All Activity

- Past hour

-

- Today

-

Is this Leather Hide Normal Grade A or Bad?

DoogMeister replied to fernwehleather's topic in Suppliers

The Economy and Craftsman grade sides I've bought from the Tandy store look better. Sure, they sometimes have a place you need to work around, or a brand - but that is to be expected with those grades. What you have may have been grade A at one time, but after having been left out exposed to light and what appears to be folded, rolled backwards, and whatever else, it isn't anymore. I agree with what has been said - if they don't make it right for you, name them so we can avoid your pain. -

I have several belts. One heavy duty belt to handle my bush gear (pouch, knife and tomahawk). One for my hip quiver for my horsebow and two "general duty" belts for daily use. One of them is going on 12 years now!

-

Leonard Galvin money clip question

AlZilla replied to Cinn's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

@Cinn I moved this out of saddlery to miscellaneous small items. Tacked onto a 15 year old thread, it was going to wither away, unnoticed. A picture of your item would be helpful. -

After a rocky start to retirement I finally have most of that past me. I am nearly full time in the leather tool shop now. With that, my goal of being able to open up the leather tool sharpening service has come about. I still have the same 15 year old policy free resharpening for tools purchased from me. If you have other tools were not purchased from me or have not been a previous customer, I can take those tools for resharpening now. I have a new page on my website describing the services and cost estimates, plus a brochure/pricelist for downloading at https://brucejohnsonleather.com/sharpening-services . Thank you! - Bruce

-

Would it be okay if I post a Google Docs link instead of a PDF? That way I can keep it updated without reposting every time something get sold.

-

Only a bit, mostly with thin flexible leathers I use a wax block to punch thru to. It lubes the hole punch every time

-

if you cant find one used check with CL Machinenbau - they still make the shuttles for the 8346-20 https://www.cl-maschinenbau.com/de/leistungen/naehmaschinen.html But do not expect them to be cheap 😉

-

Can you roll the leather up as you go to get those middle holes?

-

I found that running the spindle cuts down on the punch getting stuck in the leather after the punch. On the Latigo, I also would lube the punch occasionally by running it down into a big, plain candle briefly.

-

Hi i want to buy Claes 200-2 Machine. But the seller says it is missing shuttle. Where can i buy a new shuttle preferably cheap. Diameter of socket is 22,7mm. Anyone know something?

-

The heel on the machine pedal is typically used to bring the needle up. It still stitches in the forward direction (about half a machine revolution) to bring the needle up. And it only works if you are both using a needle positioner and have stopped with the needle down. That is, you sew along, then release the pedal, and the machine keeps moving until it reaches needle-down, then stops. At that point, you tap the heel and the machine moves (forward) to needle-up. UPDATE Looking at the manual, I see these two options: P-I "Reverse After Pedal Heel Down" P-JJ "Setting of reversing angle" This sounds to me like it's supposed to run the motor in reverse for a finite distance upon heel-tap. I'm not sure what the use case would be. Settings Can you tell us your settings for the following menu items? P-8 : Single signal synchronizer P-I : Reverse after heel pedal down P-J : Setting of reverse angle P-K : Needle up after pedal heel down P-Z : Select machine code

-

Pfaff 346-H2 won't pick up bobbin thread.

shoepatcher replied to GPD's topic in Leather Sewing Machines

First question. Is safety clutch disengaged? If not, it is out of time and you must time each hook separately. glenn -

The end cam is worn. Replace it to take out the play. glenn

-

TechSew 2750 Pro Cylinder Arm Sewing Machine - $2000 Lots of Extras

RobynR replied to RecentRelics's topic in Used

Hi, I am interested if it's still available. -

I use glazed pigskin. Thin & stiff

-

Slow setting contact glue

-

a. the drill chuck being rotatable is good as you can fine tune the alignment b. I have one of Tony's patterns and there is a quadzillion holes to punch. The press & 6 hole punch really speeds it up c. The press I have doesn't have a large reach so I can't do holes towards the centre of the pattern with the press (oh dear, how sad, never mind!) I take my pattern out side to do those holes d. you have a good height on that drill press. The leather press I have hasn't great height and I had to replace the bar on my multi-hole punch with a much shorter one and cut down the single types

-

I haven't searched that way before. Thanks for the tip. I'll give it a try. I just put my 5mm hole punch into the drill press and didn't turn it on. It was easy for me to go through this heavy leather just pulling down on the handle. Is there a benefit to the spinning other than making it easier to go through the leather? Using the press like this is a game changer for me. I think I'll be able to get my stitch lines straighter and do it without damage to my body or upsetting anyone else with the noise. Working with heavy leather, I can probably go faster too vs hammer the 6 prong punch 4-5 times to get it through. Maybe I'll invest in a dedicated press eventually, but for now I can use this and get good results. I'm not sure if the drill chuck's ability to spin with the punch in it is a good or bad thing for this yet.

-

Many thanks to all respondents! Very helpful! When I get the appropriate appliance, (and some practice!!) I'll share what I am making!

-

WOW! That is some awesome work. Very talented. I'm still new at this so thanks very much for your help. I really do appreciate it. Happy carving

-

Here is a small set of single hole punches that are made for the drill press. I used to have a customer that I made leashes for and each required 8 holes punched into 10/12 Latigo. They saved my life and sanity. https://www.harborfreight.com/6-piece-hollow-punch-set-67030.html

-

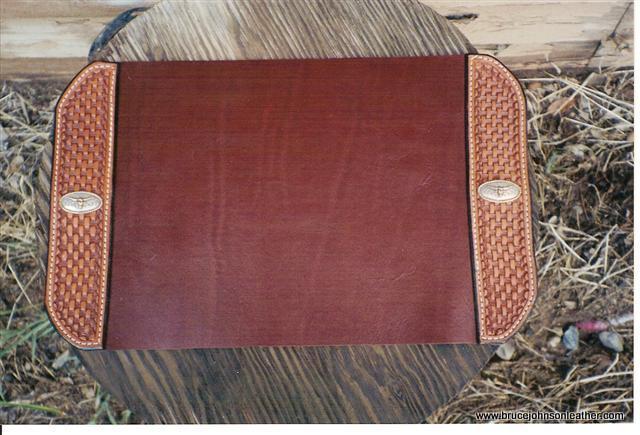

I made a couple hundred probably. Some stock and some custom. My favorites (and most popular) were made from heavy chrome tan and then tooled side panels. The veg tan were harder to clean and tended to roll a bit over time. These chrome tan could roll up in a drawer for storage and lay right out flat. Handy for the folks with living quarter horse trailers. Heavy chrome tan and tooled strips. I treated them with at least three coats of acrylic finish and they wiped off well with minimal staining. I treated vegtan coasters the same.

-

Using LW's search for "drill press" AND stitching brought up lots of hits, most not fitting what we want. Down 20 or 30 items, found a good hit. Better to try a google search like this site: leatherworker.net "drill press" sewing stitching -machine -motor Site: tells google to search the listed site "drill press" quotes tell google to include both words, not individual -machine tells google to ignore machine The google search engines are much faster and easier to select the parameters you want and don't want. Add or remove additional parameters as you like.

.jpg.eb659f0d2339304efe327ea8130096b8.jpg)

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)