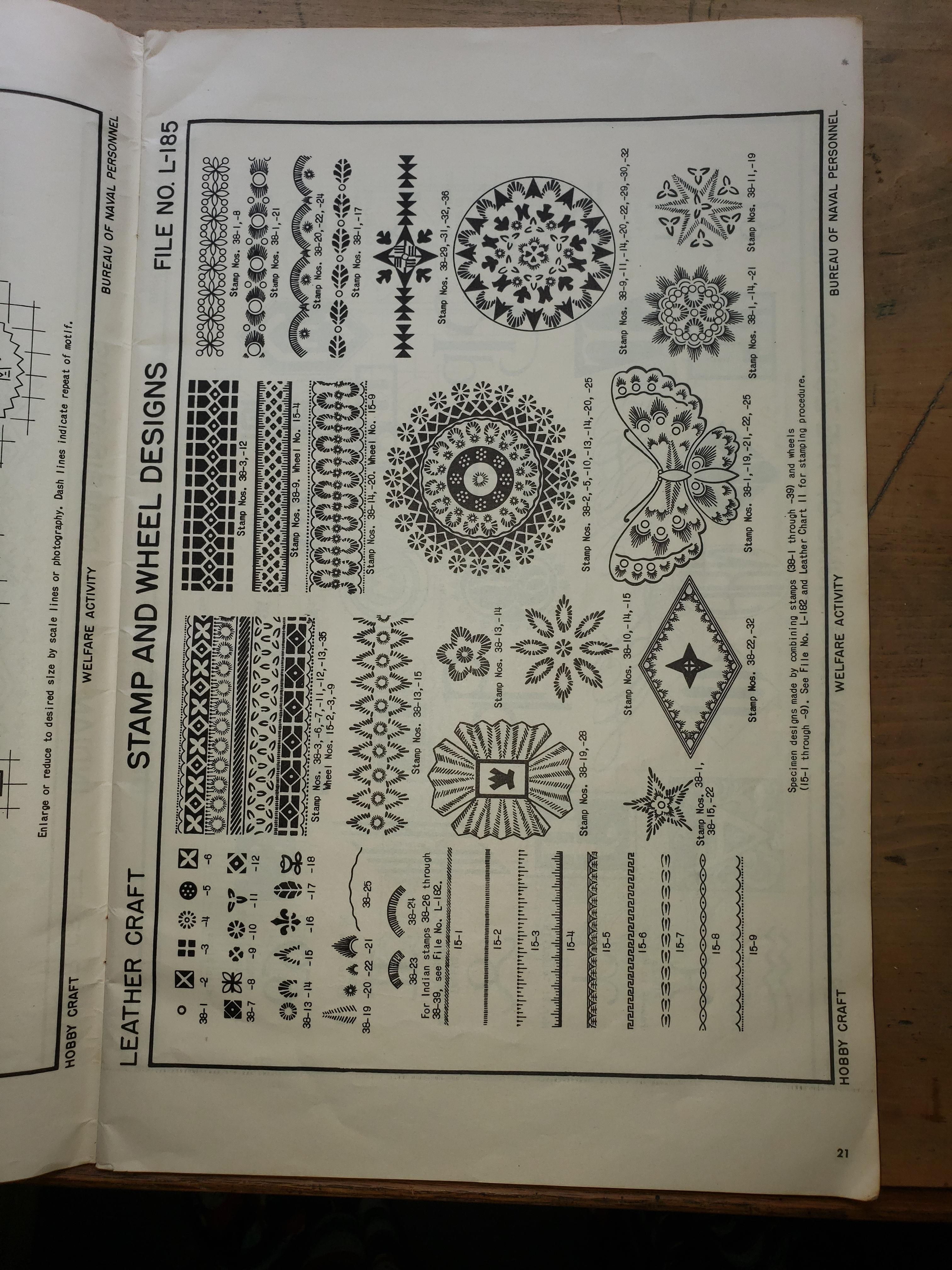

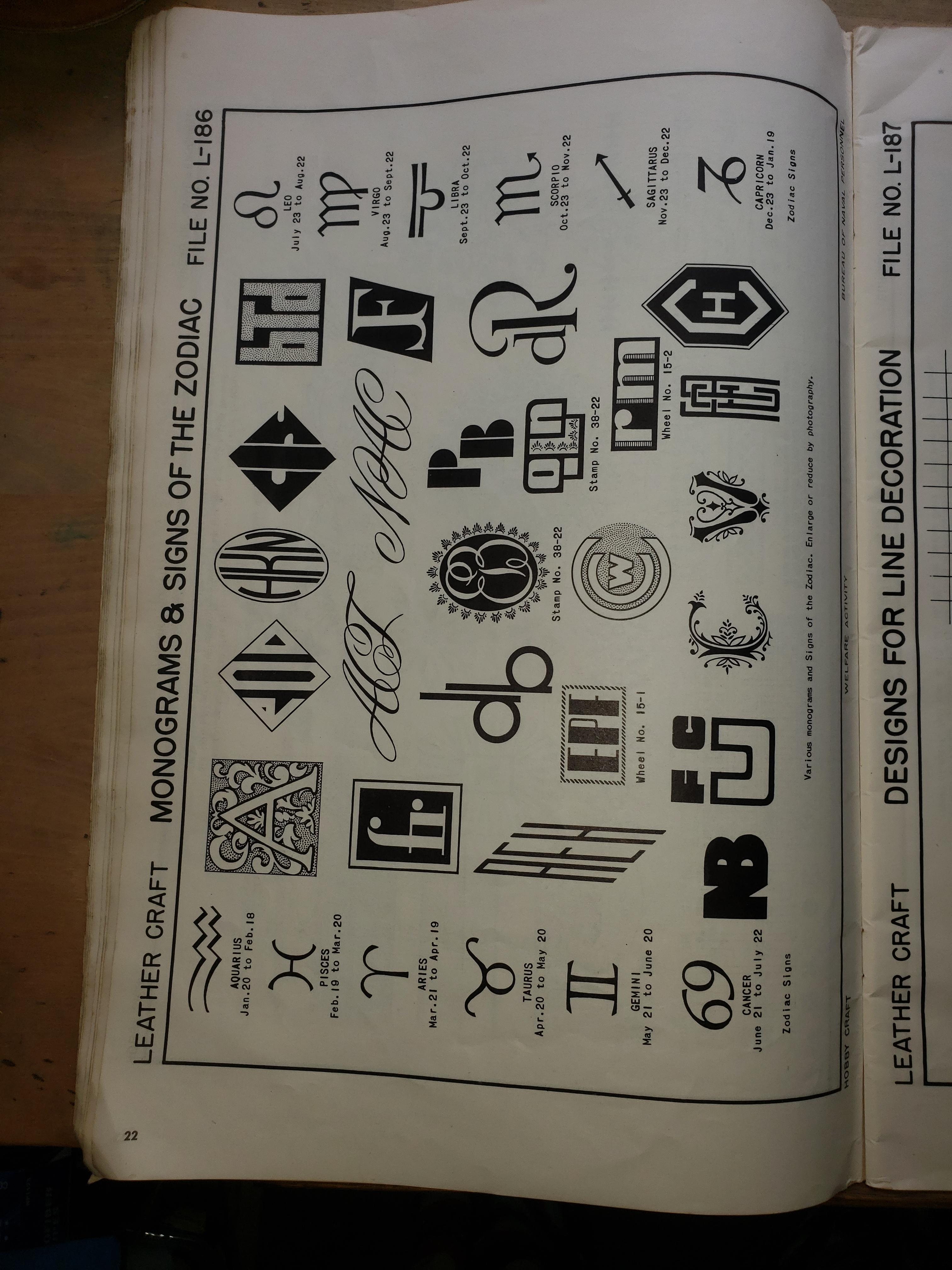

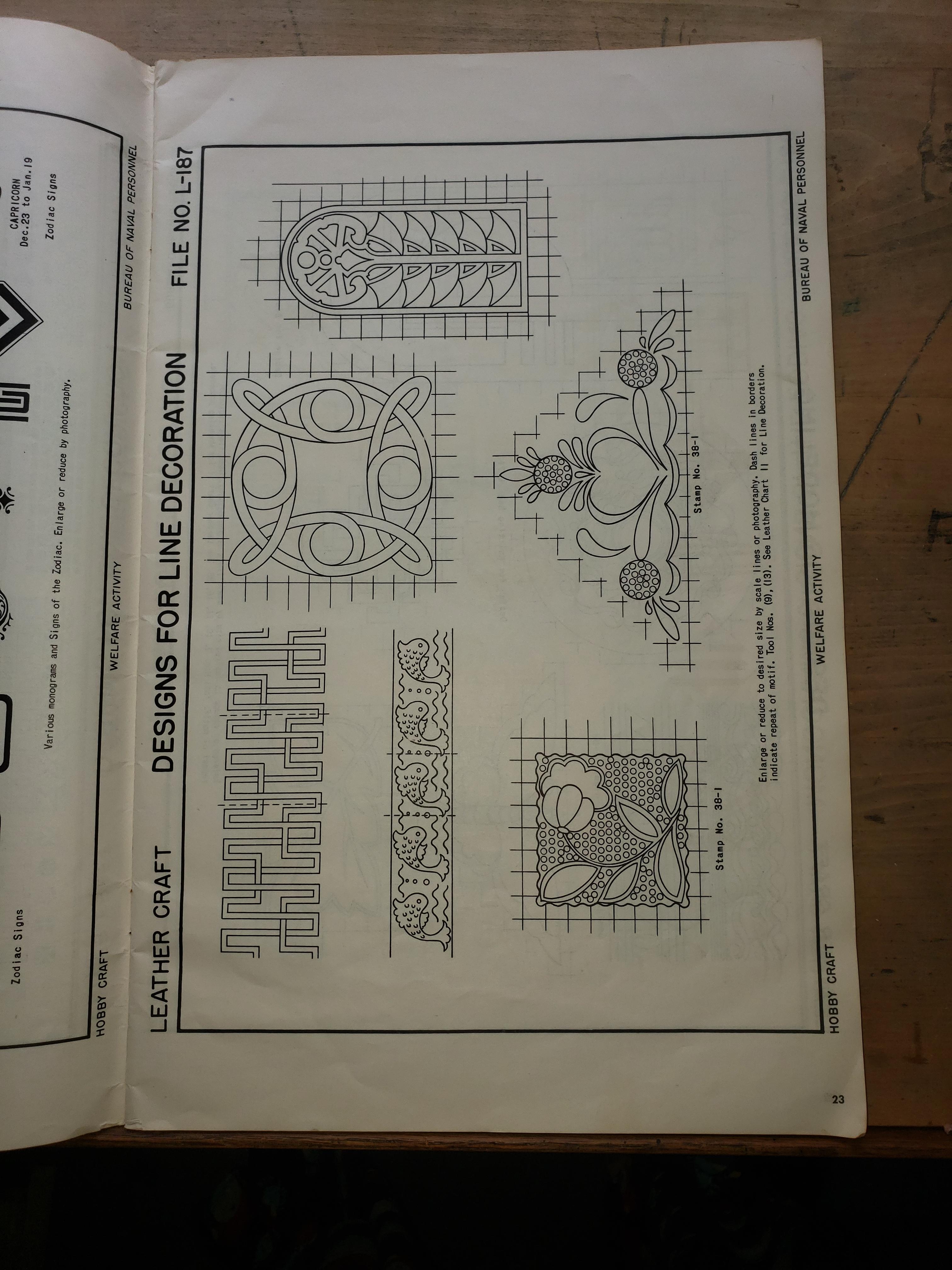

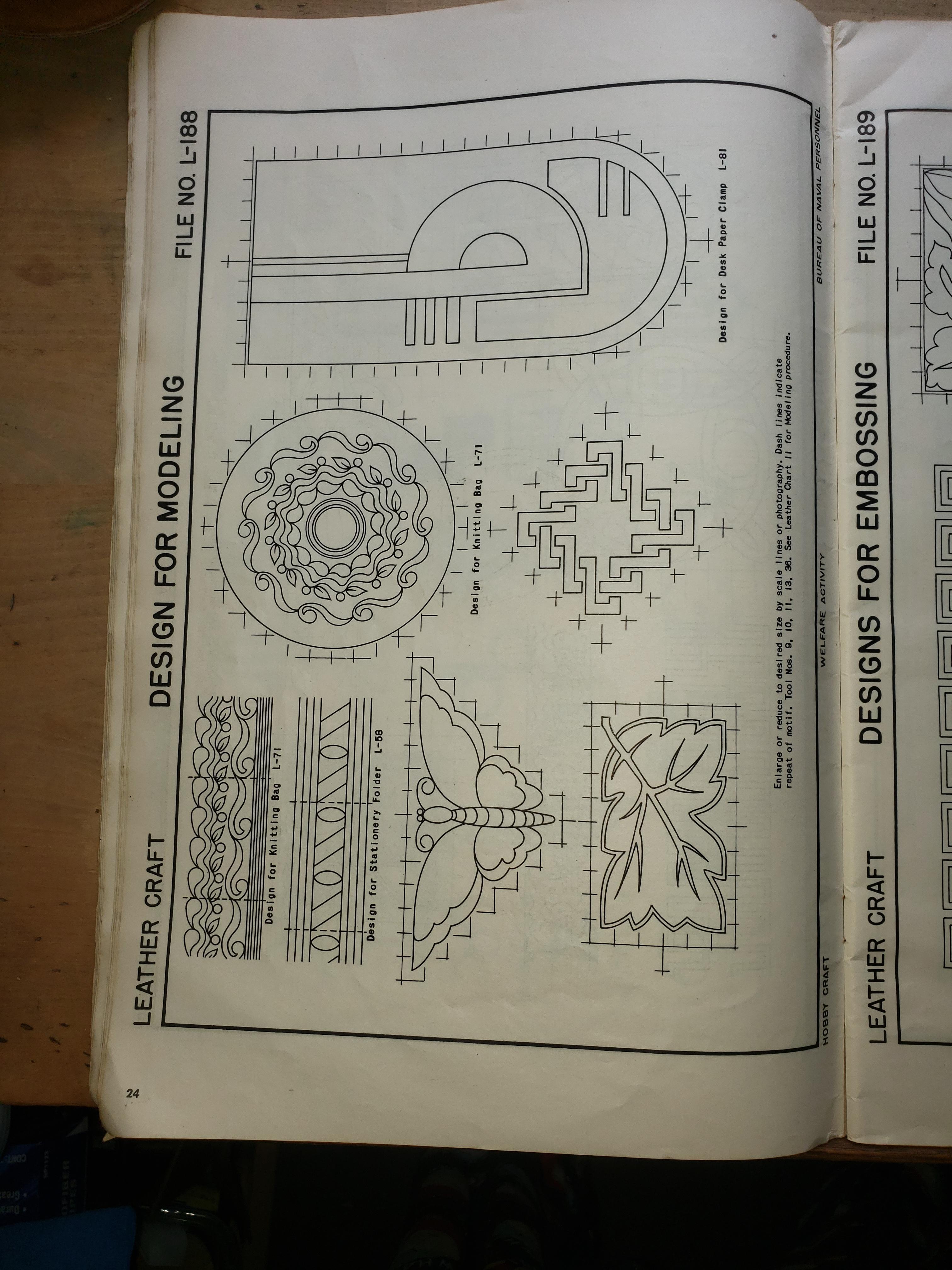

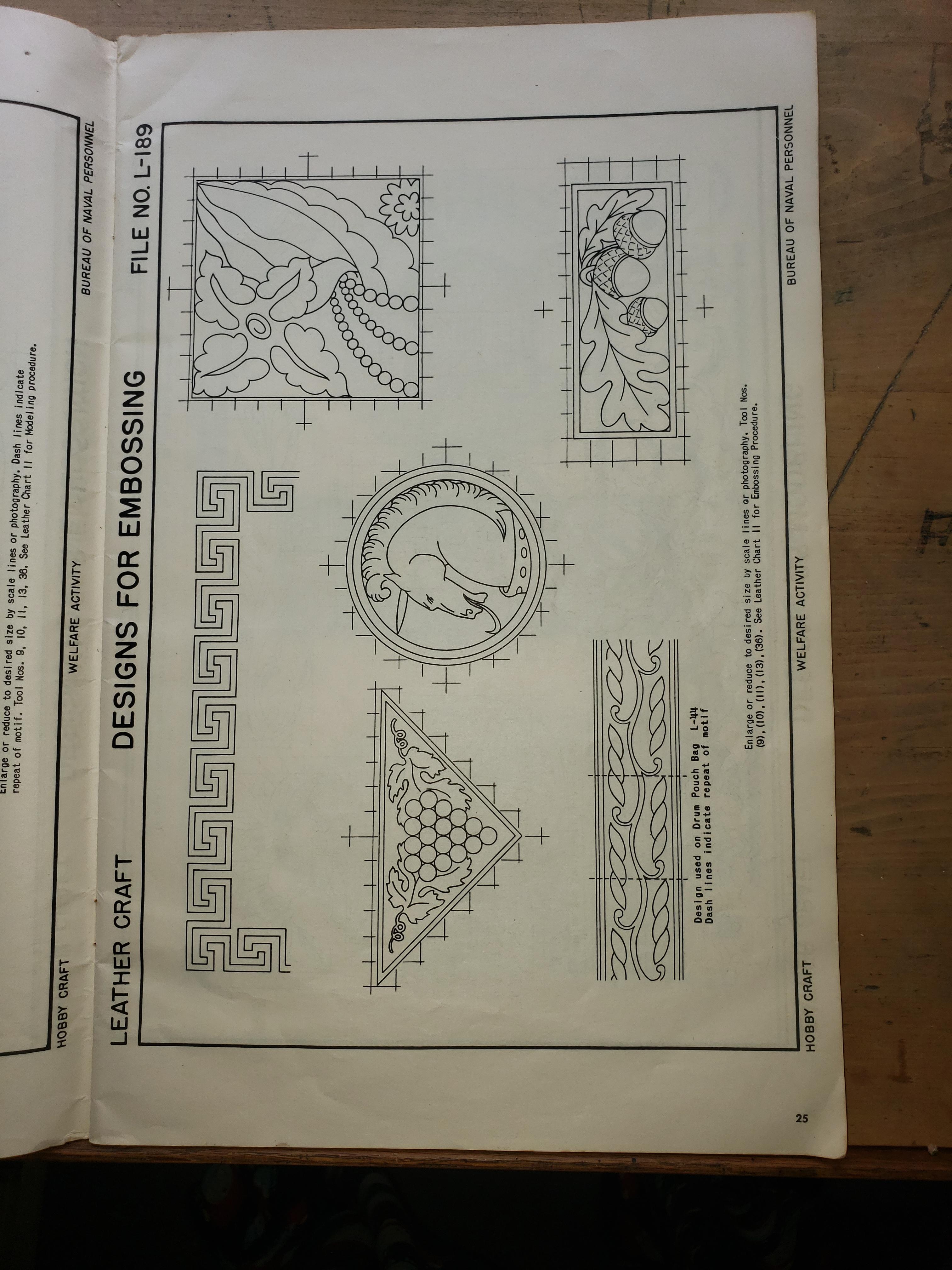

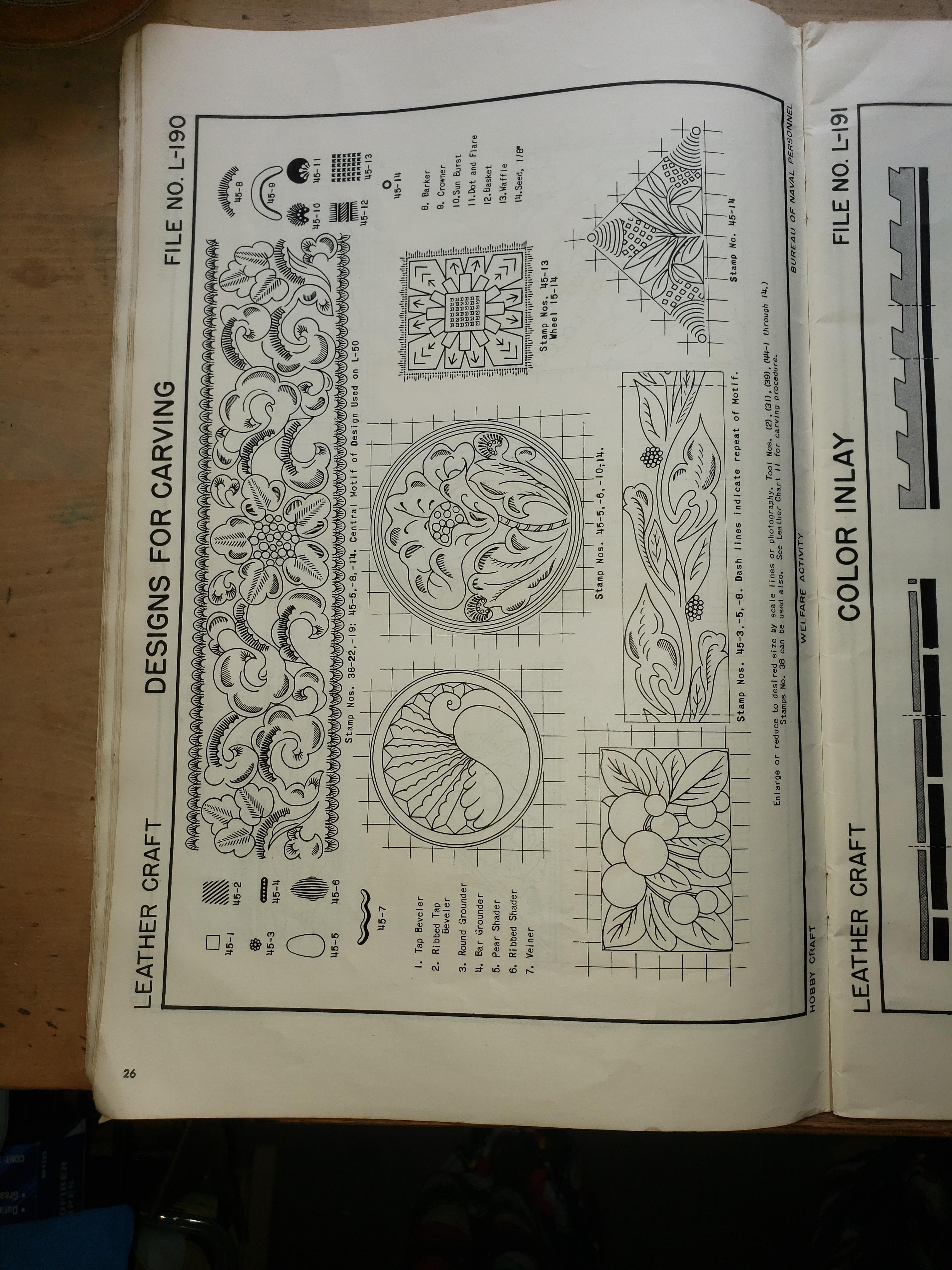

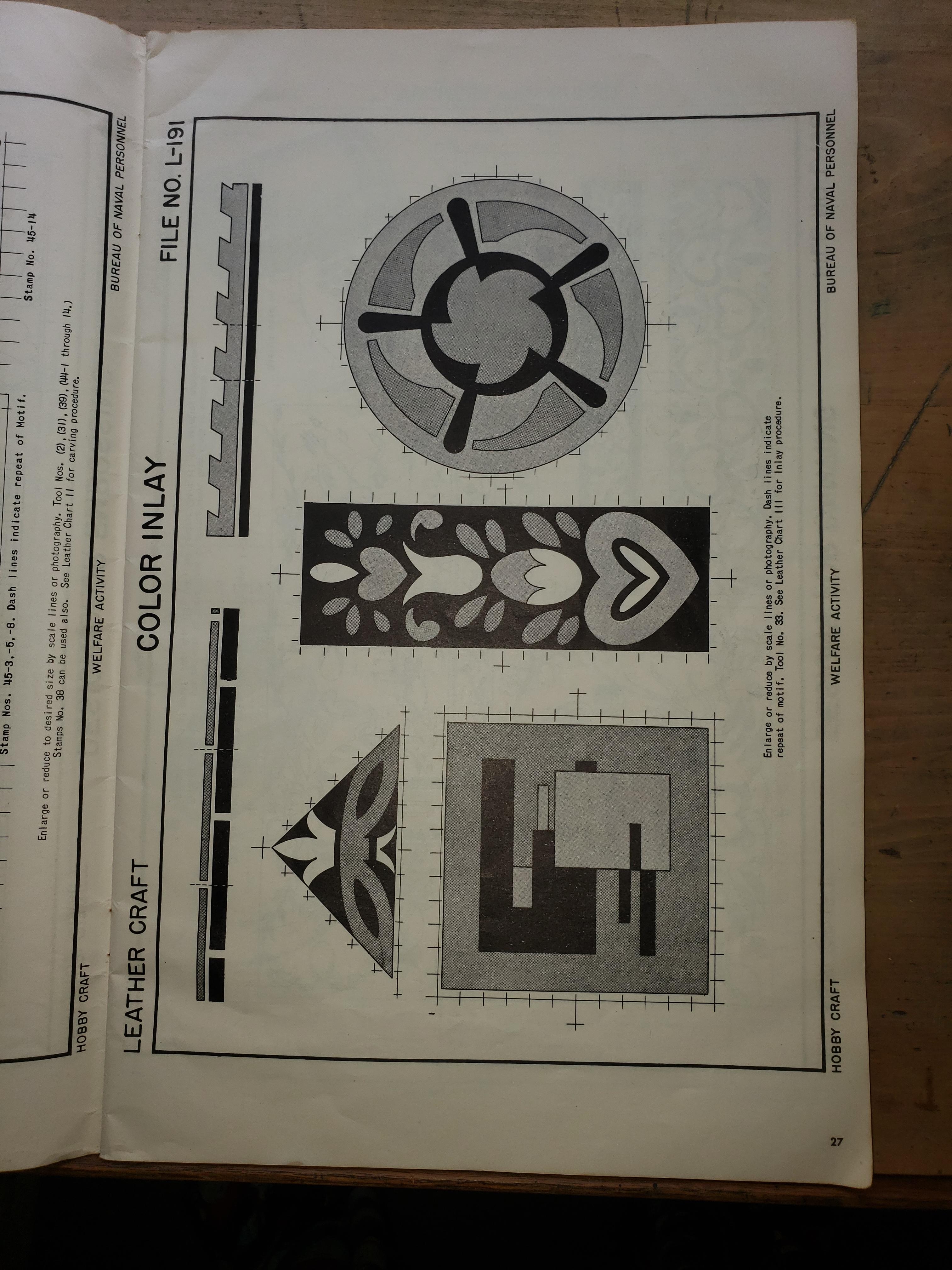

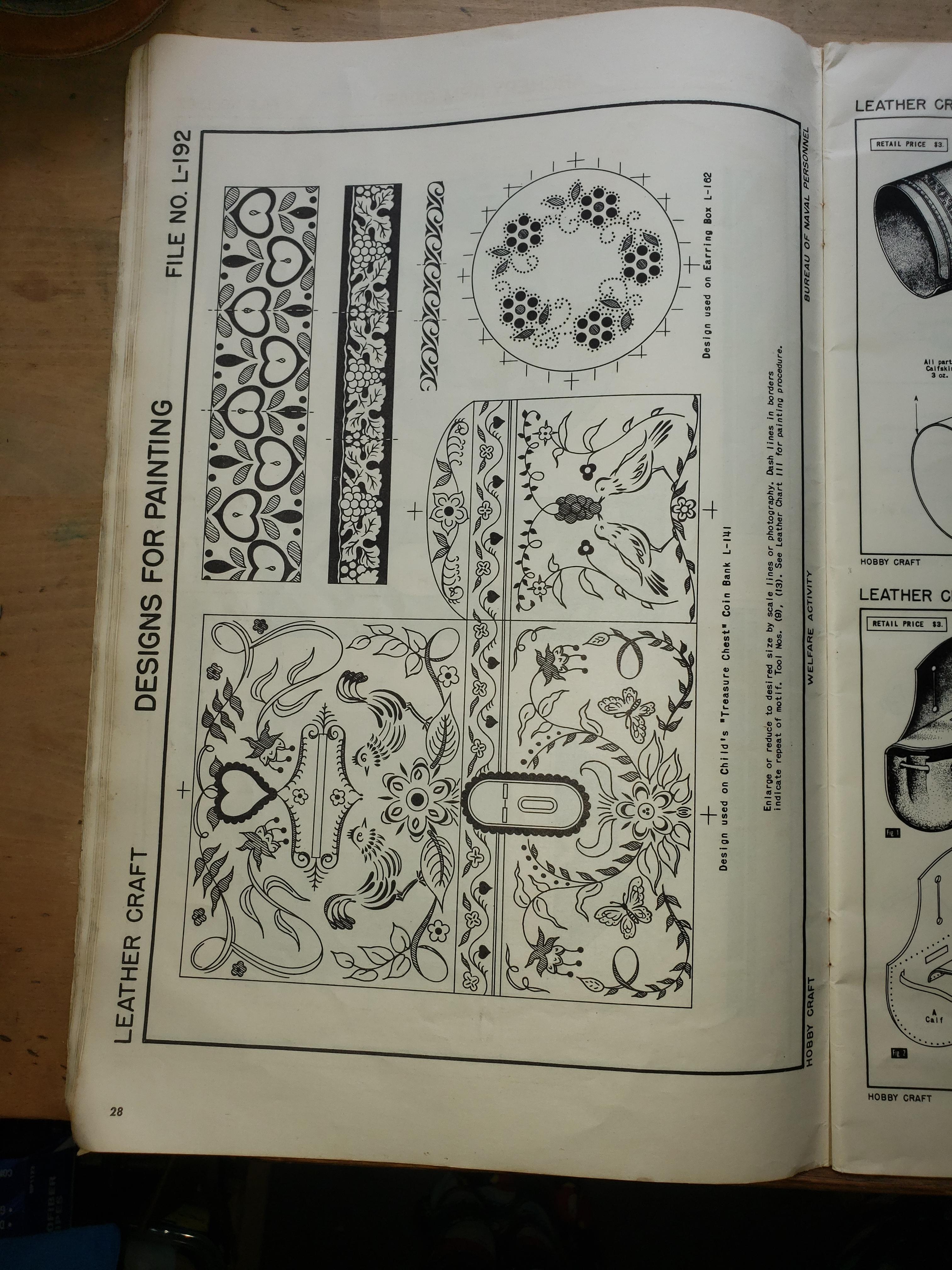

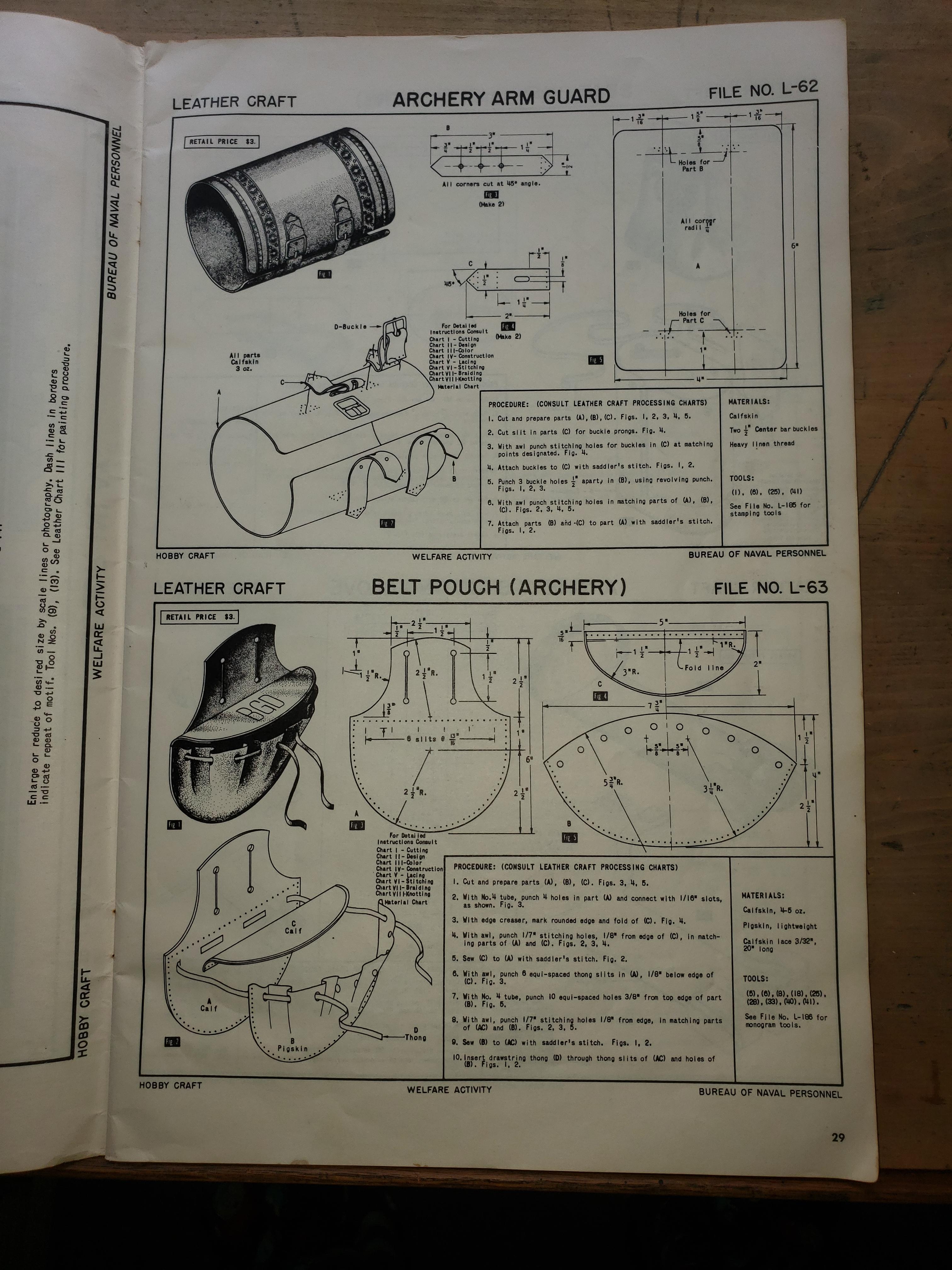

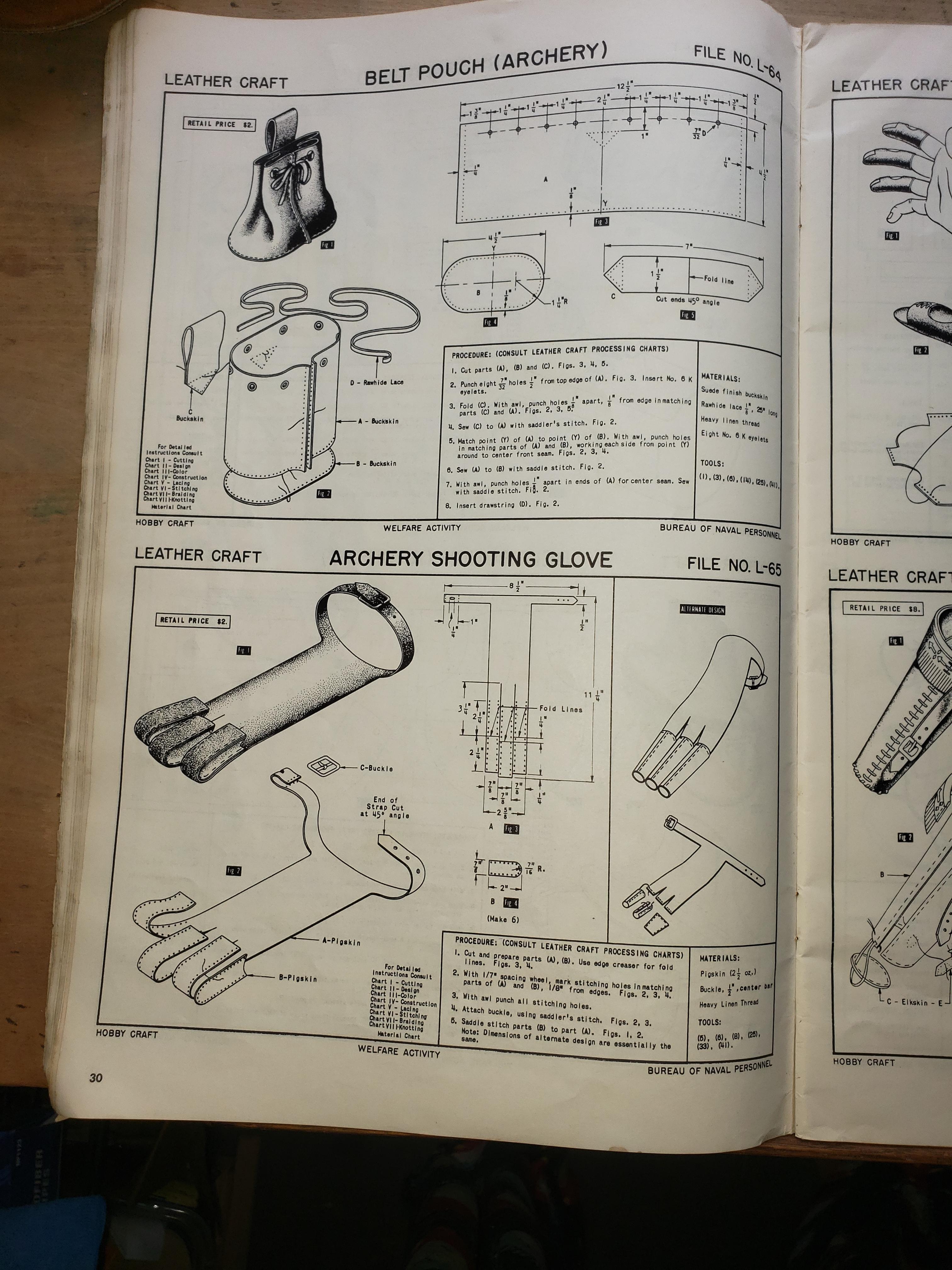

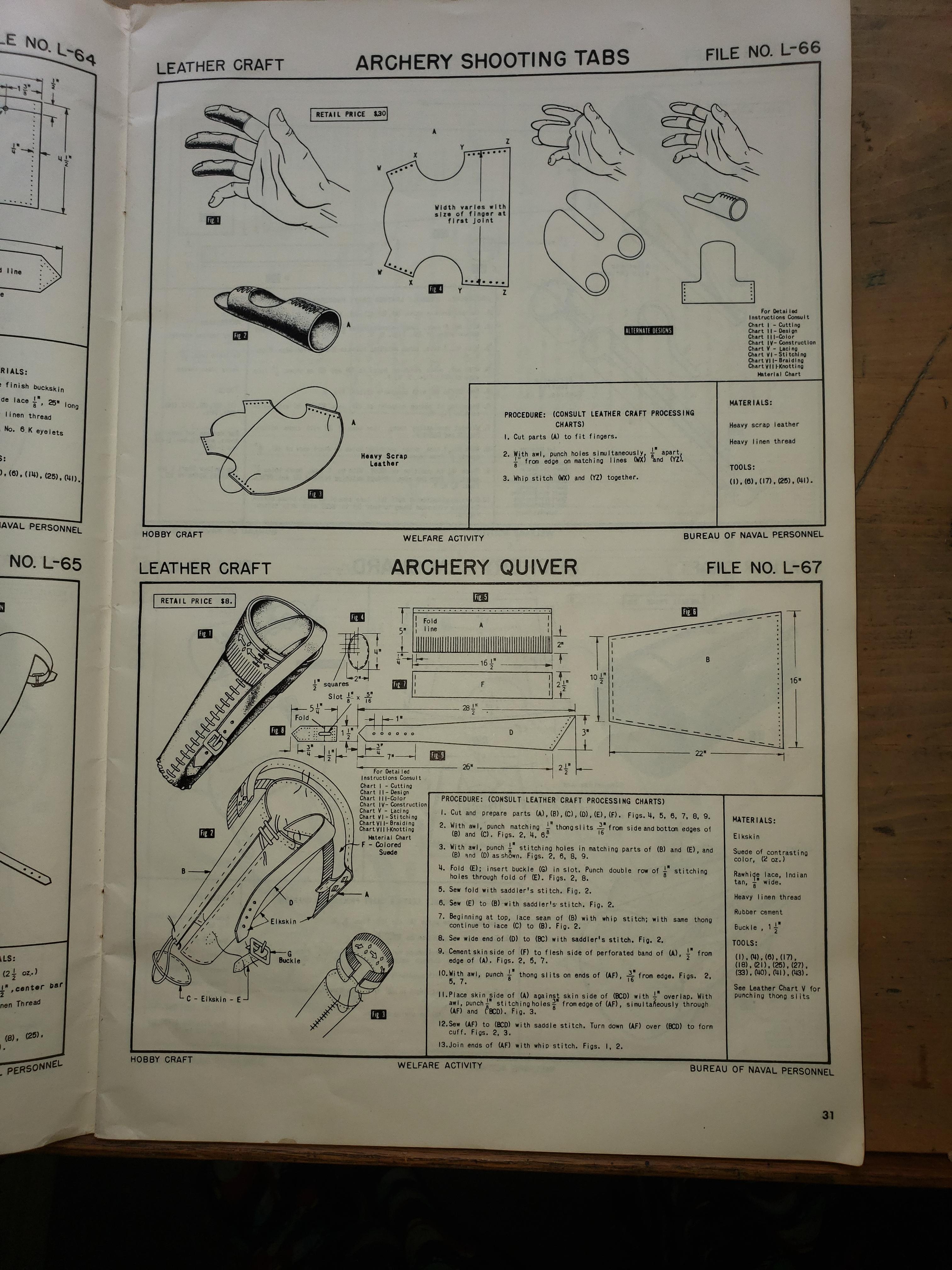

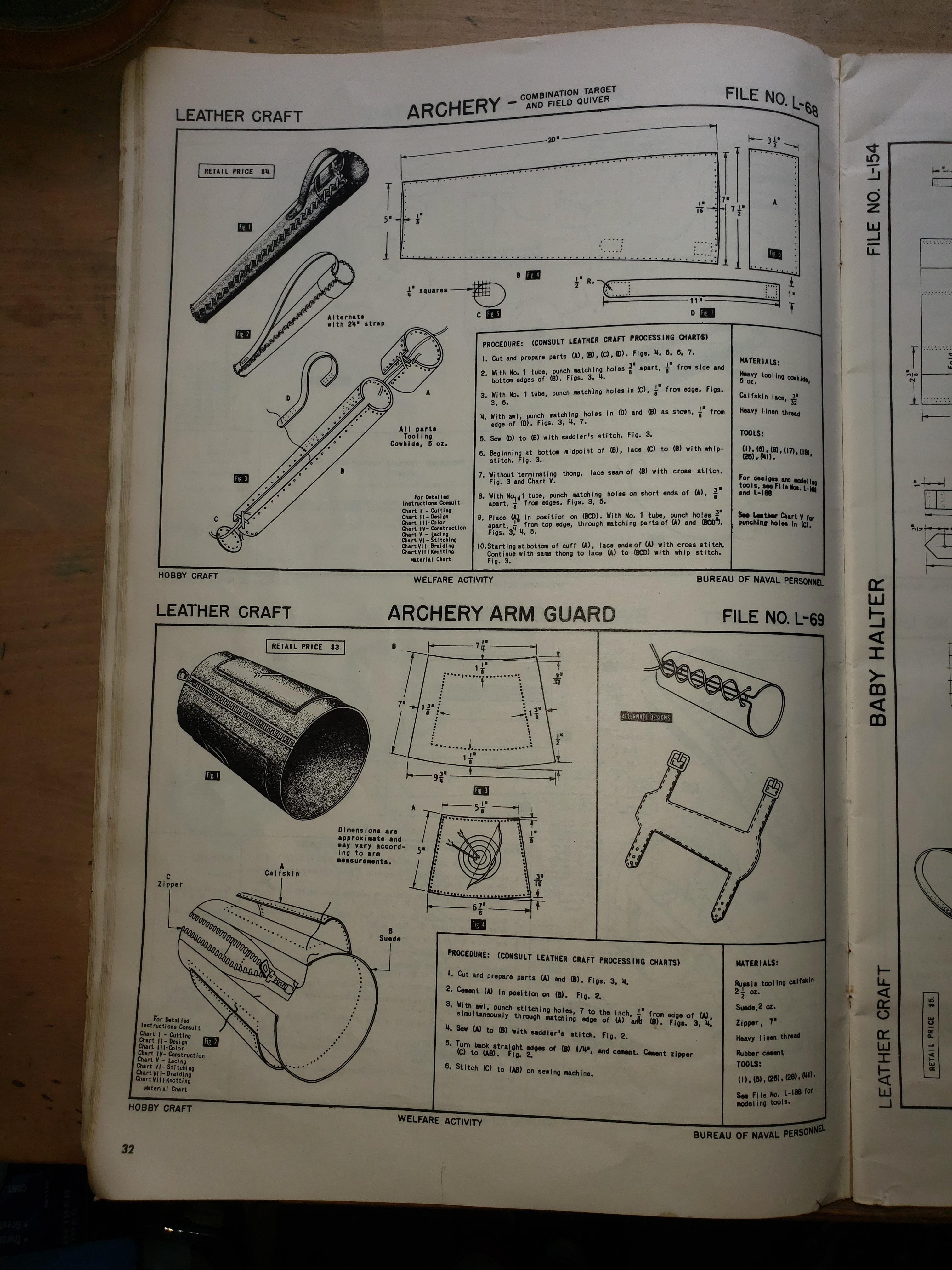

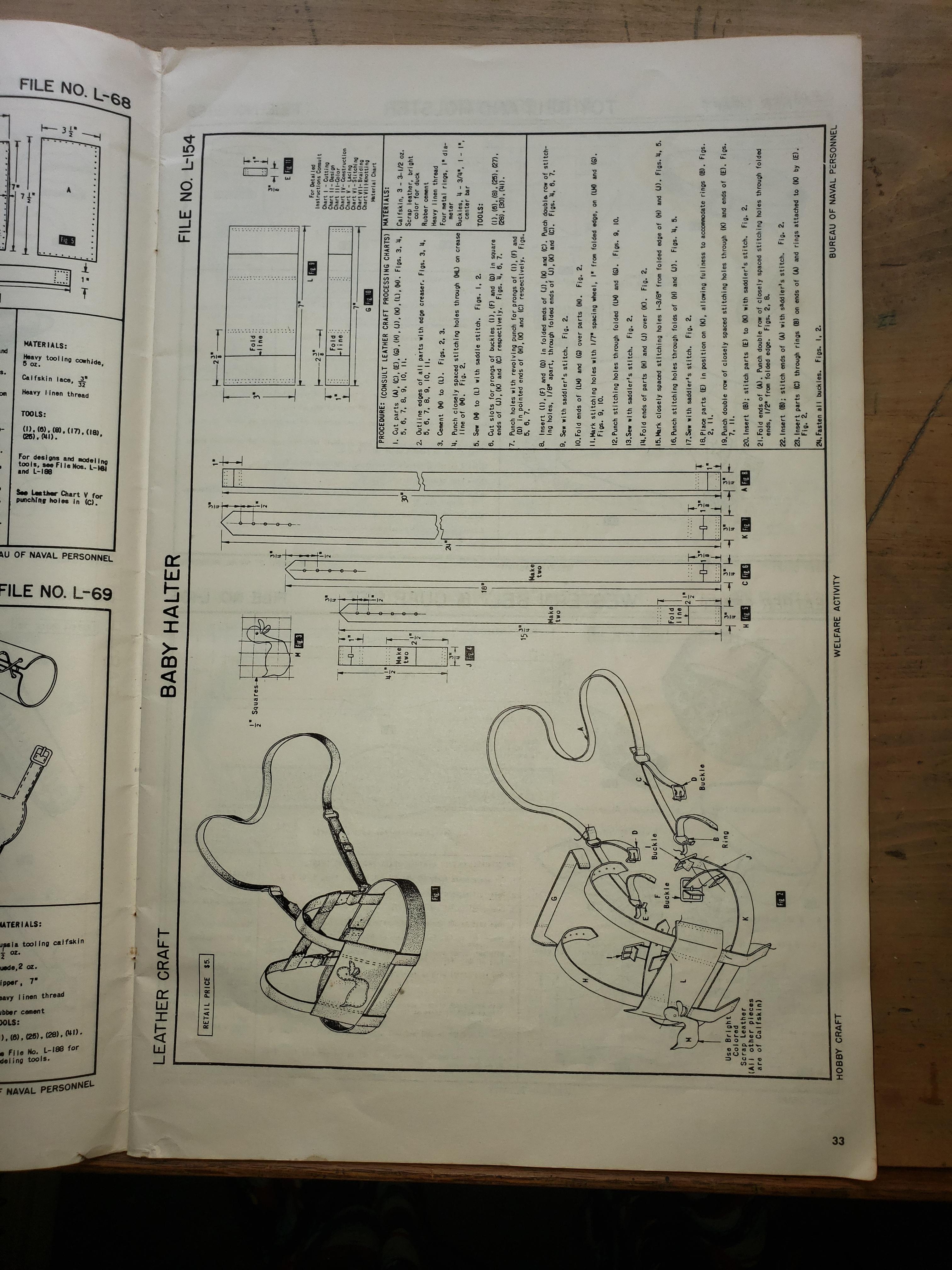

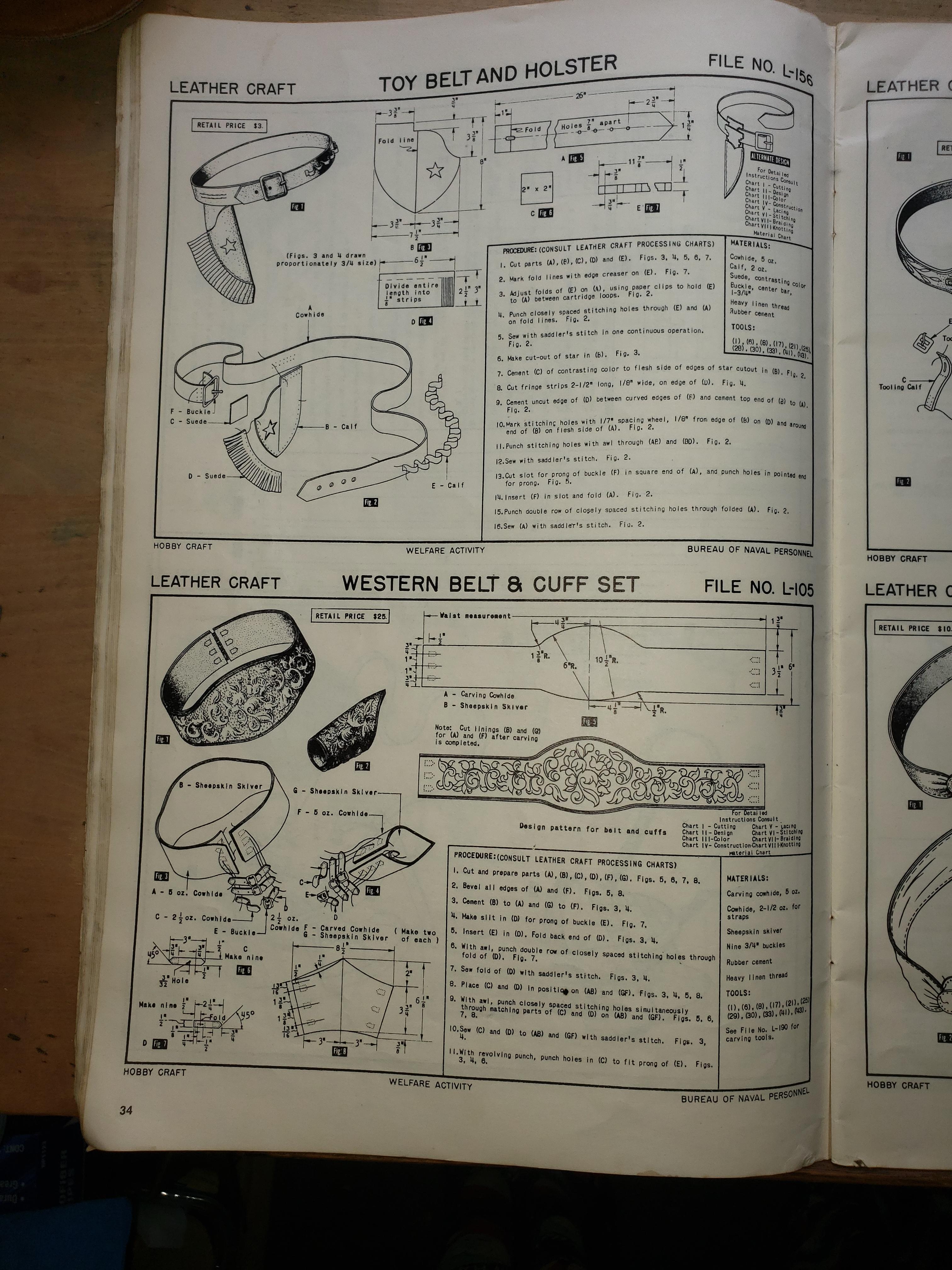

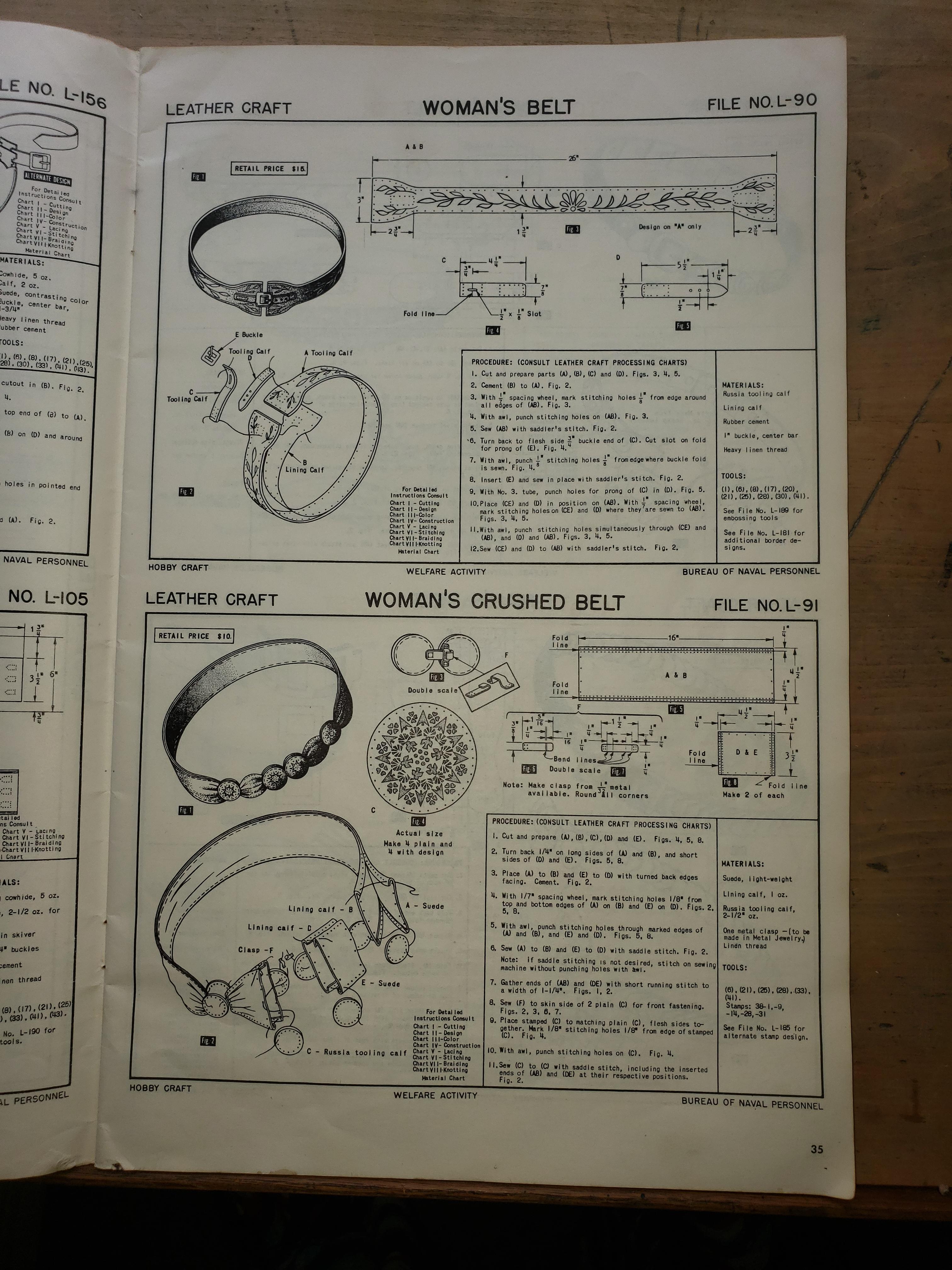

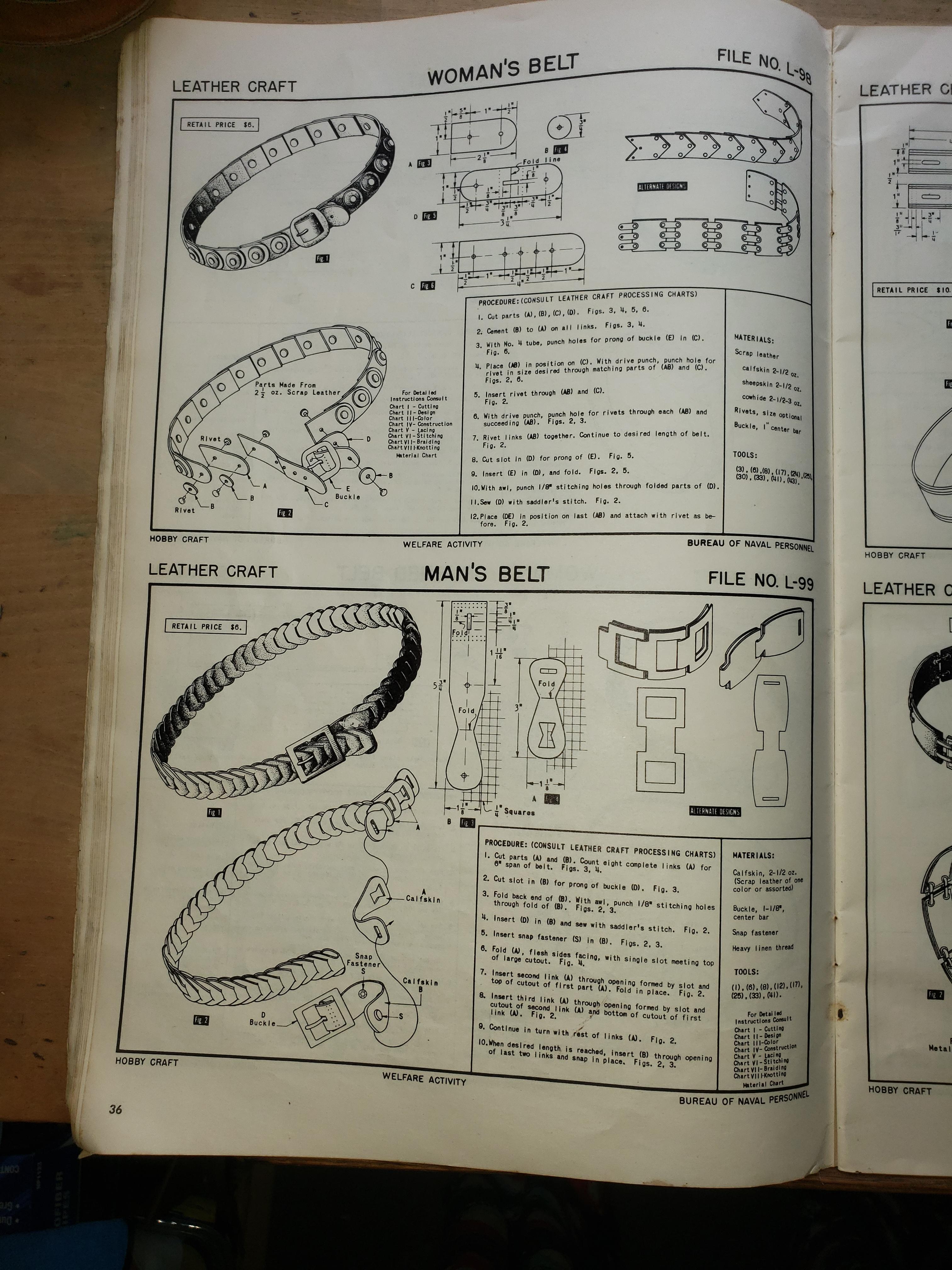

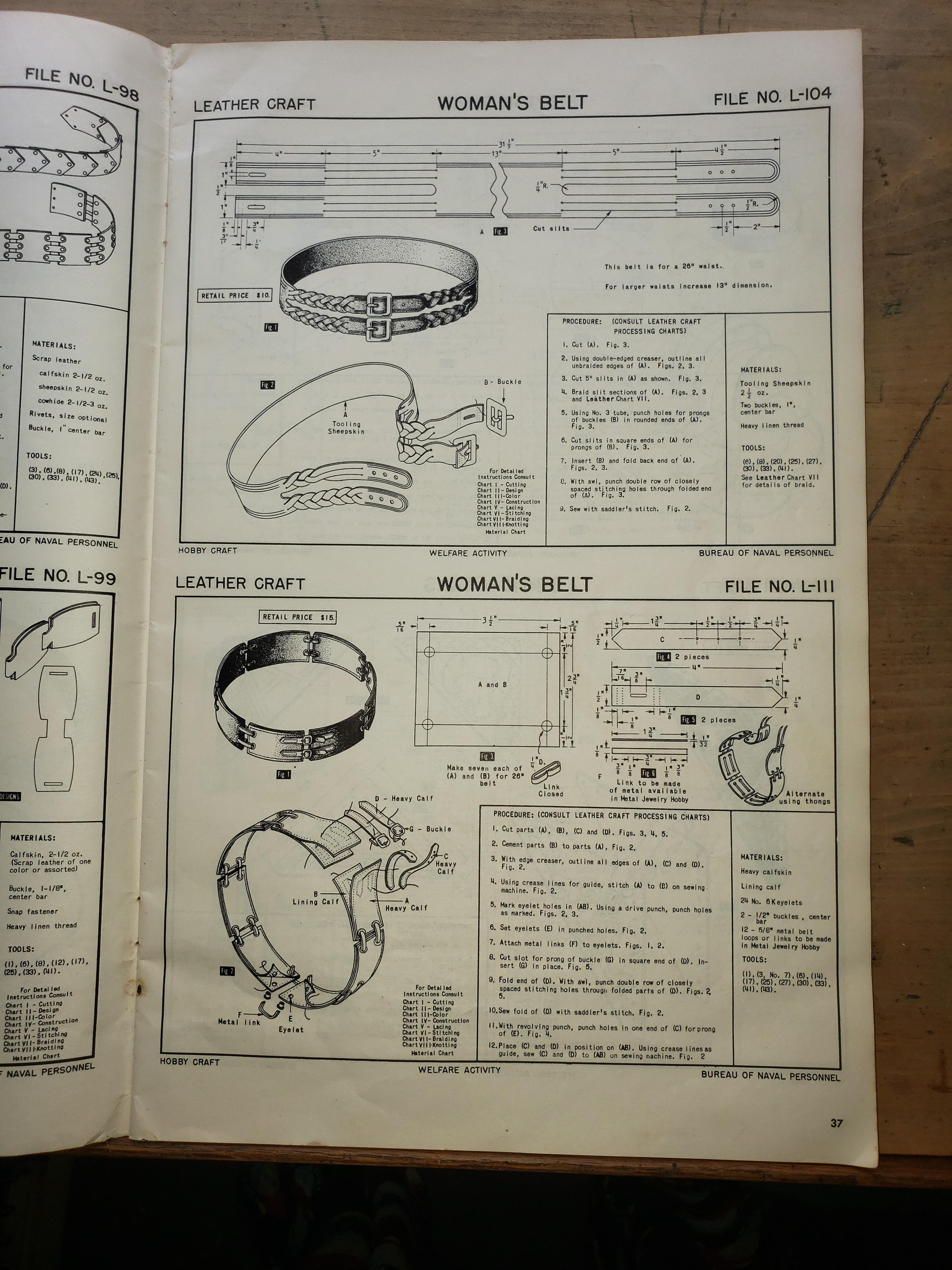

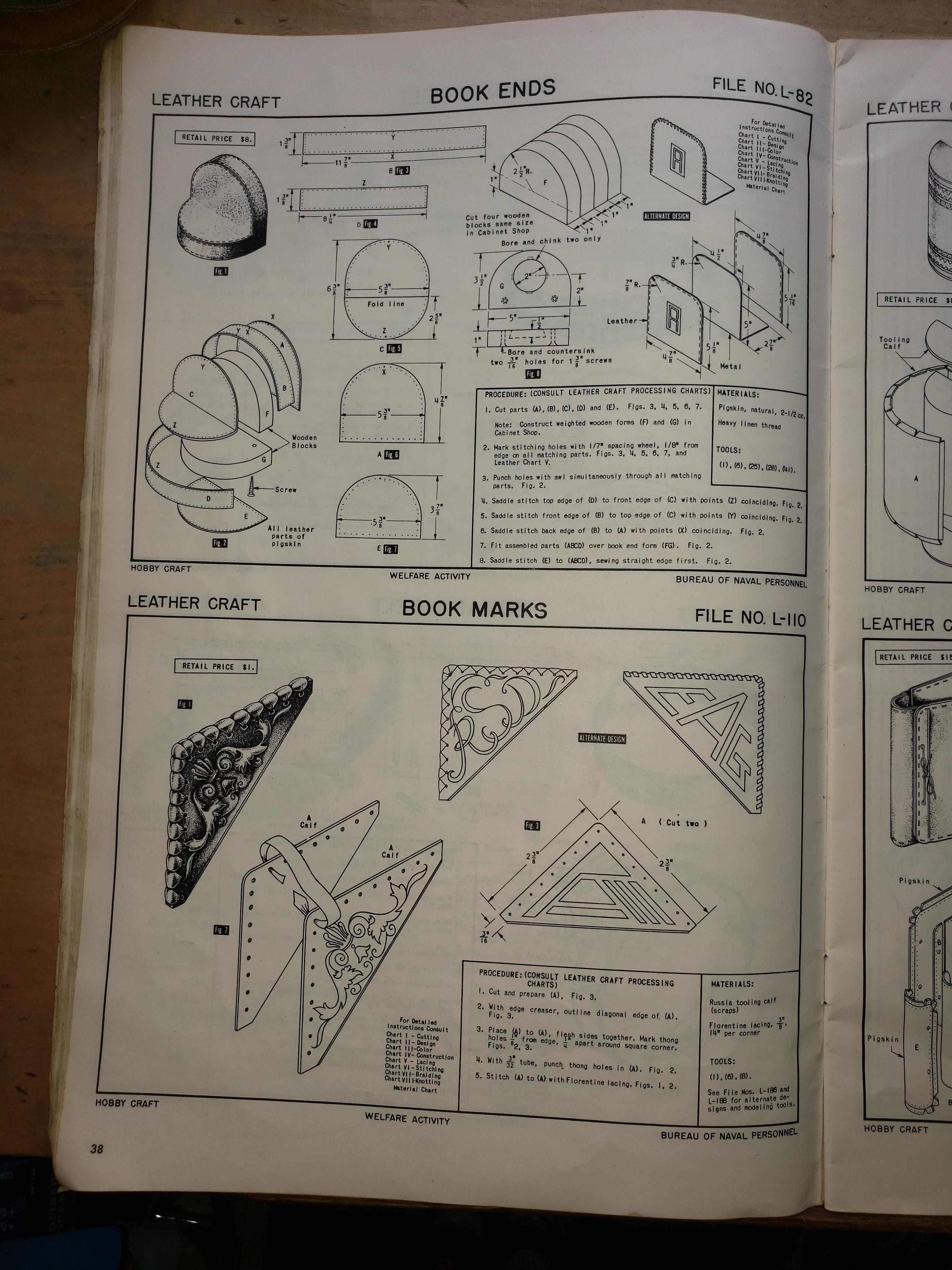

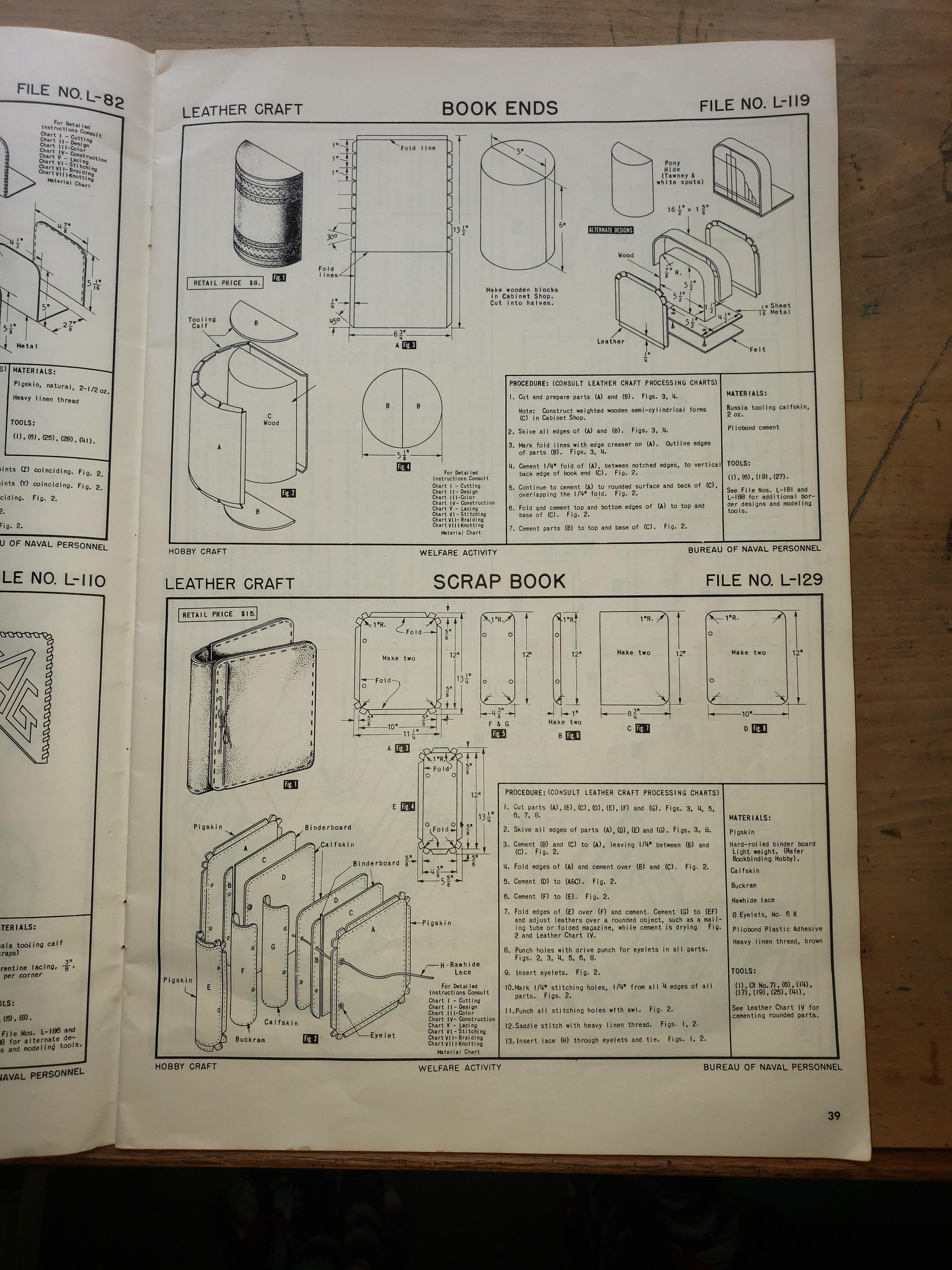

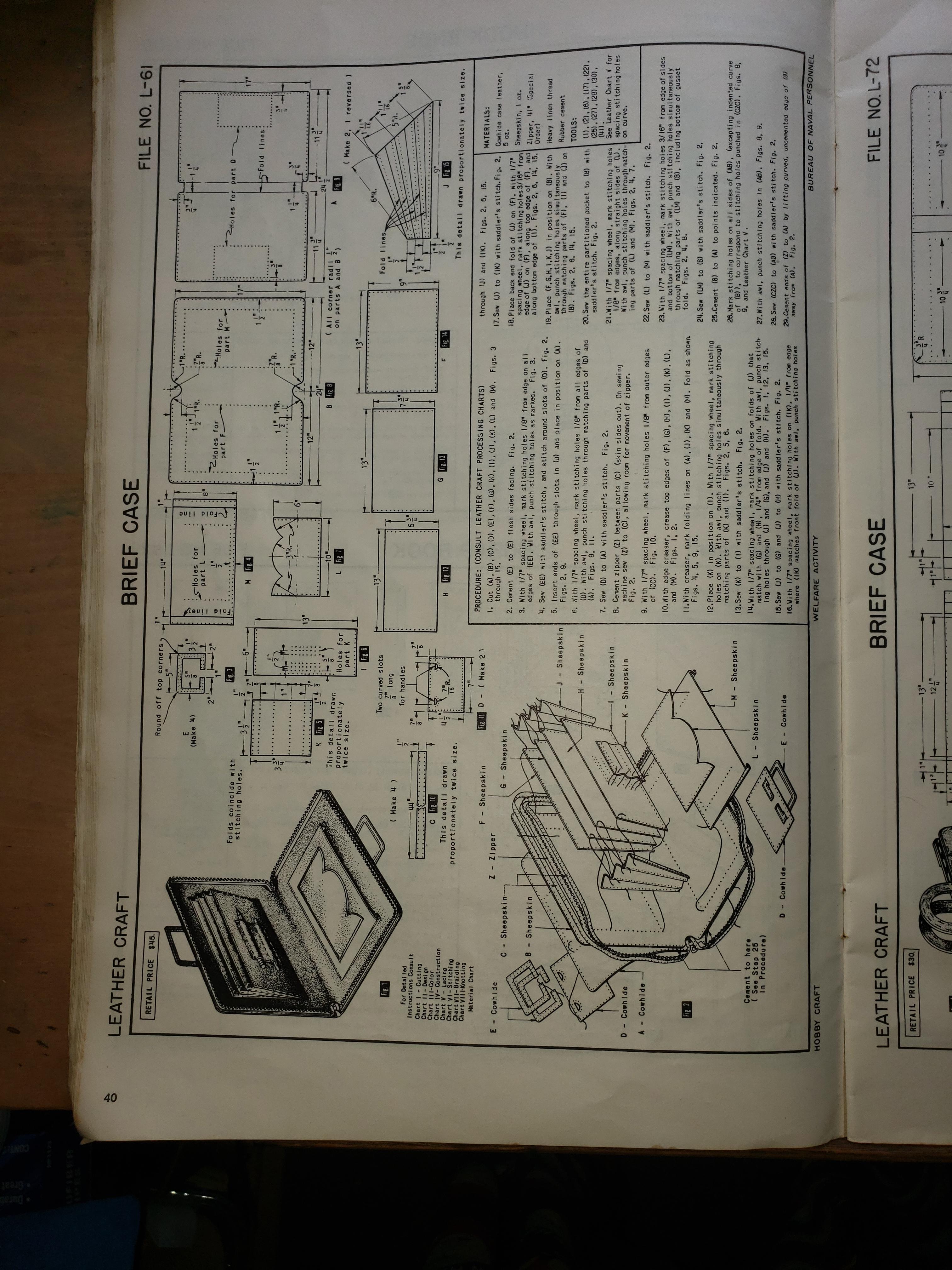

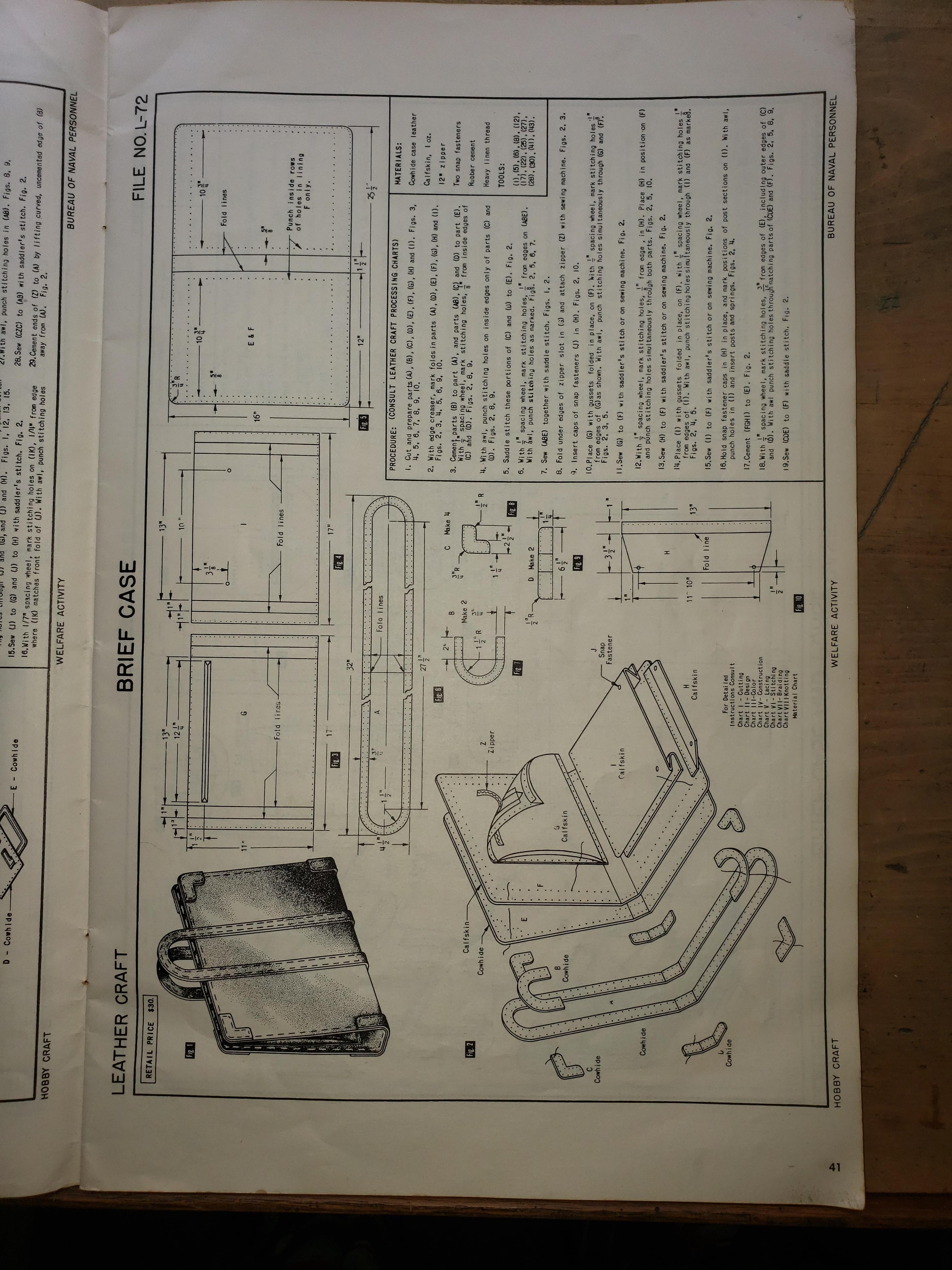

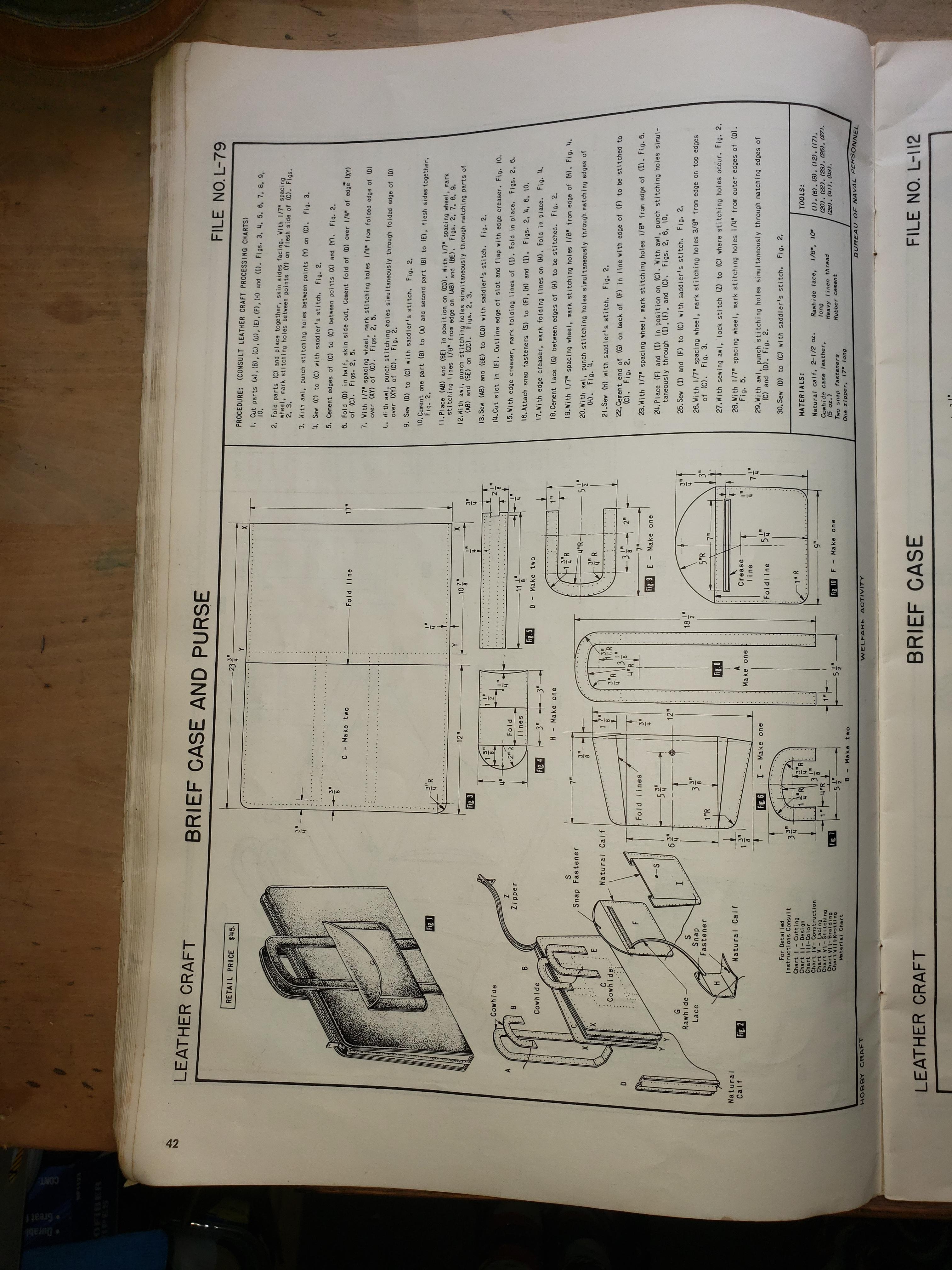

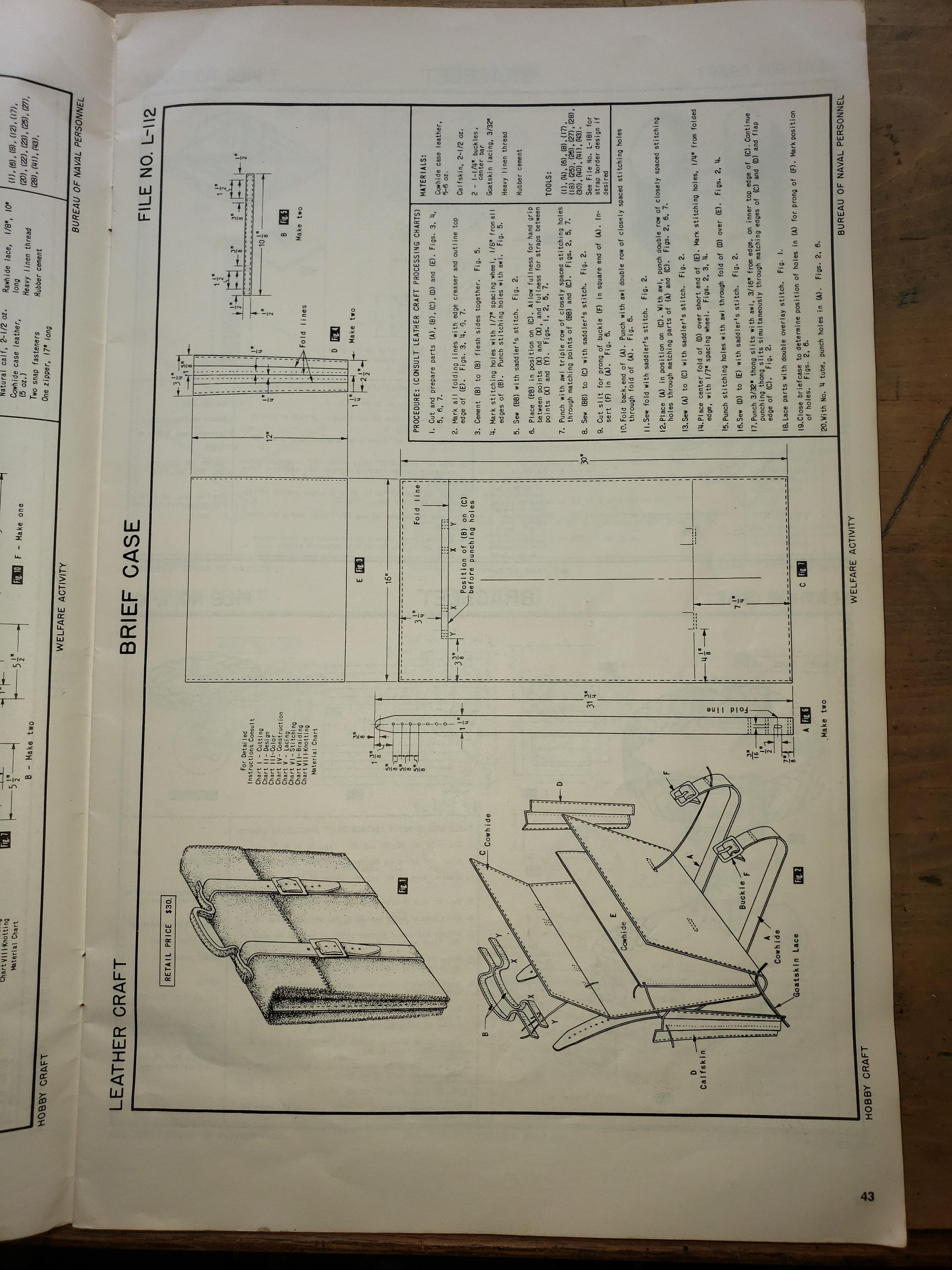

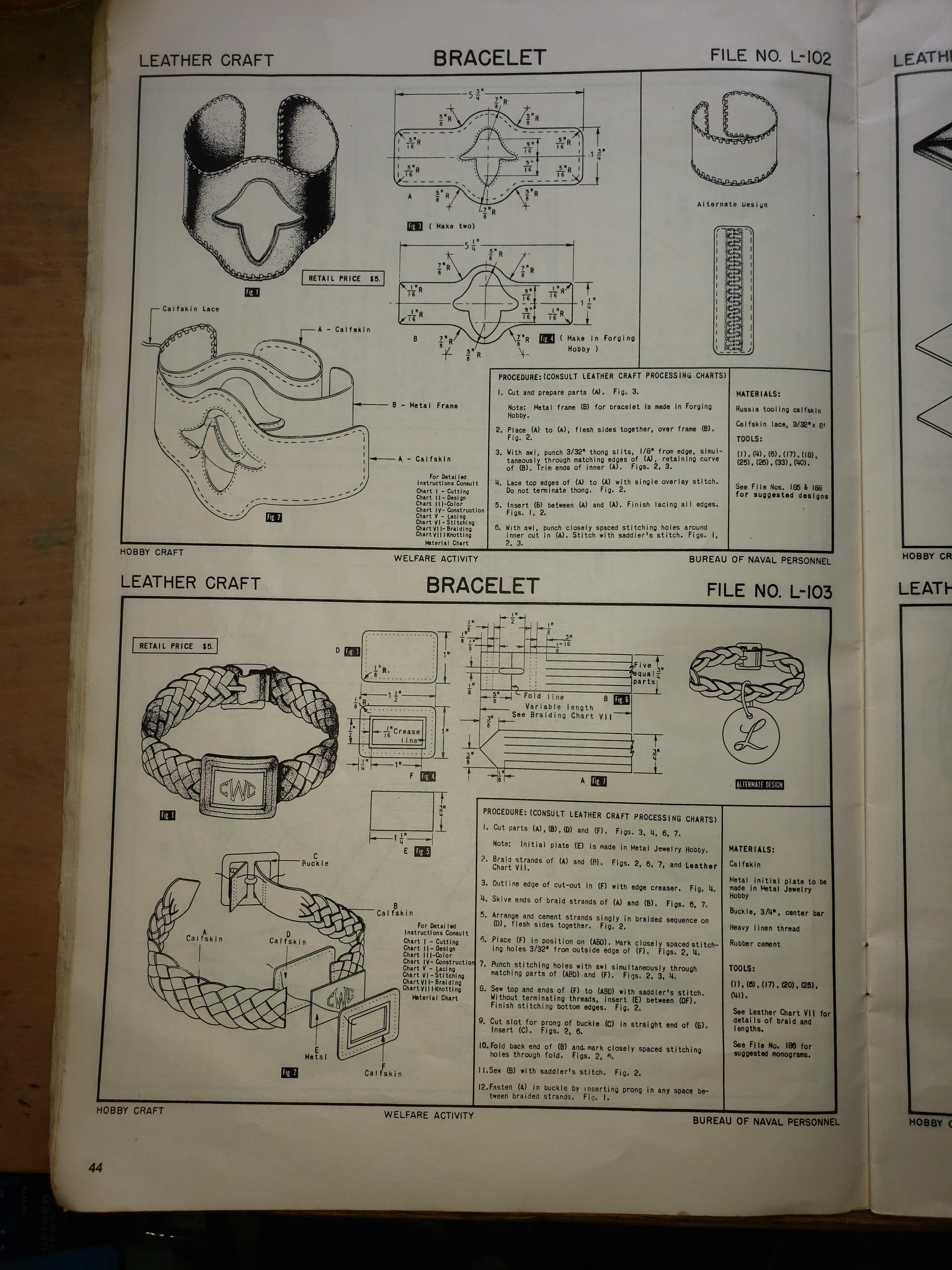

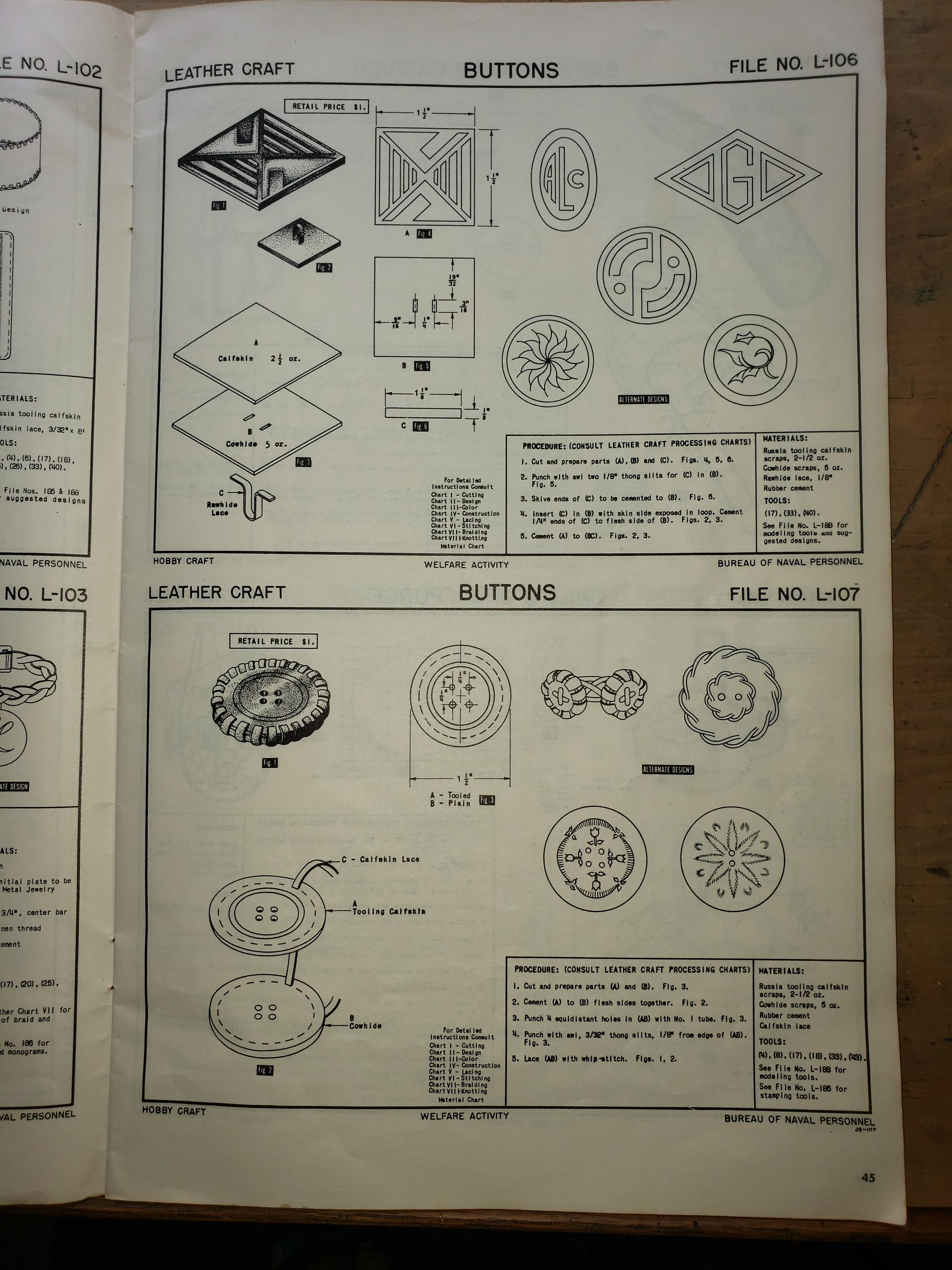

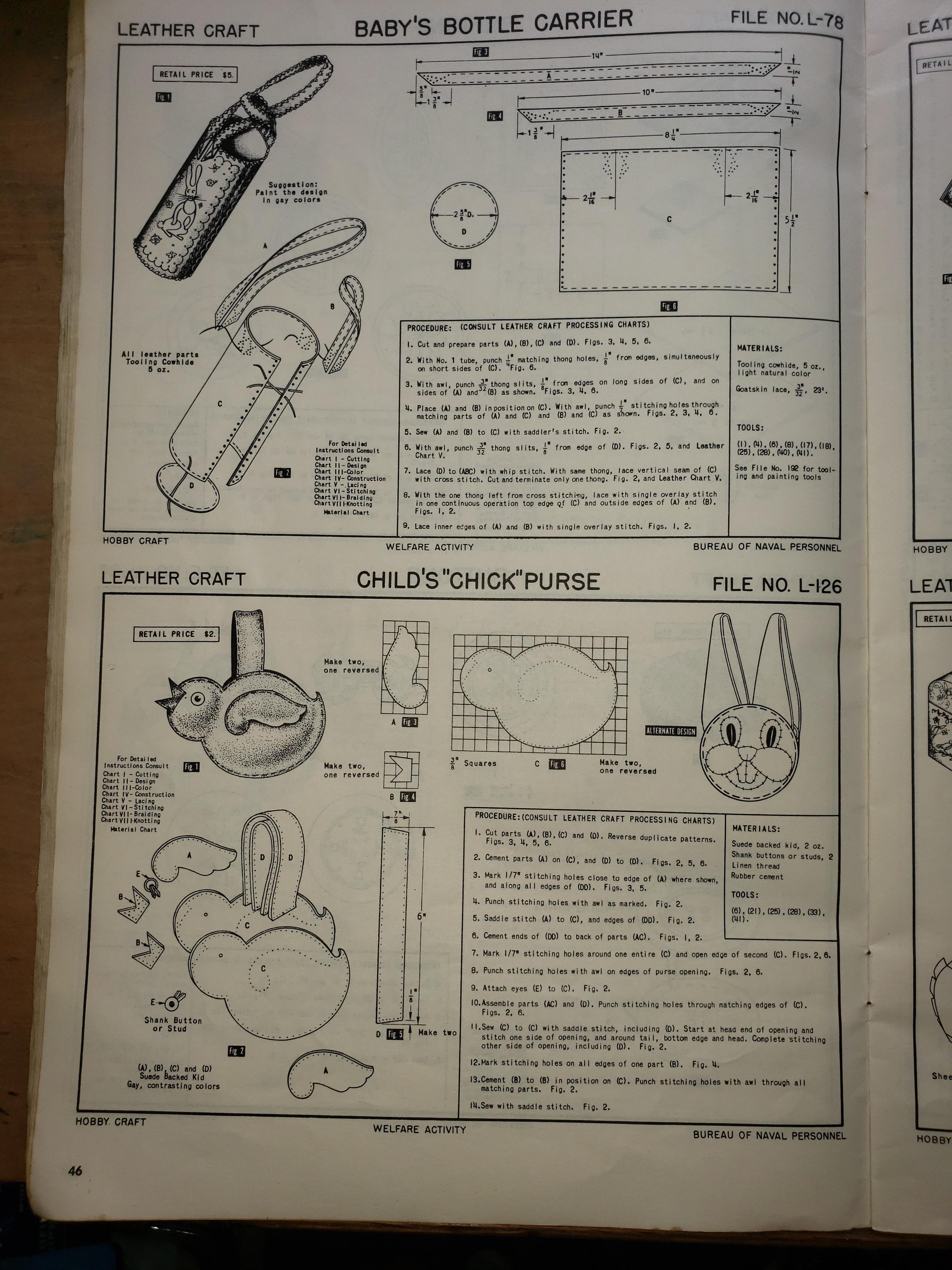

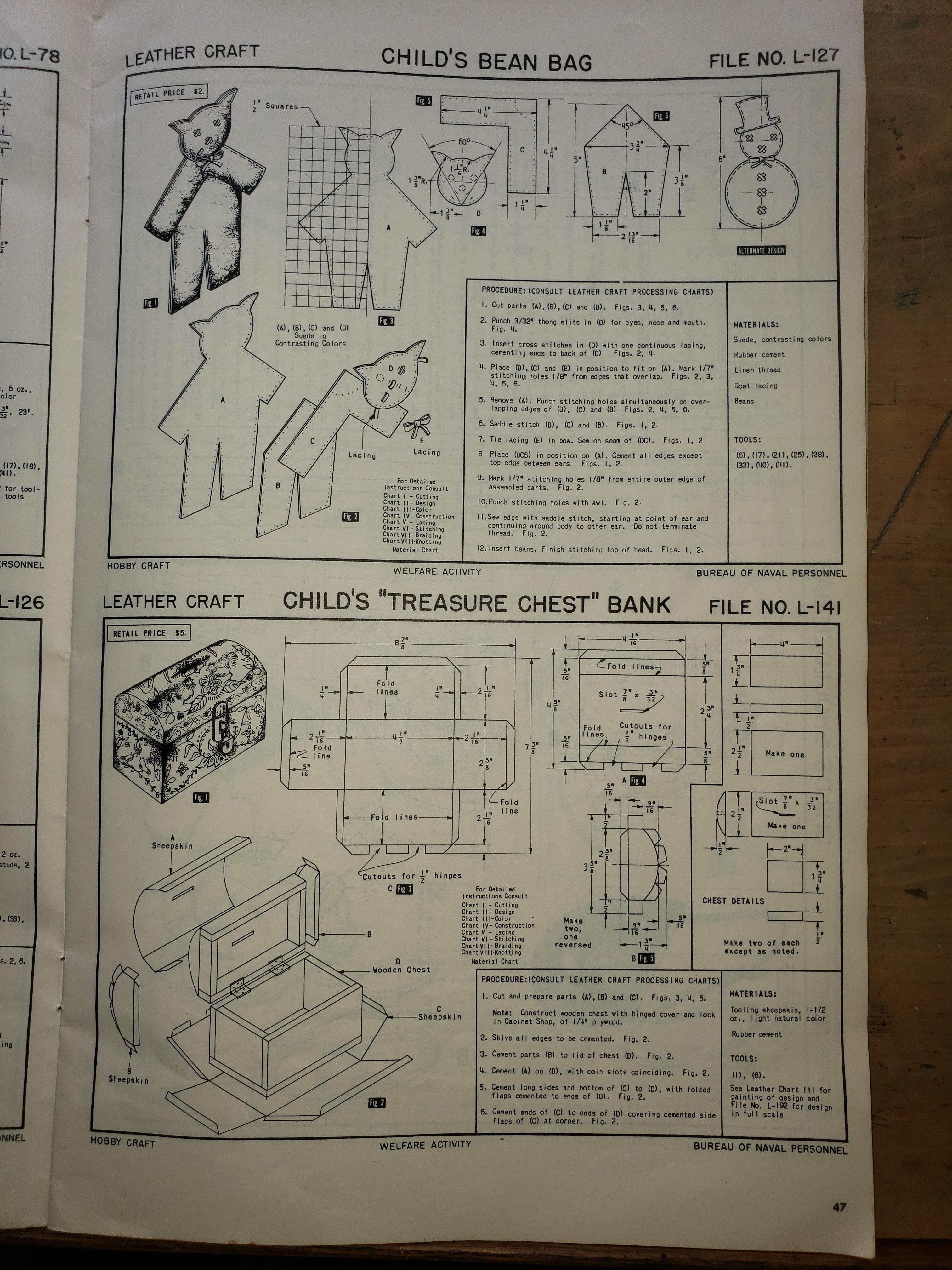

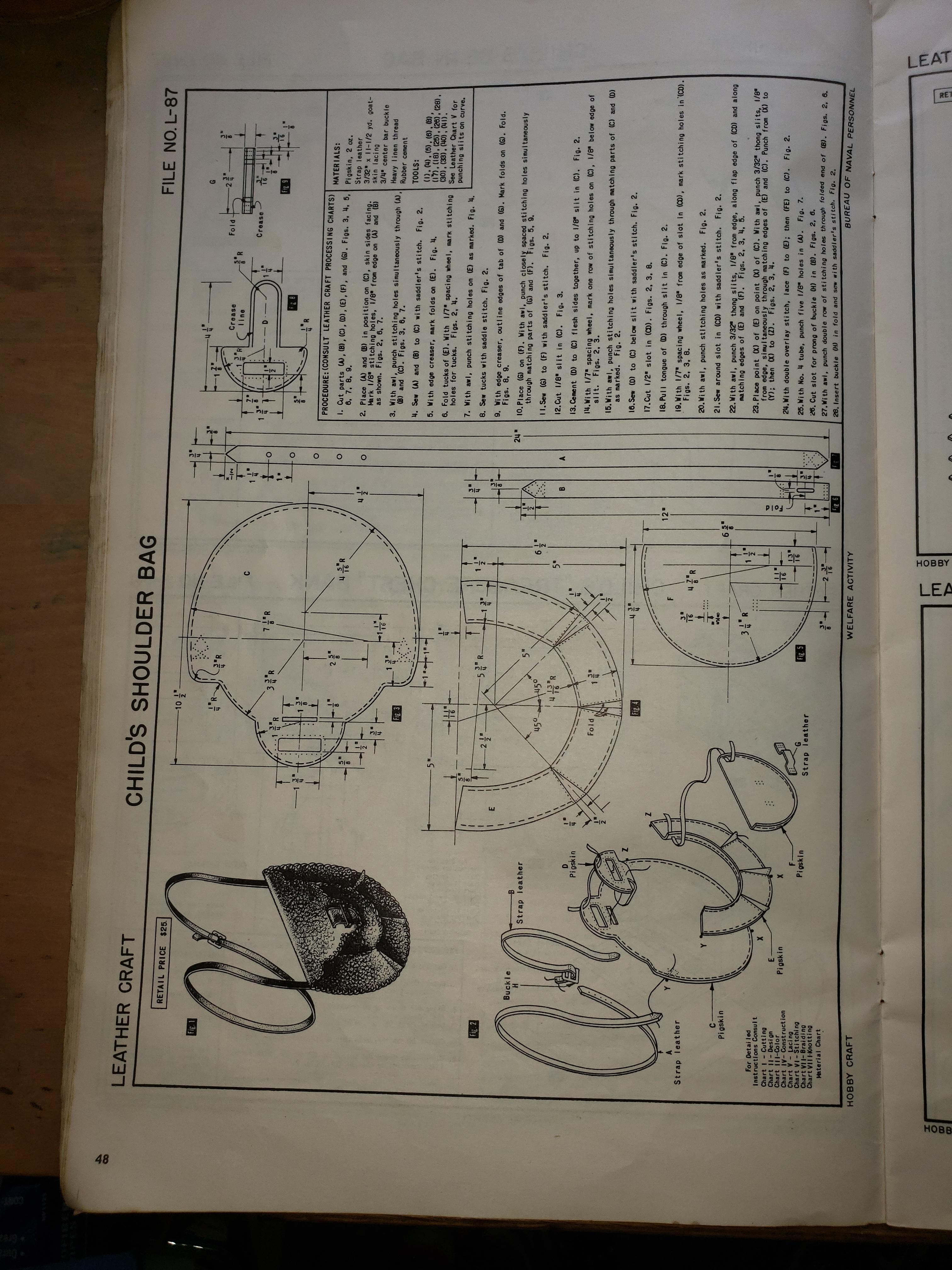

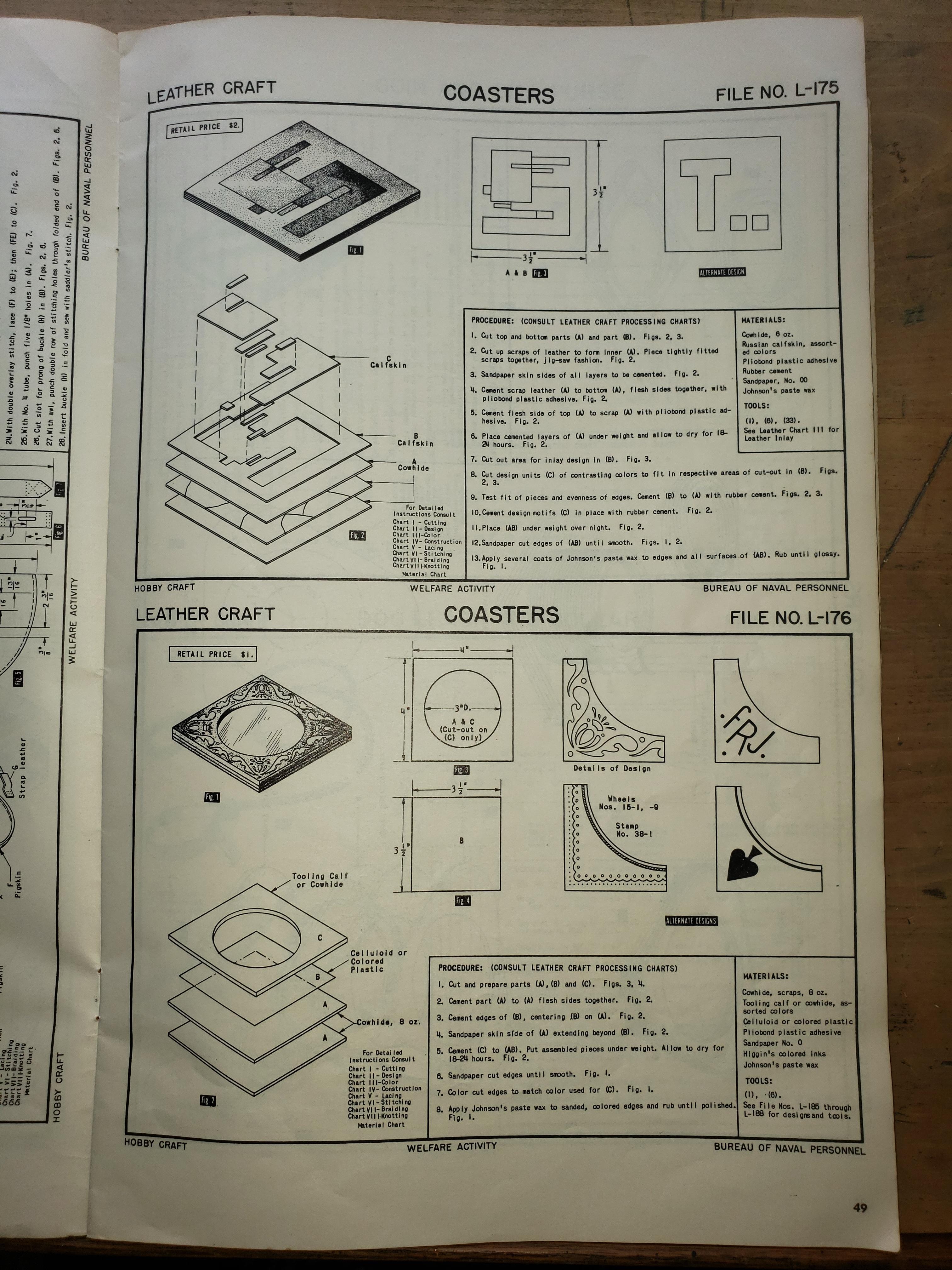

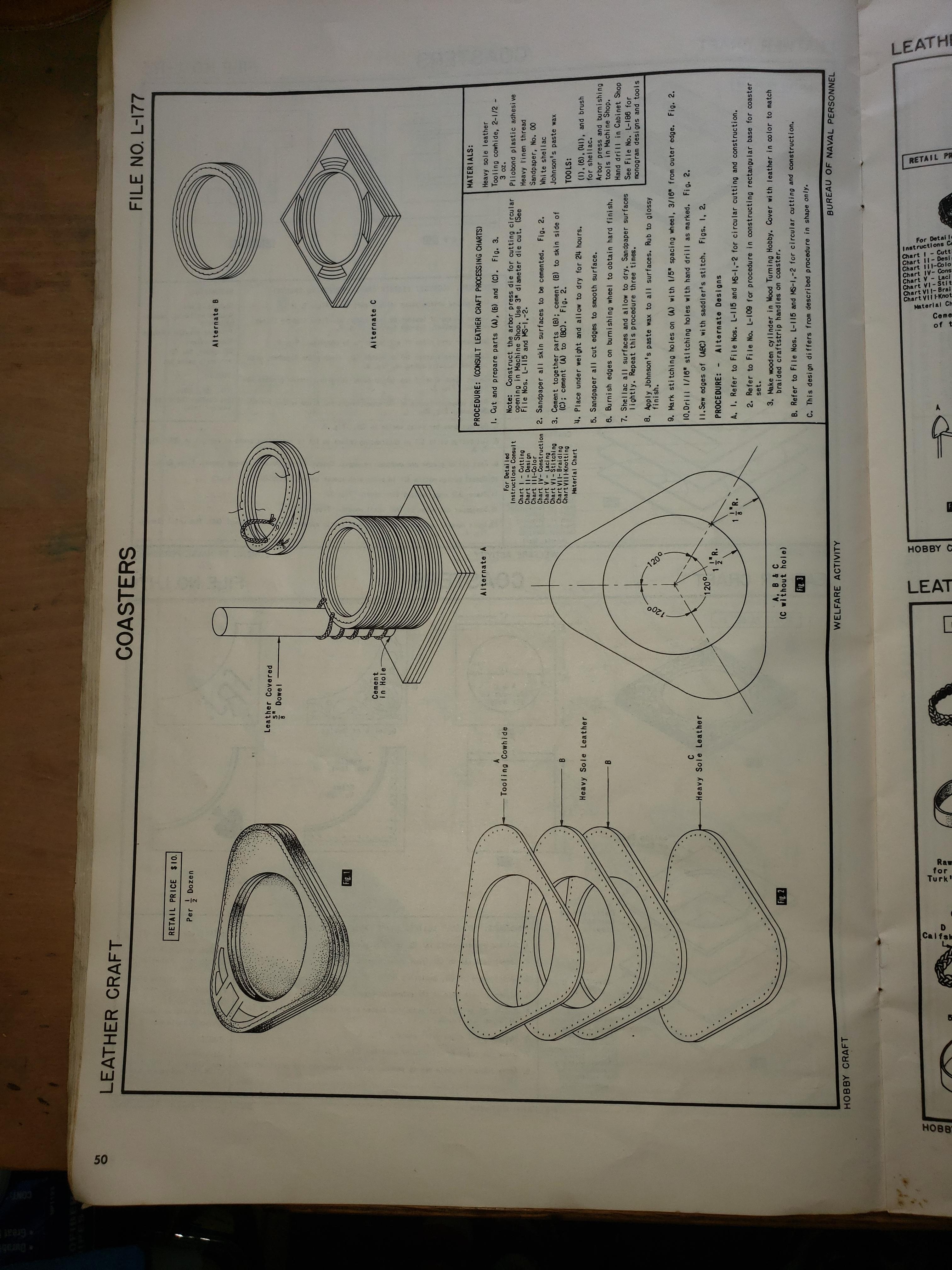

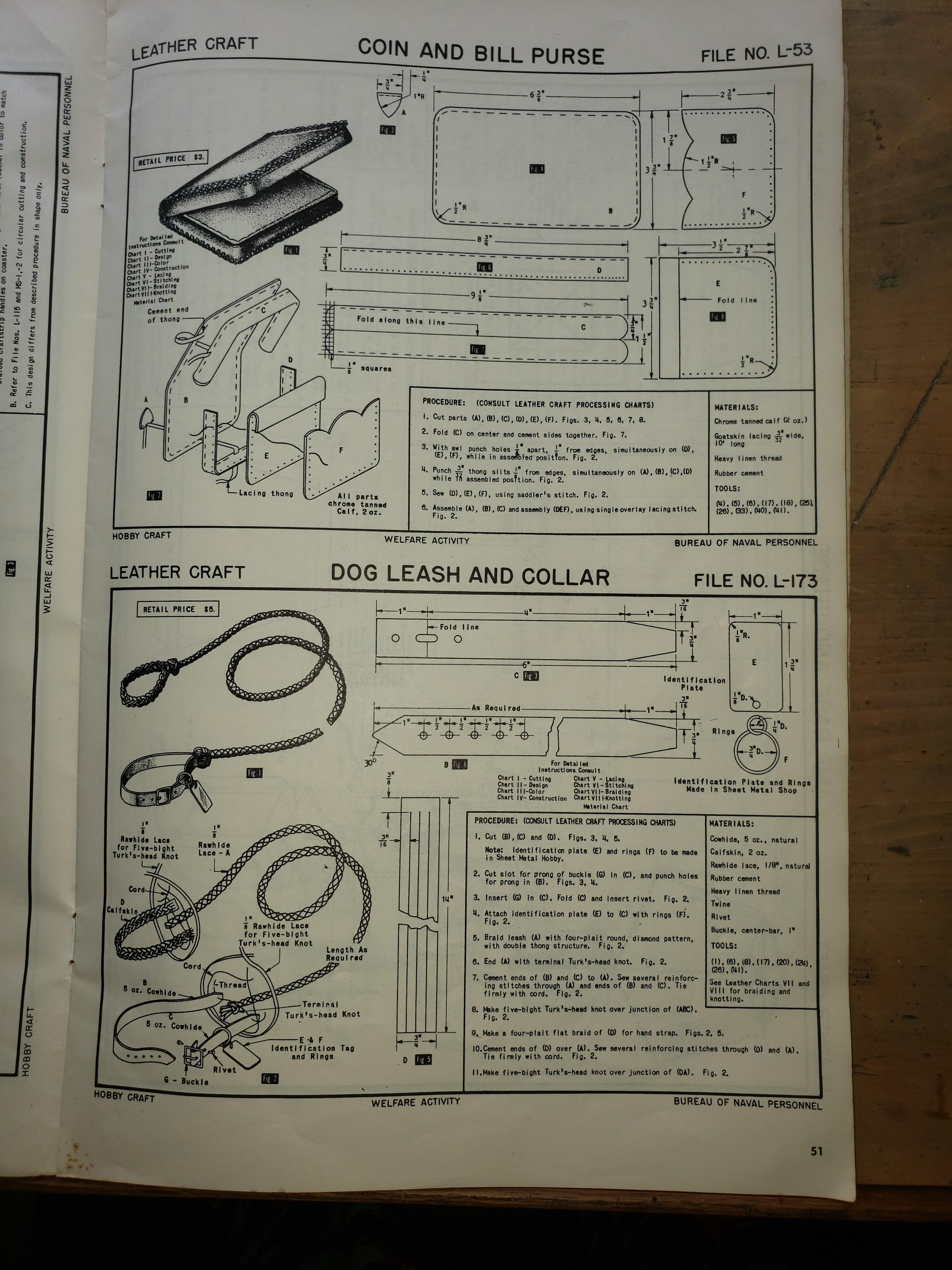

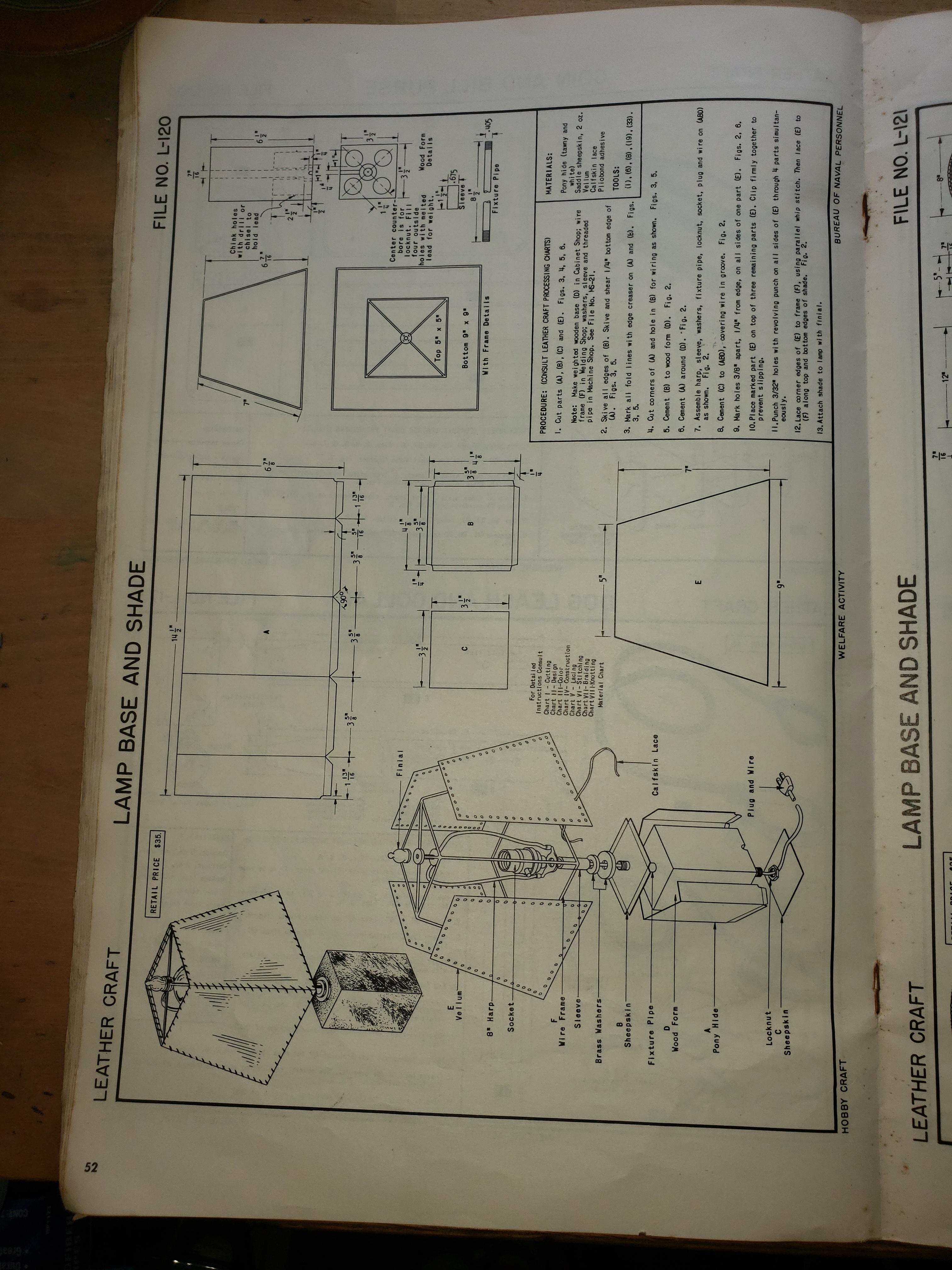

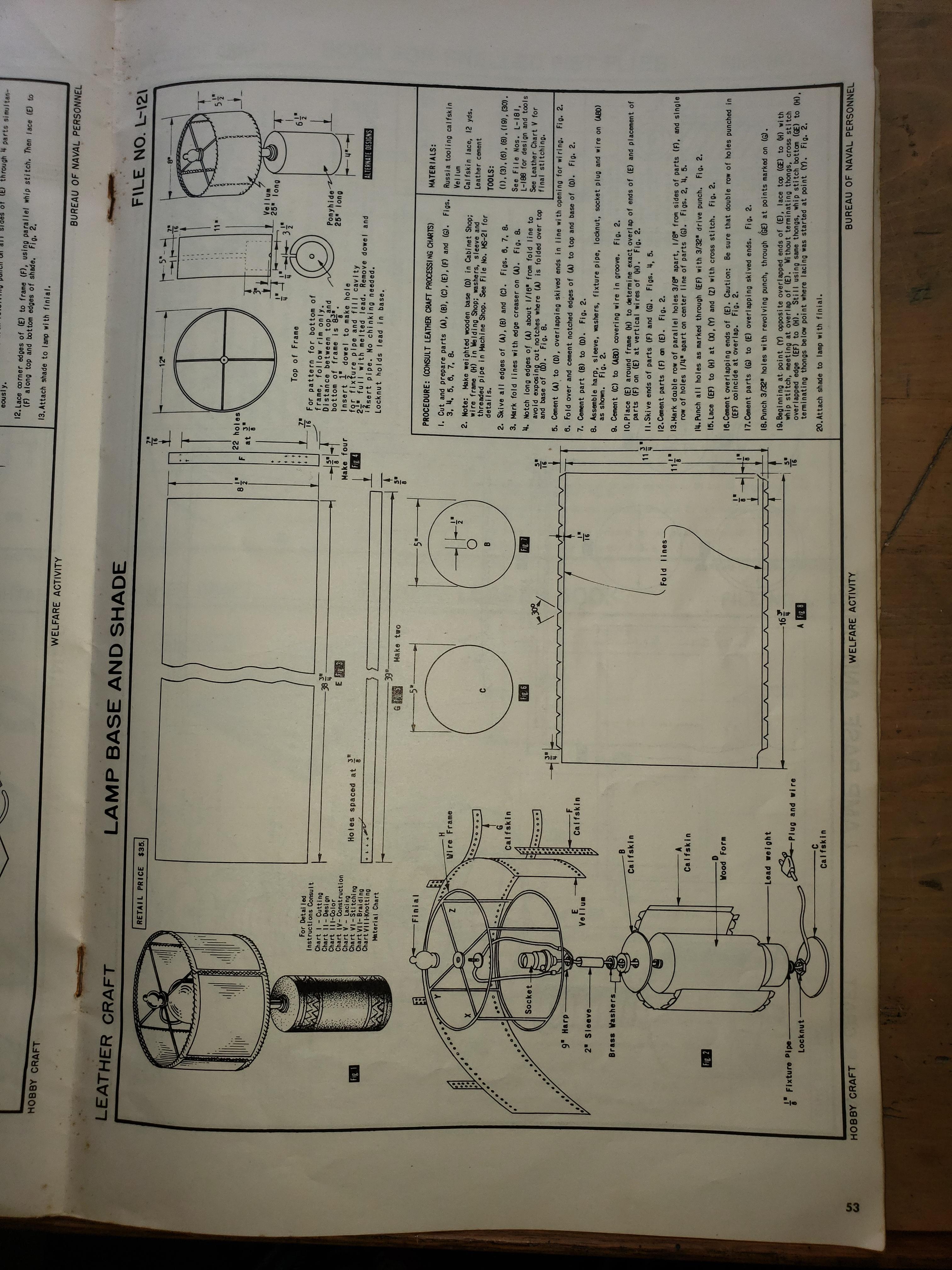

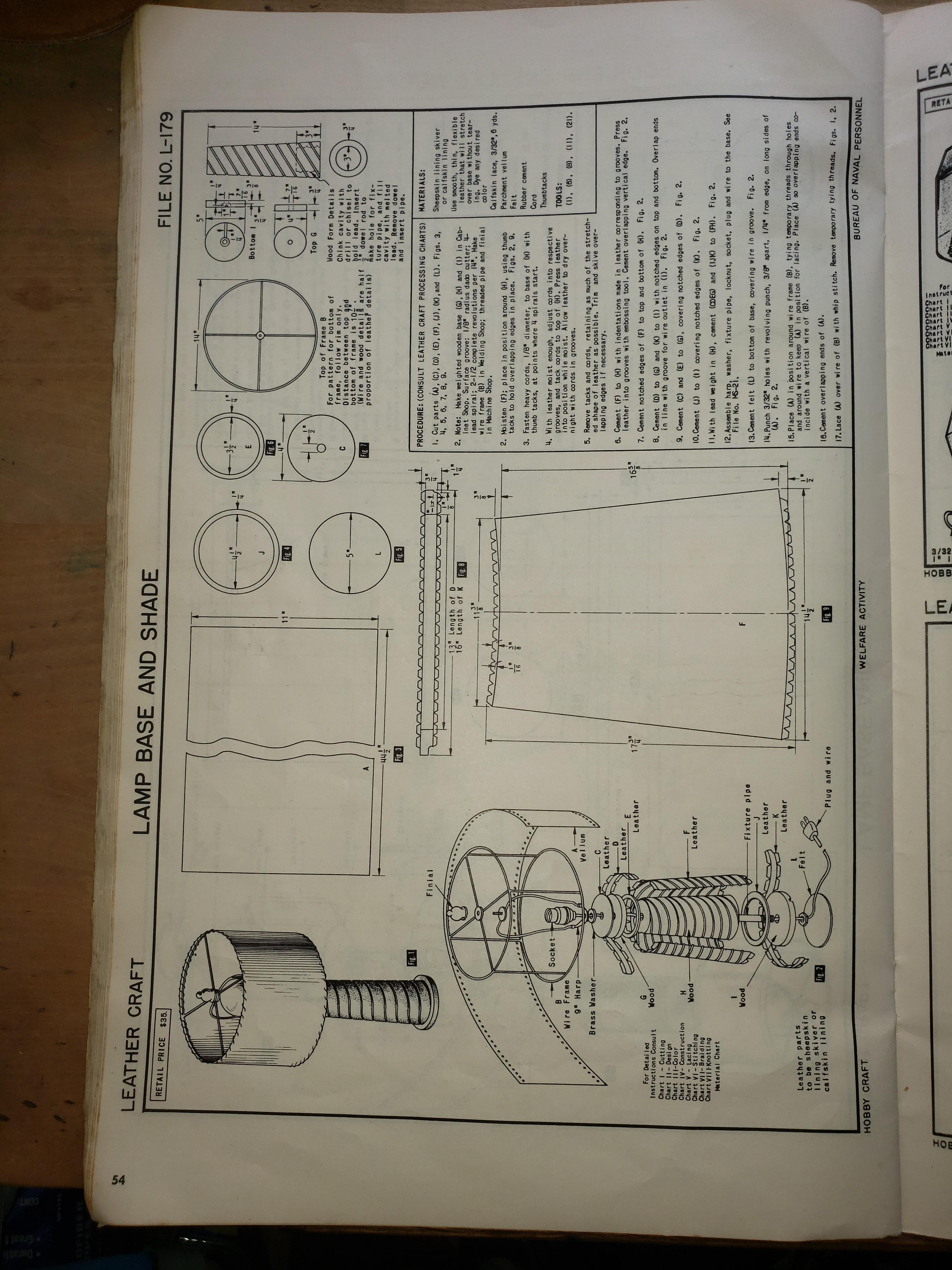

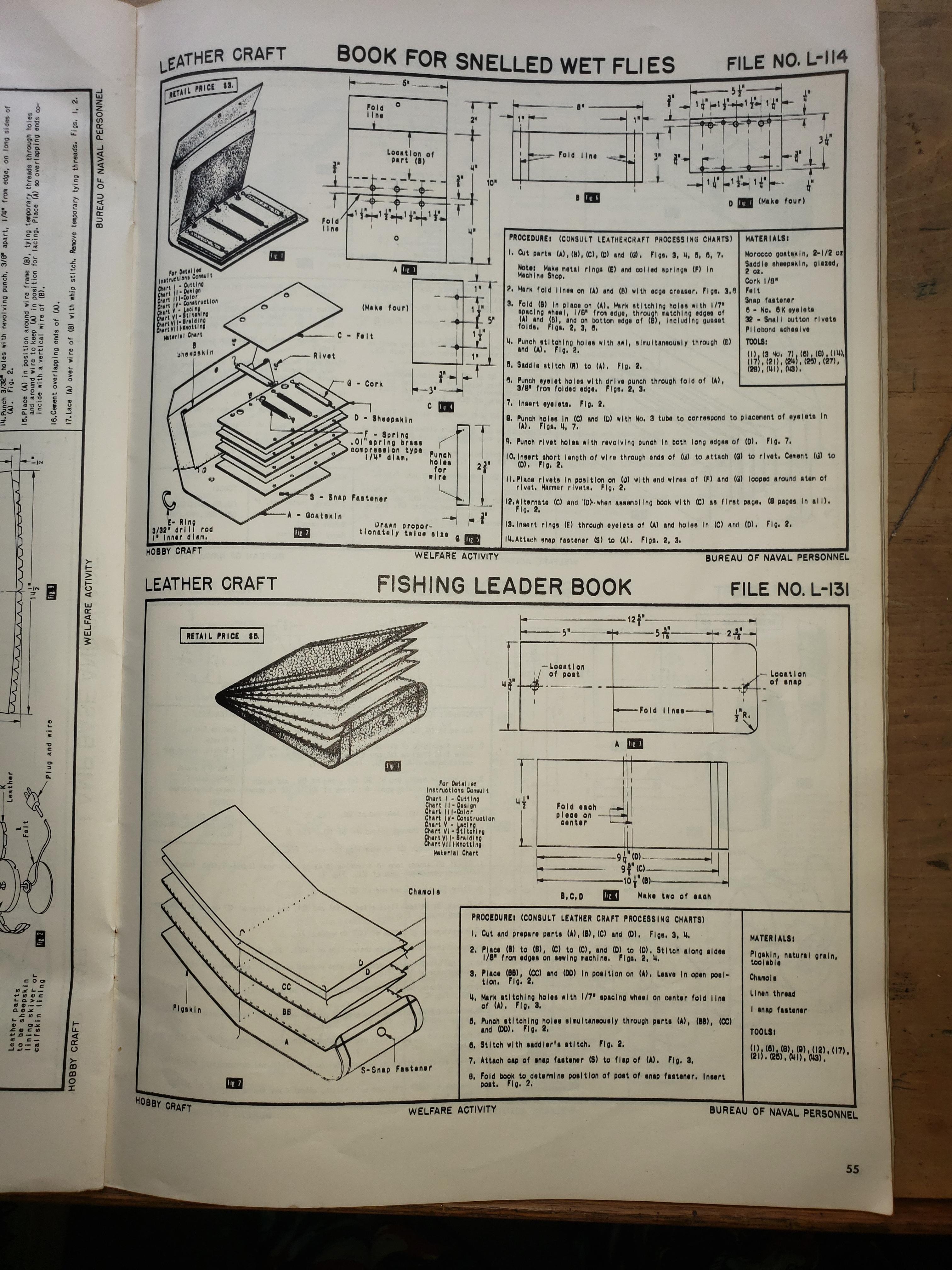

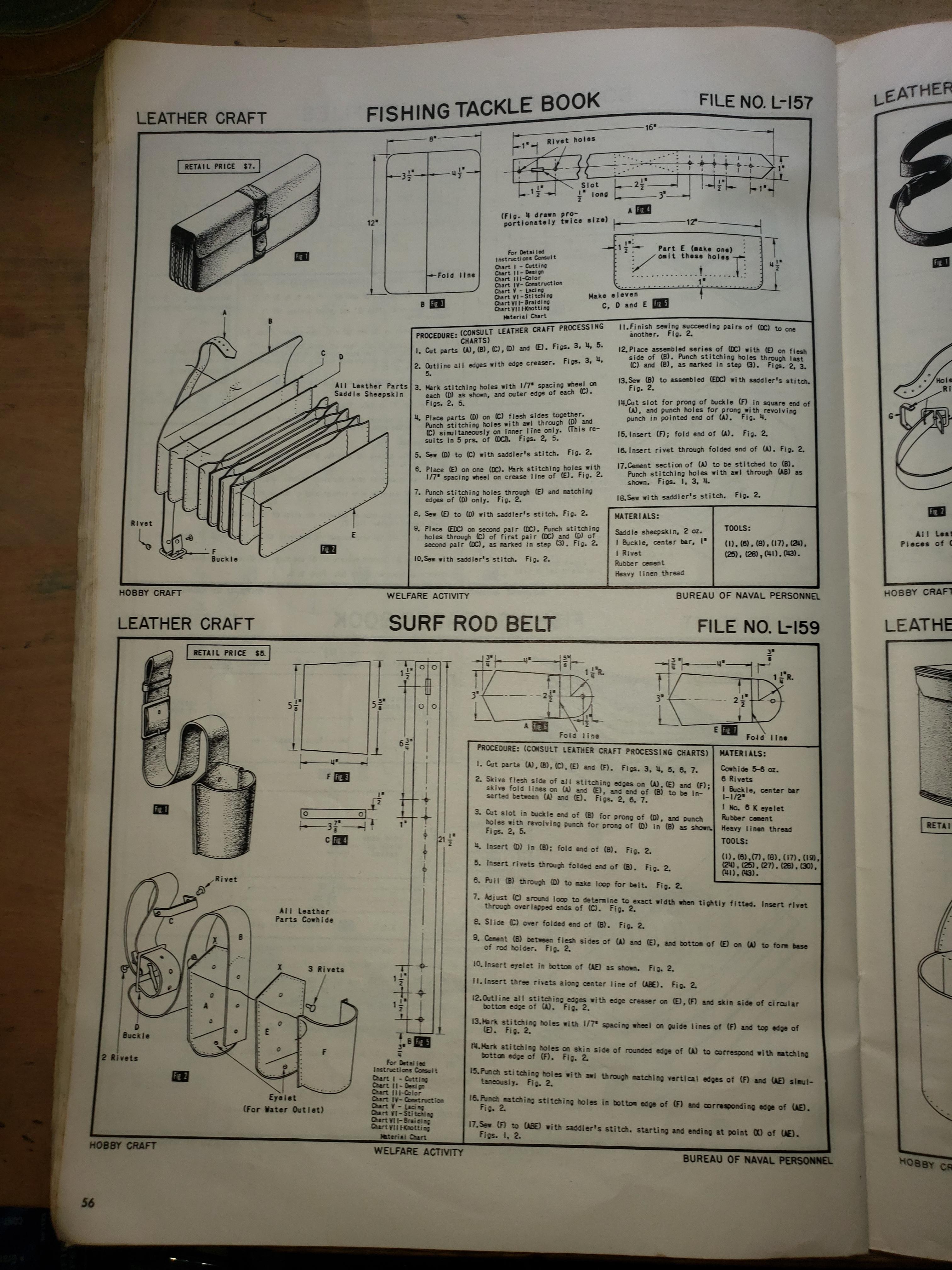

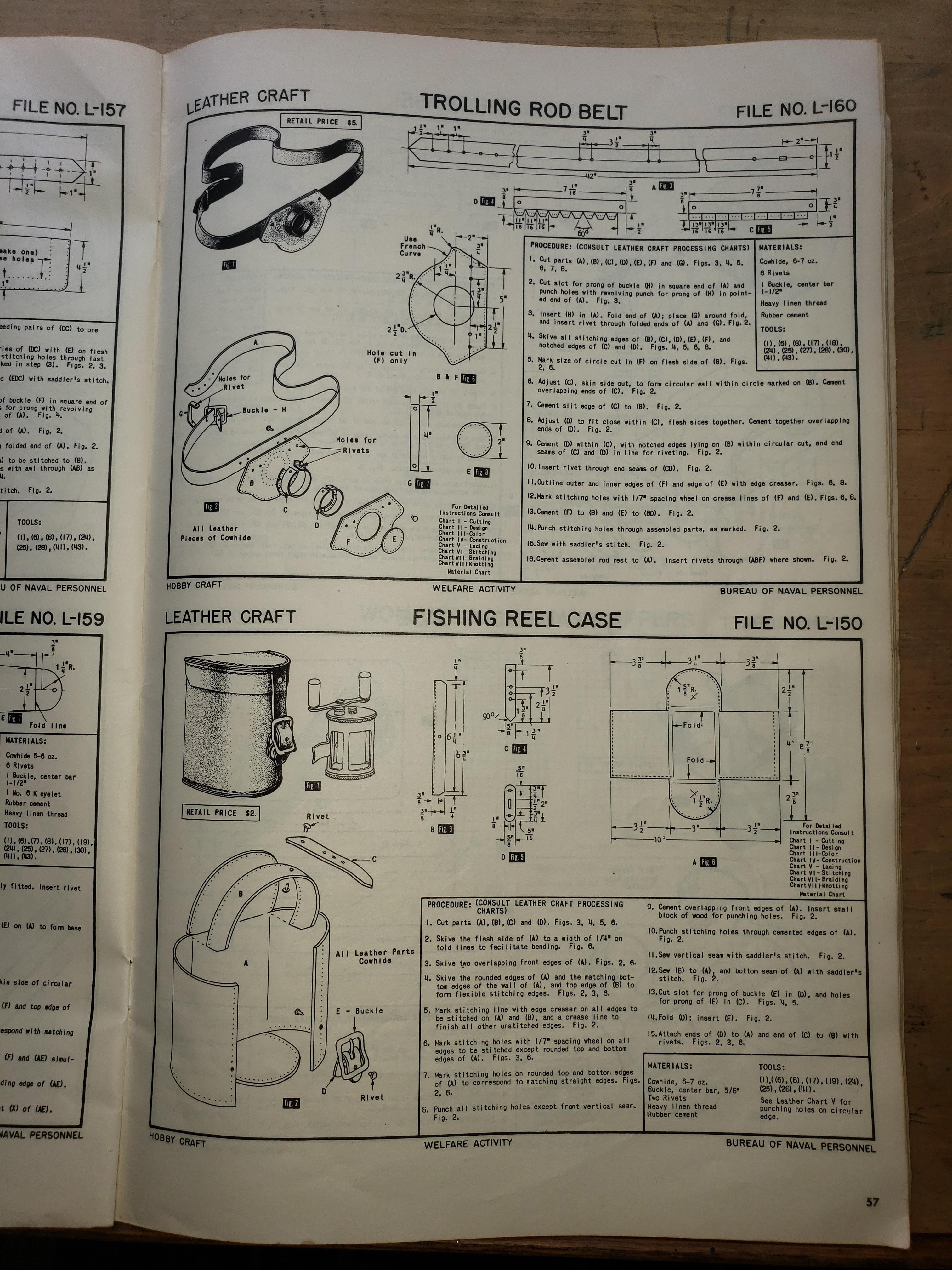

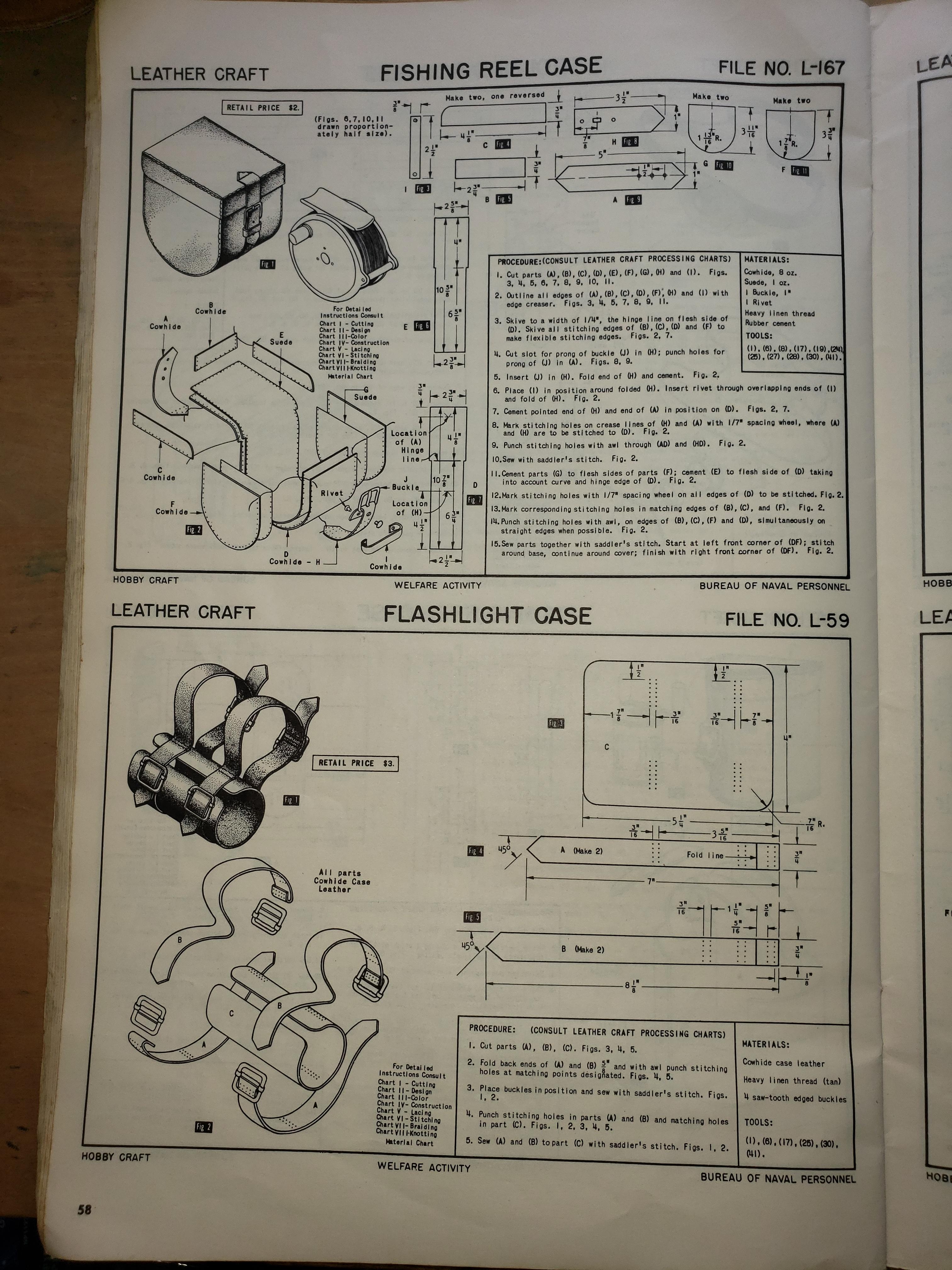

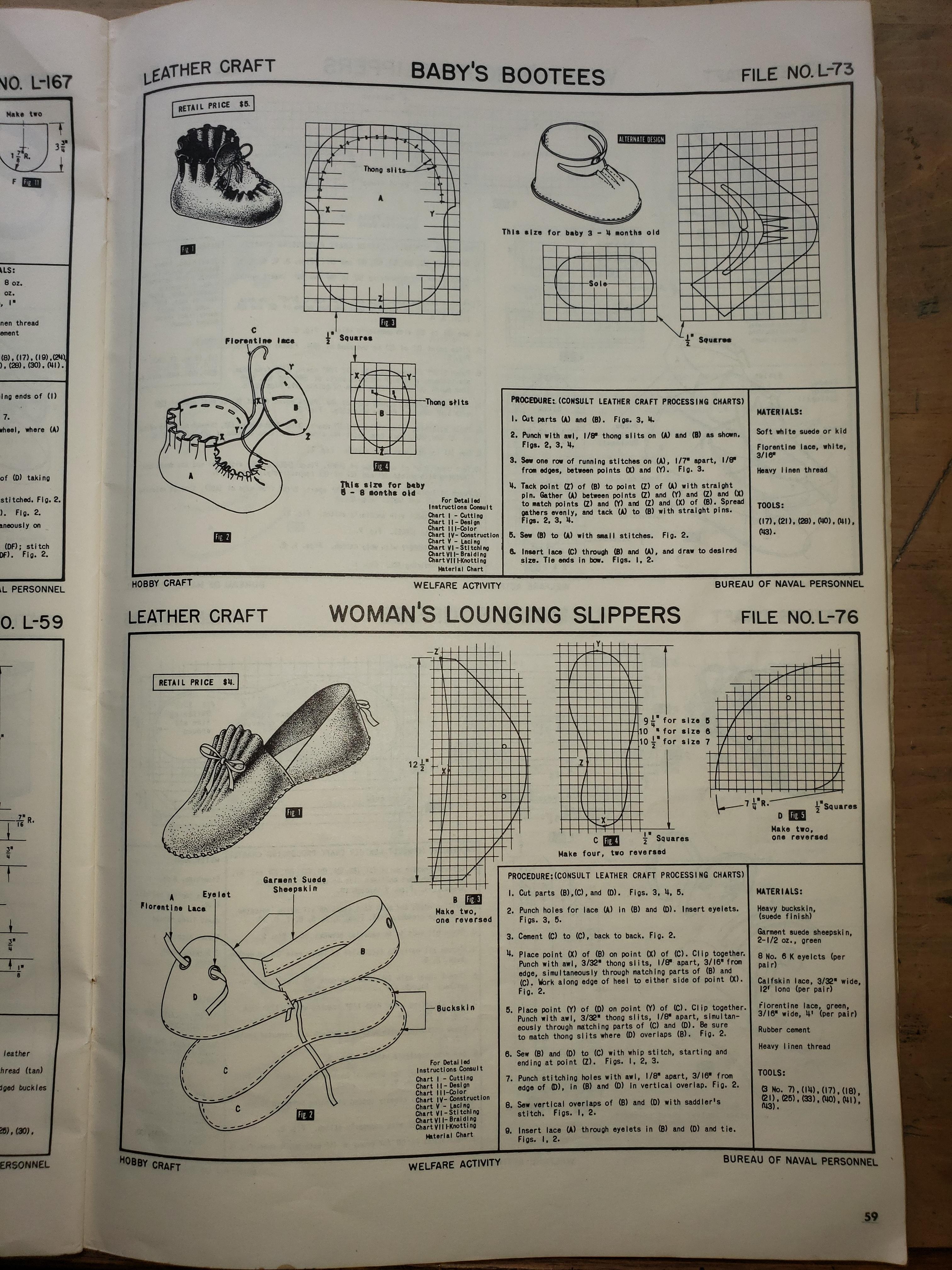

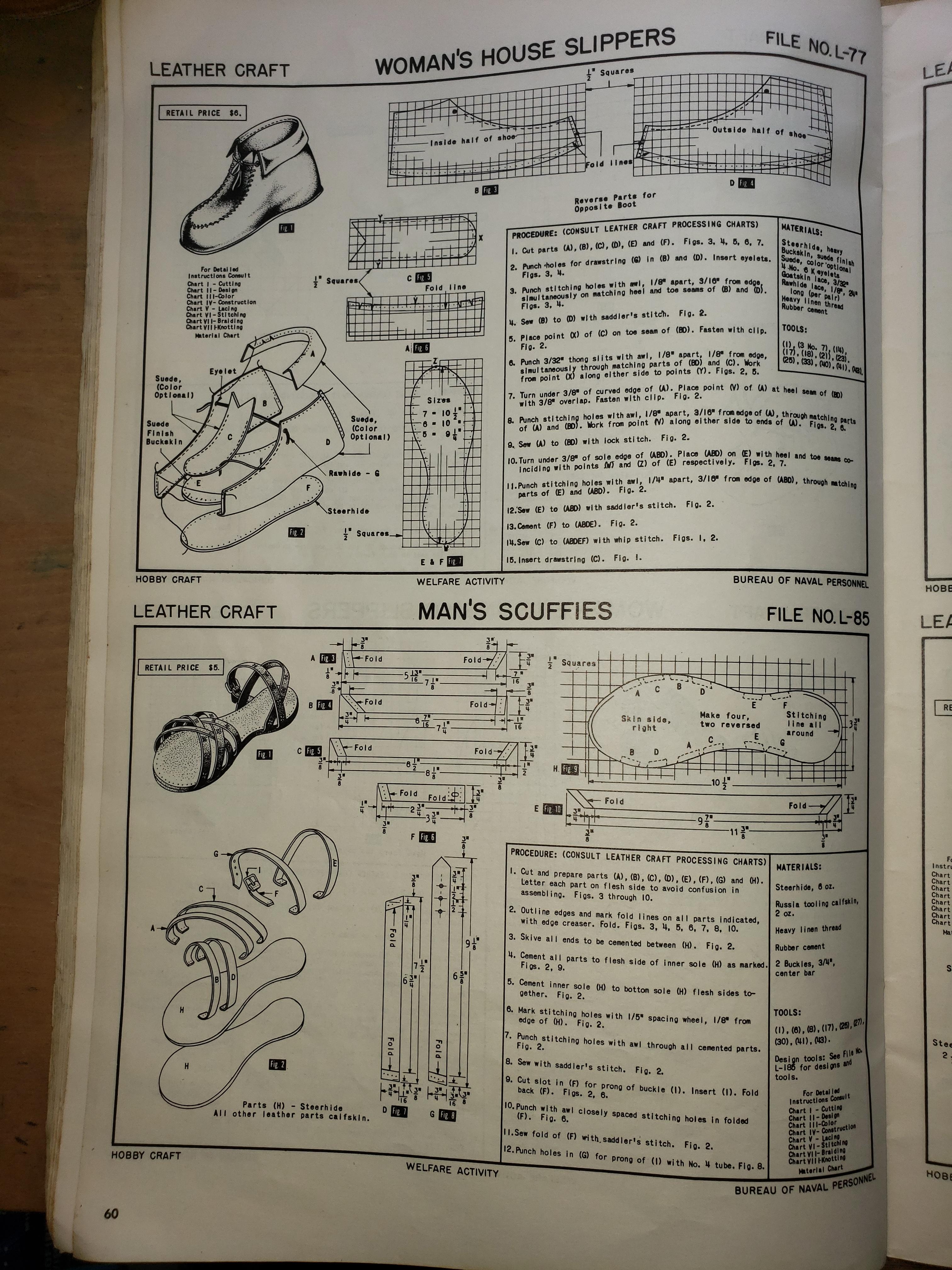

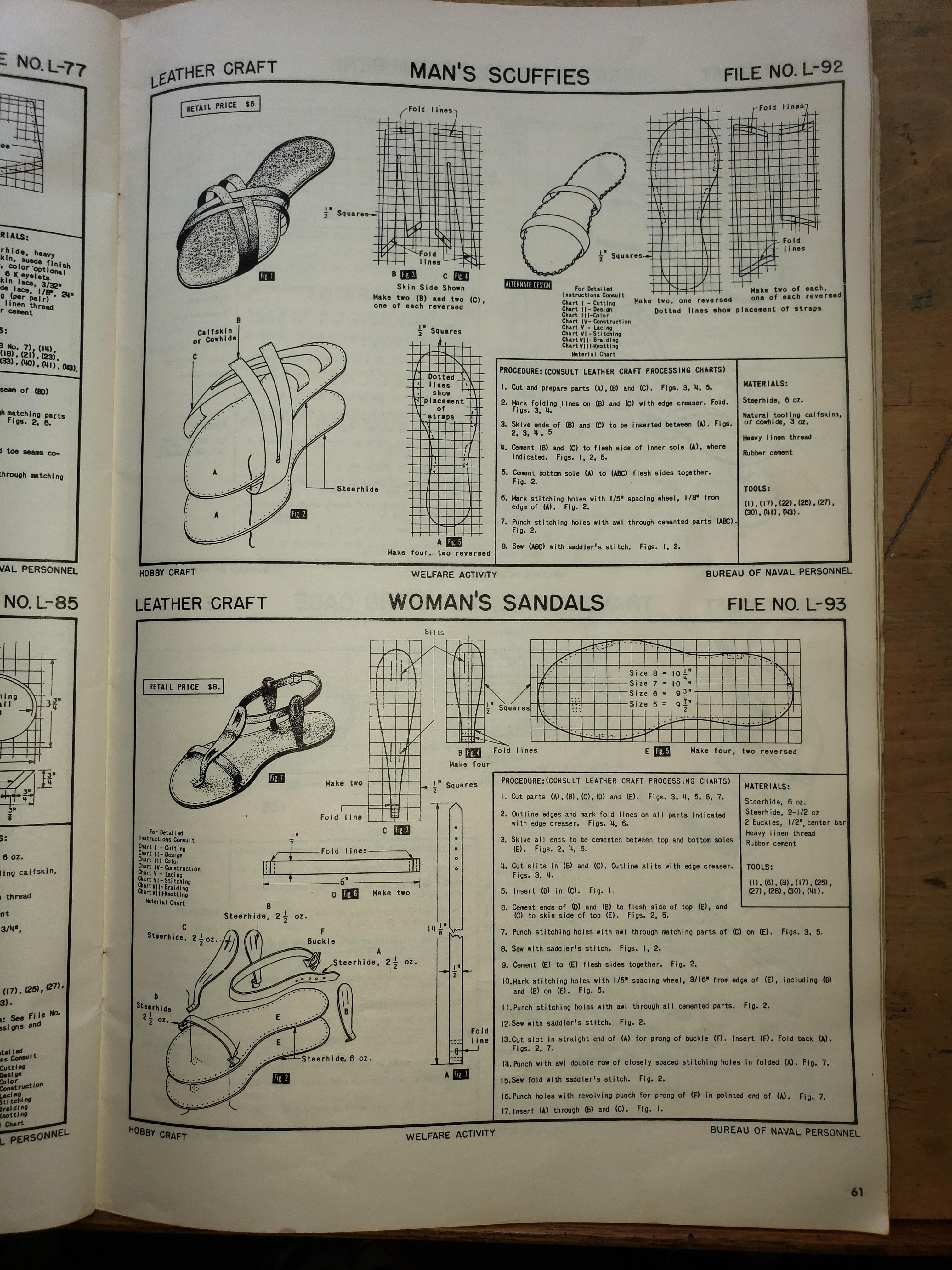

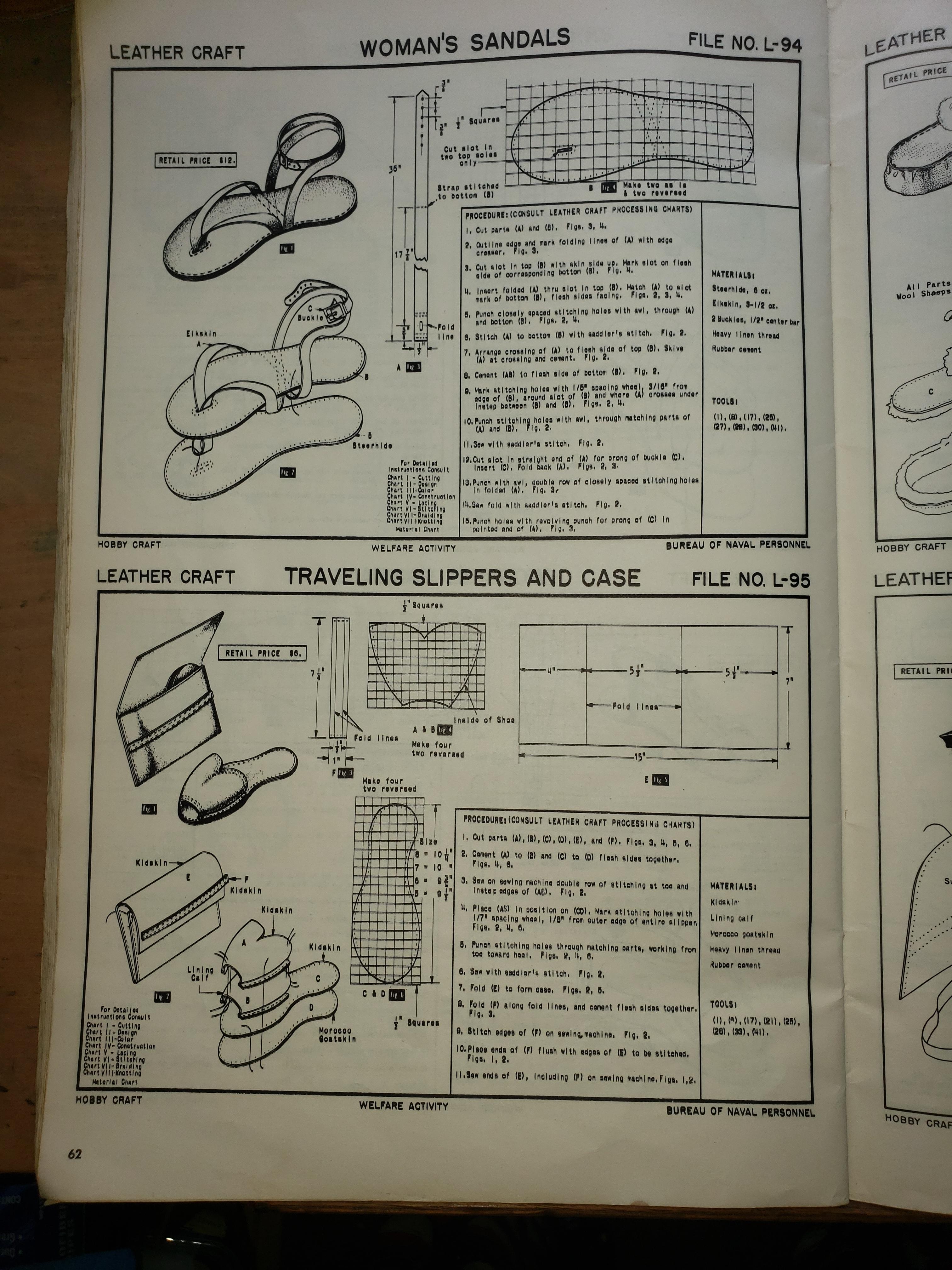

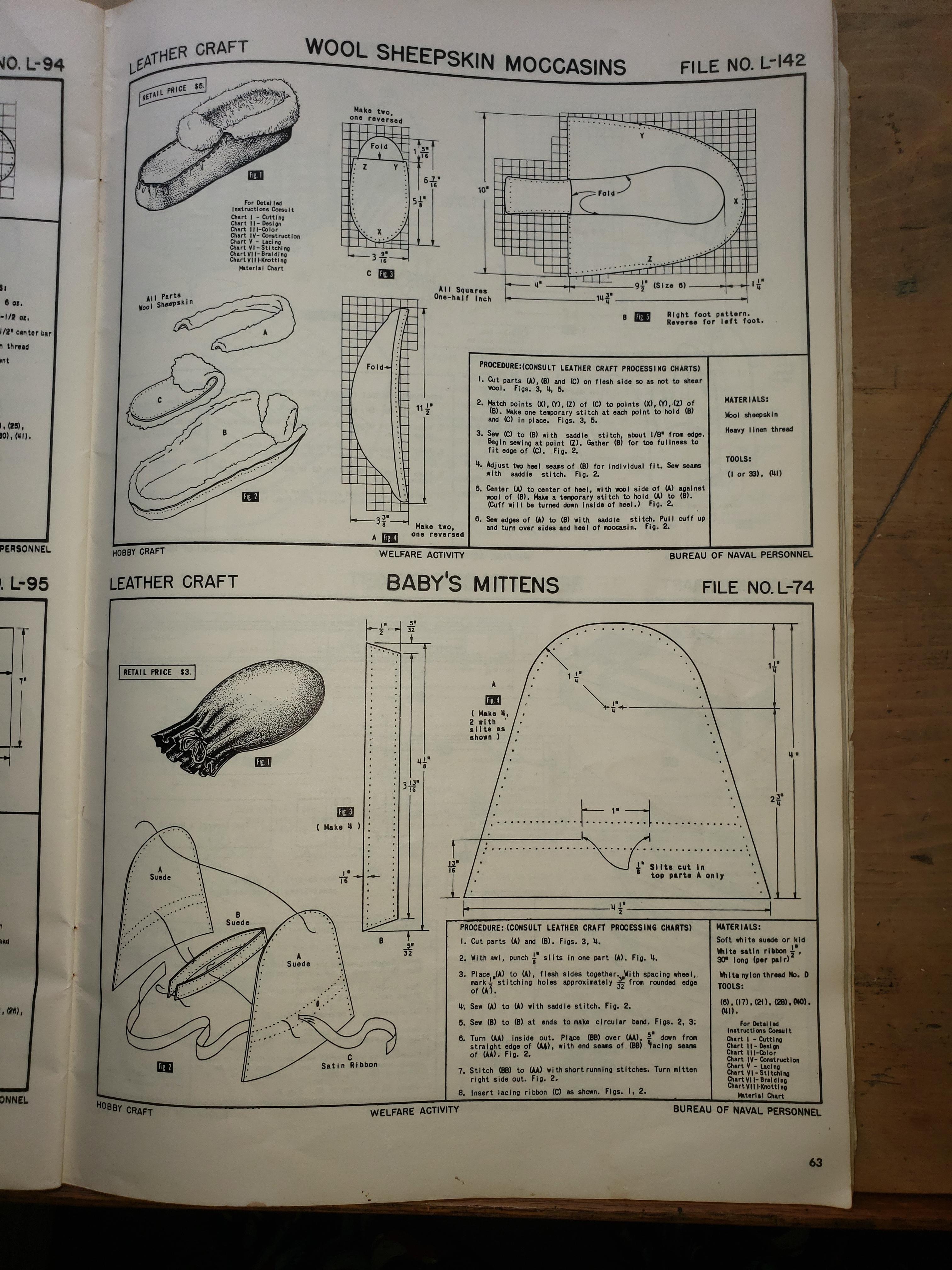

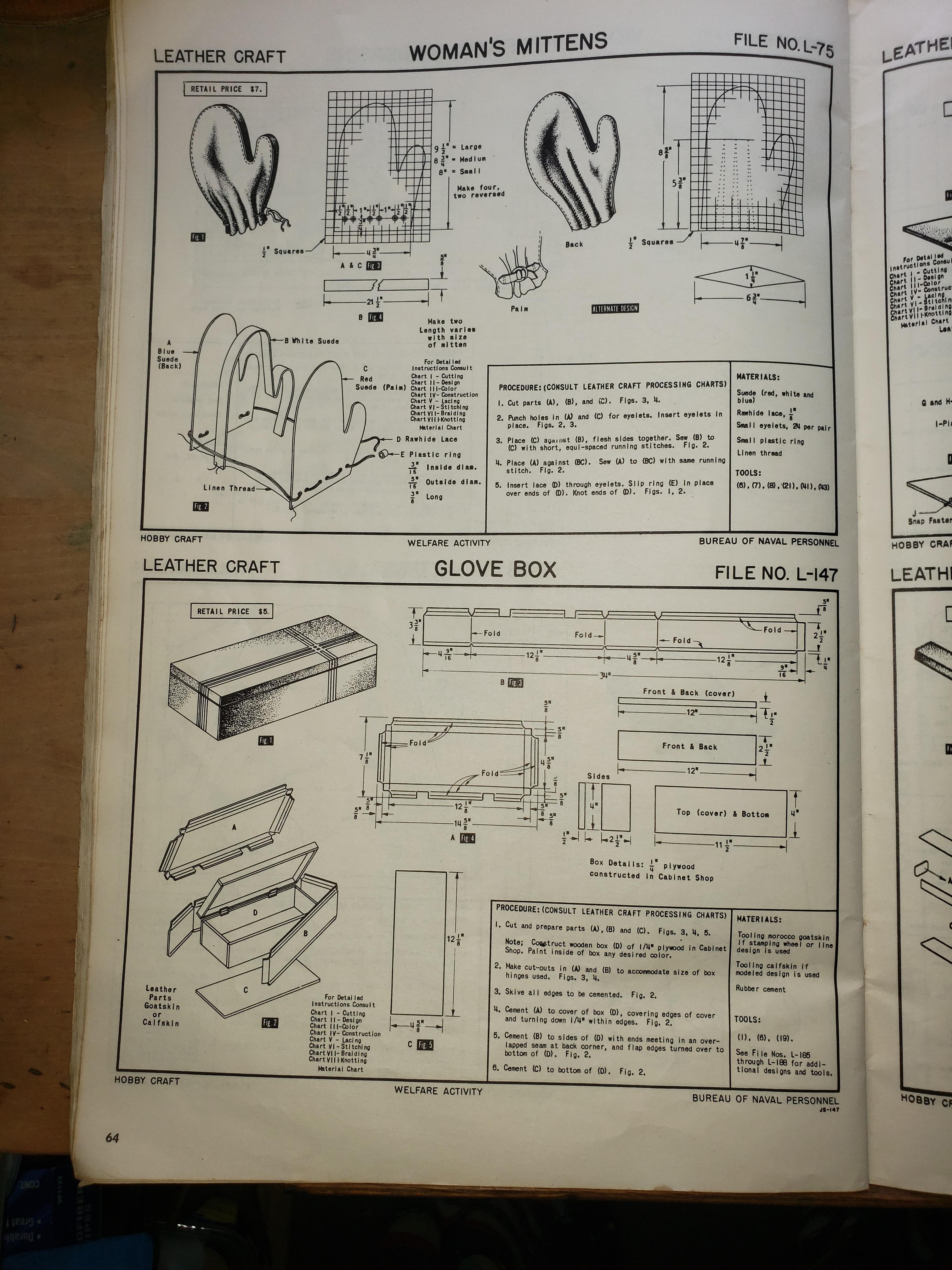

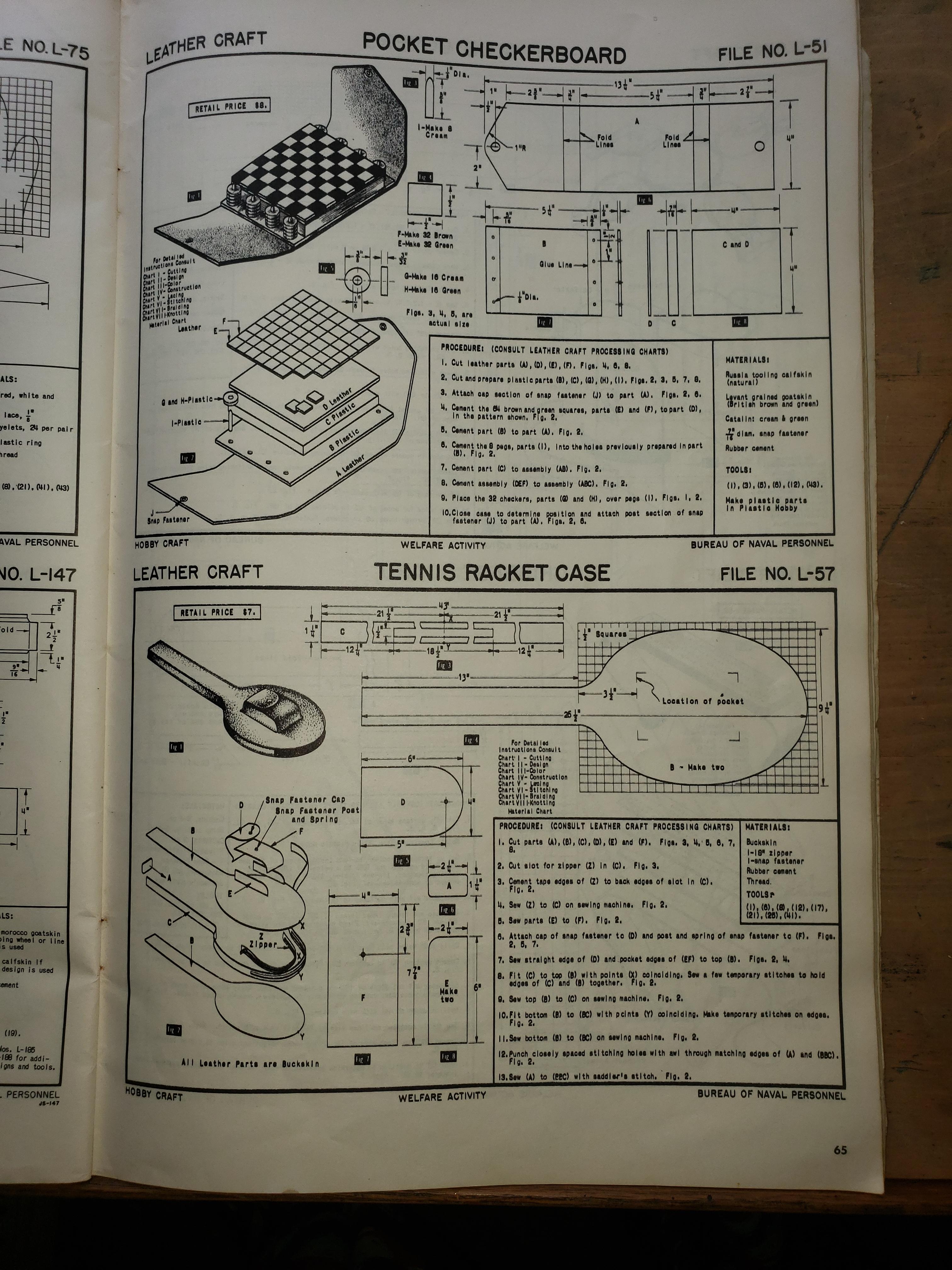

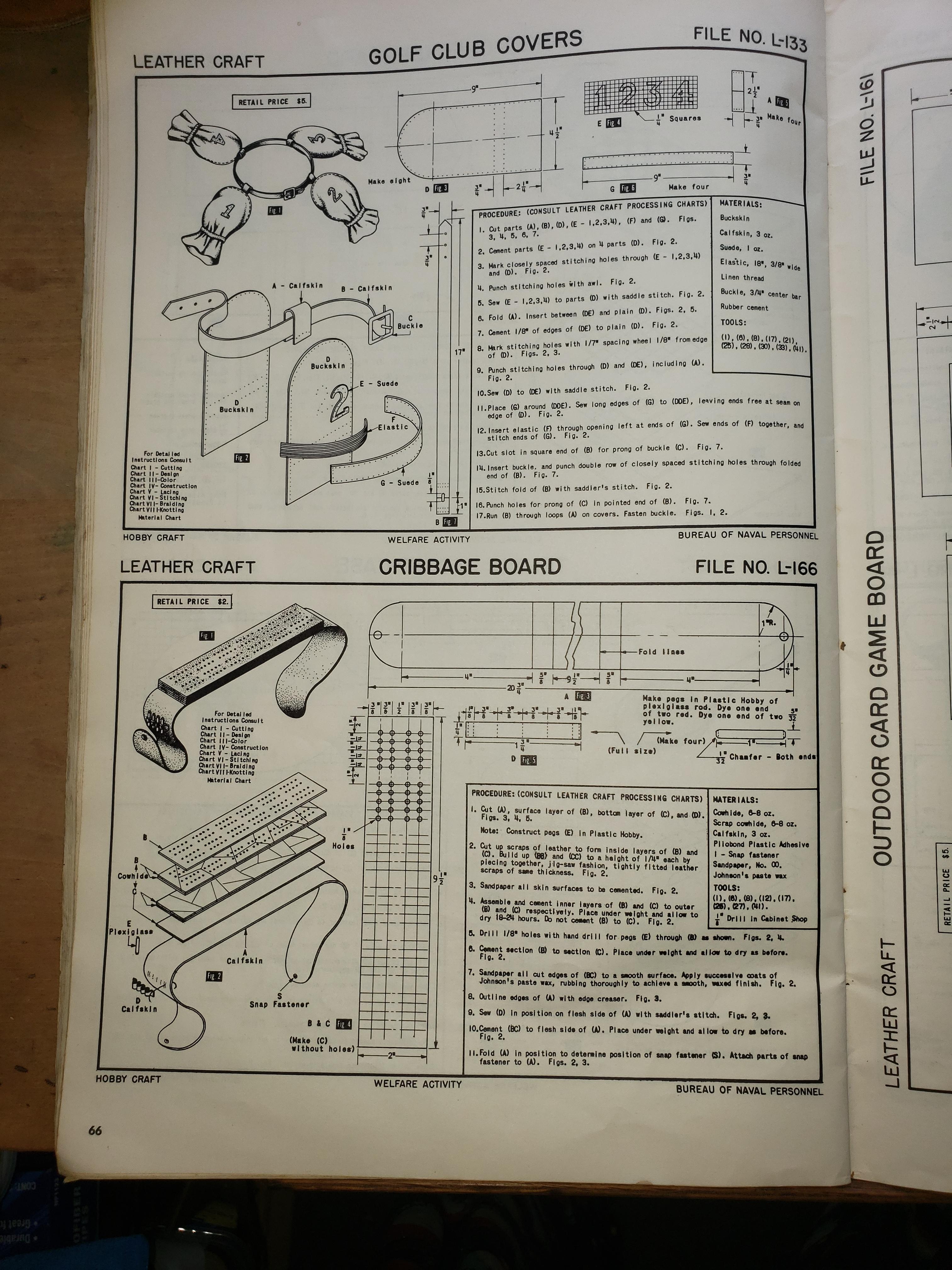

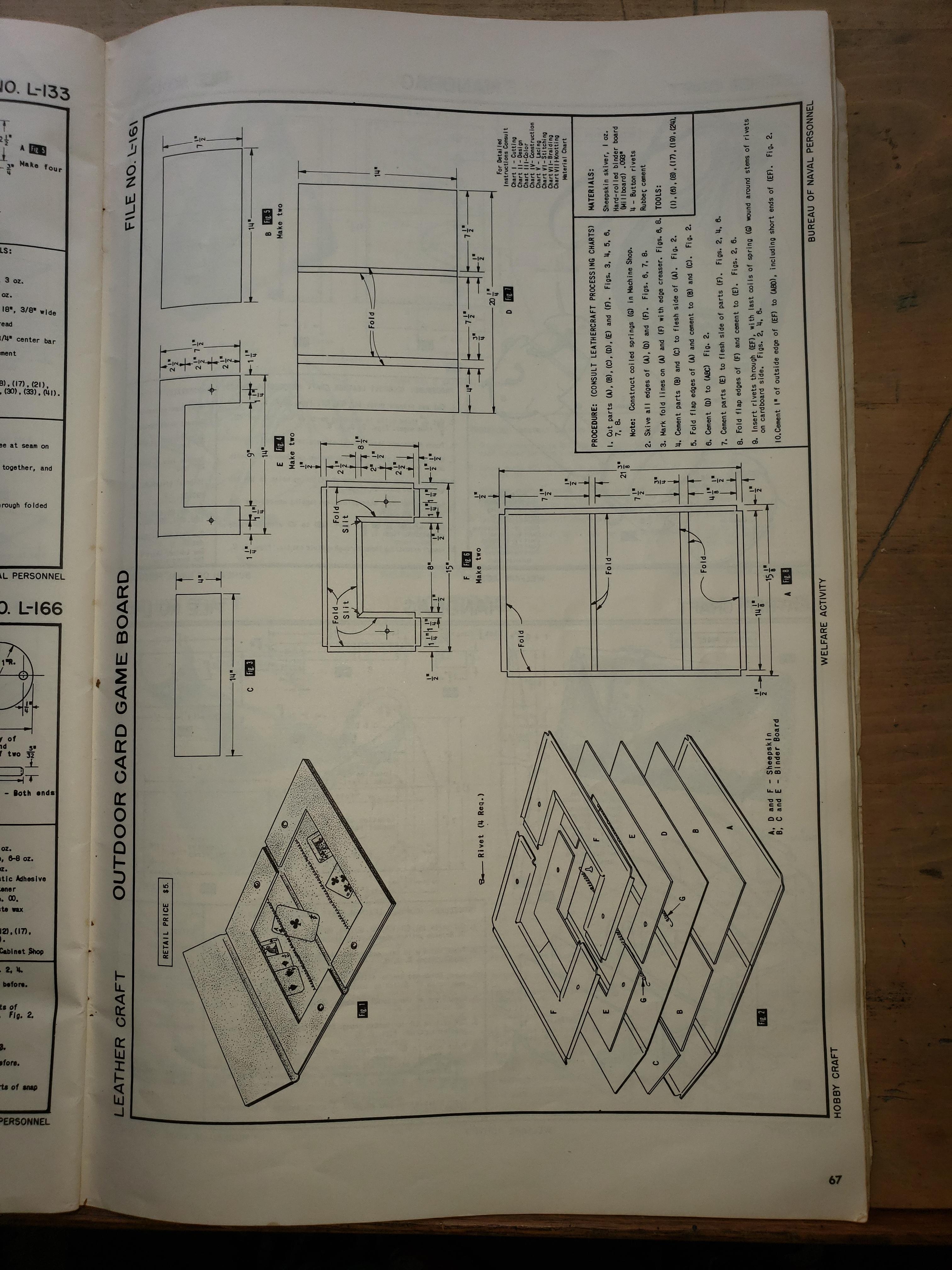

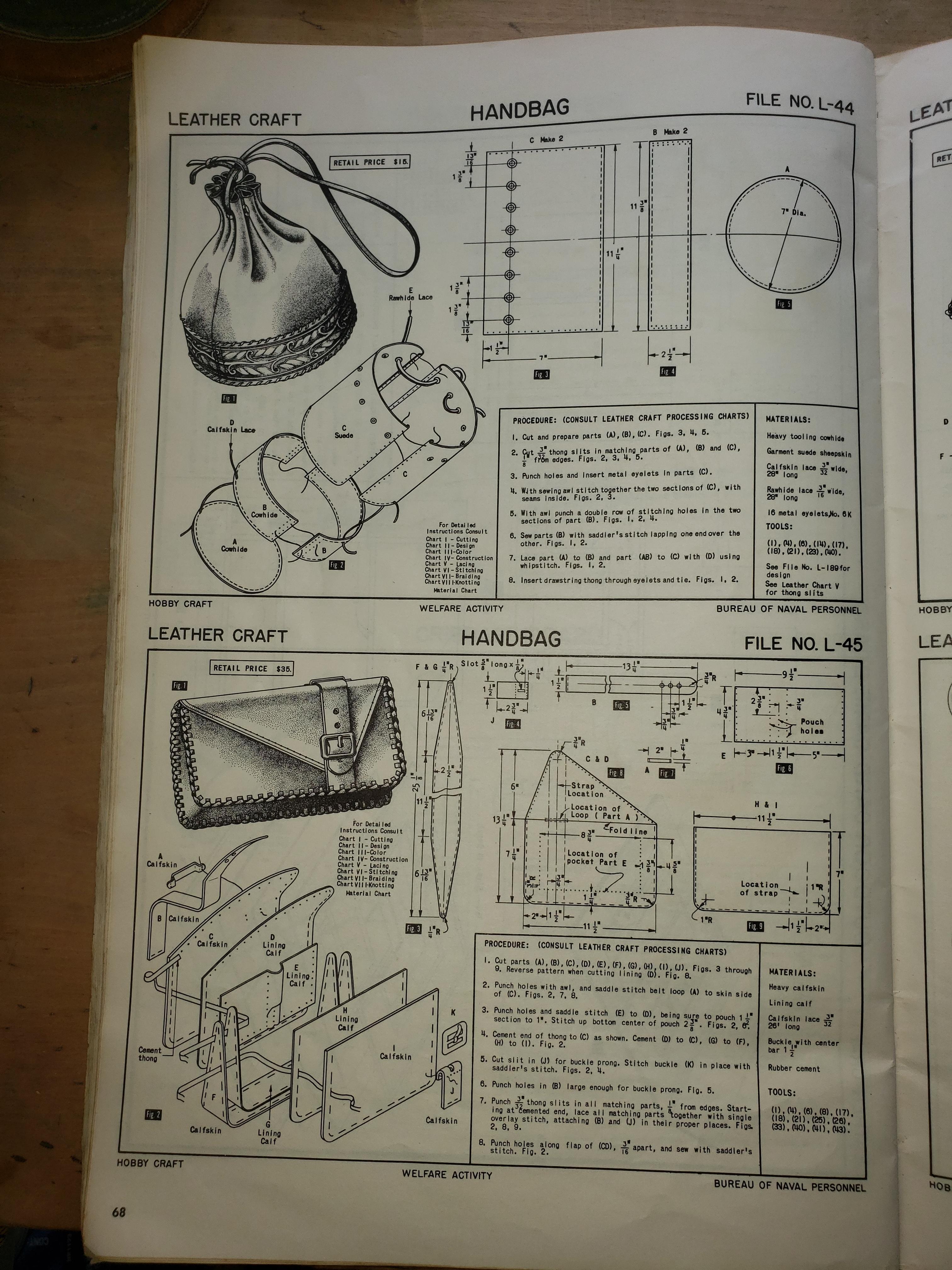

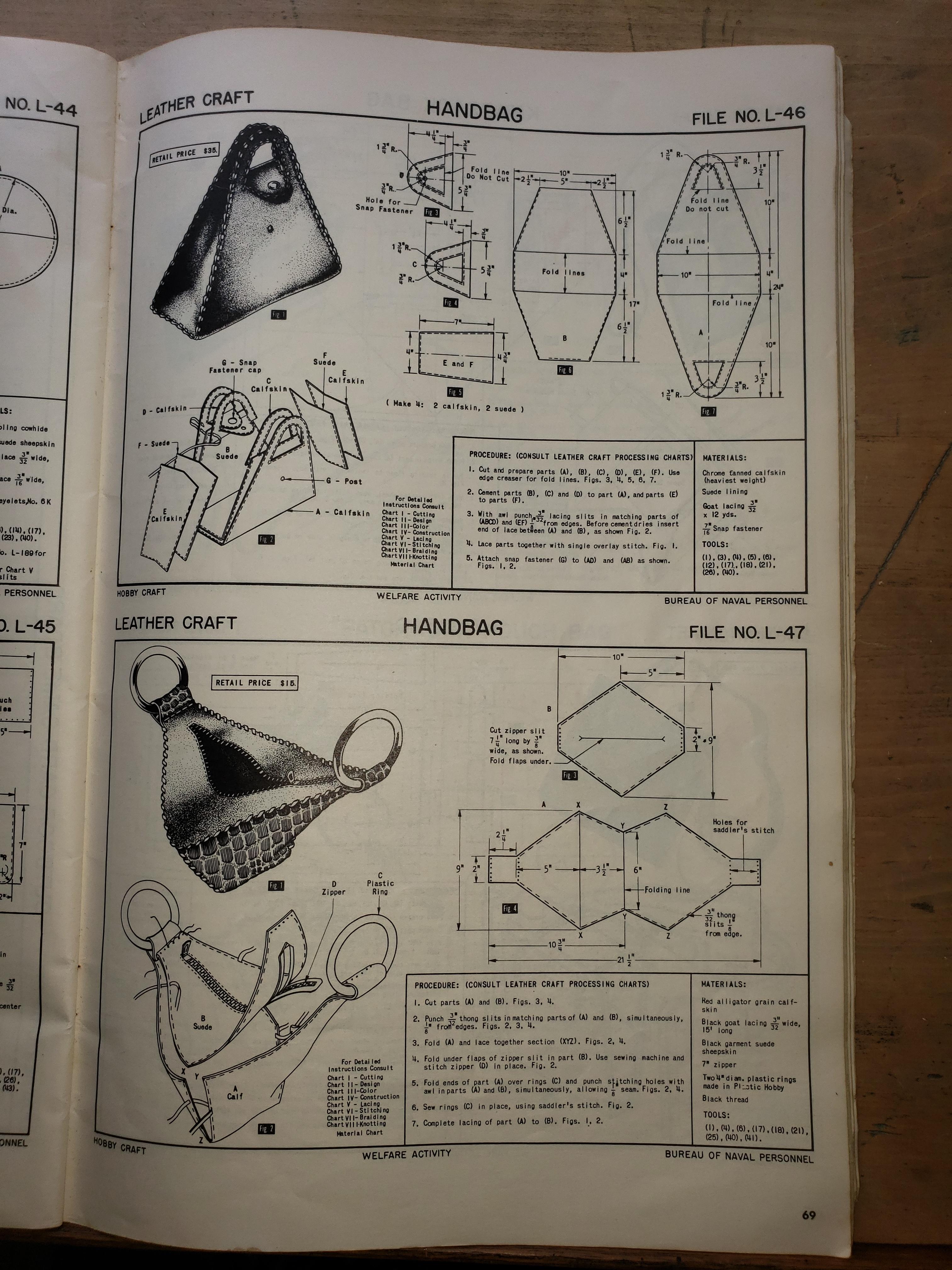

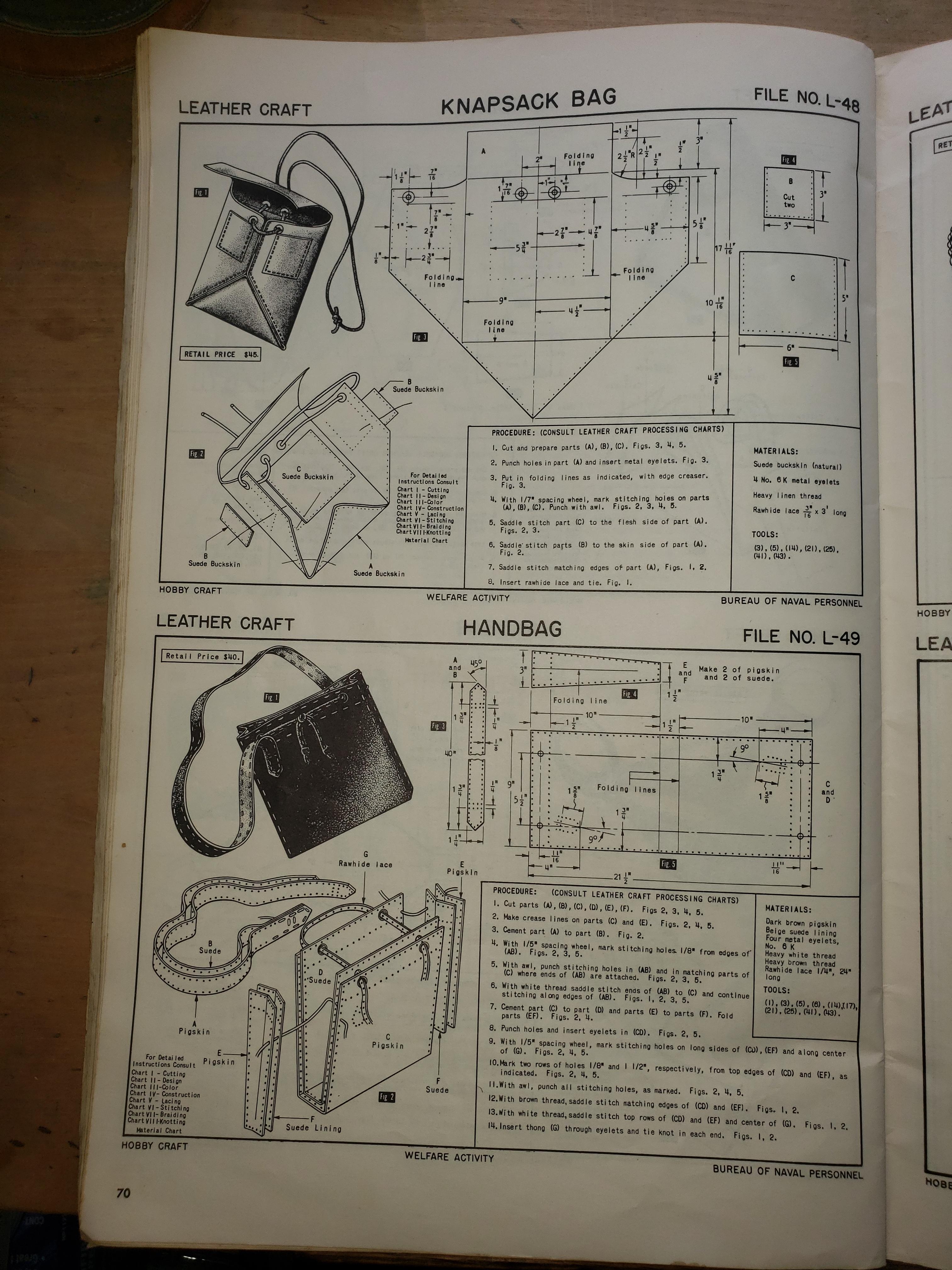

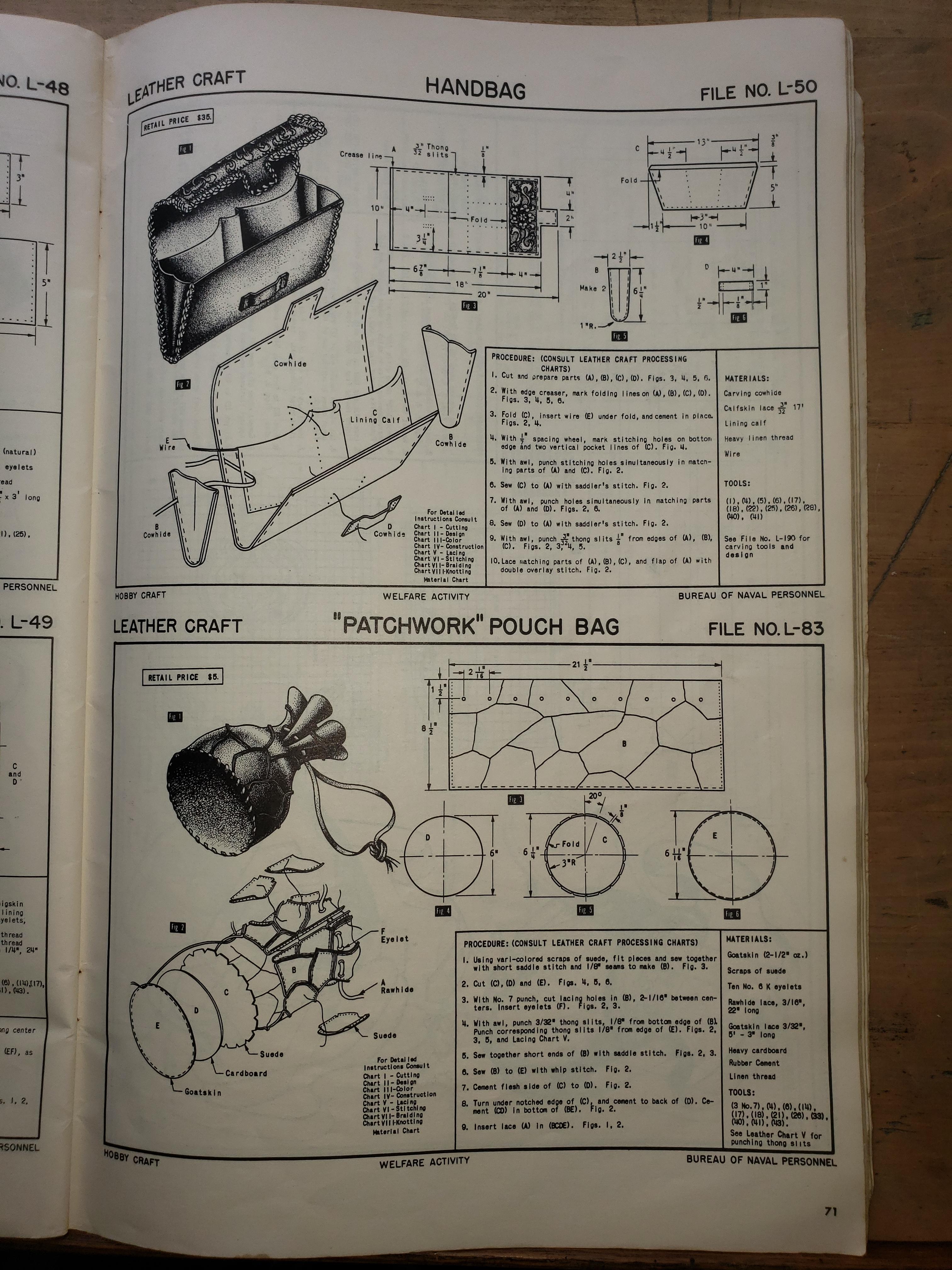

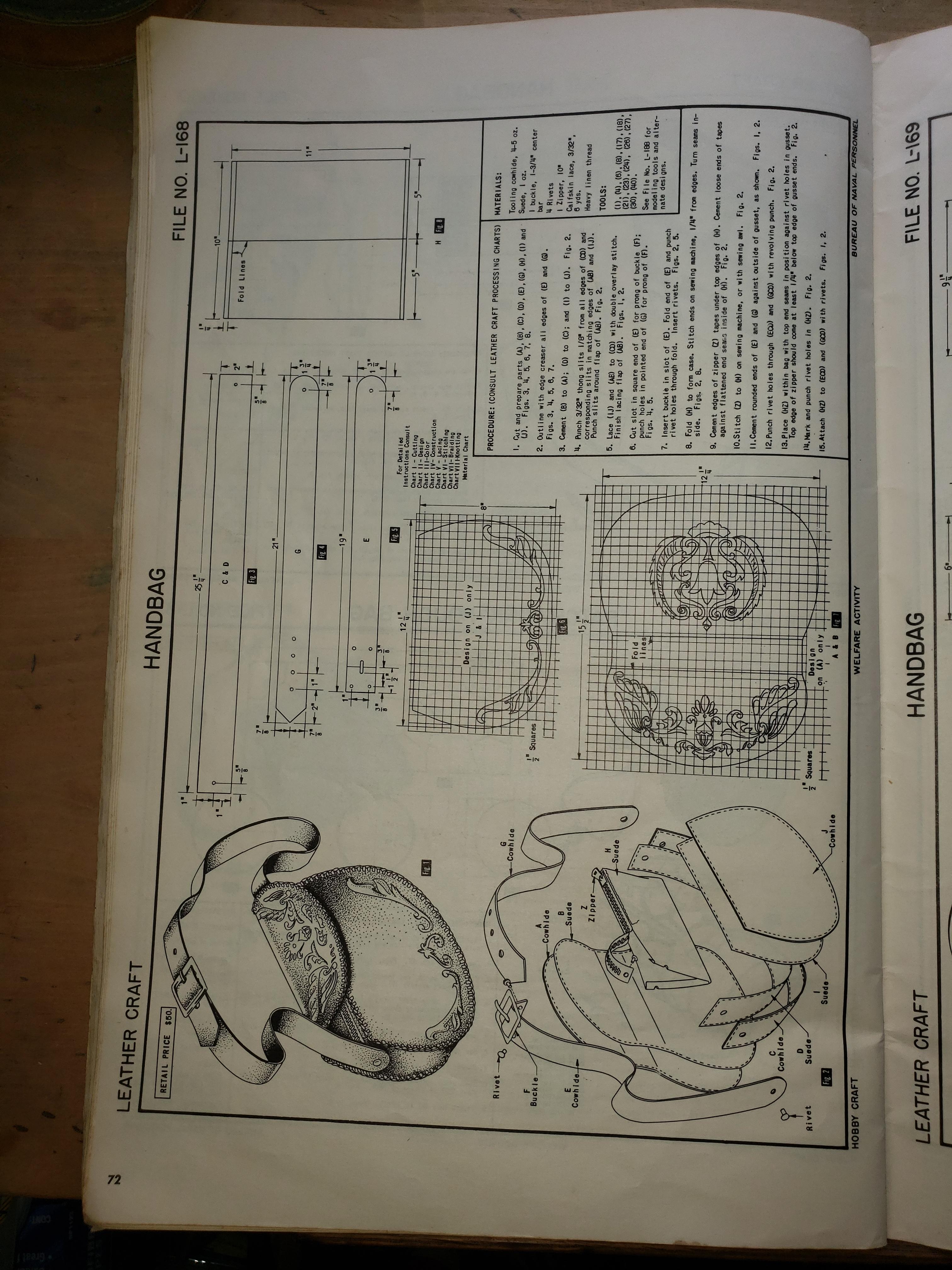

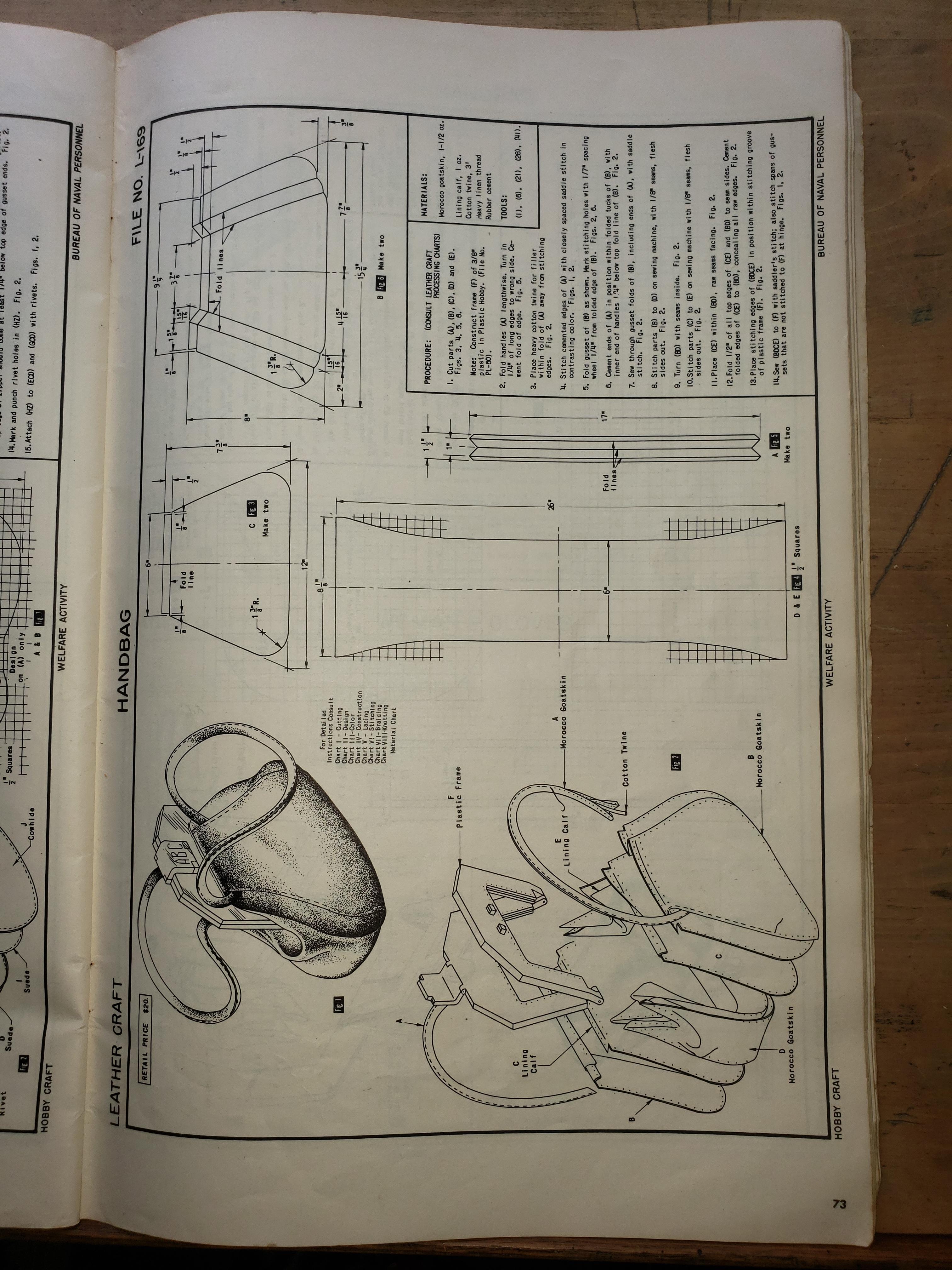

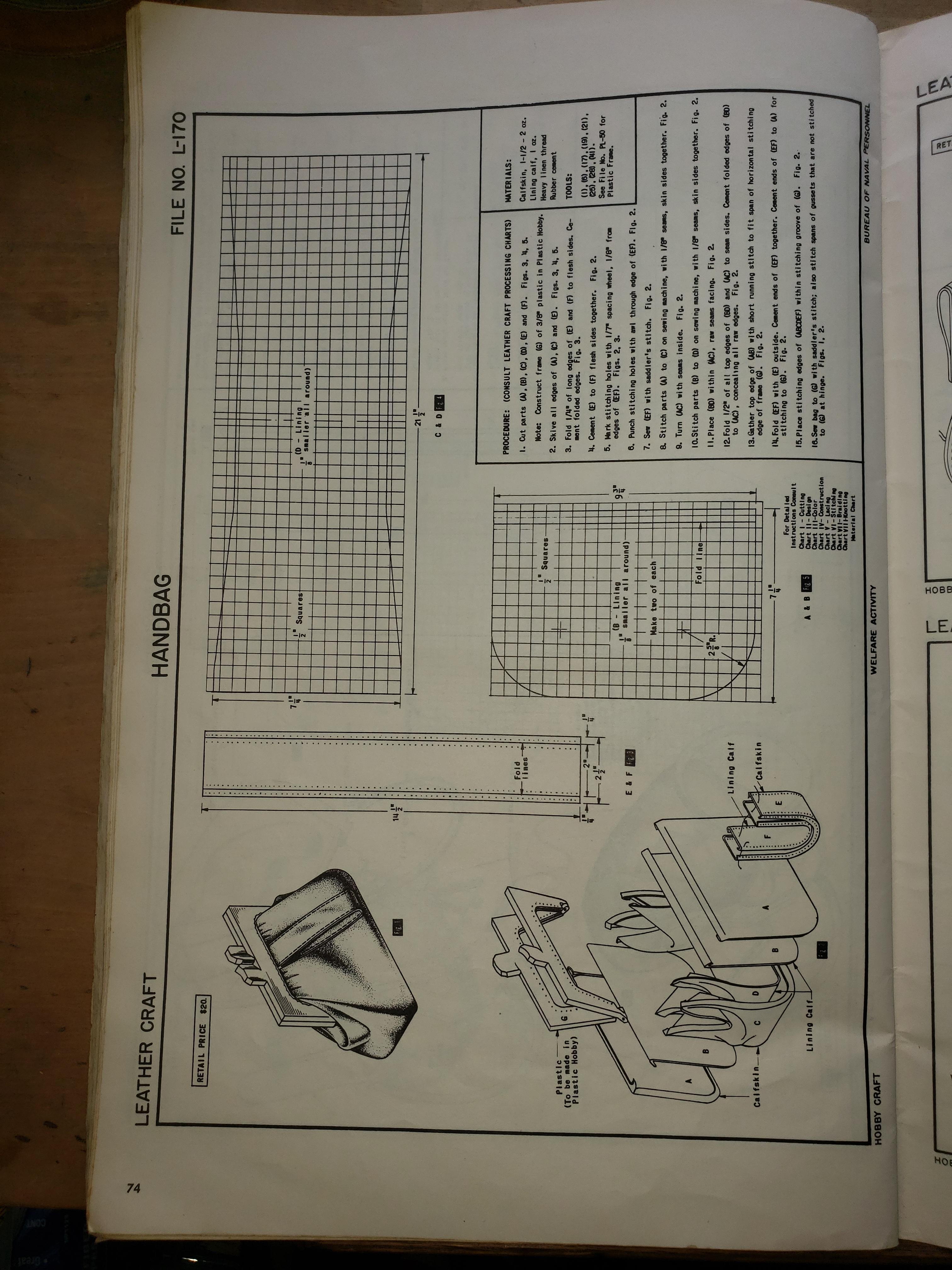

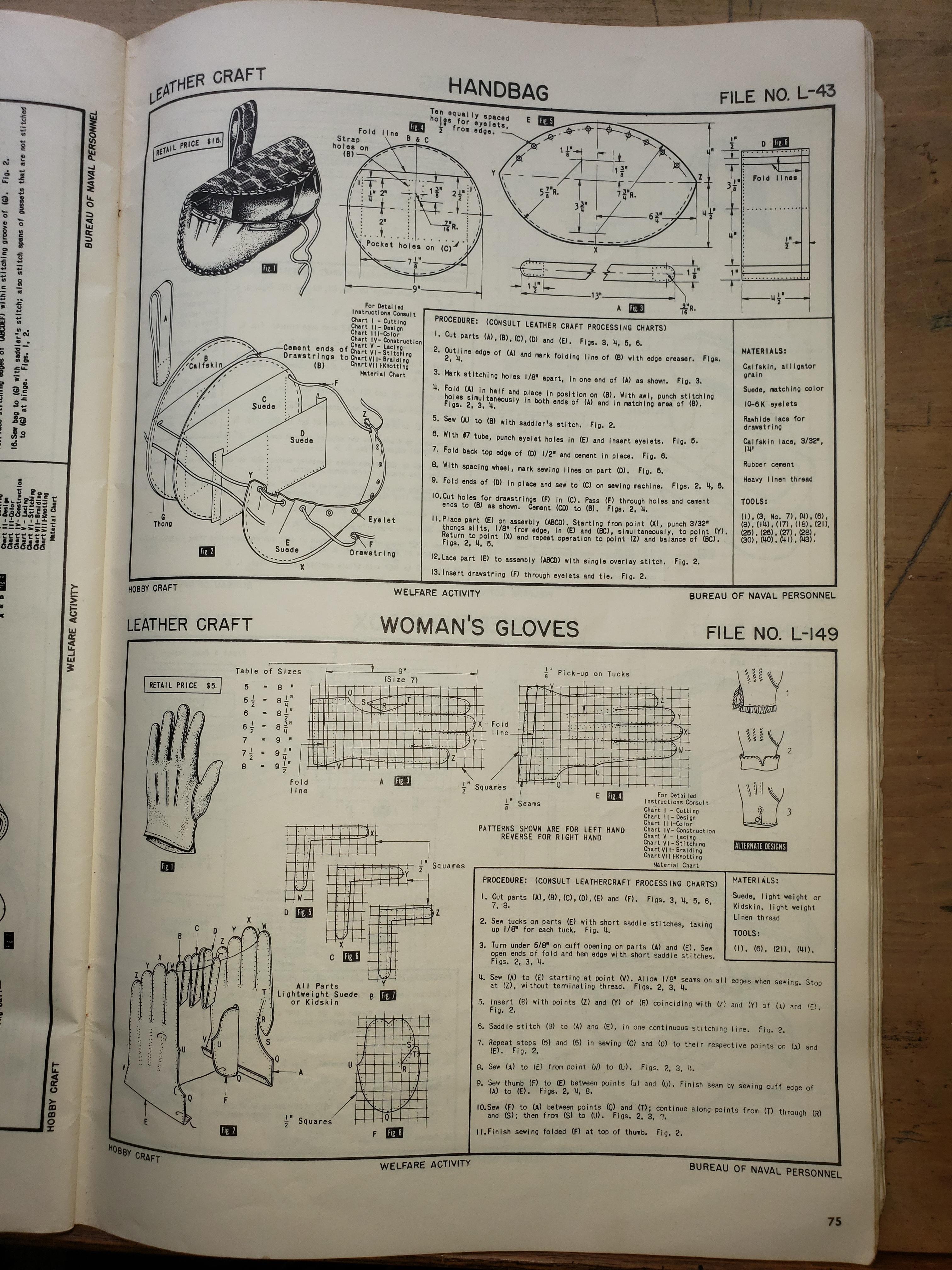

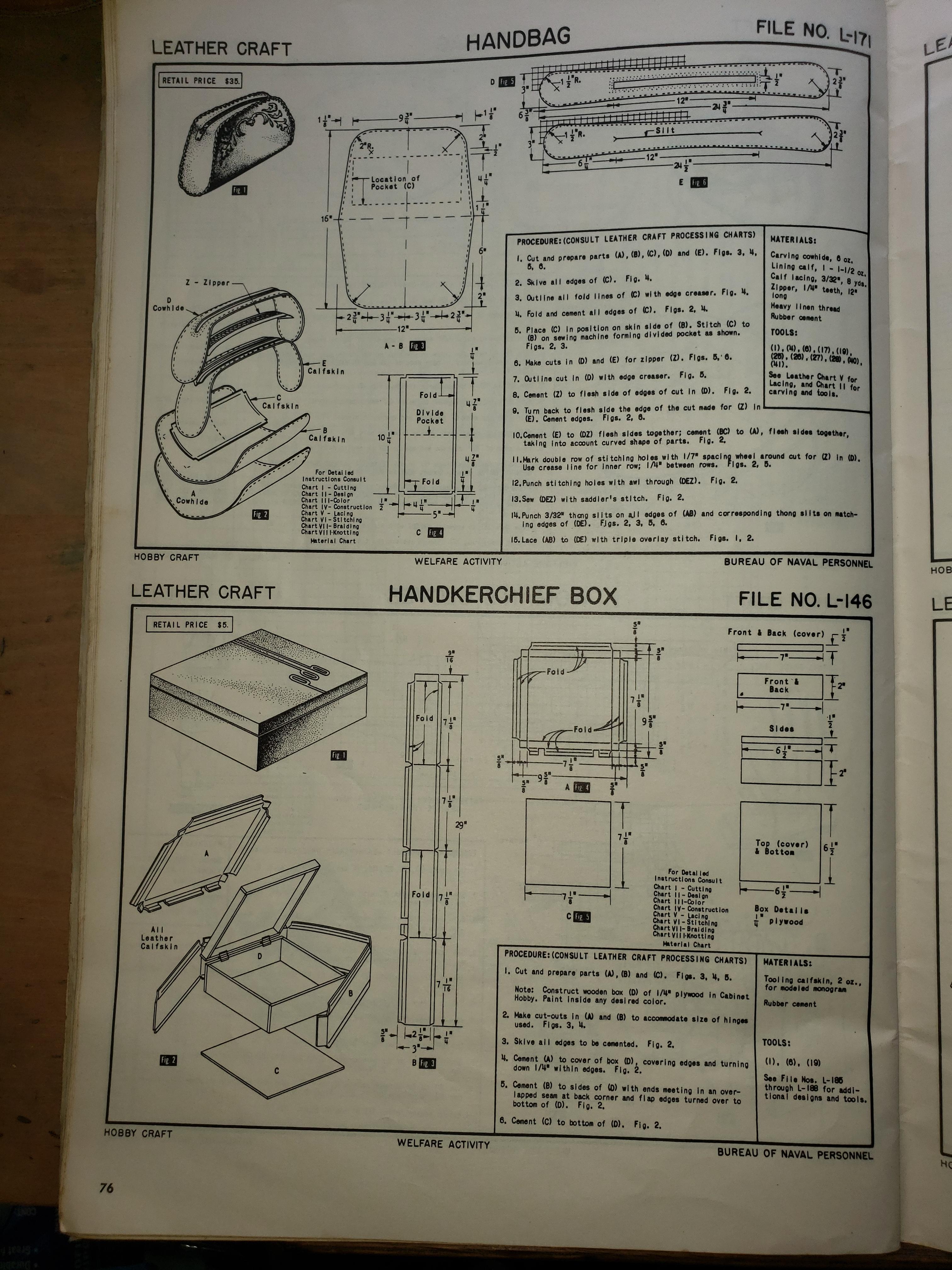

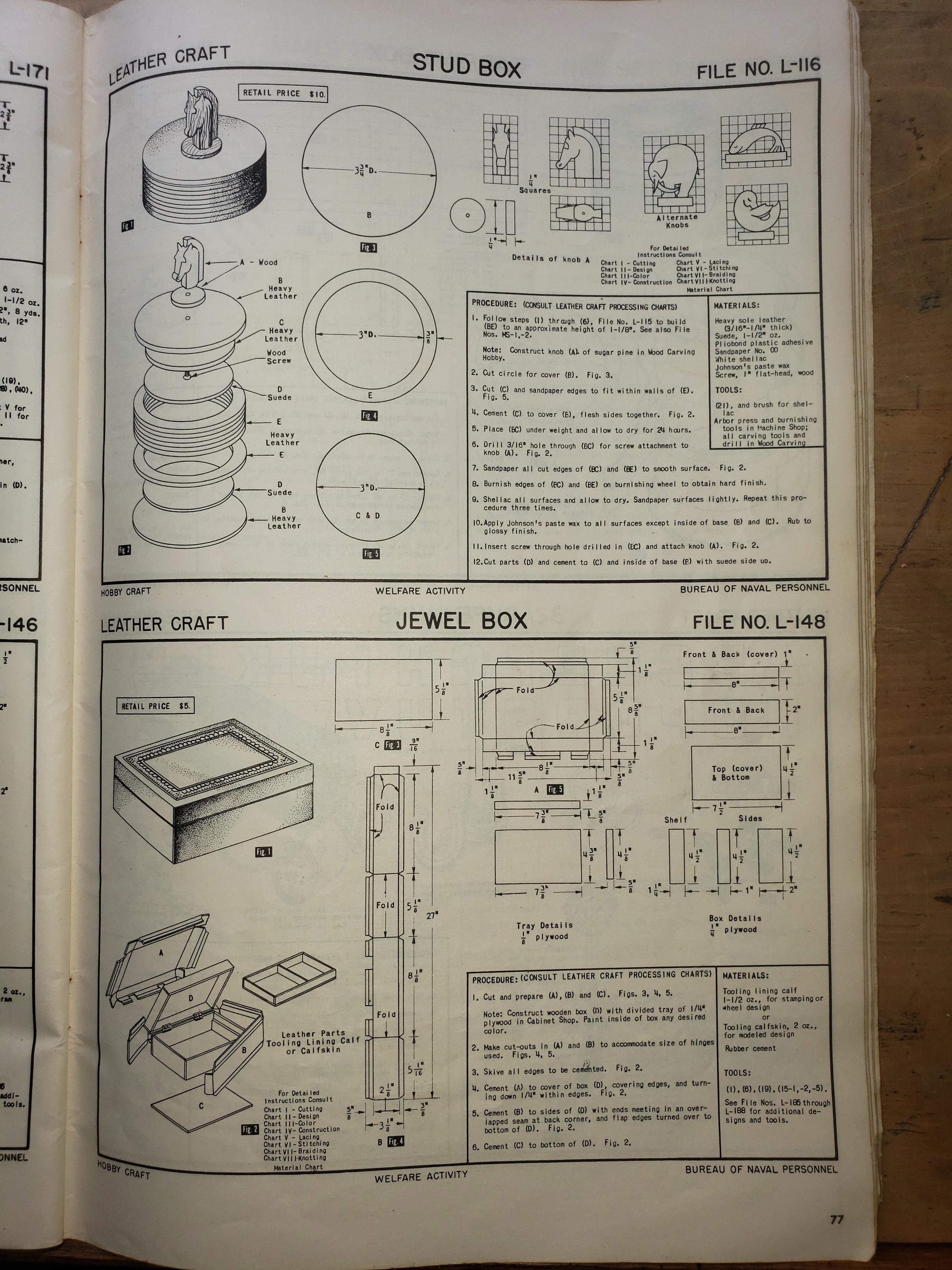

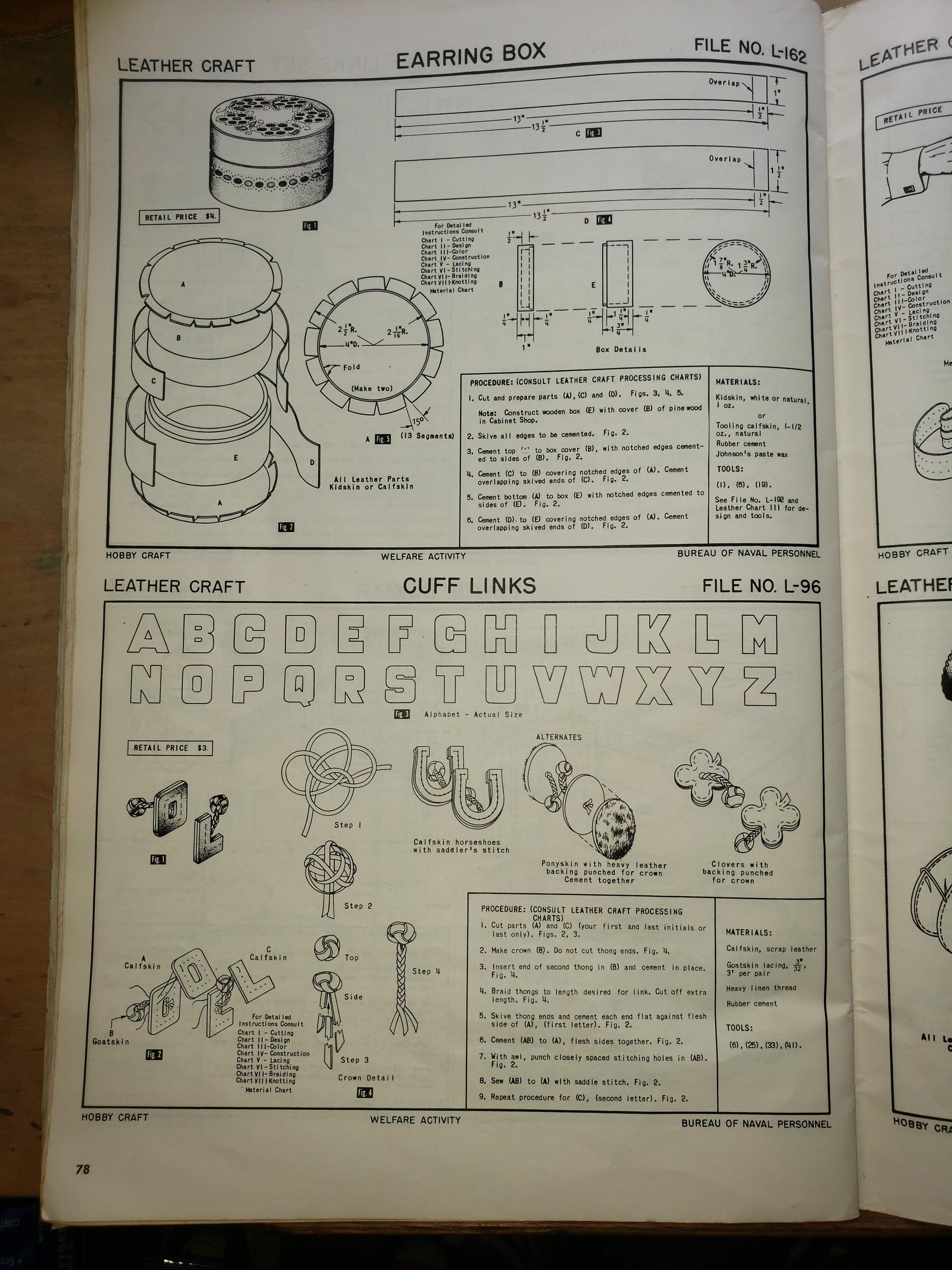

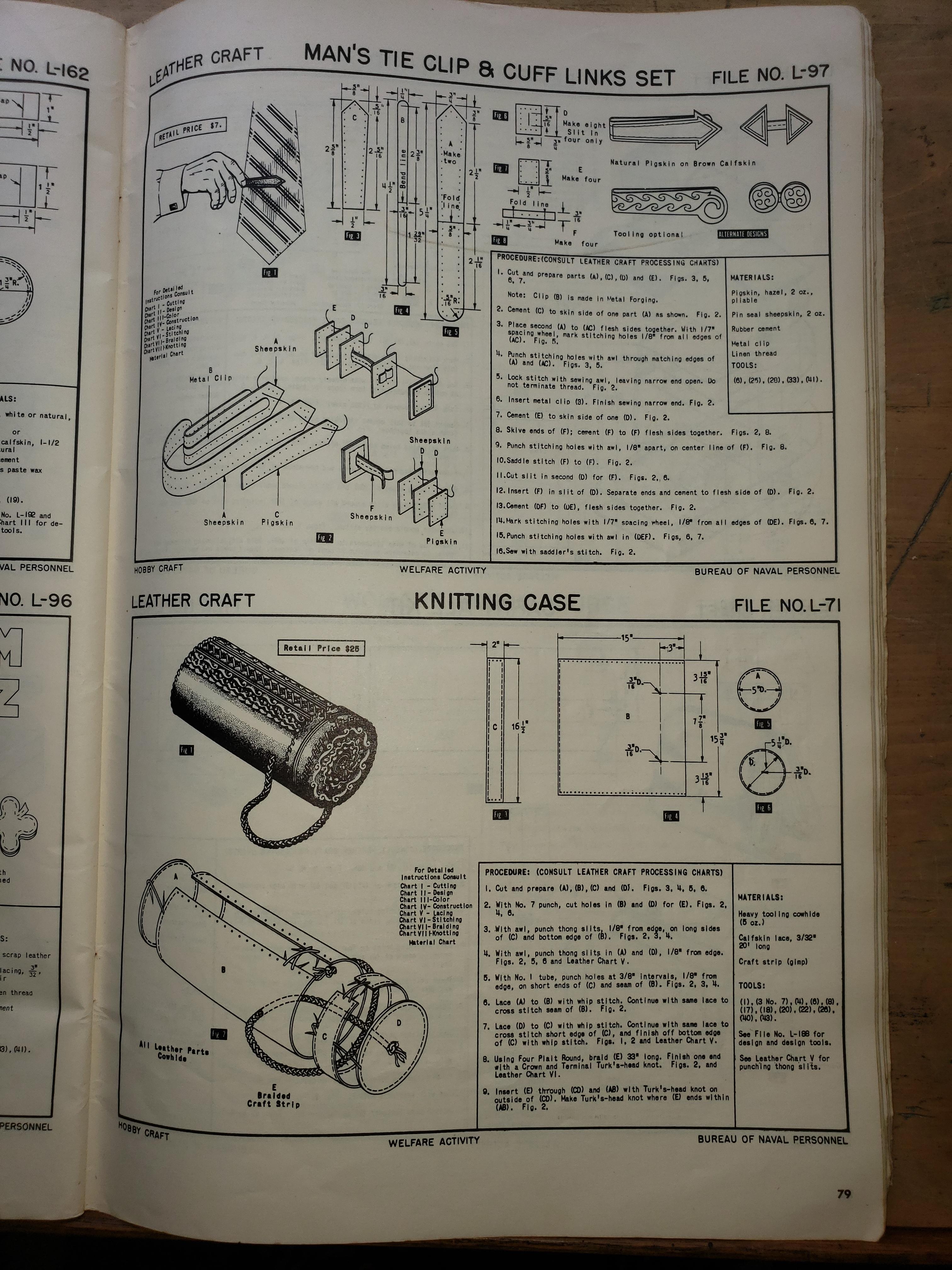

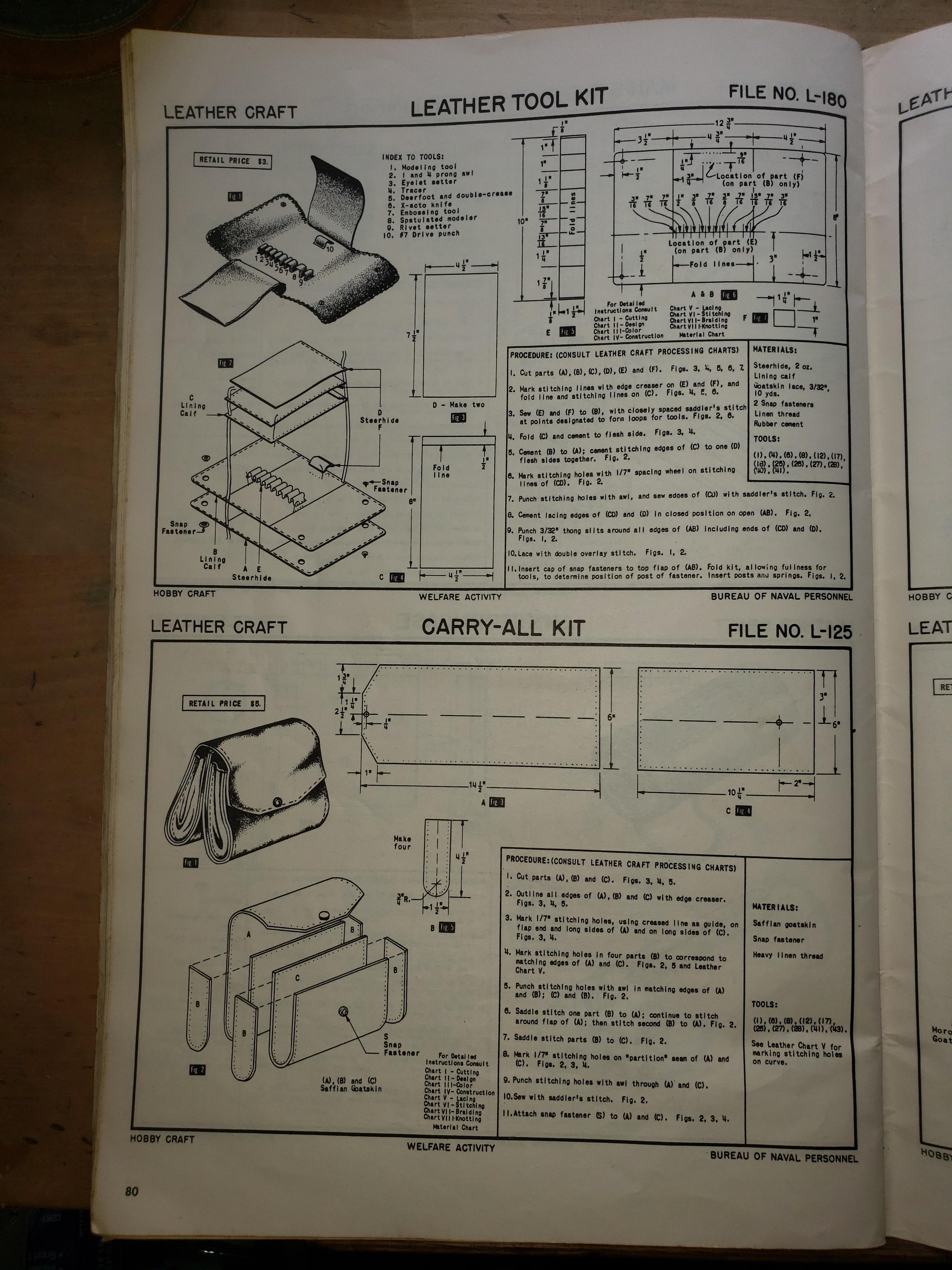

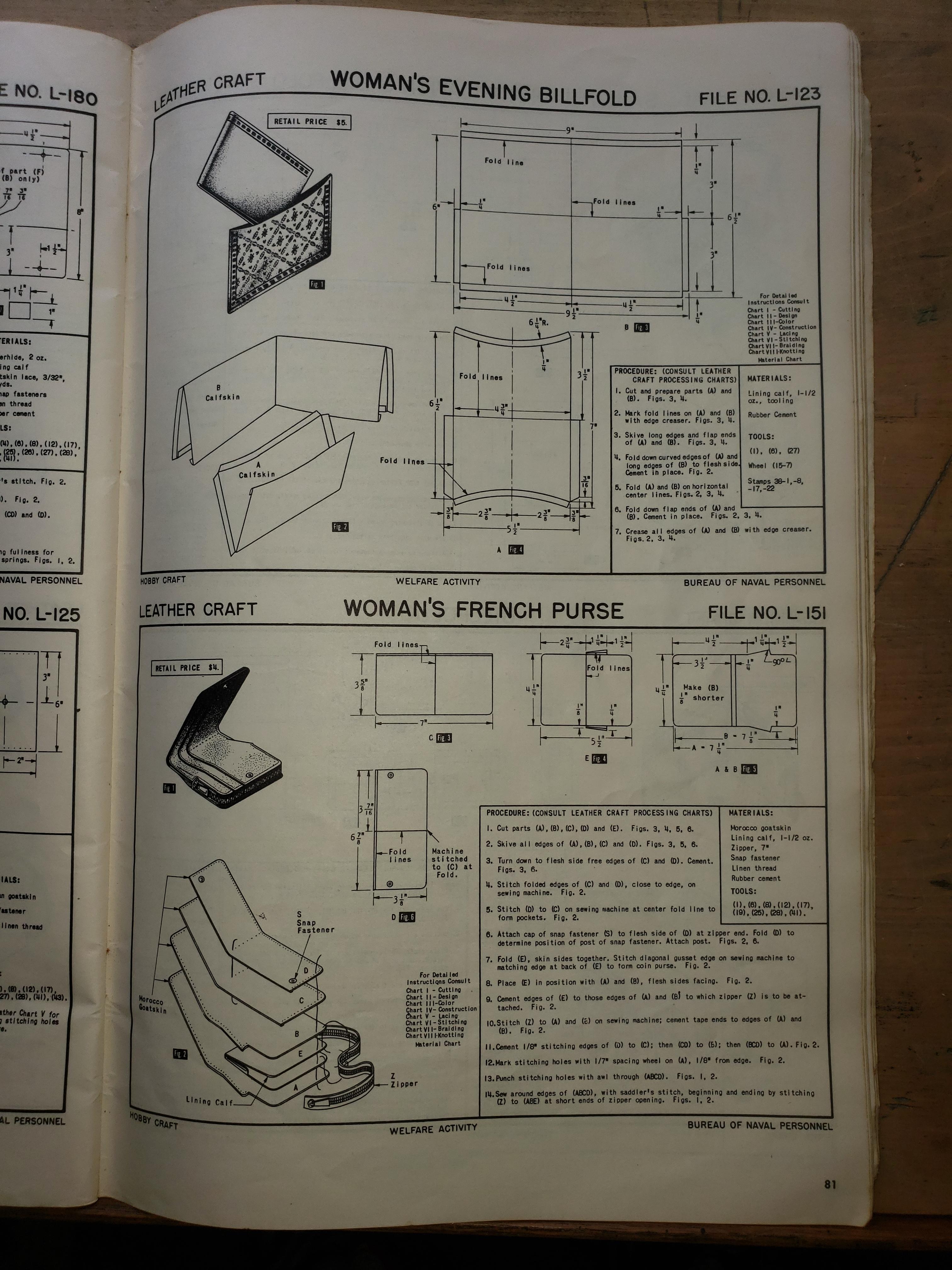

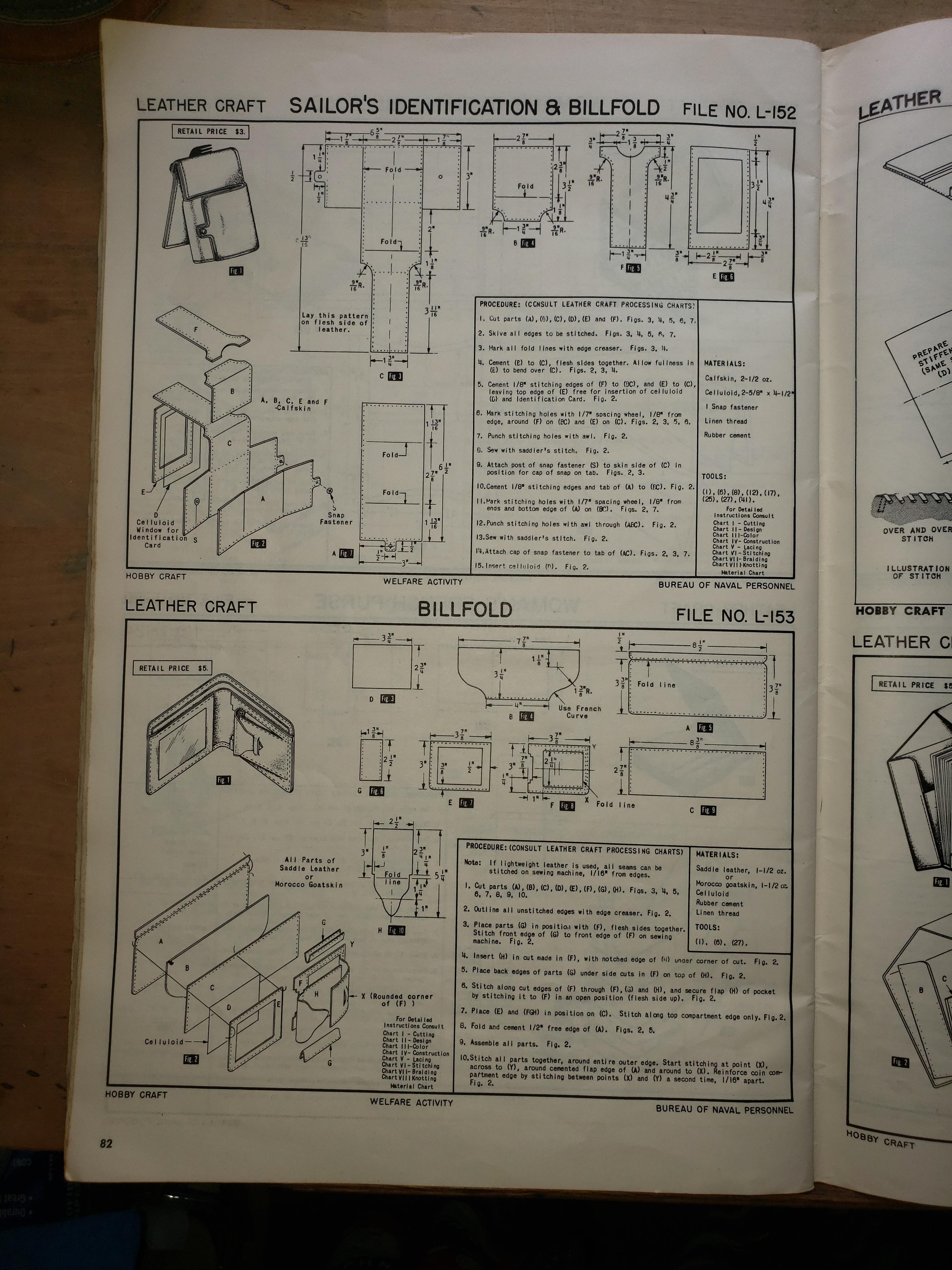

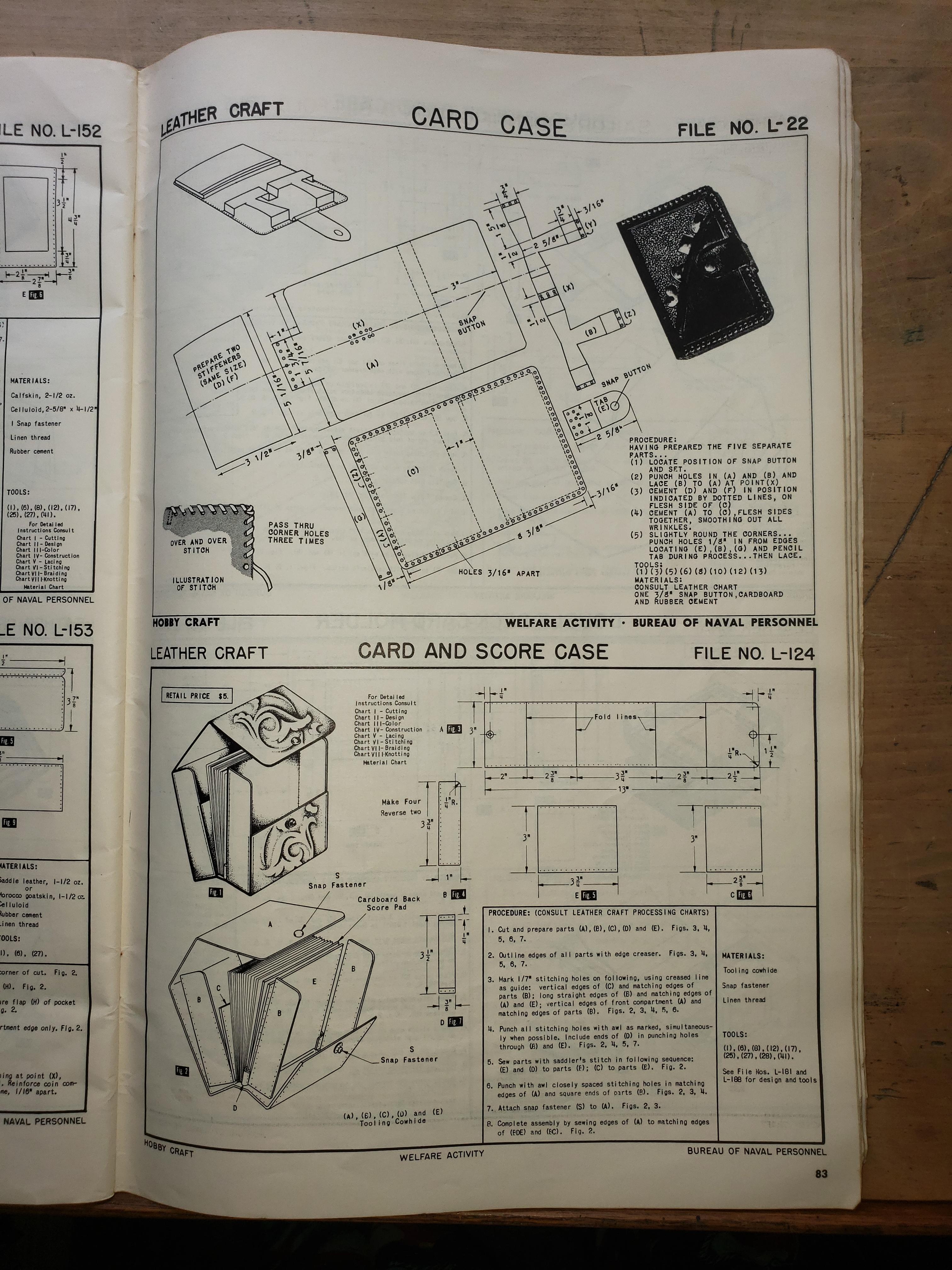

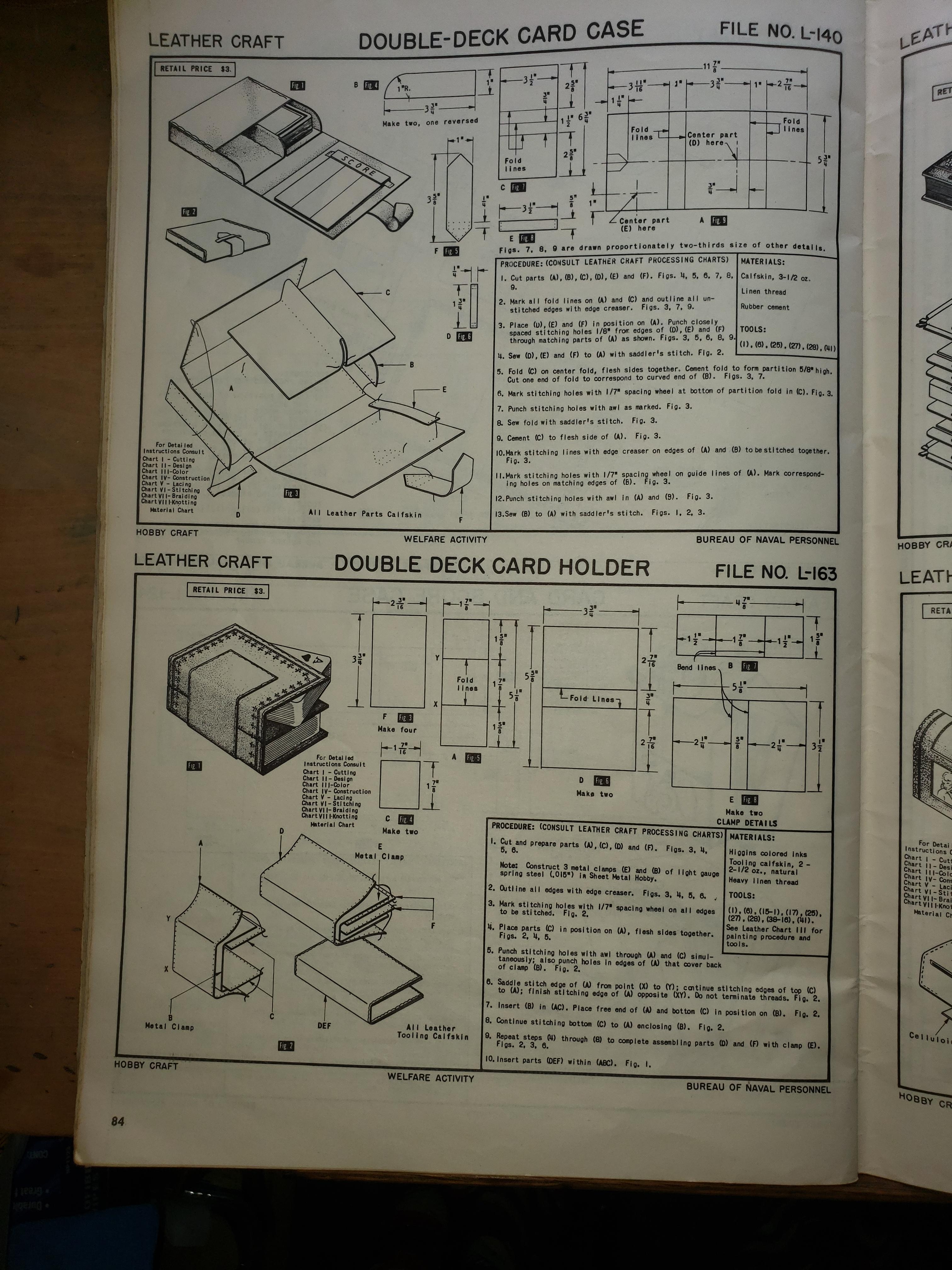

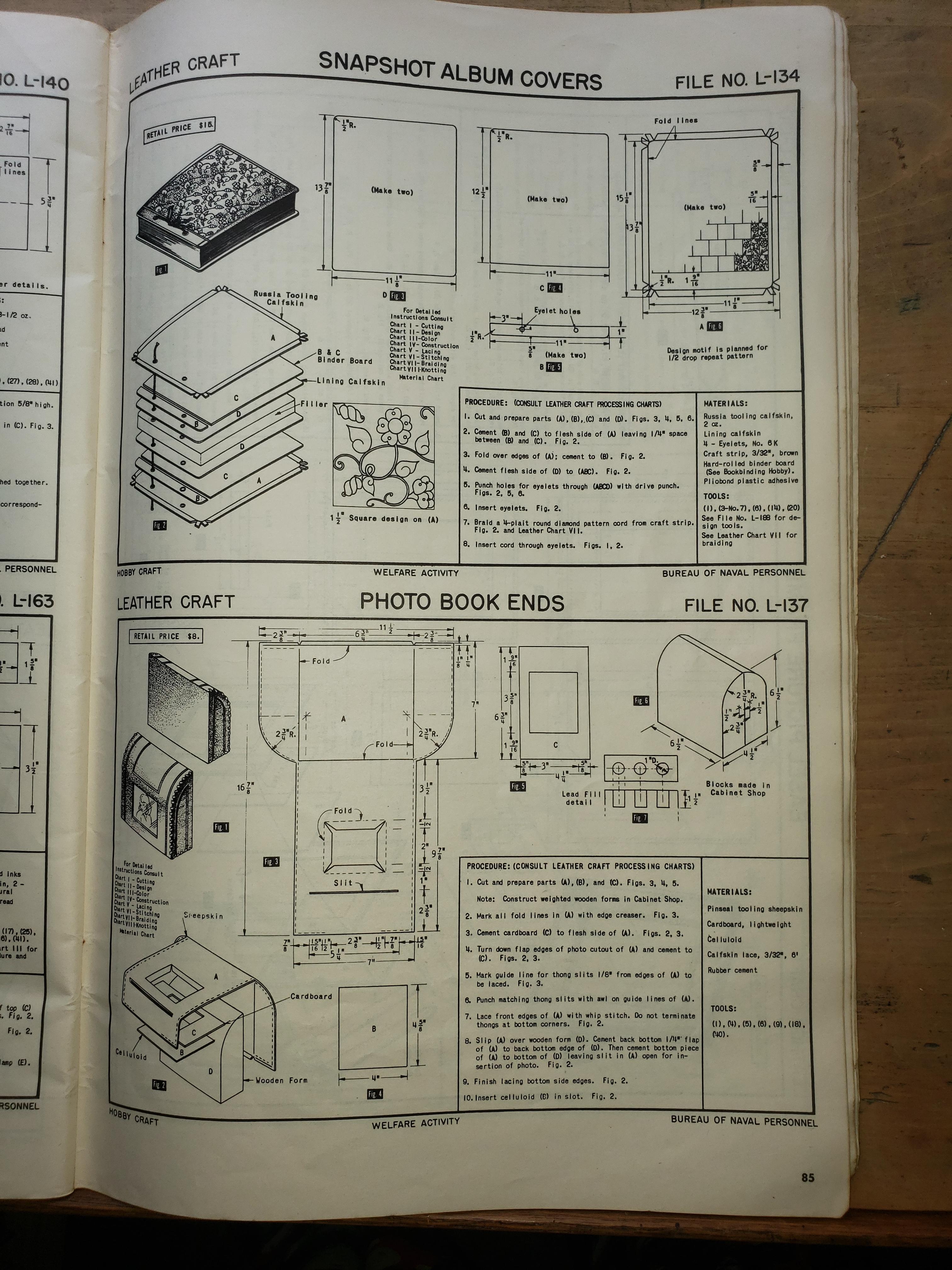

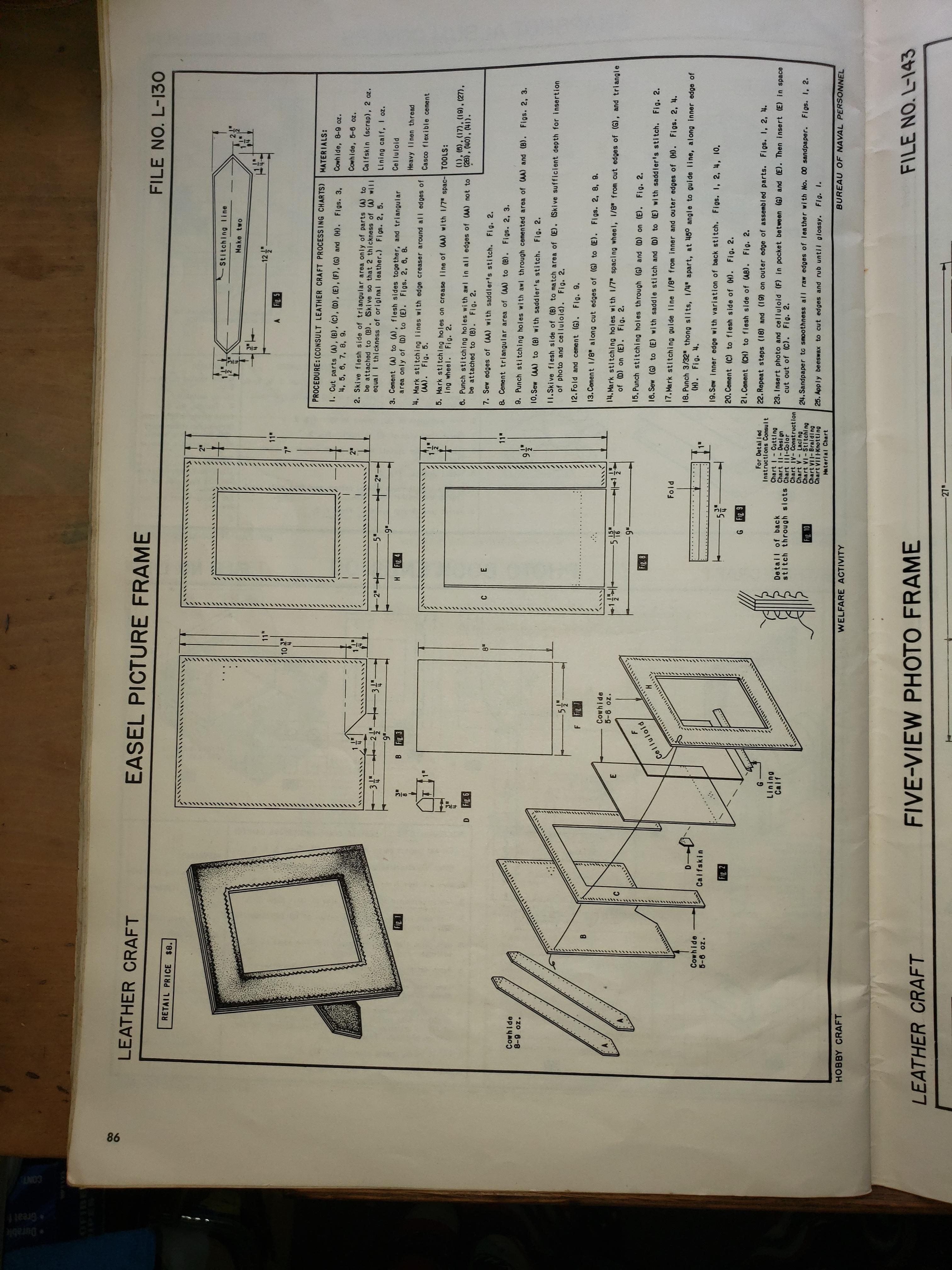

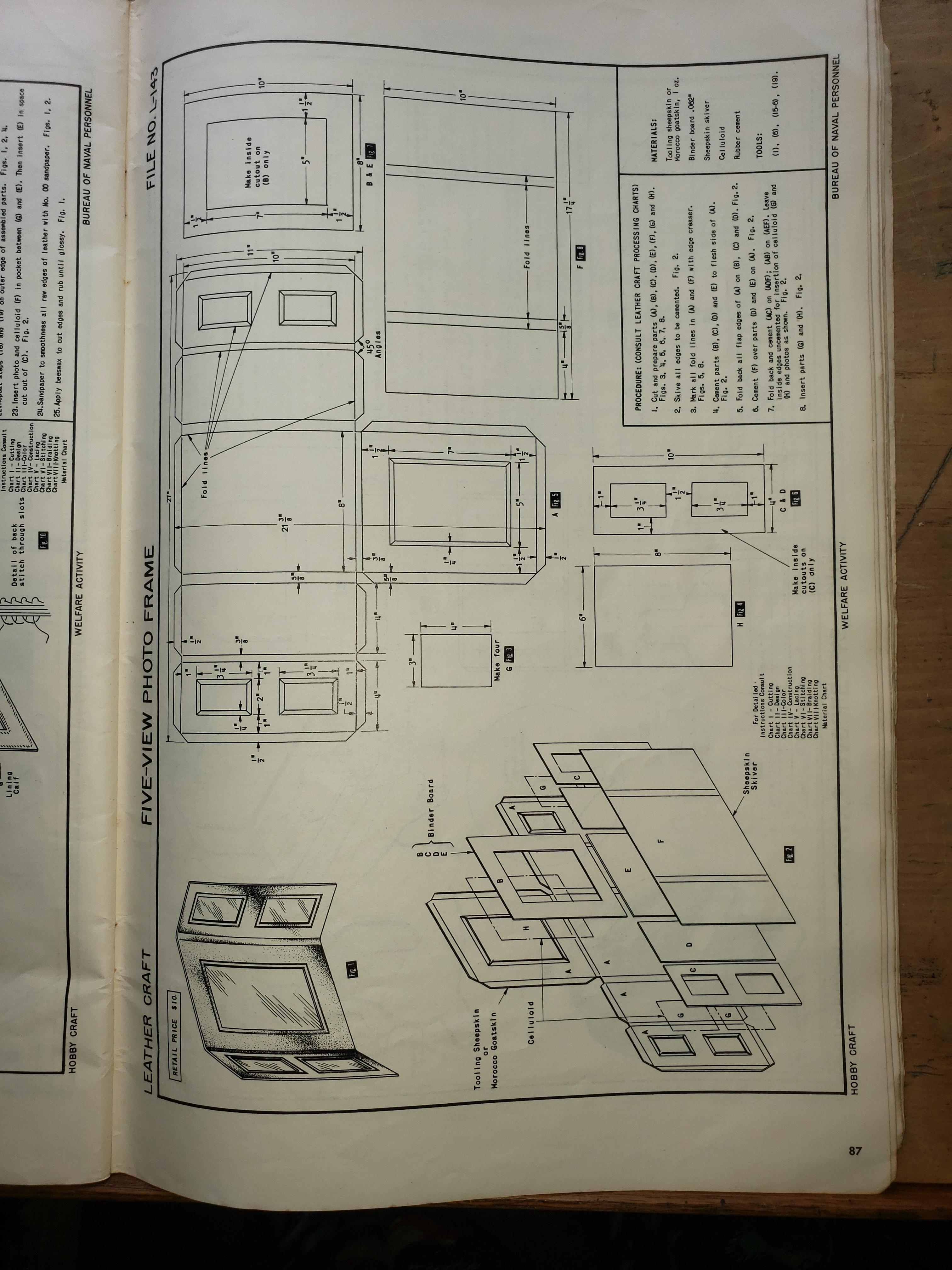

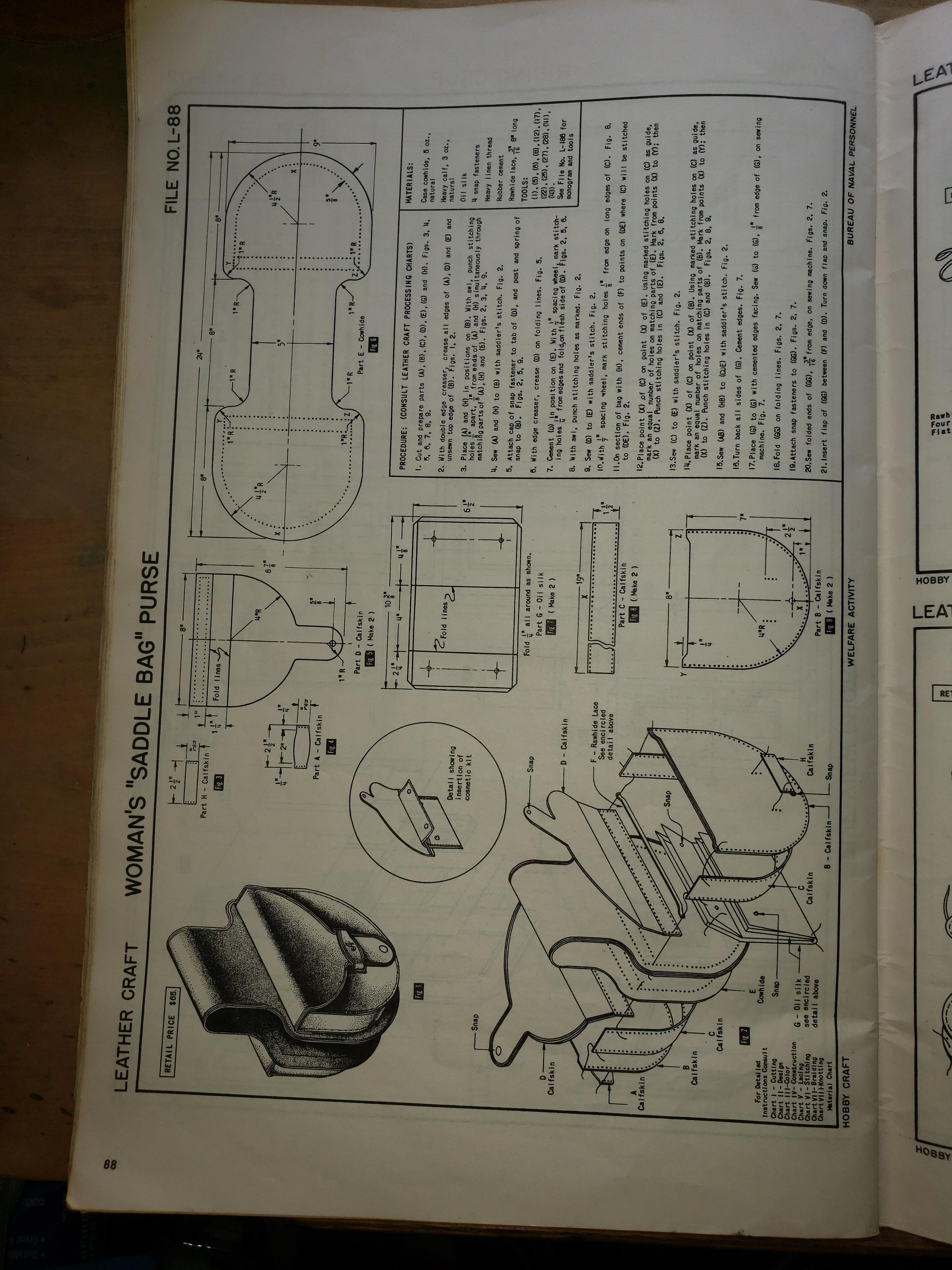

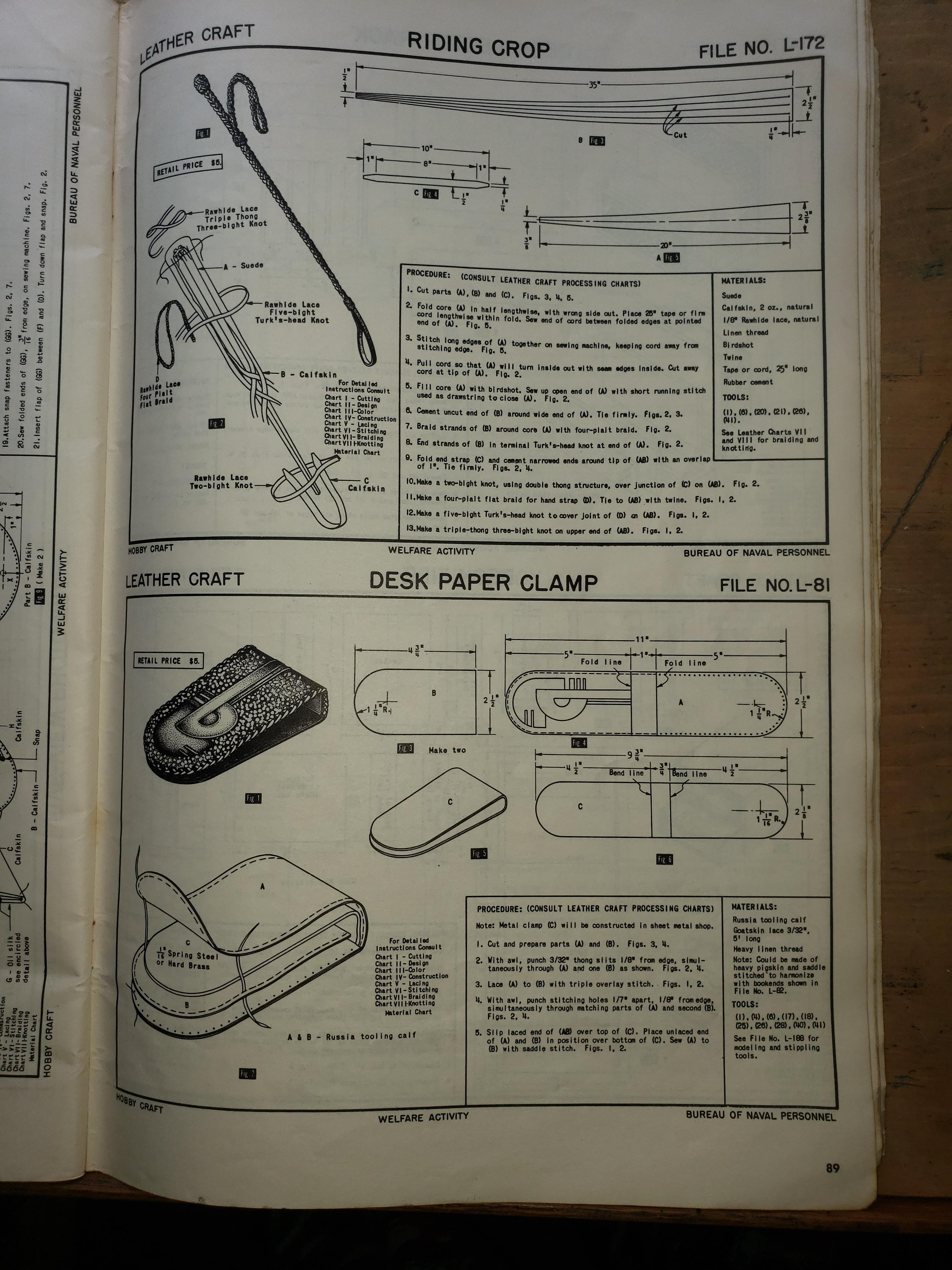

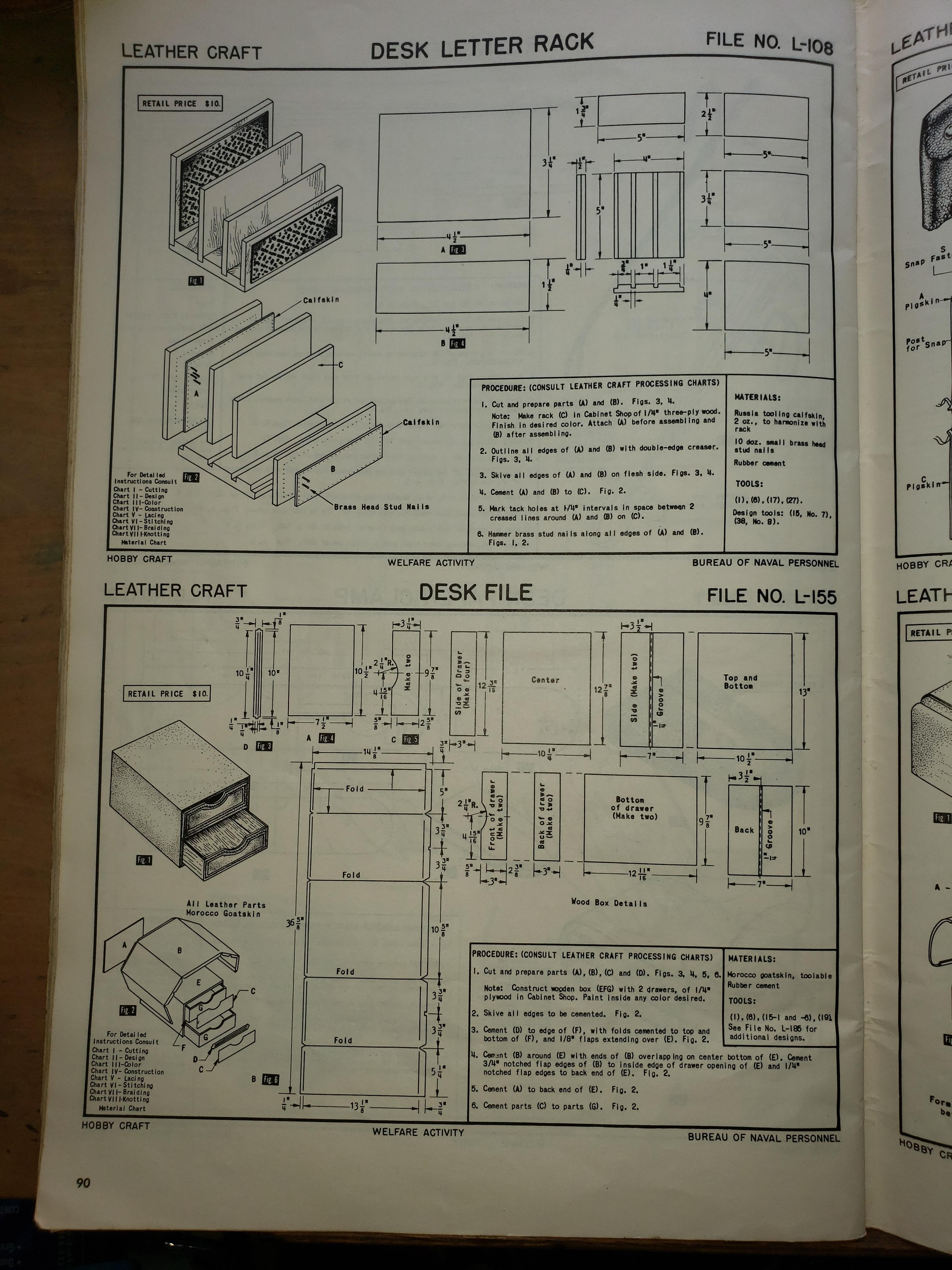

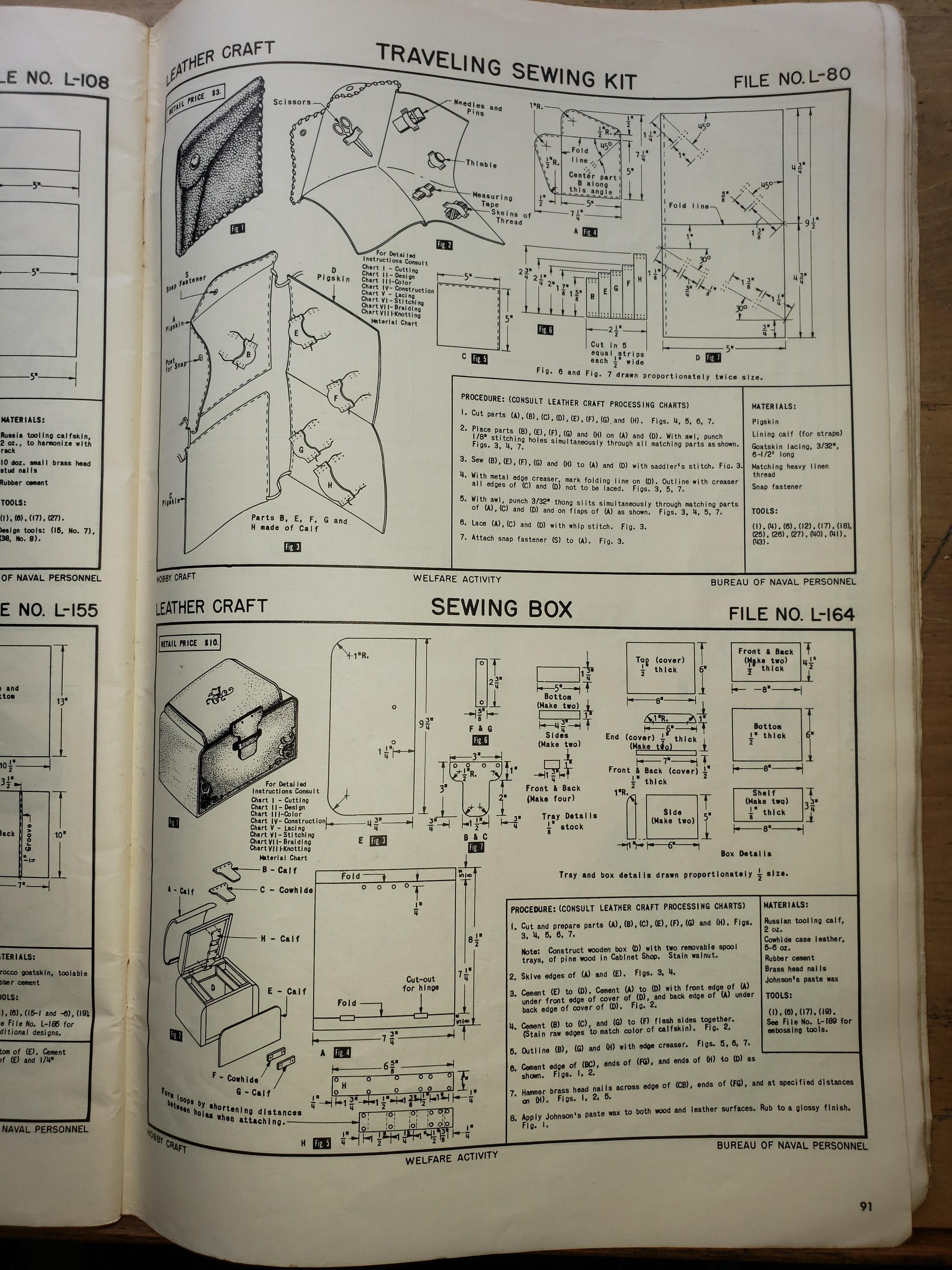

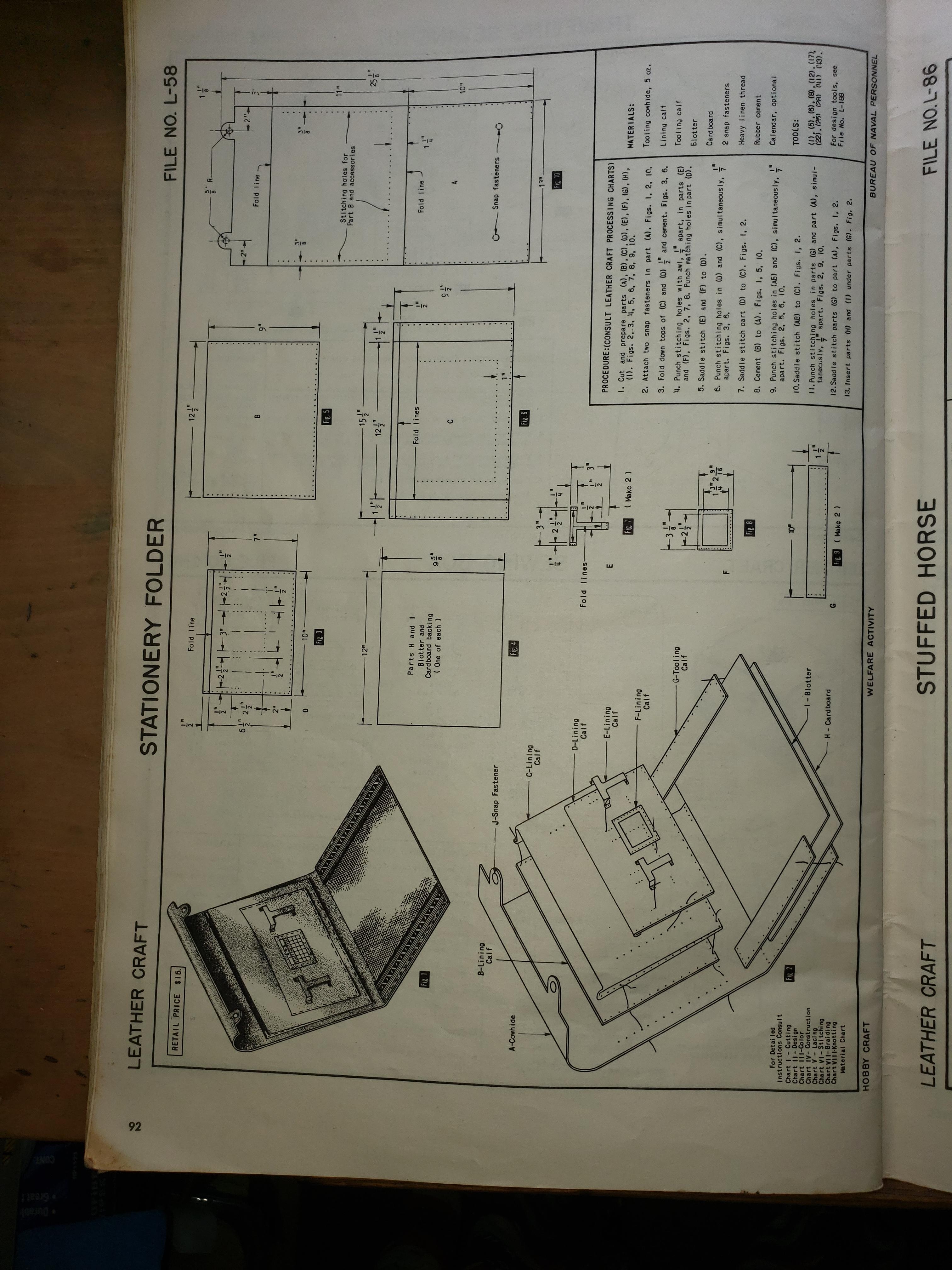

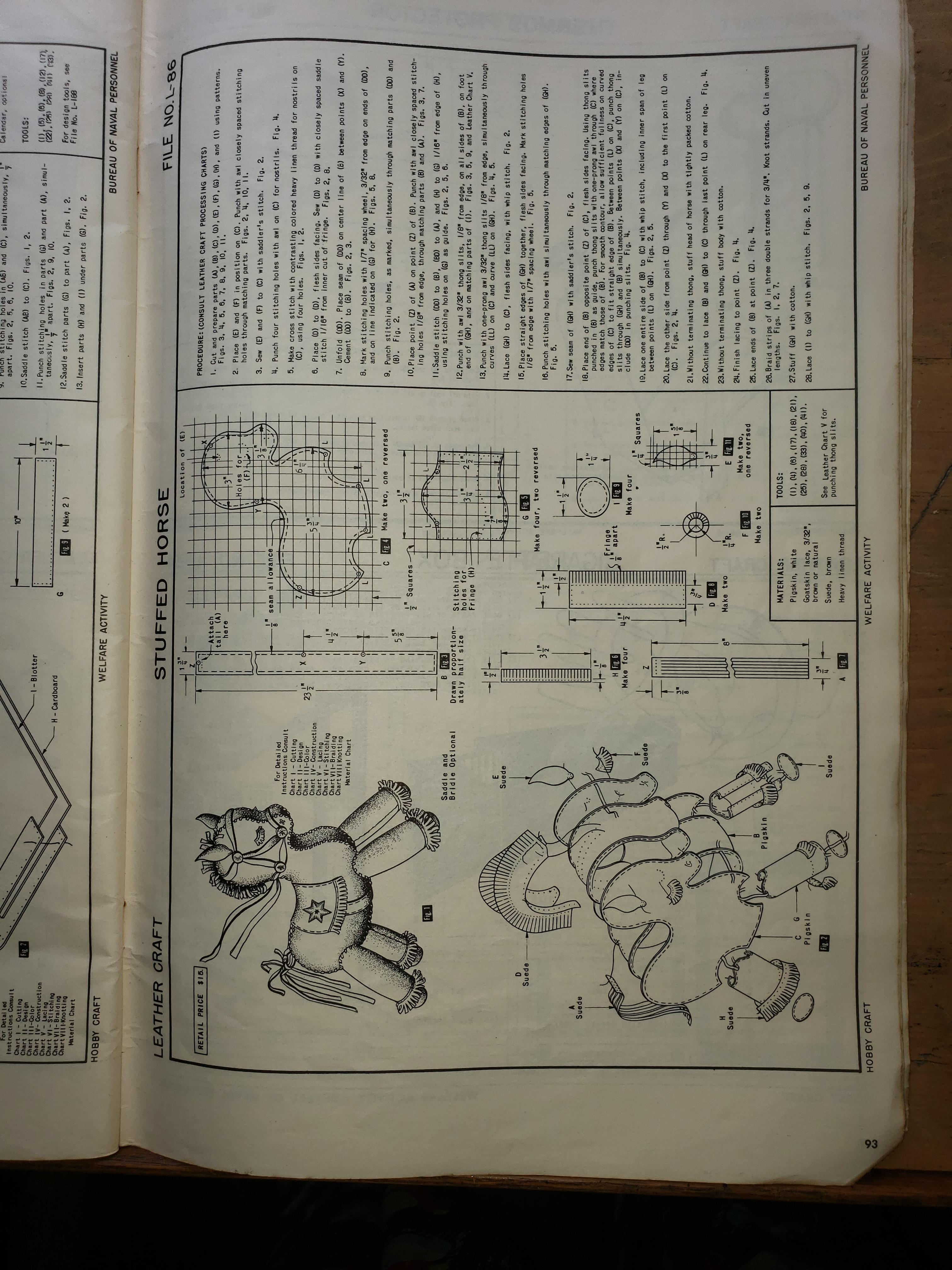

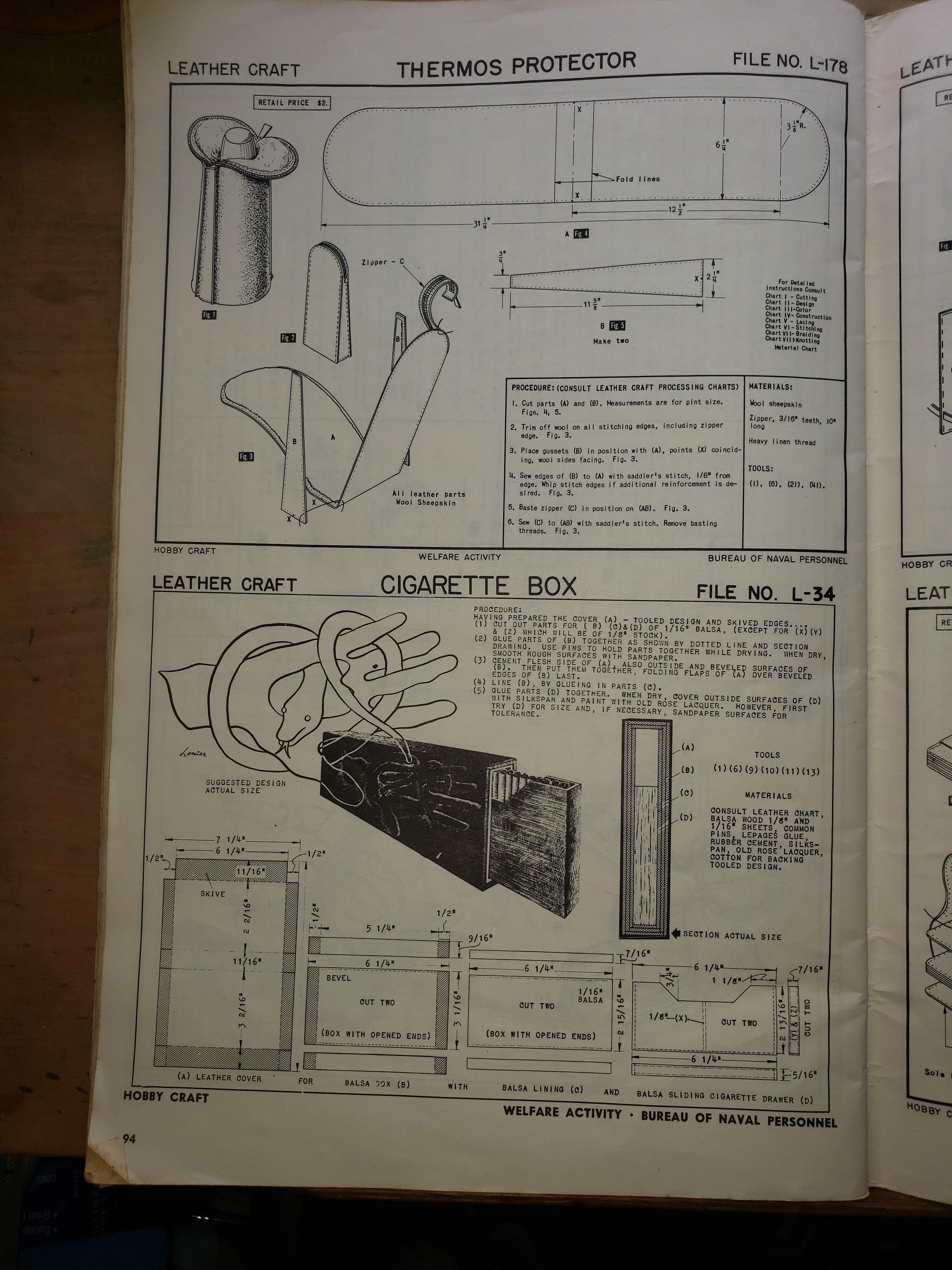

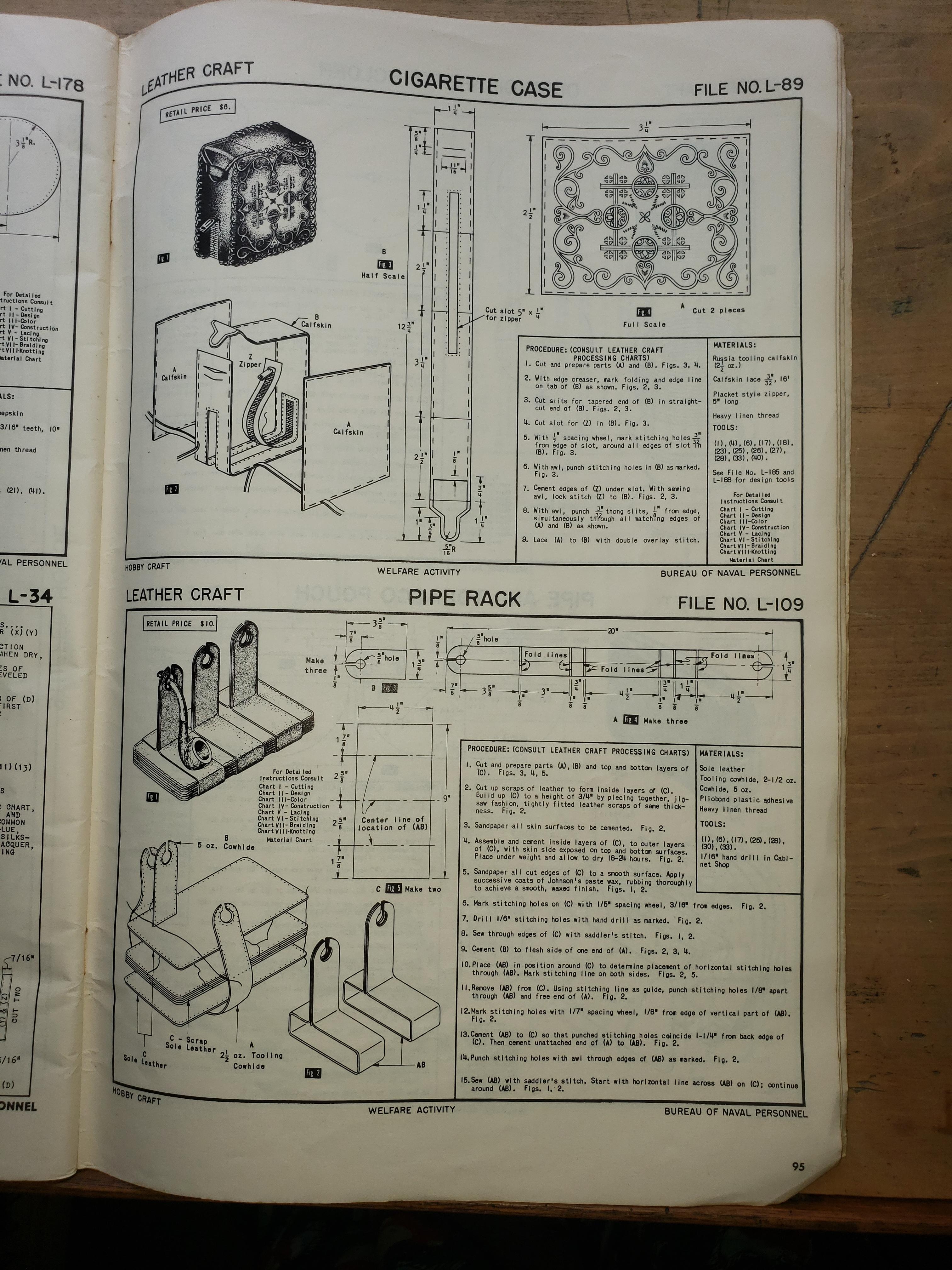

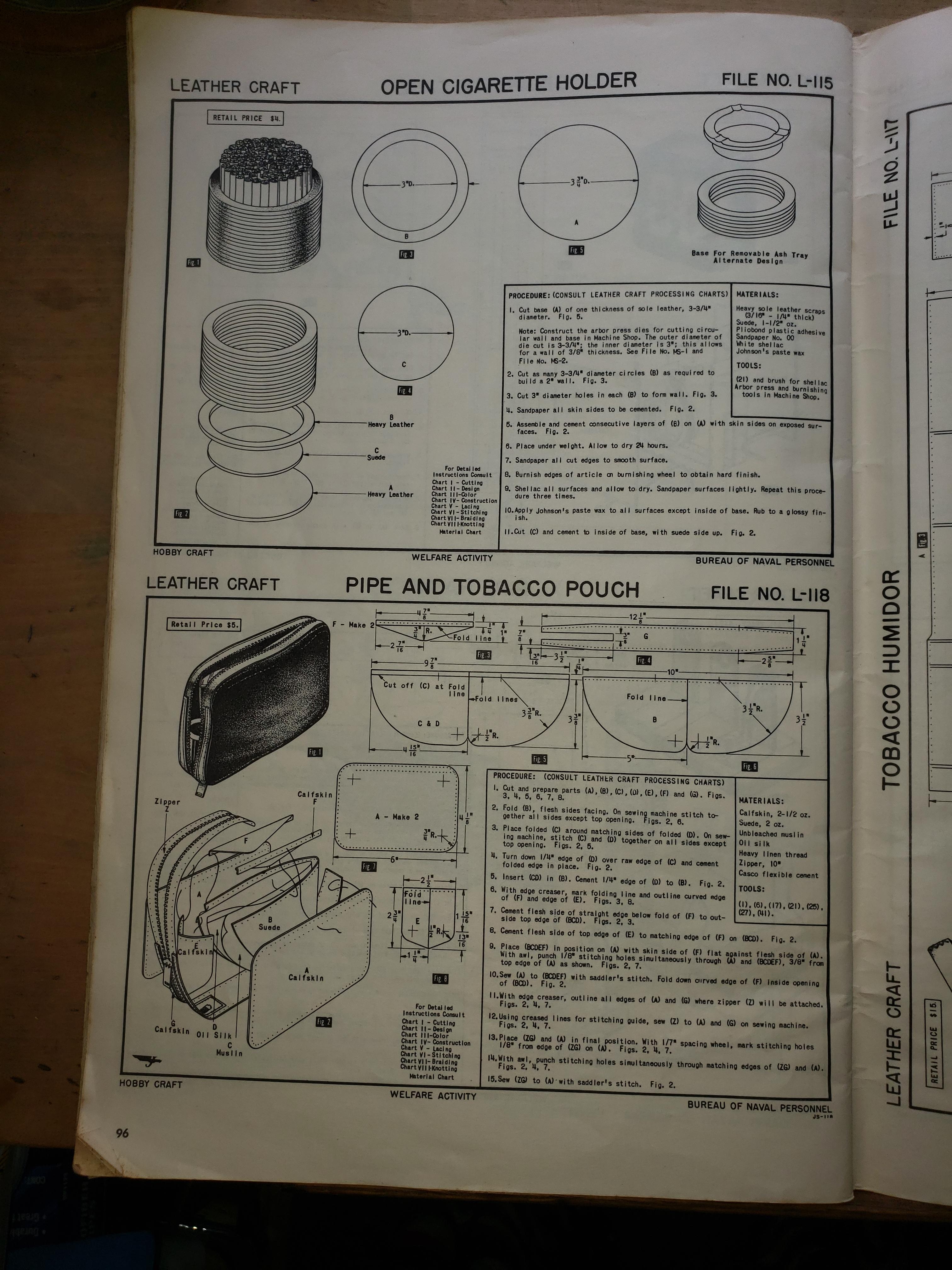

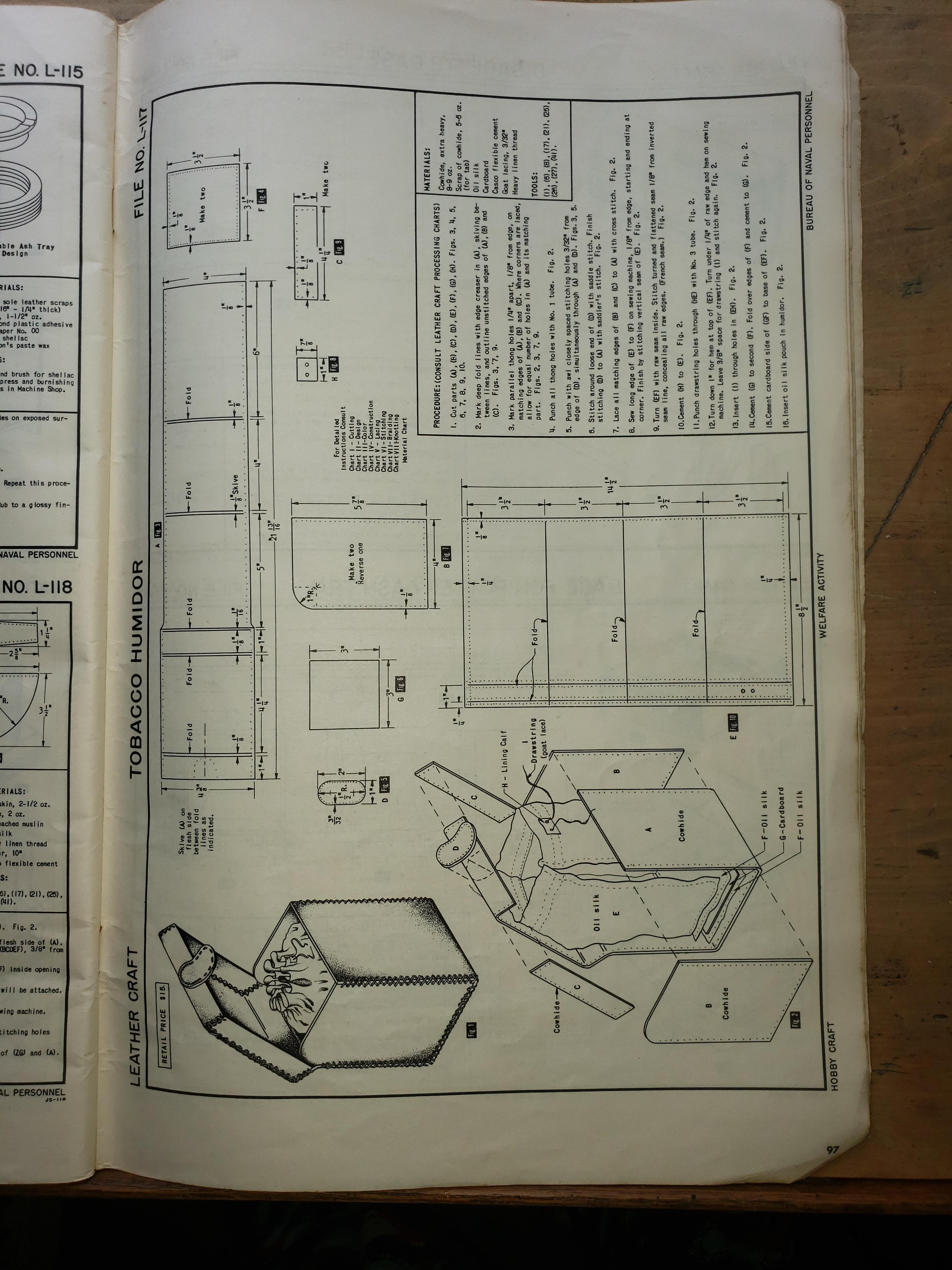

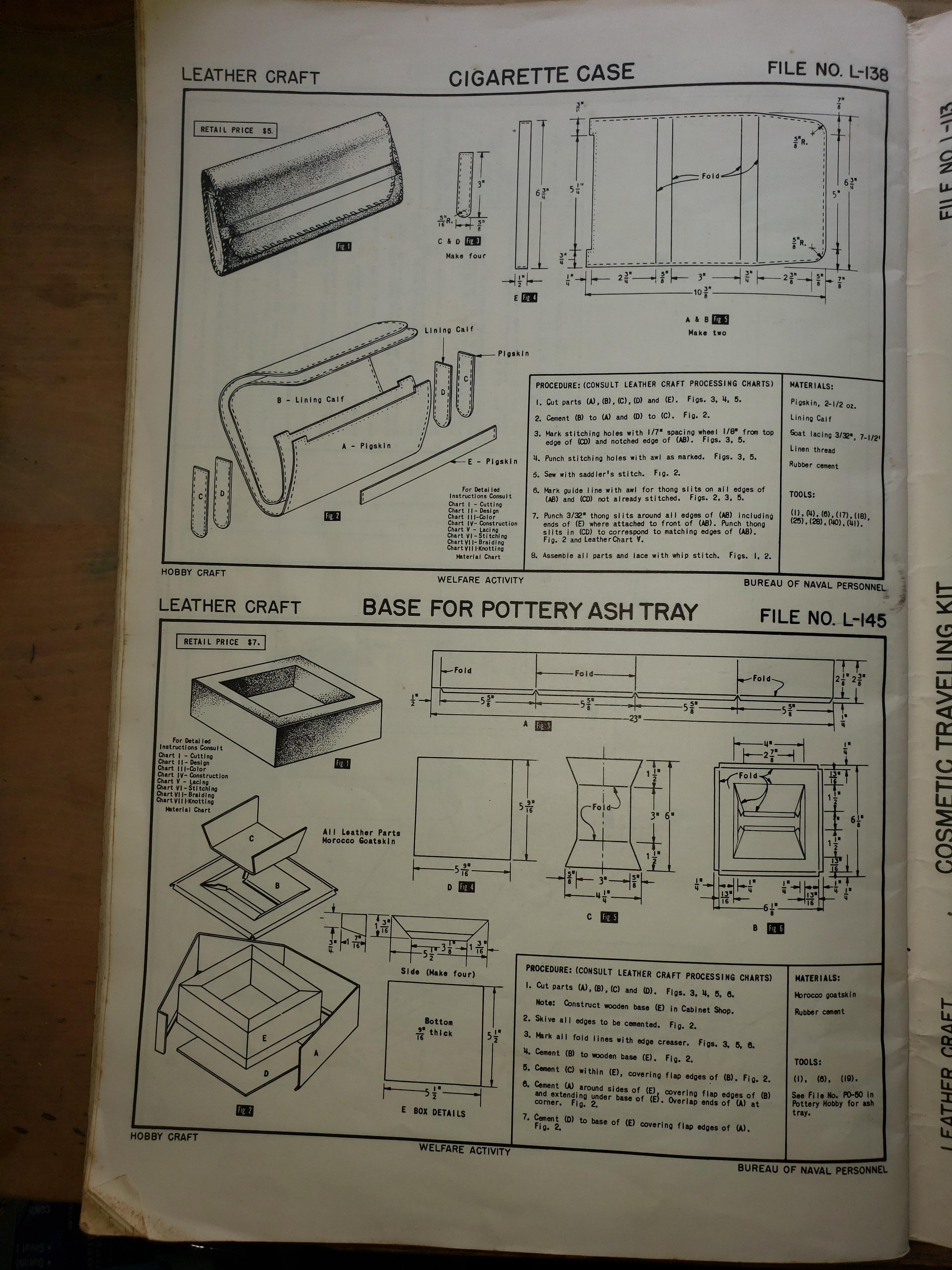

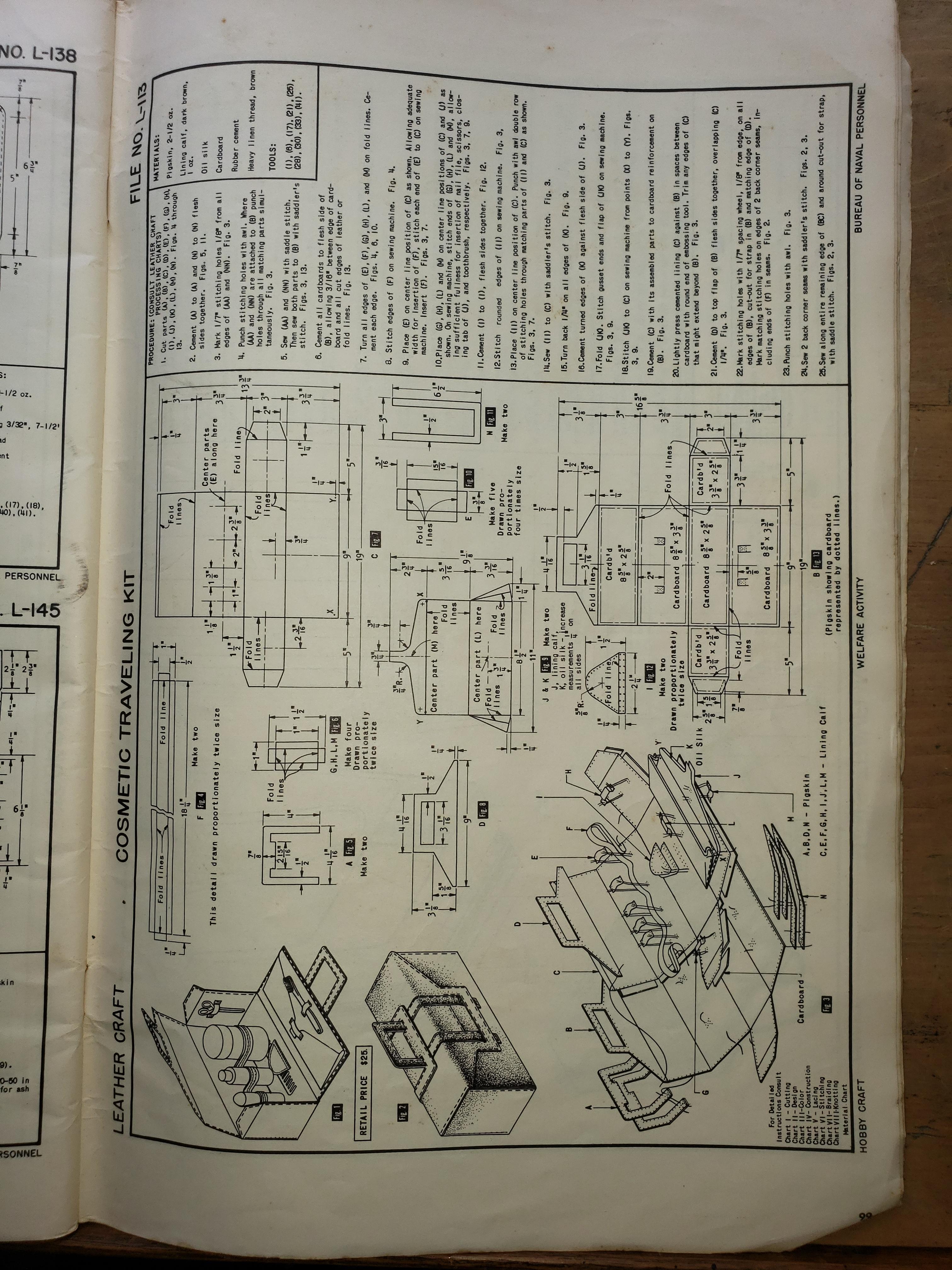

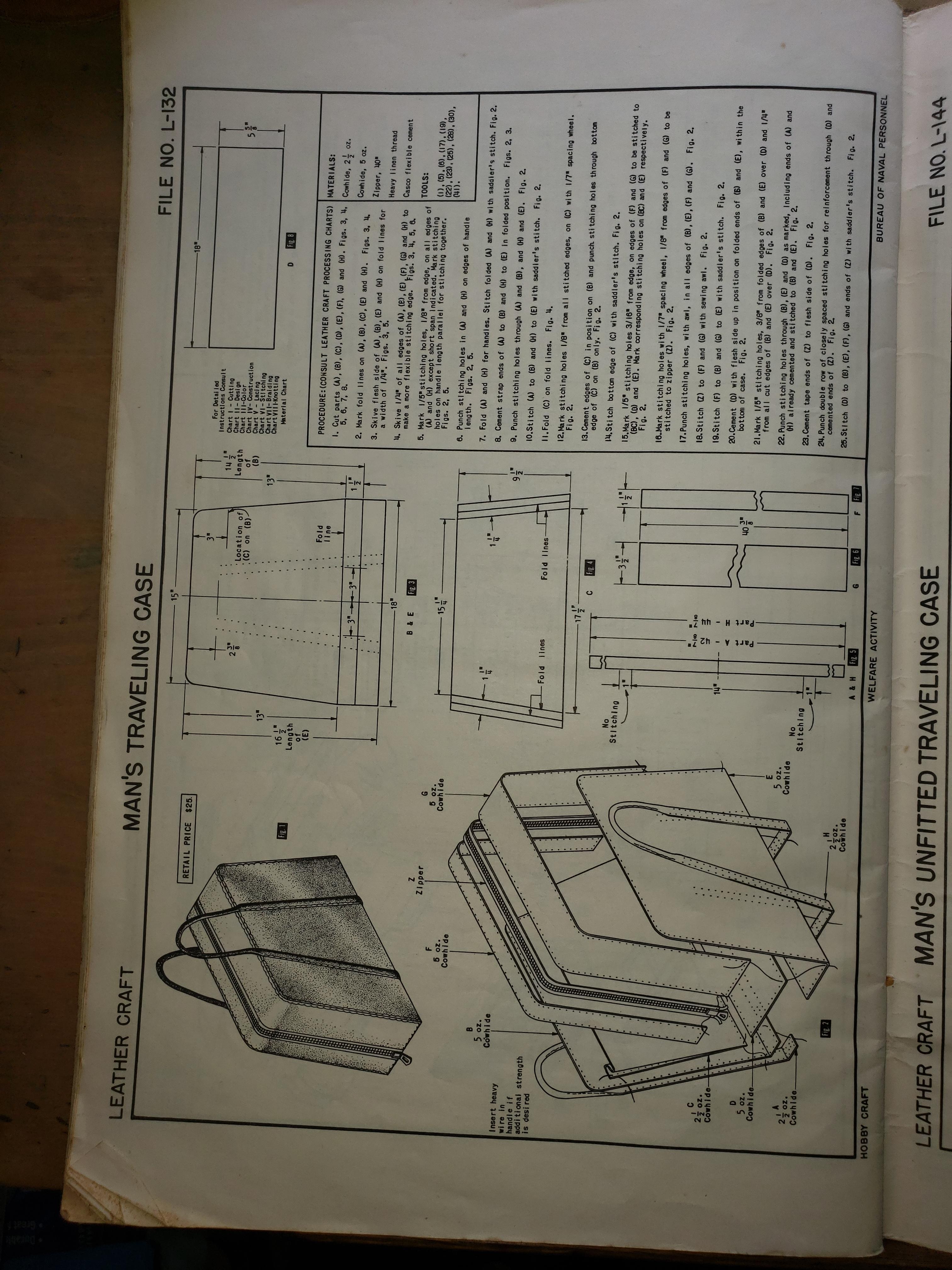

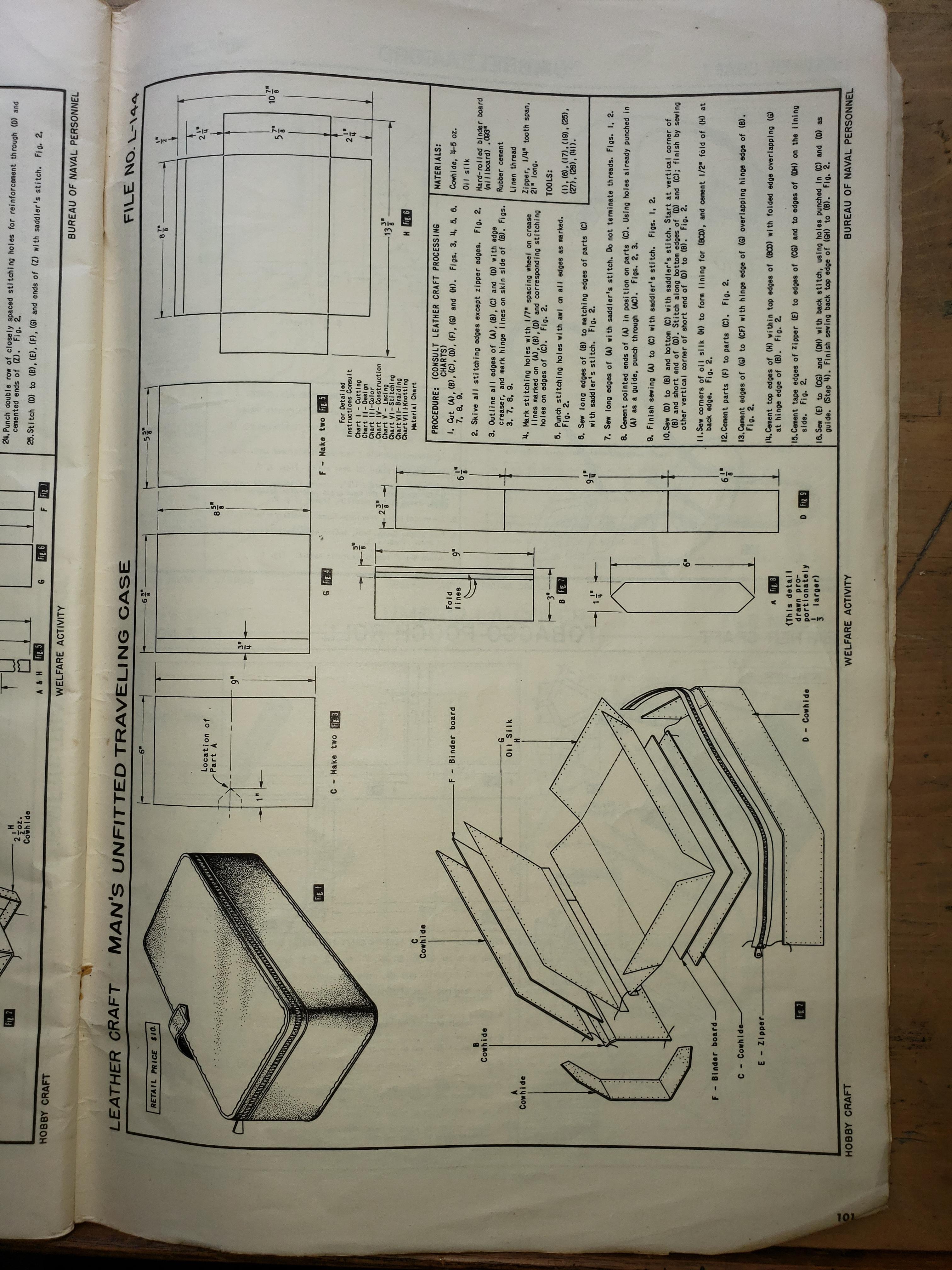

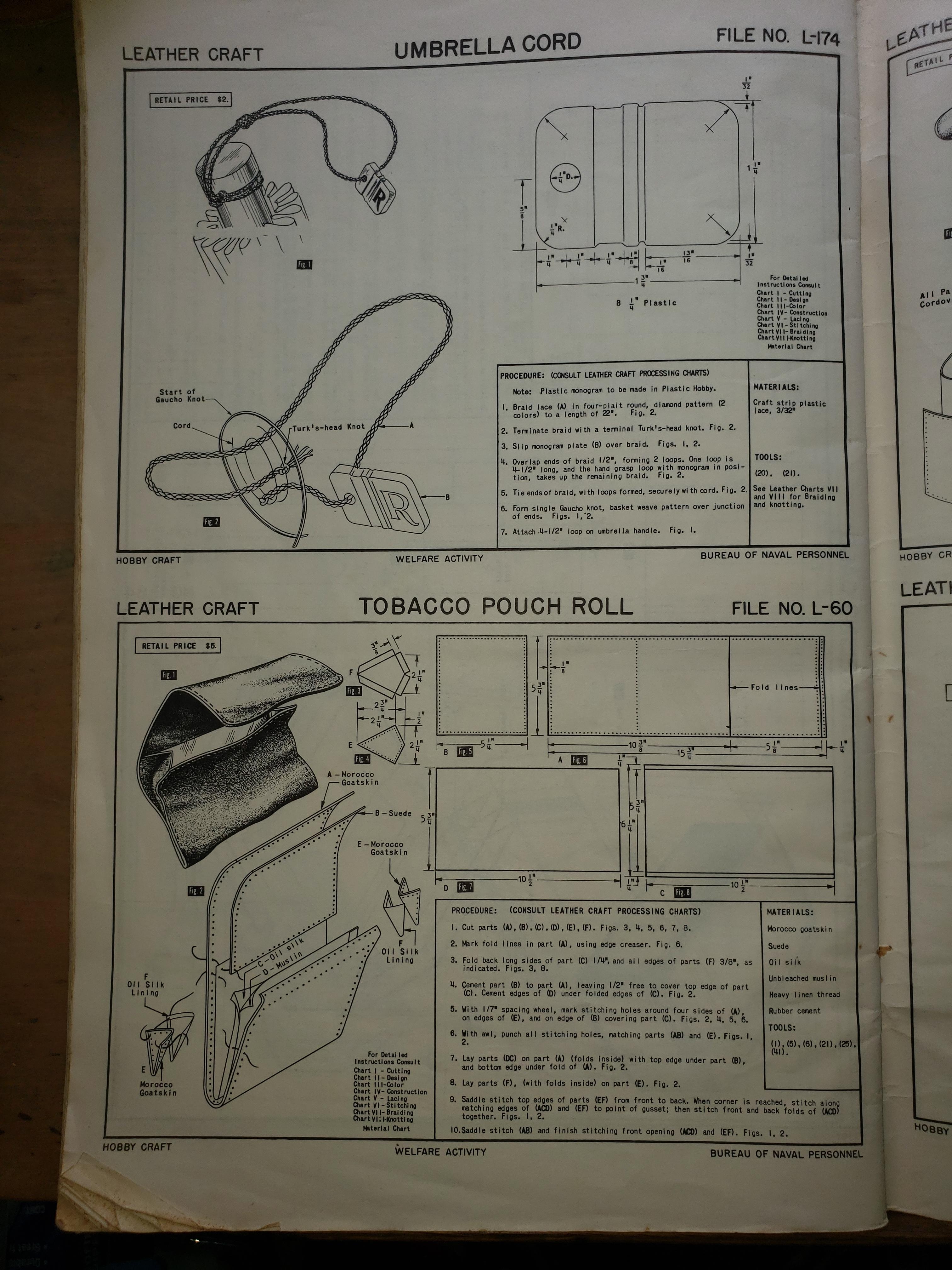

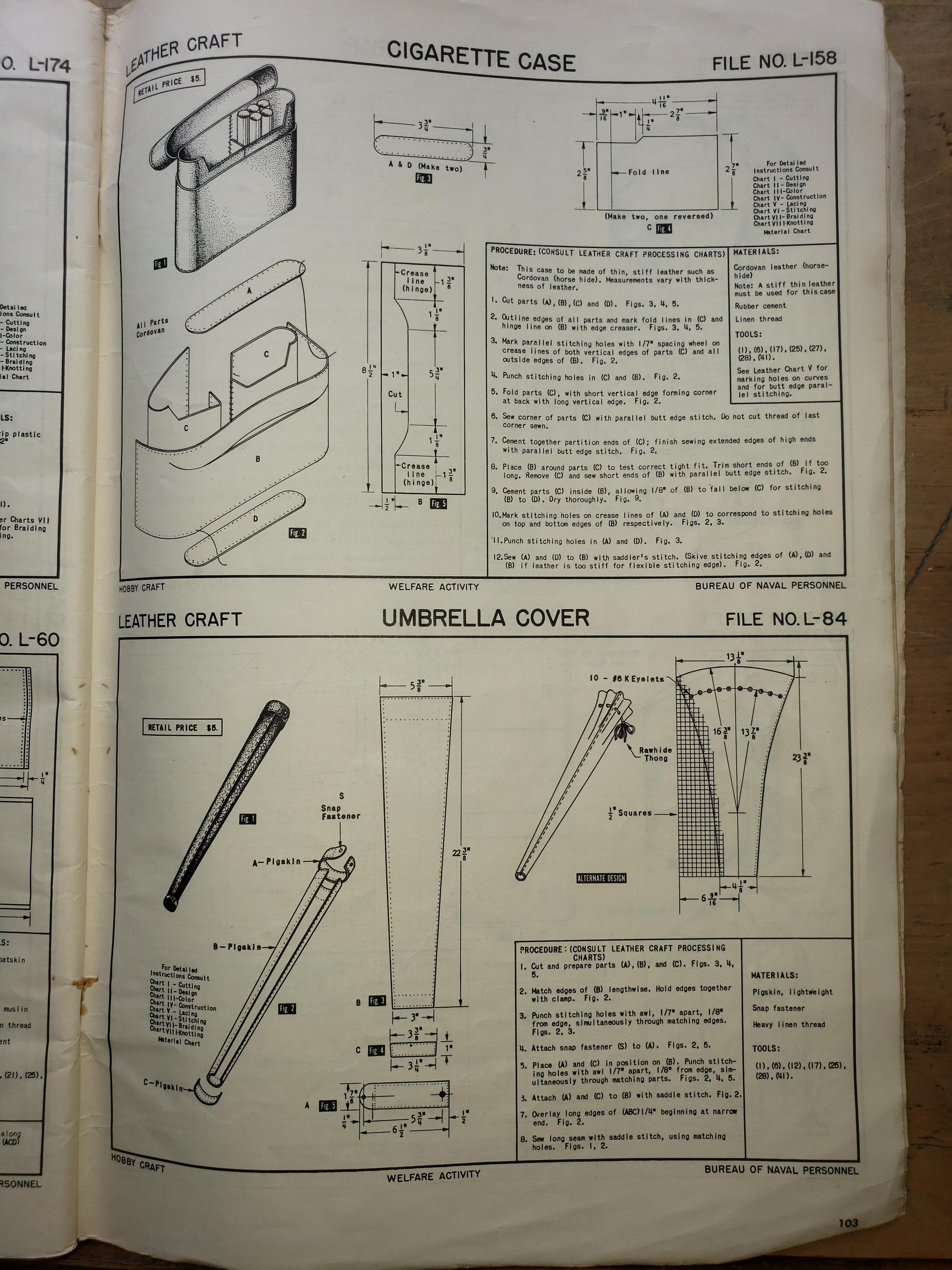

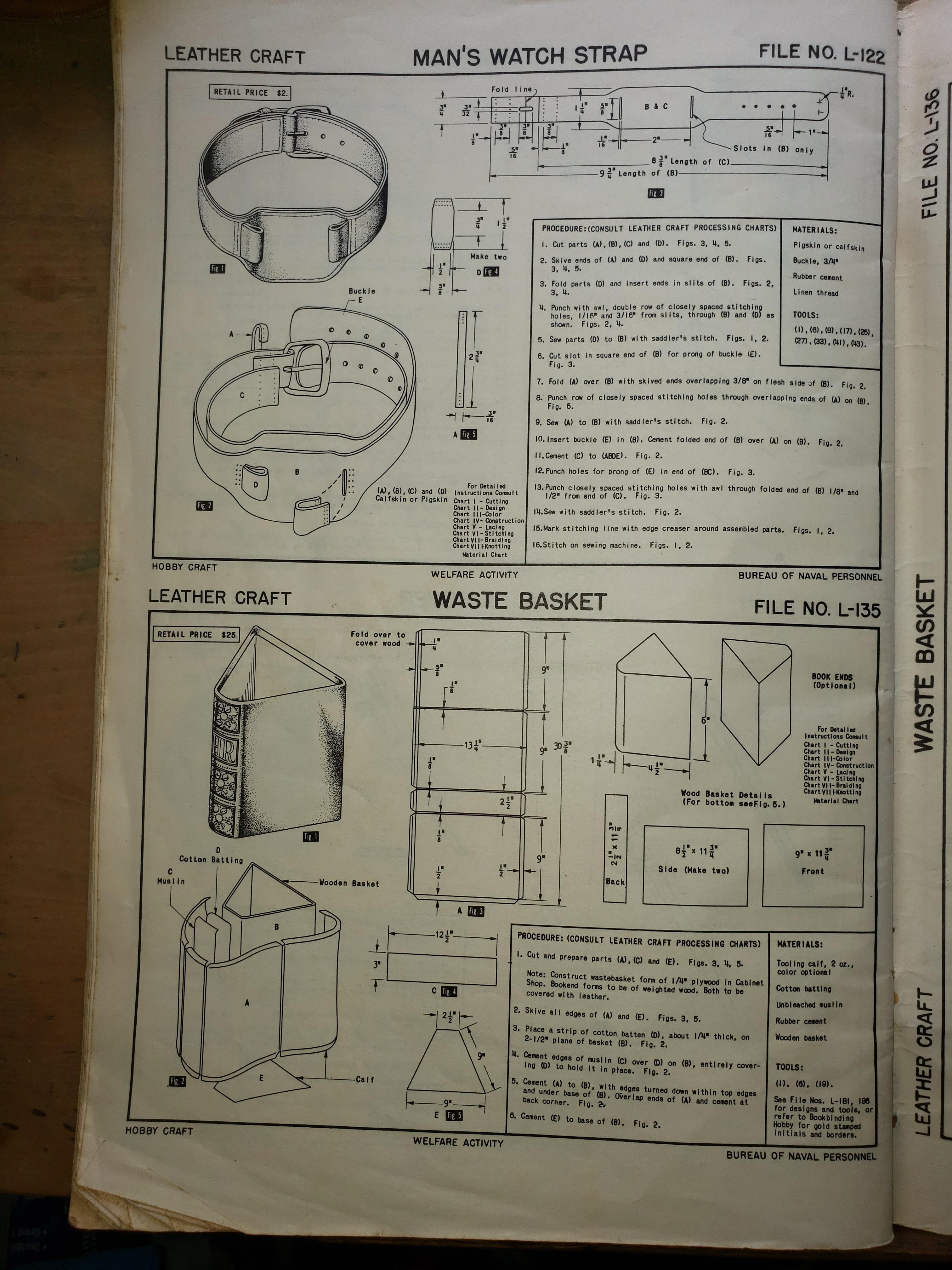

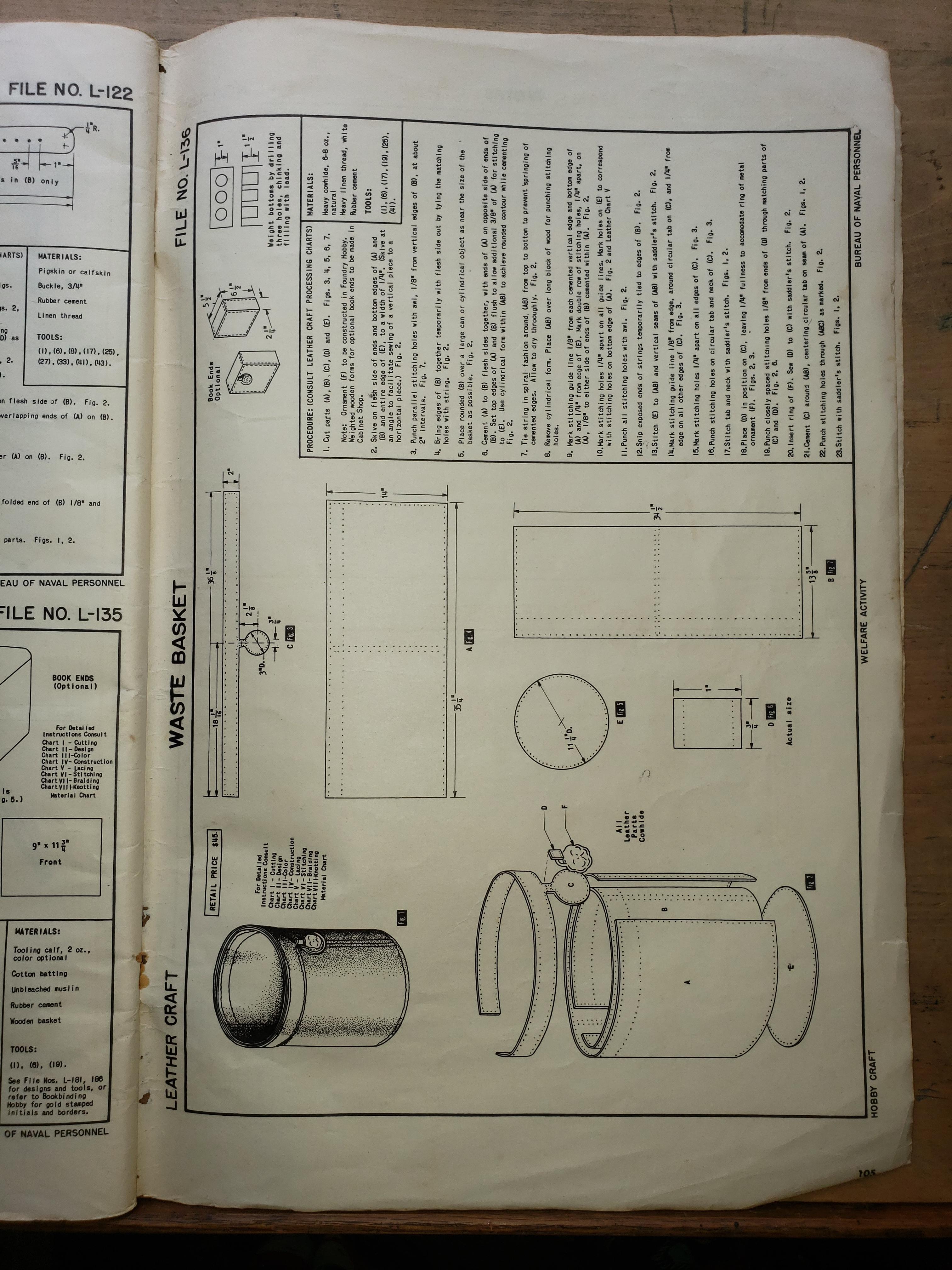

Here are photos of every page of a 1940-1950's era US Navy Leathercraft Manual. It includes patterns, locations to purchase supplies, and much more. I tried to take the best photos I could, if you want a close up of something let me know and I will try to accommodate.

-

Singer 29k1 presser foot doesn't work

Constabulary replied to MelissaViarengo's topic in Leather Sewing Machines

-

Definitely handier, if you have one. Alternative methods are good to know.

-

@GerryR a good way, but when trying to find the centre point to put a snap on a leather flap say a ruler is handier

-

btw, the magnet is glued on the inside of the leather 'key fob' pieces

-

The logo for this ruler is a square with a centre point arrow and the brand name of the ruler is Center Point which is sold by US Tape Company. I figure it was placed at the 5.5" mark just to confuse the hell out of people as it has nothing to do with measurements. kgg Nah, it's a short foot sorta like a short ton (2000lbs). kgg

-

He got his ruler at a discount, only 11" long!

-

I am lost. Isn't the center point of 12 inches, 6 inches? So why is it 5.5 inches here? I use thread. Cut to exact length of object, fold in half, hold from one end and... Voila!

-

Clicker dies, no clicker press?

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in How Do I Do That?

I do believe that you have given me the courage to attempt such shenanigans. And thanks for the bookmark suggestion, definitely works for my primary market here in town! -

As far as your steel rule and hoop go, if I’m translating Aussie to American correctly, that rule is what I would call flat bar stock, and hoop would be steel strap at our “big box hardware stores” (aka Home Depot). If so, the hoop would probably be way too soft to hold form under a press. If you happen to have a forge, I suppose it *may* be possible to heat it and use some Cherry Red to case harden it once you shape it. (As a gun guy, I assume you might be familiar with it, but it’s basically gun bluing but for the brownish color instead of blue-black). If you don’t have one, you might be able to slip one under the missus’s nose if you build it yourself (I built my coal forge for about $50, well less than the cost of my anvil, and my 1st propane forge is made from an old propane cylinder and the guts of an old gas grill. But you didn’t hear that from me… 😉). And metalwork and leather have always gone together hand in hand. Wow I went way off topic really fast. I’m assuming that you have checked with metal supply houses (the commercial variety that supply pipes/rebar/i-beams/etc), welding supply shops, blacksmiths, co-op forges, farriers, farm/tack supply shops, and web forums. (Just the sources I can think of to at least get a lead to work from.) But I have been told that common things here are not-so-common there. Oh! BBQ/smoker fabricators! Might even be able to get some of there scrap (though there’s no such thing as scrap steel. Just ask a blacksmith 😁. No I’m not a blacksmith, just a bumblesmith…) Ooh squirrel! My daughter got me a little Vevor 1-burner forge, and it’s actually my primary forge now. I think she found it while it was on sale for ~$100. 10/10 recommend. Might even get hotter than my 2-burner. Thank you, I have a difficult time finding what I’m looking for through the 100’s/1000’s of search results!