All Activity

- Today

-

Seiko STW-8B Seam length and presser foot height -

Constabulary replied to Zonker62's topic in Leather Sewing Machines

The Seiko STW-8B basically is a later / more modern clone of the Singer 111G156 with some differences but it basically is a very similar machine. How long is your maximum reverse stitch length? Usually when the reverse stitch is longer the forward is shorter (and vice versa). With other words, usually F & R are equal at approx 5mm at this type of machine (Singer 111 and later clones) so when the F is 3.5mm then usually the R is longer and I guess it is 6.5mm. -

If you have a bench vise tighten your wrench in the jaws Grab the grinder with your one hand holding the lock button with a finger Match up the grinder with your wrench and twist improvise adapt overcome hooraaaaa!!! goodluck 👍

-

Sorry to hear you broke a wing As chuck says; read books Eventually as the break heals you may get the use of your fingers again and you can do some sewing using a stitching clamp to hold the work

-

jwoldsr started following Homemade Clicker Press and Steel Rule Bender

-

I'd like to find a used steel rule die bender. Any ideas?

-

Sewing machine oil is light mineral oil. The drug store stuff is heavy mineral oil, not good for machines. I personally use 5 w 20 synthetic motor oil for industrial sewing heavy web strap, 6" wide and you can hear the difference at full speed. So much quieter, all the little clicks go away. Color is close to clear, but wouldn't use around vegtan.

-

friquant started following Seiko STW-8B Seam length and presser foot height -

-

Seiko STW-8B Seam length and presser foot height -

friquant replied to Zonker62's topic in Leather Sewing Machines

Perhaps you could post a video of the walking foot in action so we can diagnose -

Dang, bad luck. I hope you recover quickly !!! You may not be able to pound leather, but you can still read, study, and practice drawing patterns and such. maybe even some swivel knife practice. Get well soon!!!☺️

-

Hello all, I recently purchased this Seiko STW-8B, because of the triple feed, or walking foot, that I need in certain cases (sewing crystal windows on sprayhoods for example). I didn't find any interesting manual like I usually do for Durkopp, Adler, Singer...Seen the ione for the Consew 226RB but no particular procedure for these items. And my maximum stich length at the moment must be something like 2.5-3mm...And I thought it would be nuch more than that. And also the presser foot height, it was set in such manner that the foot wasn't pressing the material (was probably set for some 1/4 inch thickness) and after lowering the bar I barely get 9-10mm (lower than 1/2'). Could anyone help me mainly to set correctly this machine, stitch length and maybe a word or 2 on pressr foot height? Thanks in advance, Cheers!

-

ThisIsMyFirstRodeo started following Adaptability for 1 hand?

-

Hey all, So I broke my arm a couple weeks ago, and I’m tired of teasing myself by just staring at my workbench. I do at least have use of my dominant hand, so I did luck out in that department, but all of my hobbies seem to require 2 hands. I’m sure there are some of you with a similar experience, but how do I modify leatherwork to be conducive to 1 working arm until I get my cast off? Is it even feasible? Unfortunately, my bandsaw is disassembled to repair, and I can’t break the nut loose on my grinder to replace the stone with a buffing wheel, so I feel like I may be SOL (hope im not censored) on the power tool side. Any tips/tricks/hints/advice welcome, even if it’s not to bother. Guess it’s back to my first rodeo, AZR

-

martol joined the community

-

friquant started following Motor recomendation for Juki 1541 and needle help for highlead GA-2688l

-

Something I just remembered, while in Inkscape be sure your page size is as large as you need to fit your whole pattern. Inkscape will only export whats within the page boundaries

-

Claire H joined the community

-

Hello, This looks like the model that we use. Is this item still for sale? If so, I would like to discuss. We are not local, so I would need to assess the cost of freight and someone to come pack it. Best, Claire H.

-

@BlackDragon I use Libre office so I will try that. Thanks for the tip.

-

I also use Inkscape to make patterns. I export the pattern as a png file and open it with a LibreOffice Calc (It's free). I run a Linux system so I don't use MS products but you may be able to use any spreadsheet program. Make sure you add a measurement block in your pattern so you can adjust your printing size correctly (I do a 1"x1" square).

-

szeregowy started following SINGER 45 B8BC ( Seiko CH-8B ) FOR SALE and CAMOGA C400 Leather Splitter

-

Hello, I am selling Camoga C400 leather splitter. I can't use it at new location as i don't have a three phase hook up. Motors were rewound to 230V from 380V. I tried to use static phase converters as you can see on pictures. They are to weak for this machine. I will remove them upon sale. Machine is located in GLASCOTT ONTARIO, CANADA. I can quote and ship within Canada and USA. I can split shipping cost to some degree. Thanks Jack

-

leatherforge joined the community

-

Like the title says I'm looking at this Takajima 321L and I'm wondering if such an old machine is worth $1400. I would prefer to buy Japanese made if I can but I don't want to make a mistake with such a huge purchase. Does anyone know much about these machines? I've read the other posts about these but maybe someone can weigh in with a few more details. For one thing I'm curious if anyone knows if I could find parts to replace anything old or broken. Also I'm curious if anyone knows anything about the motor on the machine in this particular Facebook post? Any information would be helpful thank you! https://www.facebook.com/share/1AWMM2PeFe/

-

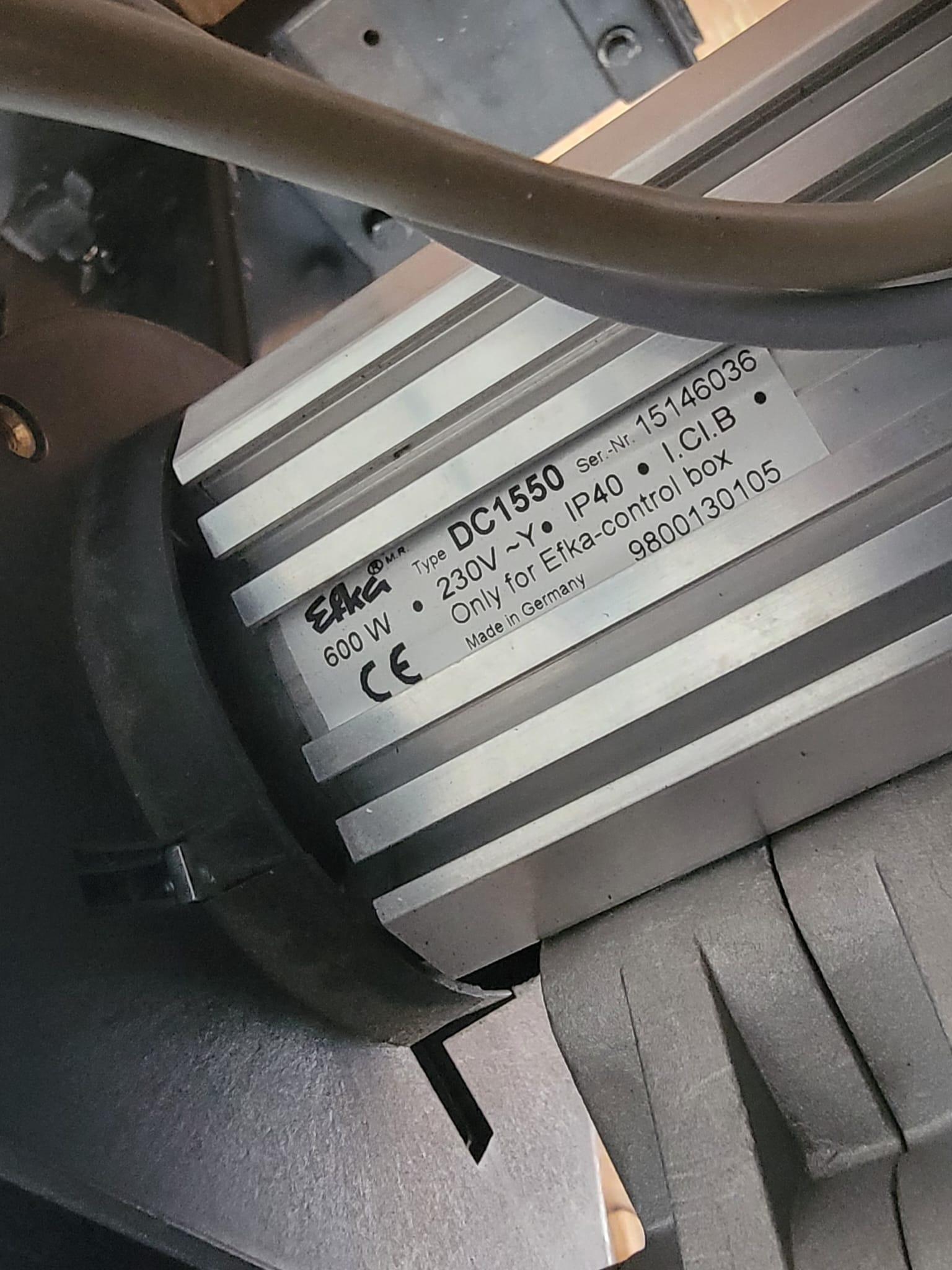

Hello, I am selling heavy duty cylinder arm, made in japan, SINGER B8BC ( Seiko CH-8B ) sewing machine used for making leather goods. In excellent working condition. Serviced regularly. Made in Germany EFKA DC1550 motor SINGLE PHASE 230V (its NOT 3 phase) with speed reducer. Lotsa spare parts and bobbins. $3500 CDN (approximately $2565 USD as of June 26) Machine is located in GLASCOTT, ONTARIO, CANADA. I can quote and ship within Canada and USA. I can split shipping cost to some degree. More info and specs about this machine : https://www.industrialsewmachine.com/webdoc1/singer/45b.htm Thank You Jack P.S. to moderator Northmount - i don't know why my IP landed in New Zealand. I know nothing about IP's and such. Regards.

-

An unconventional way to "split" a large hide

chuck123wapati replied to woo.gregory's topic in How Do I Do That?

i don't doubt that a bit. Drills with attachments aren't Sanders, lol. A belt/disc sander is standard equipment in my shop. I use it on almost every project I make. they make great tool sharpeners also.😉 -

New sewing machine! probably too much for what I need.

mbnaegle replied to gordonl's topic in Leather Sewing Machines

I'm in agreement that if you are not sewing heavy materials, it will be better to sell this machine to someone who needs it and buy something better suited to your needs. I remember working on a couple of very similar Highlead machines (Normally we don't work in import machines like Highlead, but these ones were unique). I think they were model GA2698 like the attached video, but they are built on the same deep throat cylinder arm frame as the machine above. Those machines however are configured for "up-the-arm" stitching, where instead of stitching front to back, your material went left to right. A company was setting up to use it to make leather archery quivers so each piece had 24" of stitching and then was pulled off the arm. I guess my point is a big arm like these machines have has a purpose, and it can be a pain to deal with if you are not using it. Youtube video A machine like yours is way more versatile being in the same family as a Juki 441, Adler 205, etc. which are useful to someone doing saddle and harness type work. The deep arm would be unusual, as the only application for deep throat machines I'm aware of in that industry is sewing saddle blankets, which is usually done on a flat-bed machine. If someone was trying to add leather reinforcements to custom saddle blankets and sew them roughly in the shape they would be on the horse (not flat) this machine might be just the ticket. It could also be useful in making heavy webbing slings for rigging and helicopter rescue. If setting this machine up to use, the ones we worked on were on tables that were very similar to used for Juki 441 with the same motor and reducer, but the base was much longer and more substantial (like in the video). Essentially a heavy duty pedestal stand for a big cylinder arm machine, but with an even heavier duty and wider base. With all that length and weight hanging out there, the last thing you want is for this thing to end up on the floor, so I would either invest in the proper stand, or get crafty with the welder and fab something that is going to allow the operator to fully utilize the machine, while also fully supporting it. It might also be an opportunity to incorporate a removable flat bed extension. Something like a big sheet of reinforced plywood that fits around the arm for typical work, but could be removed when you want to use the arm. -

What Pattern software do you use?

chuck123wapati replied to Chris777's topic in Patterns and Templates

A ruler, a compass, a pencil, a protractor, and a brain. I gave up computer drawing when I retired and haven't missed the constant updates, planned obsolescence, or wasting money a bit. -

I use Inkscape to create my patterns. I’m doing my first project larger than 8.5x11 and I’m finding Inkscape doesn’t have a way to print on multiple pages. There is a work-around but it’s VERY clunky. So, I’m looking for recommendations. Preferably something that is open source or very cheap.

-

When my "work van" with a 3.6 Pentastar went out of warranty 10 years ago I started using 10w30/40. Was cheaper to buy as a generic than 5W-20. I've seen no negativity over the years and have 350k on it. No apparent decrease in fuel economy or hard starting in cold either. In a general sense it makes no difference in most applications.

-

PastorBob started following Leather Class

-

I actually offer several different classes, each building on the one before. Classes are for ages 4 and up. My first class is 1.5 hours long. I have a box of show and tell items that include different types of leather, different tools used, varying projects I have made, then I have each one stamp a 4" round coaster. Each student has their own slab of marble, a hammer/maul, and an assortment of stamps. I teach them how to case a scrap piece of leather for them to practice stamping. This is two-fold, it lets them find the design stamp they like AND how hard to hit each stamp to get the proper impression. Once they have figured that out, they case their coaster and begin the leather crafting journey. Due to shop space constraints, class size is limited to 10 students and their folks. If you would like to discuss, please reach out. It is one of my passions. Here is the link to my site describing the classes if you would like more information: https://pastorbobleather.com/classes/

-

10w spindle oil is what I'd use on that machine. Many machine makers call for it. In truth you can use almost any oil including motor oil. In the past I often just used a 30w straight oil on many machines and worked great, especially older machines that I received with a bit of pre-wear. Thicker oil does tend to quiet down a worn machine a bit. Some machines actually call for a heavy oil, such as the famed Adler 205. It's Esso K68, that's essentially a first cousin to bar and chain oil. Lilly white is popular here. I find it a bit light, but many also use it for thread lube so could double up. Topic for endless debate here.

.jpeg.84c4e2b82d245c74093b810beff0365e.jpeg)

.jpeg.a53727bca12fa8b28281c551cefd7cc6.jpeg)

.jpeg.43b6016e5f848e358c1ec2a84486fd96.jpeg)

.jpeg.0877a6cd18f6379a759d6eb16f1e2831.jpeg)

-Copy.jpeg.884ed0e79671aaa28a2827ae0e5e445b.jpeg)

.jpeg.cde4bc5a722243f84b6f3bc83a90e428.jpeg)

-Copy.jpeg.3730bba9df455ca783c745a8050ec9b5.jpeg)

-Copy.jpeg.2d4538a7576d96e5e983ea665d08fac8.jpeg)

-Copy.jpeg.96206d739416b44b24ffd4d0b47f7975.jpeg)

-Copy.jpeg.612a991de78f0cf97800c83b09f97805.jpeg)

-Copy.jpeg.b25ba5c68661103e7aa00a5e6bd7b961.jpeg)

-Copy.jpeg.40fa67bebd03d6b9b8426712890c88eb.jpeg)

-Copy.jpeg.175fa403bfab025d2cb560845f76193f.jpeg)

.jpeg.3a6fcbbc67bf8212c2b926c2be333f4b.jpeg)

.jpeg.a2da40cc1d308d21f784c4d69ee5e4c0.jpeg)

.jpeg.945a4f408ec581e811cc8f0b434805b4.jpeg)

.jpeg.15eedcf9caba6bf4cc3ba19b900ecbb7.jpeg)