All Activity

- Past hour

-

Oh, I’m aware of that part — the introduction of horses by the Spanish and also the British, and their later spread is something we cover in Europe, not only in history but even in English classes. We’re taught fairly early on how the Americas were colonised, at least in Germany and Sweden. 😉 My question was more specific: I was wondering whether there were particular horse types or bloodlines preferred by the tribes using these saddles, or if certain mustang families were more commonly used. For example, horses with stronger Spanish-type influence versus those with more later Anglo-American breeding. I’ve read that some feral herds even show traces of European cavalry bloodlines, including breeds like Trakehners, which I find fascinating given their original use as military horses. I’m curious how that might have influenced saddle design and fit.

-

Welcome back!

- Today

-

Welcome back. Nice work. I'm excited for you!

-

If you can't tame your digital servo motor, consider replacing it with an analog model that has brushes. The Consew CSM-550 is a perfect replacement. I use this type of servo motor, under different brand names over the years, on all of my walking foot machines, including my huge Cowboy cb4500. Servo motors with brushes like the CSM-550 start at zero rpm, but with very low torque at the minimum speed setting. They gradually increase their starting torque as you turn the speed knob a little higher. Once in motion, you can back off to maintain your preferred speed. Adding a speed reducer can double or triple the torque. Machines with this motor and a speed reducer can start turning over at less than one stitch per second and punch through whatever is under the foot/feet.

-

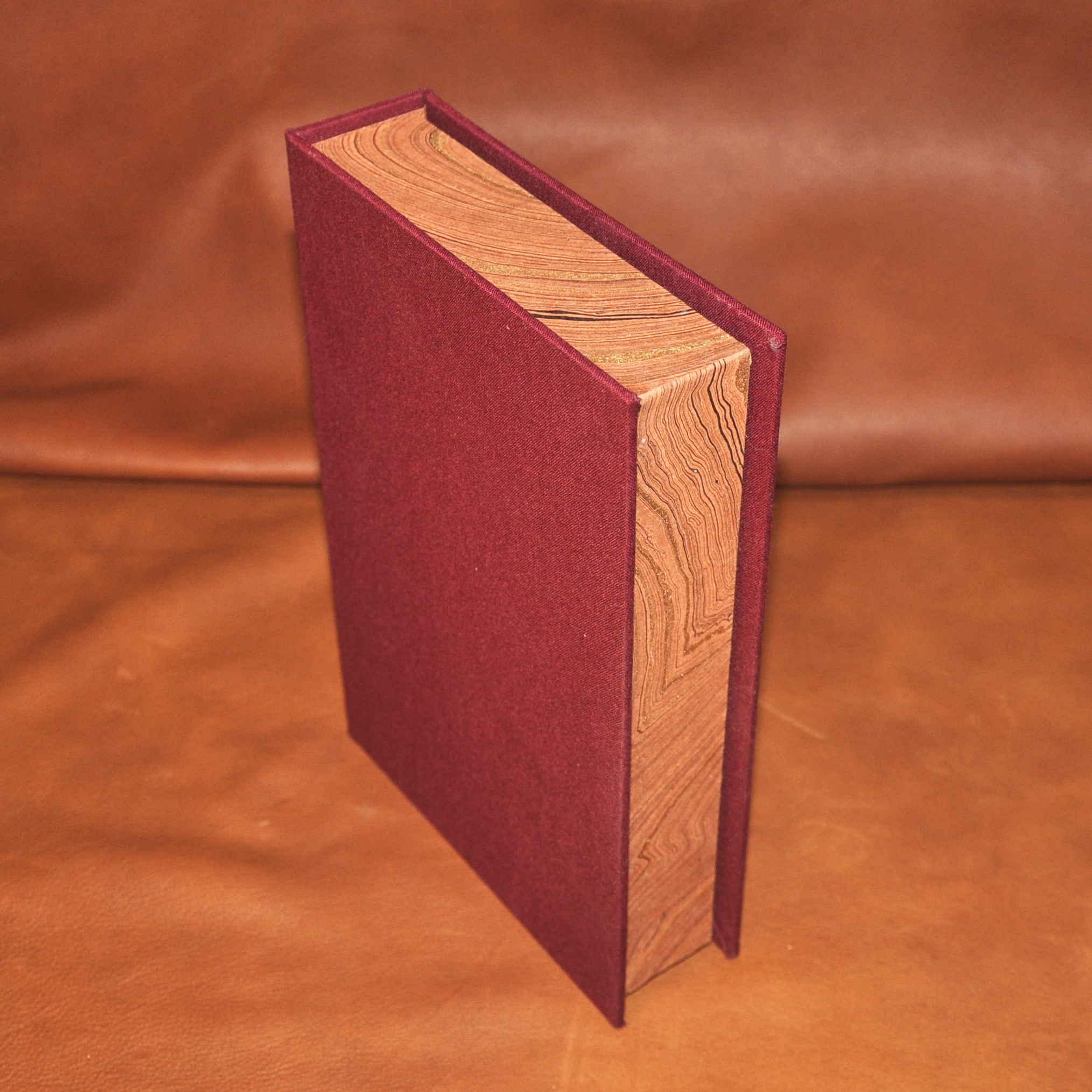

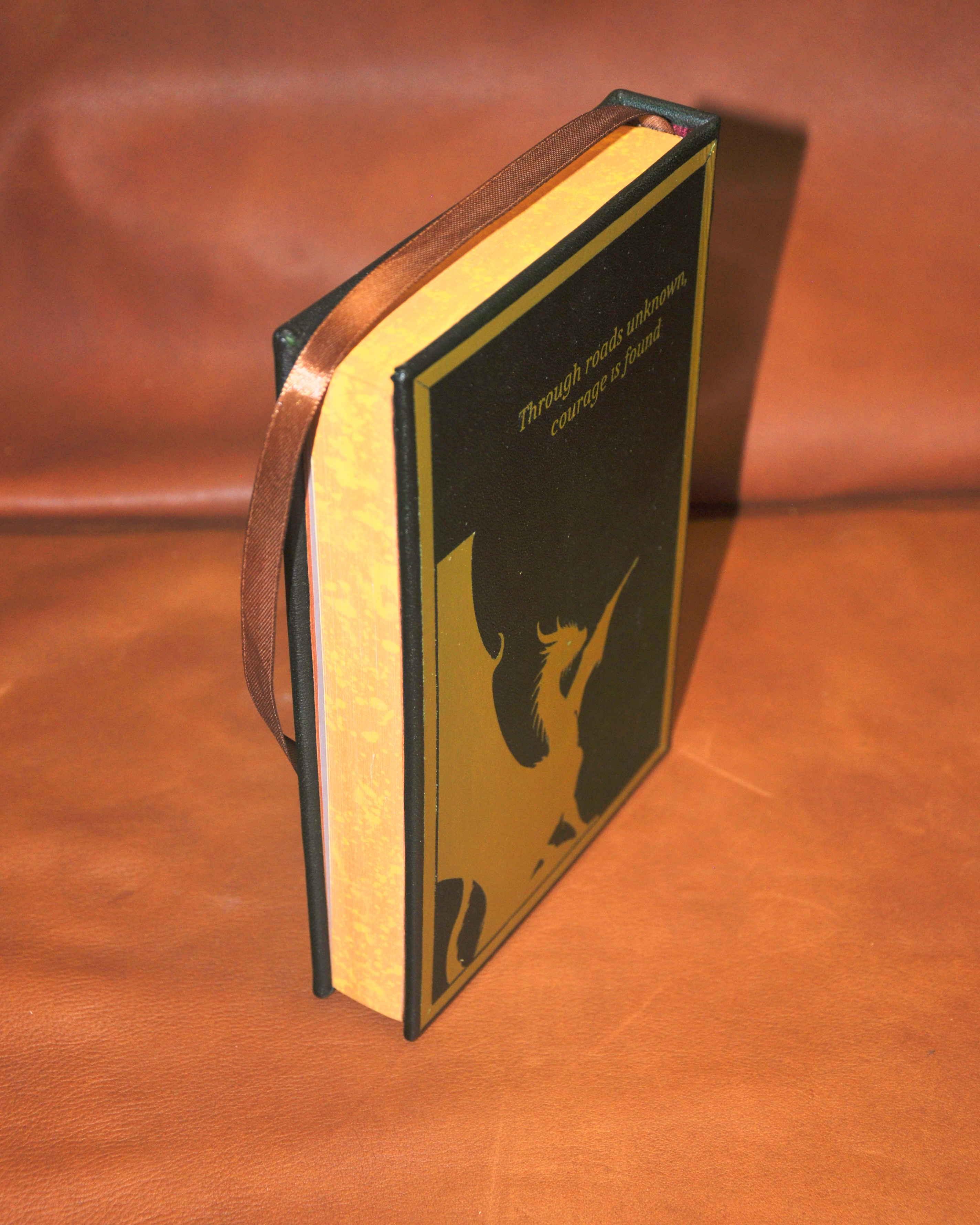

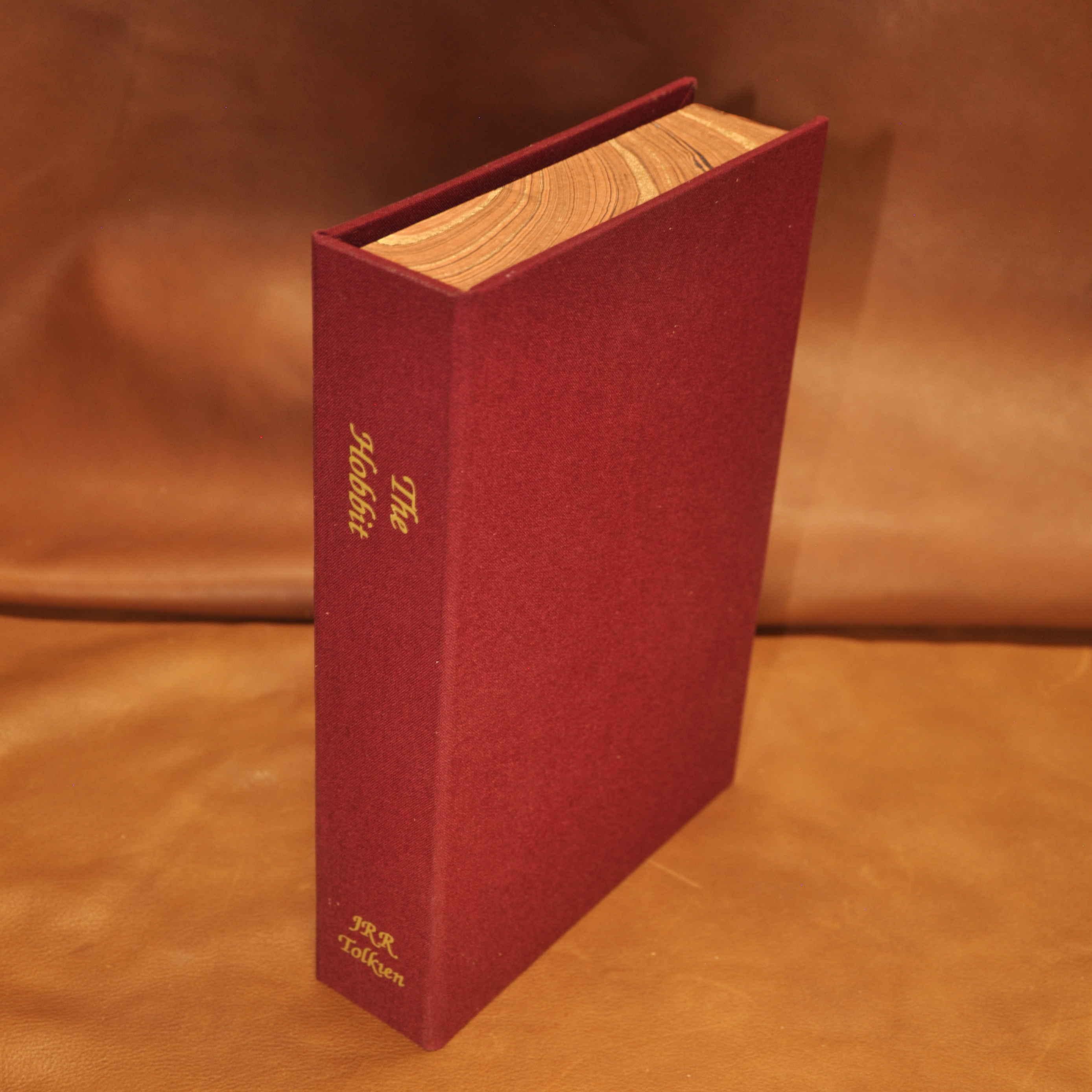

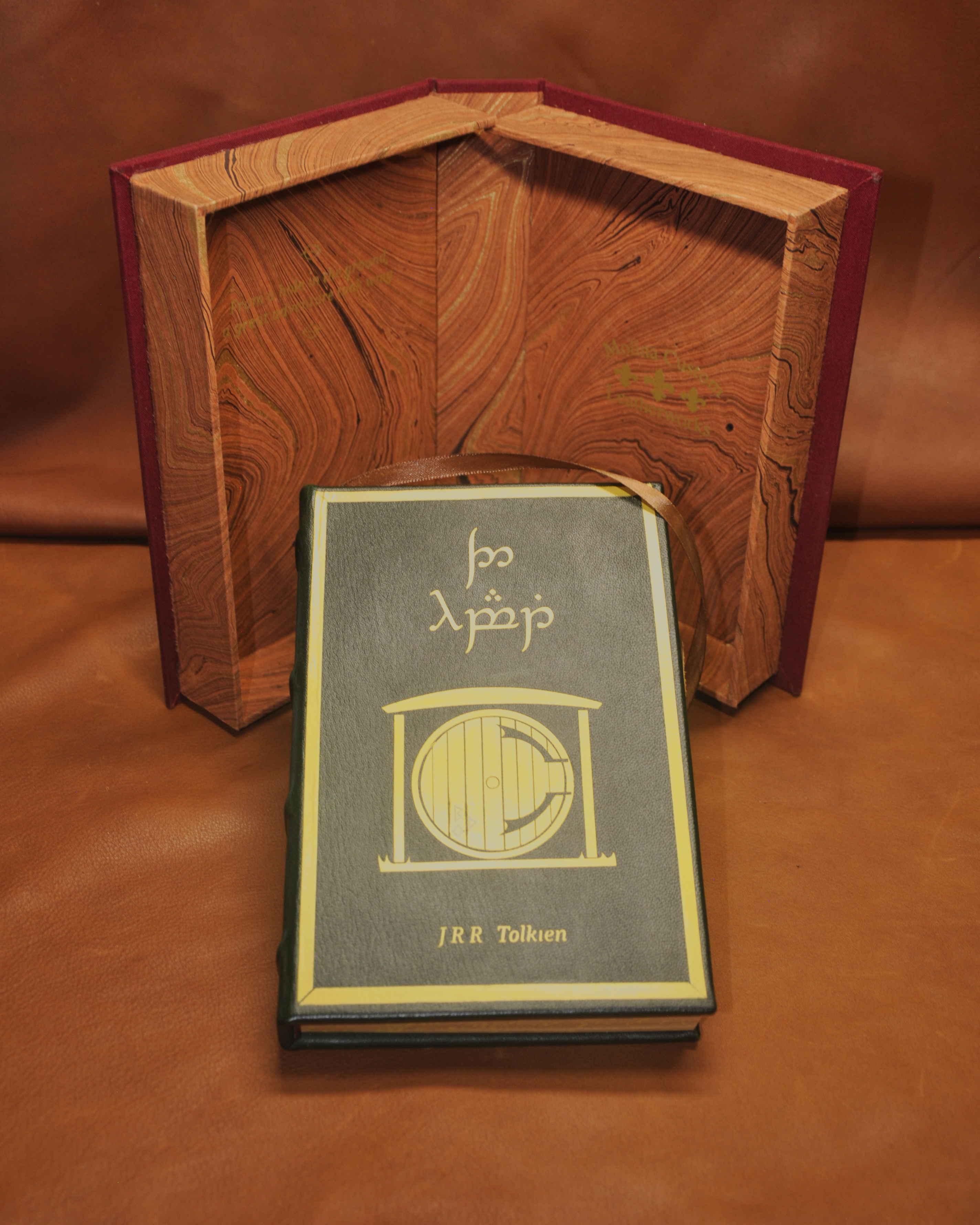

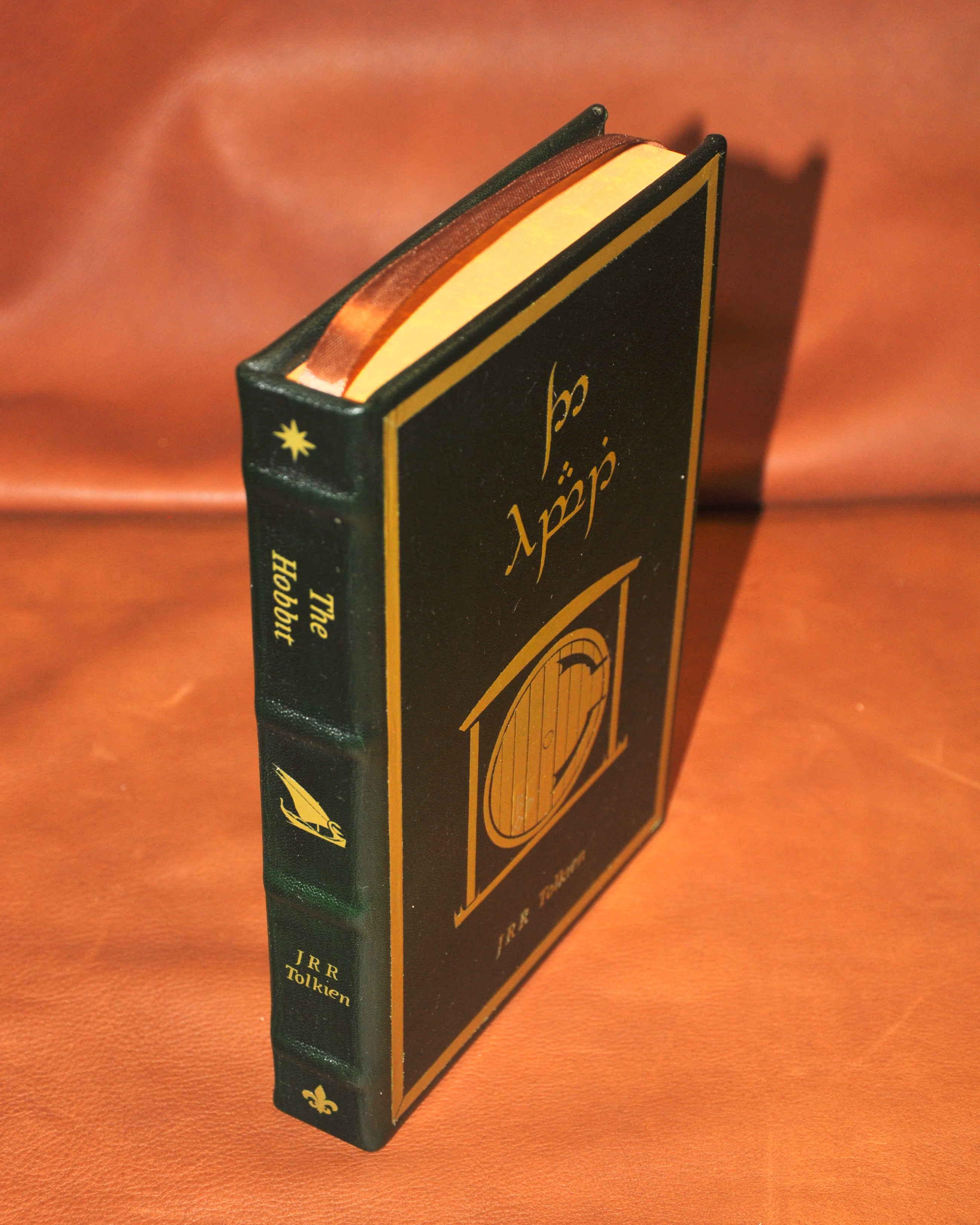

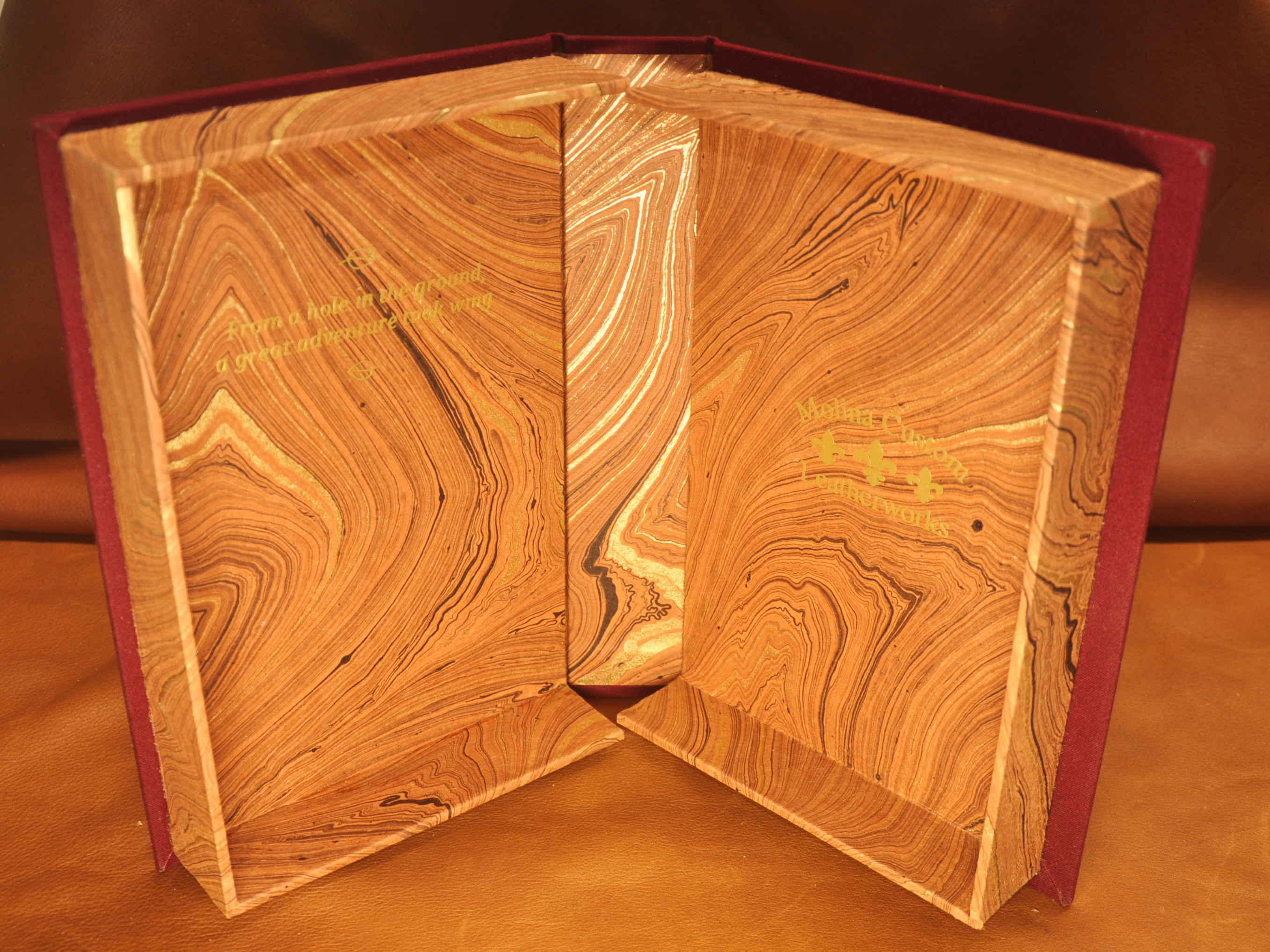

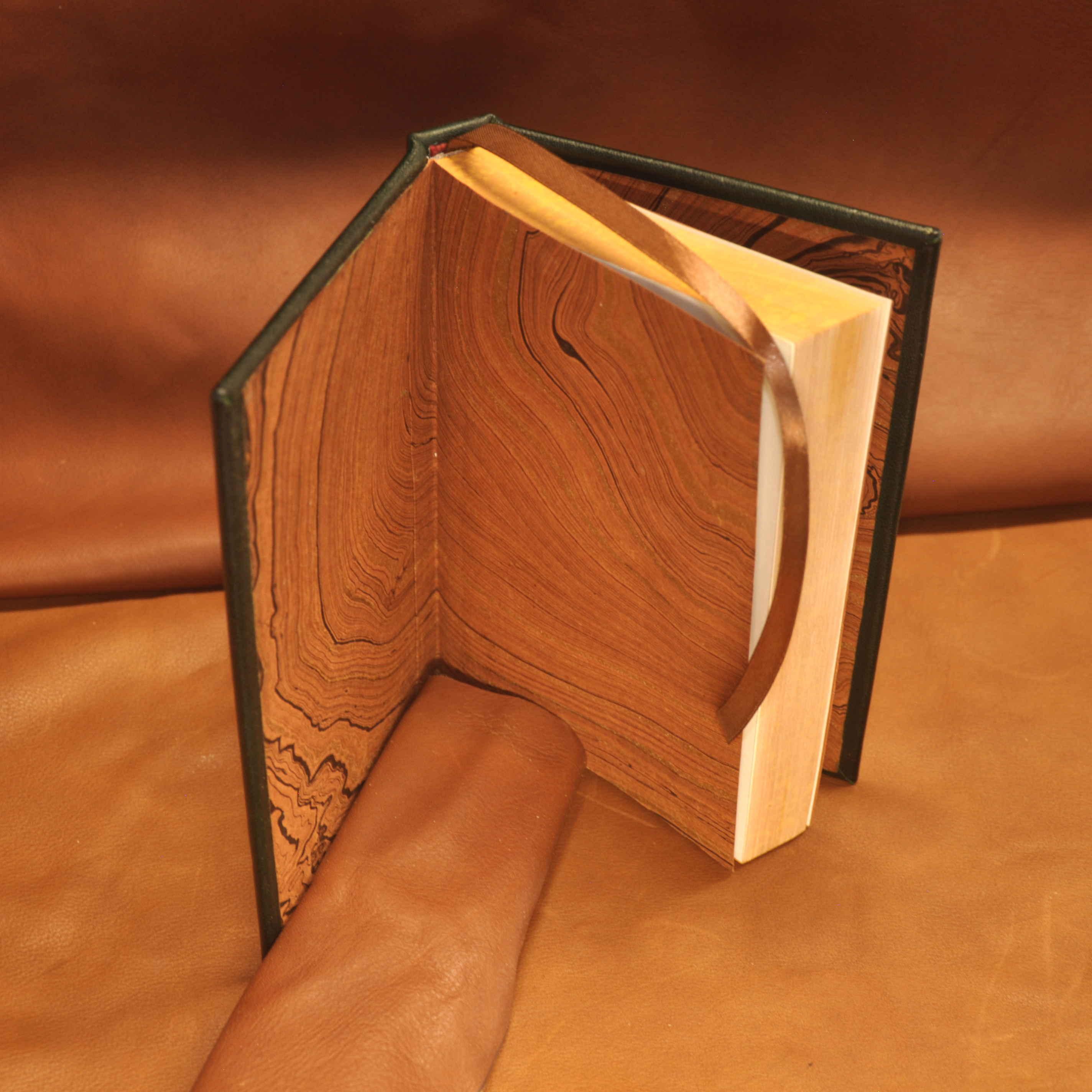

Got back in the shop after the holidays and finished up The Hobbit rebind. This one is going out to the same friend as The Silmarillion rebind I did here: https://leatherworker.net/forum/topic/132484-book-rebind/ This book has the same specs as the last but I added a gold border on the front and back, I think it ties the cover art pretty well. I used holographic htv for the "queer symbol" Gandalf put on Bilbo's door and Smaug's eye on the back cover, which are difficult to see in the pics. The end pages and the book ribbon are earth tones to represent the Hobbits love of growing things in the soil. The page edges are light brown with a dark yellow speckles.

-

Identification of a primitive saddle

chuck123wapati replied to mbnaegle's topic in Saddle Construction

The Spanish conquistadores introduced horses into North America they then became wild horses that the natives Americans caught and utilized.. You can Google them to see pictures. They roam free here in Wyoming, but are an invasive species and do a lot of damage to the winter ranges of the native animals. -

That's nice. For those who cannot master4 hand tooling or have arthritis, for example and can no longer tool by hand, it should be a boon. How do the tattooled pieces compare to hand tooled pieces? I know the effort is less but the results, are they as satisfactory?

-

This is very cool — amazing information and a fascinating saddle! When I saw the picture, I almost asked whether it might be a Spanish saddle, but since you’re in the US I assumed that would be a silly question and just quietly followed the thread. It’s fascinating to see that I wasn’t too far off and to learn how this design evolved. Congratulations on owning such a fantastic piece of history! I’d also be really interested to know what kind of horses these saddles were typically used on, build-wise. I’m asking because western saddles were originally built for rather overbuilt horses, while Spanish saddles, as far as I know, were meant for shorter-backed horses with a straighter top-line and more of compact-upright movement.

-

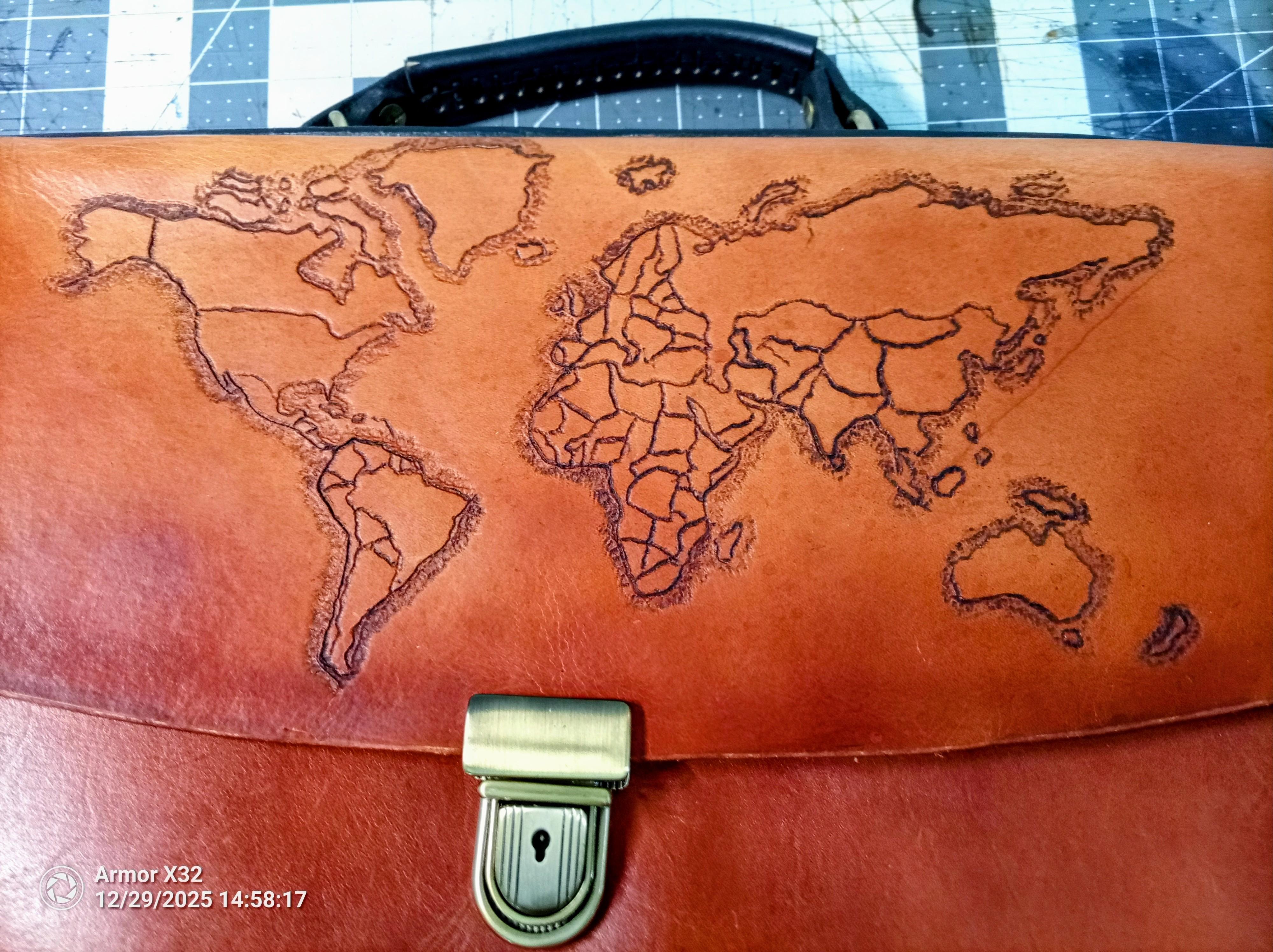

I have one and although I haven't used it alot I like it. Much of my work is with chrome tan so I don't get alot of opportunity to use it. Probably not for everyone. For those that have spent considerable time perfecting your tooling you might be underwhelmed. For those that want a tooling effect and haven't perfected the standard craft I think it can fill the need. Different type of results. I like to trace a picture and work from there. Attached are a couple pictures of bags I made using it. Both on veg tan.

-

Hey, I’ve dyed a lot of veg tan over the past year, including pieces that had been sitting around and were noticeably stiffer than normal. I’ve had good results applying a very thin layer of neatsfoot oil first, letting the piece dry for at least 24 hours. It does darken the leather slightly, but then I dye afterward without issues, as I mostly used alcohol-based dyes. If you’re concerned that the dyeing process might dry the leather out further, it’s worth checking what kind of dye you’re using. Not all leather dyes are alcohol-based. There are oil-based dyes that can give a very nice finish when paired with the correct sealer — Fiebing’s has several in their range. Water-based dyes and hybrid systems are also options. Depending on how stiff the leather is, I’d personally lean toward an oil-based dye. In that case, I condition afterward and let the piece rest for a few hours up to a day before sealing. Dye often looks much darker before it fully dries, and giving it time makes it easier to control the final depth and vibrancy of the color. Really take the rest times seriously — this allows the dye to develop correctly before conditioning, and gives the conditioner time to absorb before locking it in with the sealer. Hope this helps, and let us know what you end up doing! ☺️ Best, Tove

-

We got one at the Sheridan show last May. My wife has used it some. I played with it and thought it has some real possibilities.

-

The Tattool machine from Weaver Leather supply. Has anyone tried it? Opinions? Thoughts? There is always space for innovation, isn't it?

-

welcome back!!! That's nice work.

-

Not exactly creep but the ramp up speed is so slow it almost feels like it. The creep you mention is what I would call slip. With my motor and synchronizer, it's set up where I can get one stitch per tap on the treadle. I think buried down in the settings, I can adjust the speed as well. I don't want others to think I'm promoting one brand of motor, but if you search in my previous posts and then do a little research, you can find out more details from others to see the motor in action. After that, then you can make your own decision.

-

I have read on here that the brushed servos start from zero and have better low end torque. Verify this for yourself! I have a few brushless servos, one of which starts at 100 rpms. With a 45mm motor pulley, a 6"/2" speed reducer and the stock 3.5" machine pulley, I have a bottom end of 11 stitches per minute. You'd never really sew that low but it gives me a slow start with good control and torque. Still, the brushless motors increase in increments of 100 rpms, whereas the brushed versions apparently increase smoothly. When I need another servo motor, I think it'll be a brushed version.

-

Tomato-Ono joined the community

-

believe it or not - I run a JACK 563 servo (actually 2 of em) for many years and just recently I bought a fxcking cheap Chinese servo (for under 70€ few month ago incl shipping) and it behaves and performs way batter than the Jack - not kidding. It starts at 200 rpm and I can dial down to 100 but than it makes strange sounds. https://de.aliexpress.com/item/1005007257363563.html price on my side of the pond is 88.99€ now incl shipping (Warehouse in Germany). The Jack quality is better, thats for sure but this cheap sucker just performs better. I however have added a speed reducer too, better too slow than too fast and you still have enough end speed. But to each his own...

-

The main difference is a clutch motor is running at full rpm's (1450 or 1750) as soon as you turn the power on and like a manual transmission in a vehicle you ease the on clutch. The servo motors don't spin until you depress the "go" pedal. All servo motors have a "startup jump" with the brushless typically having a more noticeable "jump" then the brushed servo motors. You can reduce this somewhat by reducing the pulley on the servo motor, installing a speed reducer and buying a better quality servo motor. Typically the more internal coils the servo motor has the less "jump" experienced but check the startup rating of the servo motor a lot of the cheaper ones have a 500 rpm rating. kgg

-

Thanks for the info, does your new motor creep in like a clutch motor

-

1) change the motor pulley to the smallest you can find, usually 45mm 2) go with a larger pulley substituted for the handwheel 3) speed reducer 4) I tried 1 and 3 above, ended up getting a different servo motor that would start at 50 rpmand not 200 or 300, game changer -

-

Hi, I have a Brother LS-B837 industrial machine and added a sevo motor which is great apart from when starting to sew, the motor doesn't come in slow and smooth like the old clutch motor used to. When its running its slow enough but would like a smooth start instead of it jumping straight into the slowest speed which is quite slow. Does anyone know of a mod that will acheive a smooth slow start like a clutched motor does Thanks

-

Gram joined the community

-

What Age Is This Simco?

Gram replied to 1nicesimco's topic in Saddle Identification, Restoration & Repair

I have this saddle. It belonged to my aunt. She gave it to me when I got my pony in 1973. She got it for Christmas in 1955-57. -

I would reconsider by the time you change the clutch motor out for a servo barring anything else you are up to about $1100 for a machine that came to the market in 1976. If you need parts they are going to be either hard to fine or expensive. Since you mentioned the Consew 226 which came to the market around 1960 I would go more for a newer Consew 206RB-5 which has a larger bobbin and costs about $1800 new. kgg