All Activity

- Today

-

Micro Copper Burr Rivets - A Solution

Stagesmith replied to Stagesmith's topic in Hardware and Accessories

I found the set of doming tools on Amazon https://www.amazon.com/dp/B0D6724Z62 $30 is worth my time to just buy them. -

Anyone taken a cheap servo motor apart?

friquant replied to AlZilla's topic in Leather Sewing Machines

When I was in there, I found three hall sensors in position to read the permanent magnets of the rotor as they go by. I should have worn gloves when I put it back together...those magnets are vicious, and I got pinched. -

Micro Copper Burr Rivets - A Solution

fredk replied to Stagesmith's topic in Hardware and Accessories

Excellent you found a solition for your needs For a doming tool; before you cut one, there are doming setters meant for ready-rivets which have a domed head already. I have the domed setters in sizes from 4mm to 12mm in 1mm steps -

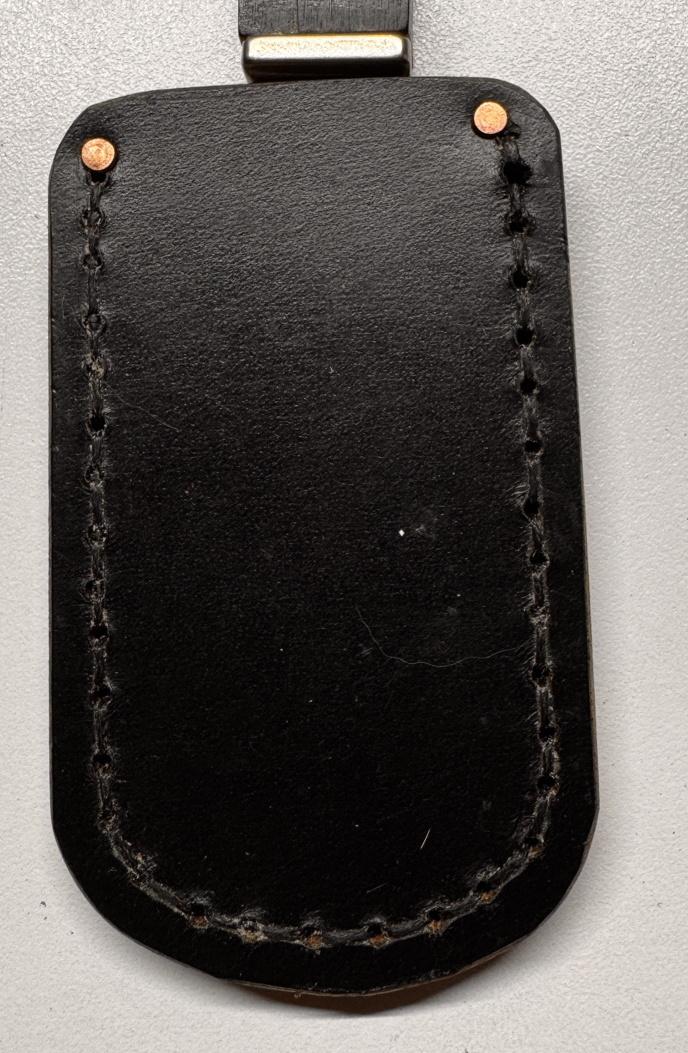

I mostly make leather knife sheaths and I was trying to find a compact rivet to end the stitch lines. I like copper burr rivets, but the smallest available are still way too large. I have found a solution that works for me. Amazon sells assortments of metric copper rivets in flat-head and round-head versions. The range is 2mm, 2.5mm and 3mm shaft sizes https://www.amazon.com/dp/B0CNCSHG3T https://www.amazon.com/dp/B0CNCT42XG I found the washers on McMaster Carr. They are sold as #1, #2, and #3 copper flat washers https://www.mcmaster.com/97565A111/ https://www.mcmaster.com/97565A112/ https://www.mcmaster.com/93661A112/ I made my own rivet sets by just end drilling some pieces of 1/4" round steel rod. You will need a #44, a #40 and a #31 drill bits. I think mild steel is fine as these will only get light use. I will probably make some matching doming tools by using a diamond ball bit in a dremel to carve little domes in some harder steel rod.

-

Mine has that too--- paddles running next to the aluminum case, shrouded under some plastic. I think simply removing the plastic cover would be a boon...

-

Jungle Designs joined the community

-

I've always seen that 135x17 is the fabric and ,135x16 are the leather. Well, this is how the 135x16s I just bought are labeled. I'm just bellyaching ... I sent the first set back because I didn't see the 135x16. Oh well ...

-

packrat6870 joined the community

-

[quote] [Agrees with Chuck!]

-

If you are fairly mechanically inclined it may work as long as you are aware of it's limitations and probably lack of product support. Definitely worth a look see. kgg

-

maagnnus86 joined the community

-

I'd get some change from 500 bucks on all of them. Seems to be a boat load of folks trying to sell them . . . from about 400 plus shipping to 485 with free shipping . . . and lots of "in between" sellers. May God bless, Dwight

-

I bought a cheap one on Amazon for $10. It works very well. I need to put an edge back on it though.

-

-

Just shows to go ya looks ain't everything you can get some good results from repurposed tools.

-

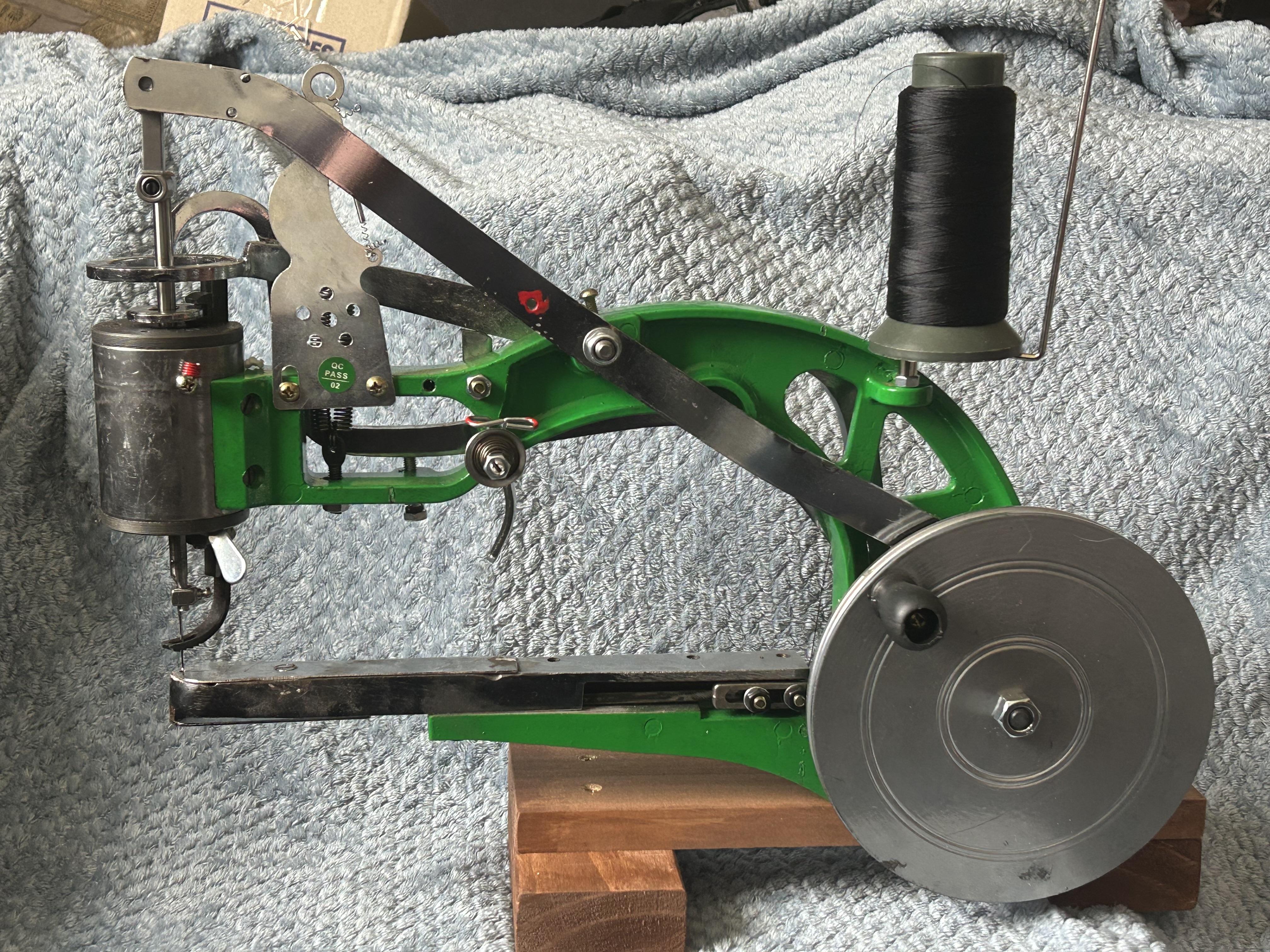

The photo of the Singer clone appears to be sorta kinda like the Singer 29K71 short arm, small bobbin, with side wheel. What is the asking price for this clone ( probably made in China). Info from this website: ( https://www.siruba.co.uk/Singer 29K Instructions.pdf ) MACHINE 29K71 (Was 29K53) End of cylinder bed is 1 inch wide and 7/8 inch deep. Space at right of need1e 12- 1/4 inches. Diameters of belt grooves 2-7/8 inches and 4-7/8 inches. MACHINE 29K72 End of cylinder bed is 1-5/32 inches wide and 1-1/16 inche5 deep. Space at right of needle 17-1/2 inches. Diameters of belt grooves 3-1/4 inches and 5.1/2 inches. Large Bobbin. MACHINE 29K73 End of cylinder bed is 1 inch wide and 7/8 inch deep. Space at right of needle 17-1/2 inches. Diameters of belt grooves 3-1/4 inches and 5-1/2 inches. kgg

-

My moderately priced servo has 100 rpm minimum speed has some shaping on the case, but not exactly cooling fans. Efka DC 1600 that I had to remove because of dead control box is completely different beast, 2 the size and weight, cooling fan etc.

-

When we moved to Israel, I took some of my leather tools but not all of them. Unfortunately you can’t buy a skiving knife here (not that I loved the Osborne skiving knife I had in the U.S.) Big Stacks Small Workshop suggested using a razor blade scraper. Fine as it goes, but not much stability. And it doesn’t work well for straight 90 degree cuts. Viktor George had the answer. On one of his Tips videos, he shows some skiving knives he made from carbon steel putty knives that he bought second hand. I found some new high carbon steel knives at a hardware store that focuses on contractors. Now it was time to get to work! Using a set of cheap diamond-on-steel sharpening stones from Amazon, I sharpened one side only, starting with 400 grit, until I had a wire edge. Then onto 600 grit, then 1,000 and 1,200. After that, my trusty chef’s steel and the rough-side strop with green rouge. Total sharpening time: about 2 hours. The result was great! It skives, trims & makes vertical cuts. I’d post a picture but frankly it looks just like a putty knife with an edge on one side.

-

Or as they say in Hebrew, Taste & aroma aren’t debatable. But in Hebrew it rhymes.

-

It sure is. I checked out the hard copy once from the library-easily 3 inches thick! He’s got some beautiful button knots in there.

-

I have a fairly new Singer . . . table top portable machine . . . it will do embroidery and a bunch of other stuff . . . I bought it with the eye on the 90 day "send it back if it don't work" idea I had with the seller. I was looking for something that could sew two layers of suede or maybe 2/3 oz veggie tan. When I use it . . . I mostly use carpet thread . . . and it has surprised my britches off at the things it has done or will do. Anything in a shirt or light jacket . . . it'll handle it . . . no sweat. I used it to put my E-6 Navy patch on my short sleeve white shirt. Name tags . . . and the like are a piece of cake with that machine. I wanted to add to the group . . . the below picture . . . mostly for jackets and stuff . . . biker work . . . etc. I live between two towns of of 45K and 35K . . . with lots of police, military reserve, national guard, etc . . . and from the research I've done so far . . . I'd have it all to myself and the little old ladies with their thimbles. Plus there is a huge Harley place a 1/2 hour away . . . and 5 different state prisons plus three county lockups . . . and all them folks need patches sewn on. I wouldn't make a living at it . . . but at a minimum of $5 for the first one and 10 bucks an hour for the rest . . . I was looking at a nice extra few bucks . . . and I don't have to create anything here . . . just stitch the dude down. Most of it hinges on two "interviews" I have to do with a couple of dry cleaner shops. If I can become their supplier . . . I'd be looking at maybe a 100 a month average. May God bless, Dwight

-

Need to sew patches . . . help!!

Darren Brosowski replied to Dwight's topic in Leather Sewing Machines

-

Option 😄 Clutch Motor See the parent article: Choosing a Motor Online mostly you will see clutch motors disparaged as a thing of the past, going too fast, with little control. Yet there are ways to tame them by slowing them down and getting better at feathering the clutch. 1. What is a clutch Just like in an old school automobile with a manual transmission and a clutch, a clutch in a sewing machine motor allows the motor and the sewing machine to move at different speeds. The pedal motion is opposite that of an automobile though— on a sewing machine you press harder to achieve full engagement, and let off to stop. 1a. What is the clutch made of The clutch typically has a cork surface pressing against a steel pressure plate. 1b. Why do they go so fast Not all clutch motors go the same speed. A clutch motor is typically run by an AC induction motor. The no-load speed of the motor is determined by the input frequency (typically 50Hz or 60Hz) and the number of electromagnetic poles (how the motor is wound). The clutch motors I’ve seen are either 2-pole (about 2800rpm @ 60Hz) or 4-pole (about 1400rpm @ 60Hz). Notice one is twice as fast as the other. You want the slower one. 1c. How to reduce the maximum speed Here are some ways you can reduce the maximum speed of the machine when using a clutch motor: Get a 4-pole motor instead of a 2-pole motor. Buy a 45mm motor pulley (the pulley that goes on the end of the motor) for about ten dollars. Add a gear reducer (about $110 for 3:1 belt gear reducer) If it’s a 3-phase motor, reduce the input frequency using a VFD 1d. How to get better at driving it If your clutch motor is hard to control, first slow it down so that its maximum speed is actually of use to you. That is, so that on your long straightaway runs you can comfortably be full on the gas. Then take the clutch apart and clean and sand lightly the cork clutch and the pressure plate. Figure out where the oil hole is for the actuating lever so you can oil it so it releases smoothly. Experiment with varying levels of spring tension on the actuating lever. Experiment with how much leverage the treadle has against the actuating lever, and find what works best for you. Practice with short stitch lengths, since this will be more controllable at first. Wiz recommends greasing the clutch surface, but I have not tried that yet so I don’t have any data. 2. Is a Clutch Motor the Right Motor for Me? Choose a clutch motor if: You already have a 4-pole (1400rpm) clutch motor You like driving manual automobile transmissions You appreciate the extra challenge You are good at adjusting things You don’t want to use a needle position sensor You are going to gear it down anyway You have a 3-phase clutch motor (allows using VFD to slow it down)

-

Thanks for the kind words-means a lot! After wet-forming, I used Weaver's 'leather firmer', since I want my holsters to be as stiff and sturdy as possible. After that, there's a dip in Resolene, and that's the entirety of the finish. The clip is mounted to slotted posts mounted under the reinforcement piece wrapped around the mouth of the holster. Larry

-

Problem using a TandyPro Deluxe Leather Splitter

DieselTech replied to Coloradoguy's topic in How Do I Do That?

I think your blade is not quite sharp enough. Plus if the blade is dull & you are taking a big bite/cut you are actually stretching the belt some & resulting thinner/thicker cuts on the sides of the belt. -

Problem using a TandyPro Deluxe Leather Splitter

TomE replied to Coloradoguy's topic in How Do I Do That?

My older Tandy Pro splitter doesn't have the additional depth locking screws on both ends of the roller. It seems that the strap is getting pinched on either edge and drawn up towards the blade in the middle. I don't have an idea why that would happen. Does this occur when using different parts of the blade? Have you tested different leathers of varying thickness/temper? Is the roller centered on the edge of the blade? Also, I don't understand the need for the 2x4 clamping the strap. When I split straps I don't have any pressure on the strap entering the splitter. I am careful to pull the strap through at a consistent angle, slightly lower than horizontal. -

Here's a manual: https://www.manualslib.com/manual/505004/Pfaff-145.html#manual Here's a guide to the numbers and letters: https://leatherworker.net/forum/topic/89283-an-introduction-to-the-pfaff-numbering-system/ Here is a good video by Uwe on timing in general: https://leatherworker.net/forum/topic/36127-pfaff-545-safety-clutch-and-timing/page/2/#findComment-442262

-

Problem using a TandyPro Deluxe Leather Splitter

fredk replied to Coloradoguy's topic in How Do I Do That?

I think your 2 x 4 is giving too much localised pressure. Giving it more pressure to cut deeper in the centre than the edges Can you try a wider lever bar?