All Activity

- Past hour

-

Cowboy Outlaw question on accessory compatibility

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

but then the roller is no longer flush with he needle plate - Today

-

I'm back working with my Scout Council in Las Vegas. Last week I completed an inventory and discussed with them what they need. Below is a list of item I'm trying find for them. If you are willing to donate anything on the list we would appreciate it. In addition, if you want or need a donation letter from the Council, they will provide one. If you would like to make a cash donation, please contact me. I have approval to raise funds for the Leatherworking tools they need but they need to be specified for that purpose. Donations can be sent to: Las Vegas Area Council - Scouting America Attention Donna Sword 7220 Paradise Rd Las Vegas, NV 89119 Please notify me what you are sending and any tracking numbers you have so I can head over there after it arrives. If you need a donation letter please include the following info (from IRS website) The name of the organization; The amount of cash contribution; A description (but not the value) of non-cash contribution; A statement that no goods or services were provided by the organization in return for the contribution, if that was the case; A description and good faith estimate of the value of goods or services, if any, that an organization provided in return for the contribution; A statement that goods or services, if any, that an organization provided in return for the contribution consisted entirely of intangible religious benefits This is not everything they need. I will provide a more comprehensive list towards the end of January. Mallets - Preferably Rawhide, yellow plastic or bakelite. But wooden ones are needed too. I estimate they need 130 of the preferable ones and around 40 wooden ones. Poundo boards - they need about 60 of the 12"x12" size and around 150 of the 6"x6" size. Large tool handles - They need around 150 of the large tool handles. They need to have the little bearing on them that holds the 3d/Alphabet stamps on them. Small tool handles - They have almost zero of them. They need around 300 of these and need to have the little bearing on them too. Handle stamps - We need lots of these. At least 1,000 of them 2D/3D stamps - As many as we can get. Stamp Sets - Sports, emoji, geometric, cartoon, native american, Mini Pictorial. etc... 1/4" stamp sets - Funtime, Tracks, Adventure, Bugs, Discover, etc... Alphabet and number sets - Standard 3/4", 1/2", 3/8" and 1/4" 8137 or T8137 Leather shears - As many as we can get Needed only for the merit badge tool sets: Swivel knives - they need around 60. Granite Blocks - 12"x12" Need around 60 of them. Handle Stamps - They need 60 sets of the 6 or 7 stamps that are included in the basic tool set. Plus any others you wish to donate. Alphabet and number sets - Any and all are welcome including incomplete sets. #1 and #2 edge bevelers. they need around 60 Super Shears - I'd like to get around 30 of them. I will add additional items as we determine our needs.

-

To sand the edges or not to sand

Tommy217xxx replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

I’m terrible at cutting so I have to sand or it looks pretty bad. -

To sand the edges or not to sand

HandyDave replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

Single edges get sanded to smooth up from cutting out with knife. Layered edges get sanded to level everything out for a better finish. With layered pieces I want the edges to look like one piece or as close as possible. As for grits. I keep a 80 grit on my bench top belt sander it helps to even things up on alot of the thick welted projects I do. And I keep a 120 on the disc. Then any beveling that needs doing and a final once over with 220 by hand. I actually like to very lighty damp the edges before the 220. This I what works for me. - Yesterday

-

Spent five days in hospital up to almost Christmas. Too many things going on to elaborate at this time. I desperately need to get rid of lots of leather tools etc, I have including hides. Going to hang onto my electric sewing machines. I have quite a few Kangaroo hides of different colors. Will try to list them as I can get them suitable for photos. It has been a long journey for me since 1953. It has come time to make it possible for someone else to enjoy what I have been blessed to obtain. Will try to make the items attractive in price without giving away the house. Ferg

-

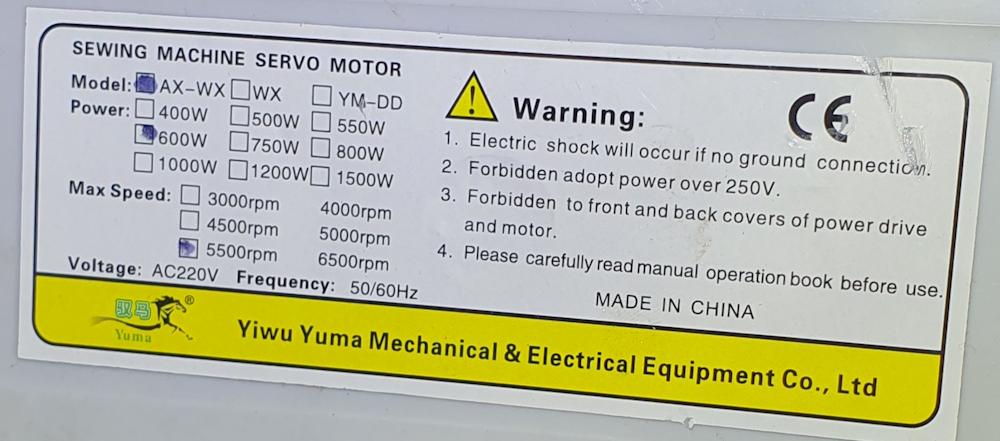

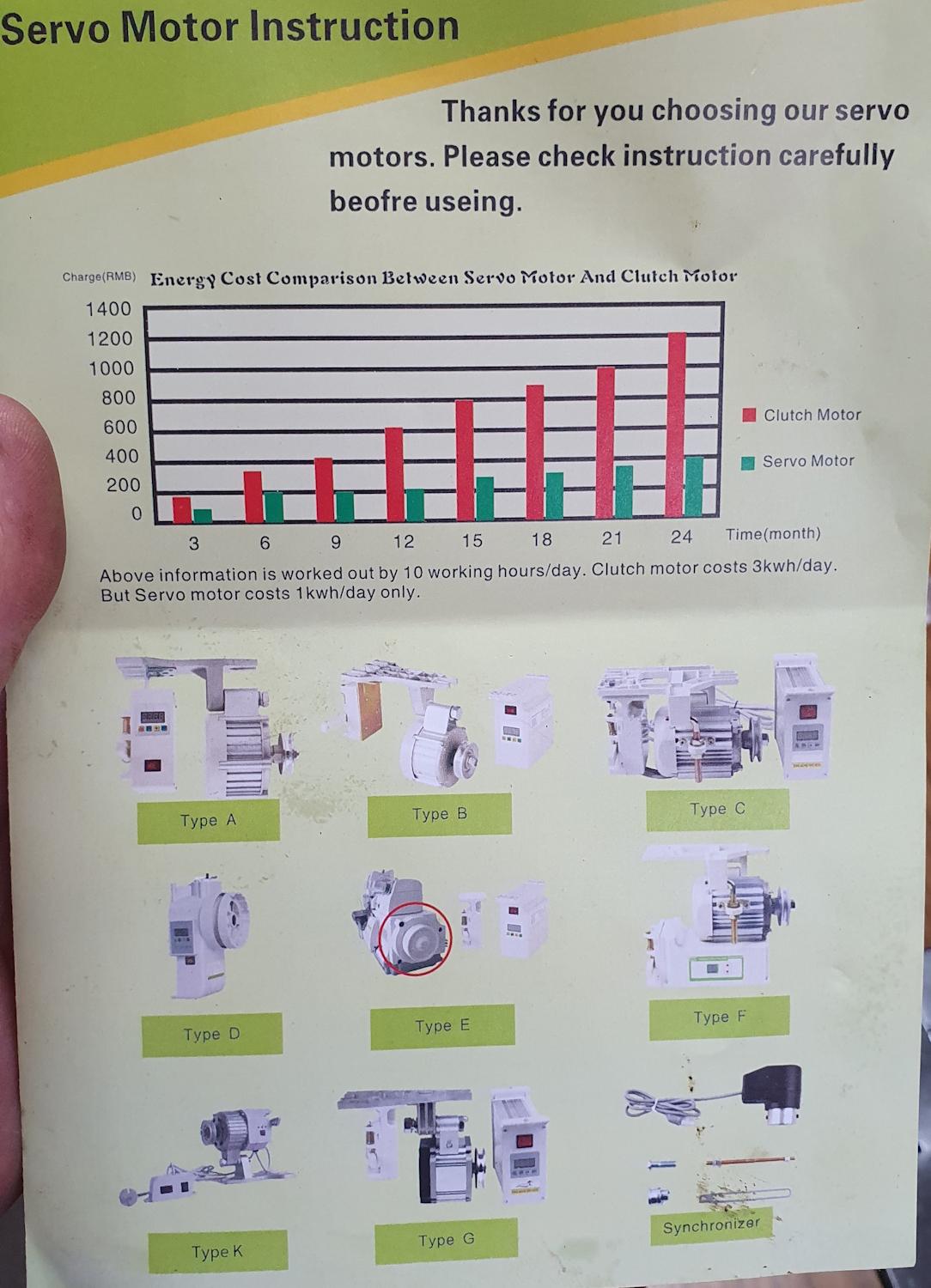

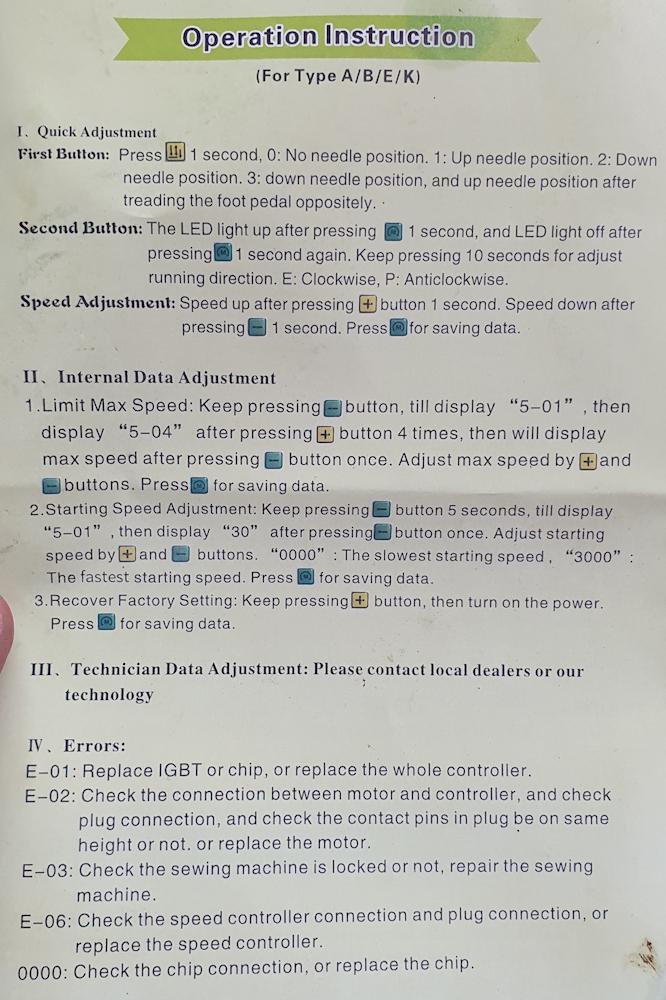

Thanks Toxo, initially I had no idea what you were telling me but after seeing this thread and Uwe's reply (post No5) I now understand why this may happen. It's a safety feature of some controllers where they only allow a limited number of turns of the servo motor when the foot pedal is released. The controller is expecting to see the needle positioner signal "real soon" after the pedal is released and shuts the machine down if too many many revolutions pass without seeing this signal. Of course with the pulley reduction the motor may spin multiples of times before needle positioner signal is seen. With my servo system being el-cheapo it may work in my favour if such safety features have not been implemented LOL. Keith

-

Thanks very much guys. I found pinouts for another servo brand on this thread so I checked mine and I got +5v at pin 2 of the needle positioner connector (referenced to pin 1), so it appears this may be a standard for these types of drive. I've sent a message to the Ebay seller telling them I cannot access the needle positioner settings so I'm currently at the mercy of their service and knowledge of the product they sell. According to the pinout on the above referenced thread if I can access the settings I may be able to test the positioner operation with a simple switch to inject signals onto pins 3 and 4. I've attached a few photos of the drive and the instructions. Keith

-

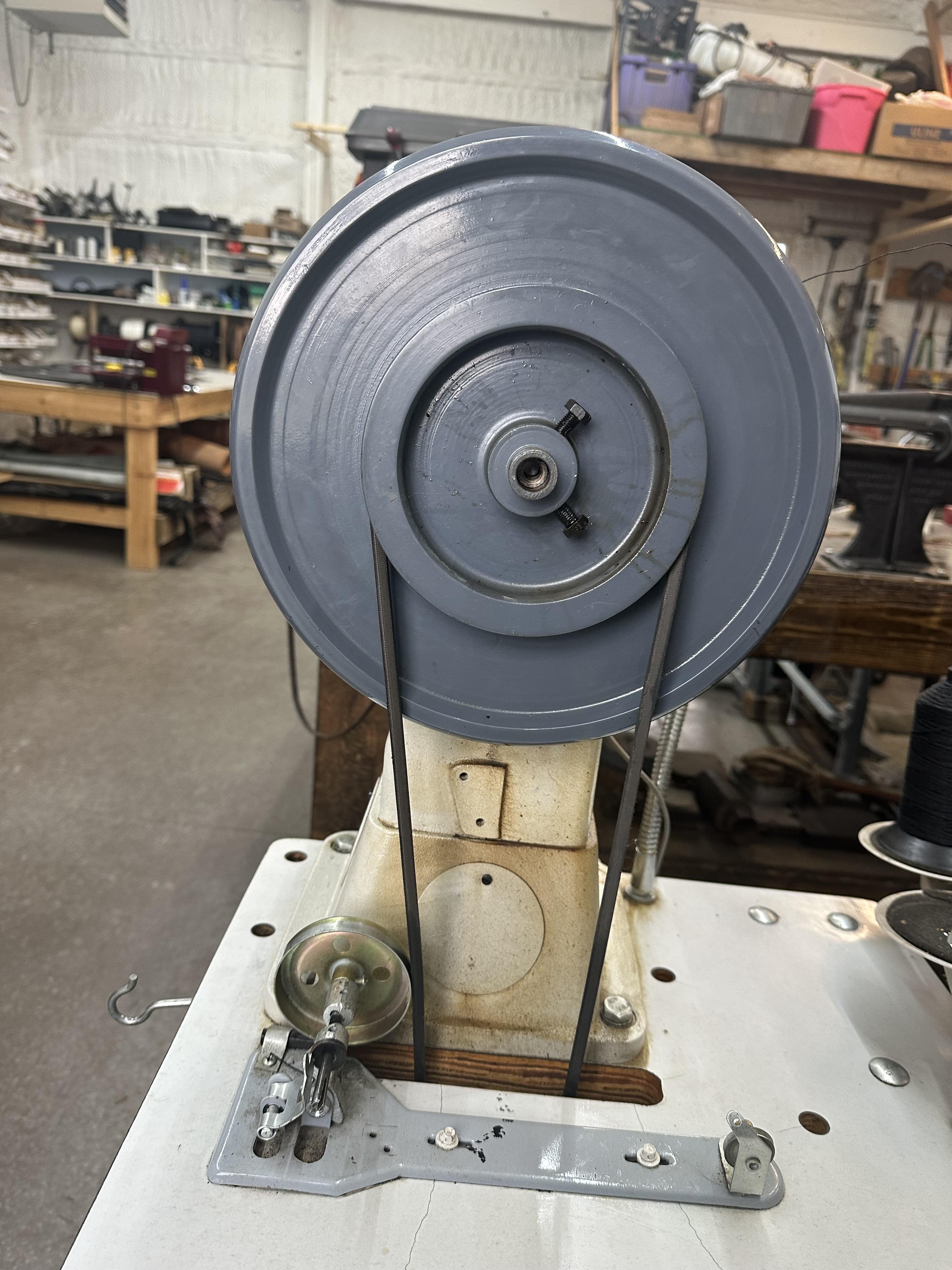

How to unclog the oil system on this cloned Juki DDL-8700? This is the first pumped sewing machine I've worked on. Machine has been sitting for about five years. Actual model number is FEIT DCL-8500N. Pump The oil pump appears intact. At low speed (200 rpm) it appeared to not pump at all, so I disconnected the vertical output pipe at the top and kept increasing the speed until around 1700rpm oil started spewing out the top of the vertical pipe. So there's at least oil now on the upper hook bevel gears. Splash Test But there's another tube that feeds the hook, and I'm not seeing any evidence of oil near the hook yet. In this video the man does a splash test with a paper towel to check how much oil is reaching the hook: https://www.youtube.com/watch?v=hQCUZs1-vUY&t=163s Here is my paper towel, still dry: Valves I have opened the valve that regulates oil to the hook: and also opened the valve that regulates the oil to the needle bar crank assembly: but still not seeing any on the hook or on the needle bar crank assembly. Tthe user manual says that when machine is new or anytime after it's been sitting idle for a long while to run the machine at 3000rpm for a period of 10 minutes. So far I've run the head unit a couple minutes at 2400rpm (checked with tach). I want to see evidence of oil flowing before I run it enough that it really needs oil, if you catch my 22. Filter? Earlier in this same video the man cleans out the filter in the pipe behind the hook: https://www.youtube.com/watch?v=hQCUZs1-vUY&t=59s so perhaps that will be my next move. As for the needle bar crank, I'm not sure sure what to disassemble to clear the way. Water Worth noting perhaps that I did find evidence of water in this machine. The oil pan drain plug is rusted in place and I did not manage to free it. Not even with mild application of a kitchen torch, a few hours soaking in diesel, and an impact driver. 🤷♀️ Also the old oil looked milky. And in part of the presser bar I found a couple drops of water concealed within some drops of oil. But I don't really expect water in the past to clog the oil pathways Manual I'm using this as a manual: https://www.juki.co.jp/industrial_j/download_j/manual_j/ddl8700/menu/ddl8700/pdf/instruction_eg.pdf

-

emmobee joined the community

-

Cowboy Outlaw question on accessory compatibility

dikman replied to bigsig11010's topic in Leather Sewing Machines

A couple of washers under the edge guide to level it maybe? -

@KyLeatherMan, I moved your post to our Marketplace area. Please review the rules, linked here and be sure you're in compliance. For sure we need a price and location and you need to address your willingness to ship. Thanks for listing it here and good luck with your sale!

-

Got a picture of one??? May God bless, Dwight

-

val_vok joined the community

-

Used Cowboy leather sewing machine has been taken excellent care of! Reason for selling needed a bigger machine for specific use. Please contact me at (502) 295-6683 for more details. Can send video or FaceTime how it works.

-

Mighty nice looking. Good hand stitching. The handle looks good, too. It looks to be rigid enough to not fold when you have a heavy load. All around good work.

-

Cowboy Outlaw question on accessory compatibility

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

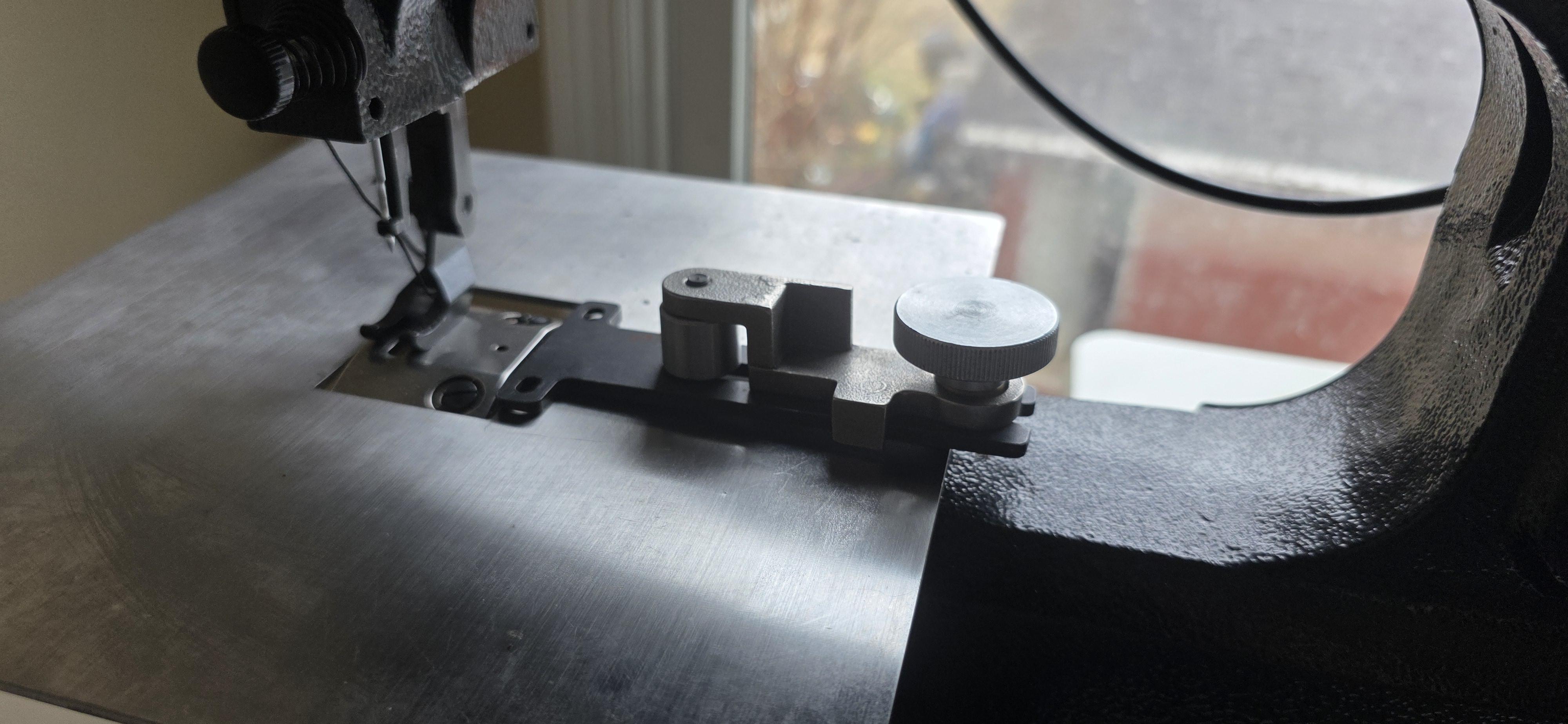

or you make a flat bed attachment where you can screw on an edge guide or modify yours. I once made this FBA for my Singer 45D91 but on mine I cannot use the 441 roller edge guide but the OEM Singer 45K edge guide that mounts on the flat bed steel plate insert. Note the 3 holes in line. Thats where I can mount guides and accessories. -

Cowboy Outlaw question on accessory compatibility

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

The guide appears to be for the JUKI 441 + clones. So w/o knowing the CB Outlaw but knowing Singer 45K´s, Adler 5 / 105 and so forth I´d say either flat bed or edge guide. A suspended flip up edge guide probably is the better option when working with a flat bed. maybe something like this https://de.aliexpress.com/item/1005008728390412 or check this thread: -

If they all have the same connector, then I would say they are probably interchangeable. However, this is also similar to saying are all digital servo motors the same. While the positioner is really nothing more than a switch to mark where the needle is in the up and down position, there is the issue of quality - much like servo motors. I recently purchased a Kinedyne motor and positioner, the positioner when compare to a less expensive model actually feels better. When opened up to dial it in for my machine, it's obvious the quality is much better. I should also say that there are separate dials that are adjusted for the needle positions and an optical sensor for those wheels, whereas with the cheaper model, you rotate the hub that connects to the handwheel to dial in the needle positions. Just my experience with a couple of them .....

-

I have the steel flat plate on my Cowboy Outlaw. I also have the edge guide. When the flat bed is installed it makes the edge guide tilted to one side. My question then is are these two supposed to work together or are they mutually exclusive? Any help and guidance greatly appreciated. Pics attached i hope

-

To sand the edges or not to sand

Dwight replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

I've used 120 for 20+ years . . . never had one complaint May God bless, Dwight