All Activity

- Past hour

-

With our current crop of "leaders" there's no chance we can emulate the US. So, Japanese hardening but without the clay. Just had a thought, why didn't you make an antler handle? That would put it into another class.

-

My answer is, that it is a bit more expensive, to make a motor drive with good low speed control, and there is not sufficient demand in the market for that. EFKA do make expensive motor drives for sewing machines with a wider speed range. In more technical terms, you got an issue with measuring the speed of the motor. For my drive I use another DC motor to measure speed, at it provide a very fast response. But it got brushes that will wear out in time. The normal way is to use digital encoders of some kind. For good low speed control, you need a speed loop response of within about 1 ms. If you have got an optical encoder of 100 lines (as I have seen on some the servo motors), the minimum speed will be 10 rounds/sec or 600 rpm. You can get more expensive encoders with 1000 lines - and then you get minimum speed of 60 rpm. But some of these encoders can then get problems at high speed due to a high optical frequency. There is more ways to measure speed, but in general it is not that easy, and it can become more expensive to do it. Another issue is how you control the winding current. The cheep way is to use three digital hall sensors in the motor, and it becomes a somewhat raw way of control the winding currents at low speeds. It is the old way of doing it for BLDC motors. More modern principles use the term Field Oriented Control, FOC, and they use other more expensive ways to measure the position of the rotor of the motor, and they use current waveforms near sine waves. But I think the pedal could be improved without extra costs, and it puzzles me why no manufacturer have made a change here. You need to focus on the force, that your foot provides on the pedal, because with your muscles you can control force much better than a position. For me the lowest speed is with a force of 4 Newton (0.9 lbF) on the pedal and 40 N (9 lbF) on pedal at full speed. For some pedals it is like 20 N for lowest speed and 25 N for highest speed, and to me it makes the machine much harder to control.

- Today

-

Maribel joined the community

-

I’m a little lost. I am reading everybody’s comments, am I able to use this particular crystal white #22 oil on my Jin (Juki) NA-11UT. And Juki 9000 DDL FMS? Thank You

-

virg77 joined the community

-

Means Ranch joined the community

-

MG8095 joined the community

-

Virginia Steptist joined the community

-

I made a bible cover once out of some black leather I got from a book binding place, beautiful leather, then I did a saddle tan lace around the outside edge, holes cut straight along the edge, then put a nice twist in it so it looks the same inside and out, looks kind of like a diamond shape. The job came out beautifully, but I'll tell ya I felt all sorts of self-conscious about it. Just me, but no lace would have been just fine; I remember thinking God's words don't need to be jazzed up. A funny thing is, I didn't think of that until it was all done. That cover is no longer on that book. LOL

-

Dummy gun

wizard of tragacanth replied to KillDevilBill's topic in Gun Holsters, Rifle Slings and Knife Sheathes

KDB, Thanks! That's good news. I ordered a S&W Bodyguard 2.0 -

Please create a new album in the Leatherworker Gallery and post these pics and videos there. https://leatherworker.net/forum/gallery/# Stuff posted and hosted by 3rd party host gets lost when the host changes policies or the owner moves or deletes his/her posts on the 3rd party site. This thread may be very important to someone down the road. They would need to see your pics and videos. This is the best place to put them.

-

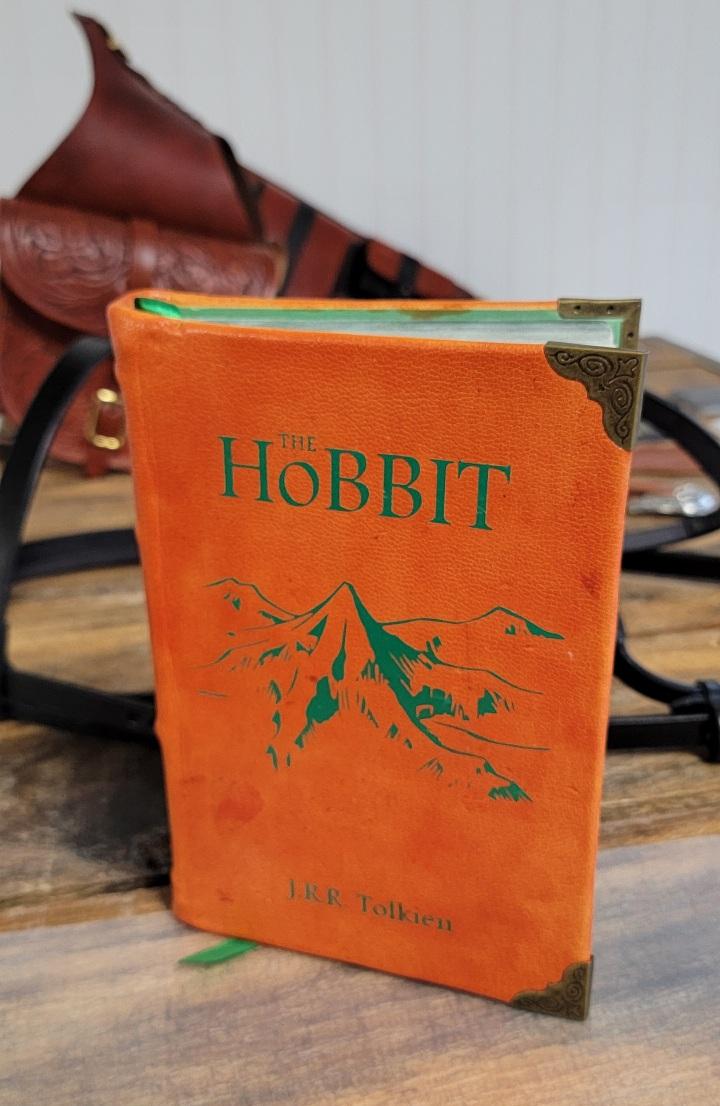

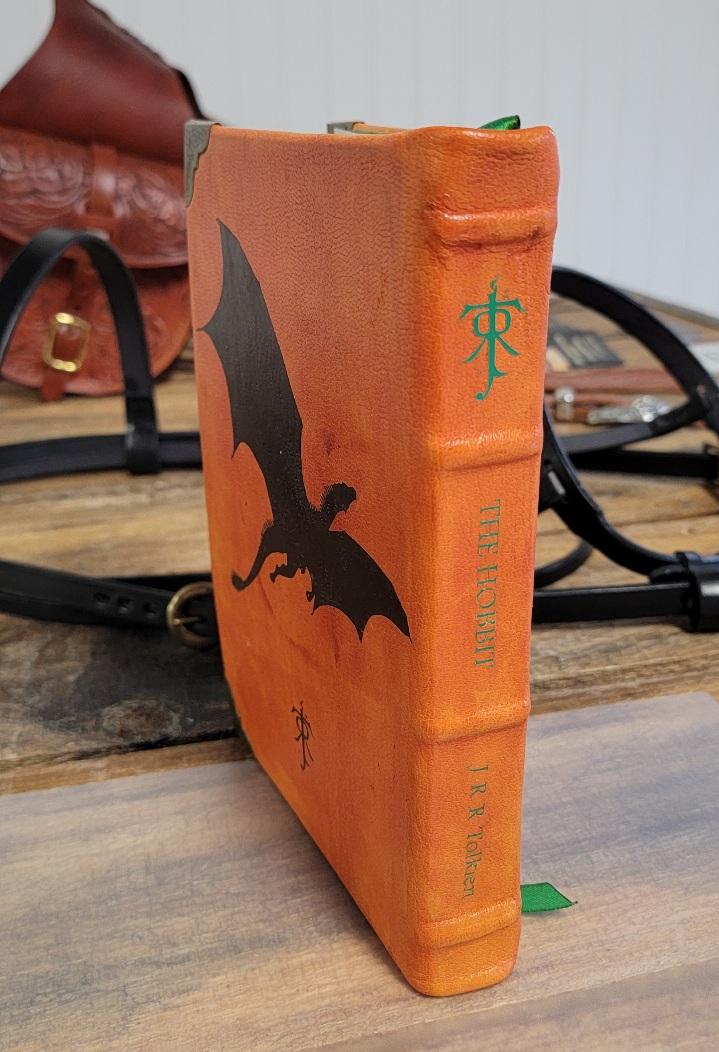

I have a dictionary in my shop that I was going to try 'one day'. So far, my attempts have seemed a bit pedestrian. That Hobbit book looks awesome! Maybe I'll revisit that notion, and take some of the advice offered to @4knights Cool beans!

-

CraftyWeasel13 joined the community

-

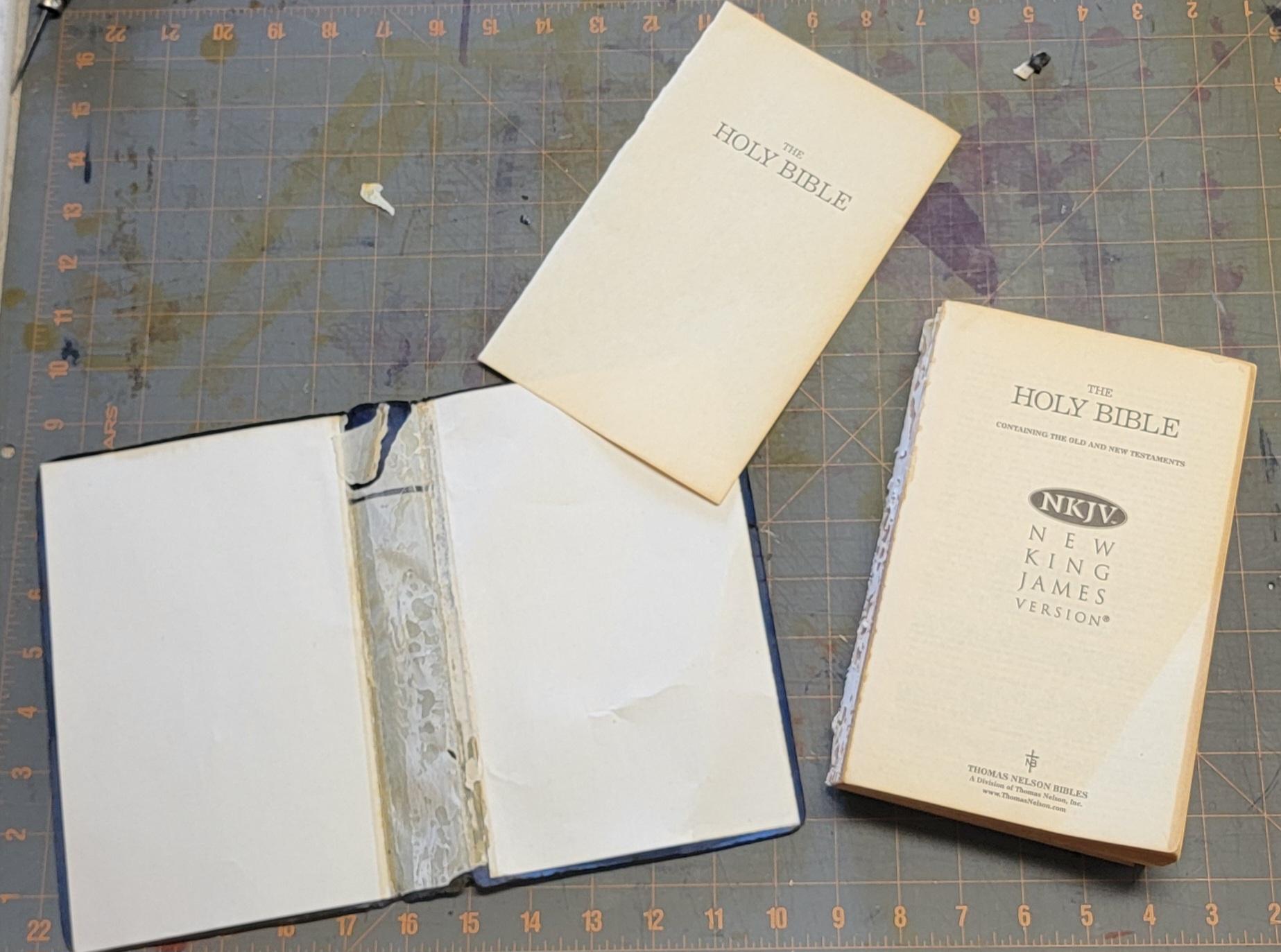

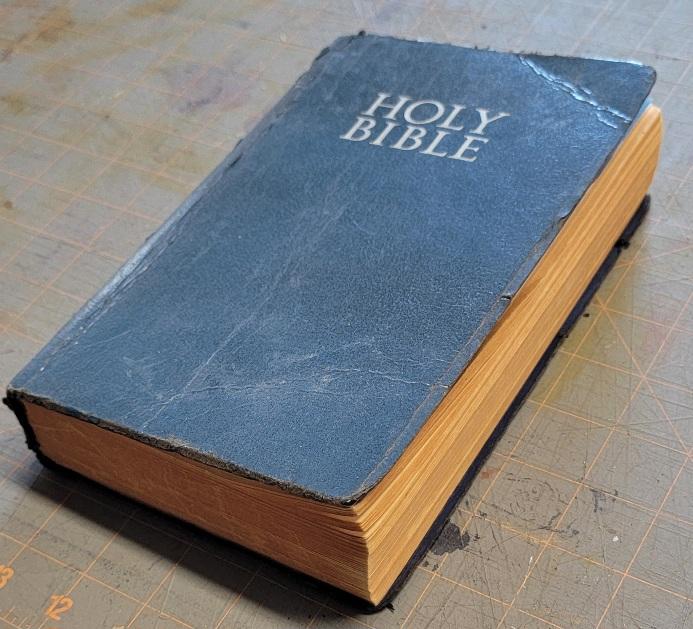

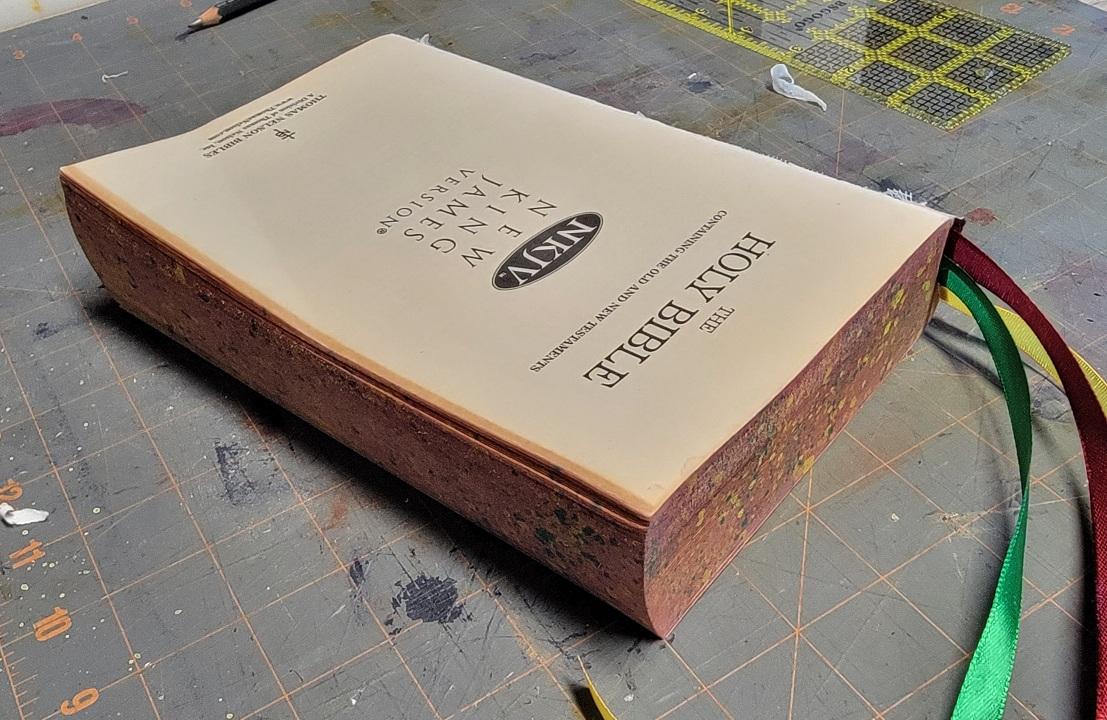

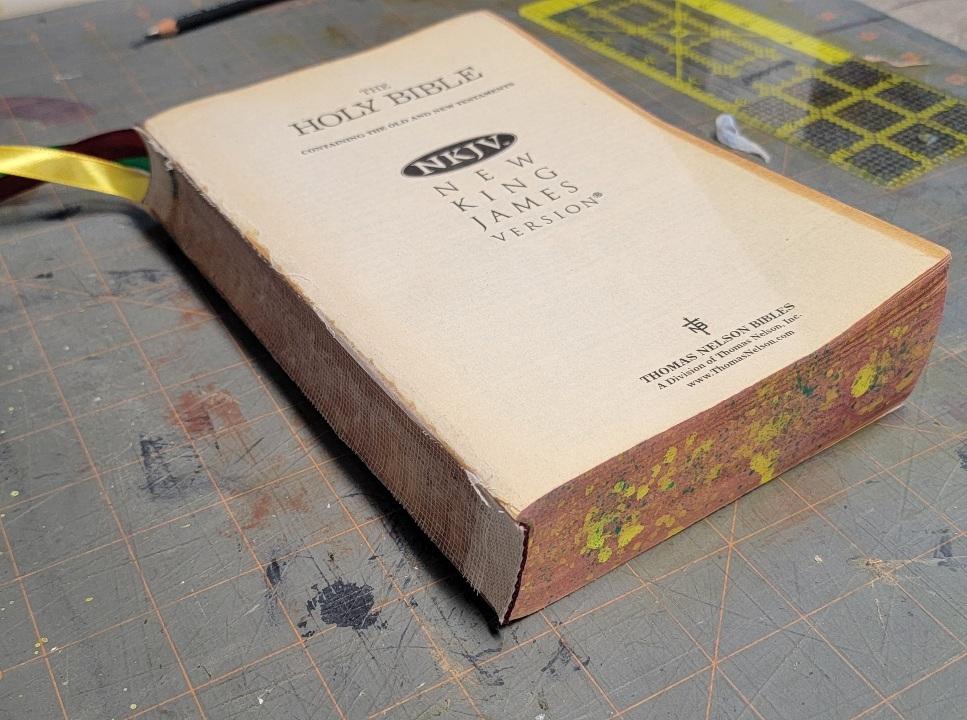

I'm currently doing some book rebinds. My plan is to rebind and sell a few books from time to time. Generally books are rebound in 2oz leather and good quality binders boards for hardcover books. Going thicker than that makes it difficult to fold over the edges, going thinner means the leather will wear out faster. On my bench at the moment I'm rebinding a soft cover Bible. I'm going to use poster board and 2oz veg tan. You can probably do 5oz you'll just have to mitigate the curling of the leather after tooling.

-

Yeah, that was pretty dumb of me! If I found my exact truck in a junkyard, we wouldn't be having this conversation. Lmao 🤣

-

I haven't made any cuffs yet, but I have bought a set without any padding twenty years ago. It was pretty decent and if asked I'd probably base my own design off off those. The only improvement I'd make would be to ensure the edges of the cuff that touch the skin of the wrist would be smooth (instead of a square cut leather strip). Whether to pad or not probably depends on what you want to achieve: if it's for some soft kinkyness or as a fashion item, padding can make it more comfortable to wear. If it's intended for restriction, do know that padding can be compressed so that the wearer of the cuffs could wriggle out. Tightening the cuff would prevent that, but that could also potentially restrict blood flow.

-

You don't need thick leather for books, but you can use whatever you want to. I've made a few sketch books, bible covers, and vow books for weddings. There is a lot of info on the forum, i would search bible covers, book covers, vow books and such. you will also want to get info on bookbinding in general. Good Luck!!!!

-

They also don't glance off as easily as a hatchet or a small axe, and one of the main reasons I started carrying them instead. They are much safer around kids; for that reason, I have half a dozen hatchets or so, too Yeah, it will outlast me by far, I'm sure. It's going to Elk camp in a couple of weeks for its break-in by the fire pit. I got a great temper on it. I quenched just the cutting edge and left the spine soft, so it should be a good, strong, springy blade. It sure took a nice edge; it's scary sharp. I understand that completely and agree, I'll just quote our Pres. on our immigration problem, then leave it at that. "Turns out all we needed was a new President." I pray you folks at some point can also do what we were able to pull off. And yes, I taught my kids how to use sharp tools !! Thanks, man.

-

You just might check with local veteran groups . . . there are people who help veterans with "problems" . . . they find leatherworking as a resource to help them work thru their "problems". If you are not a veteran . . . they may welcome you anyway as someone who brings another group of ideas that may spark a better interest than key fobs, wallets, and belts. Plus . . . you may find someone there with your same interests . . . the help could go both ways. Columbus Ohio Tandy has a really great one . . . and I know the instructor . . . he's a cool dude . . . and apparently it is really helping some of the guys. May God bless, Dwight

-

If I were making it for you . . . I would do "PARAMEDIC" in larger letters . . . Your job is outstanding . . . so your "title" should be too . . . unless of course the unit has certain limitations. Plus . . . just before you quit on the shield . . . go over the back with 2 or 3 or 4 more coats of 50 / 50 resolene and water . . . that valley between the shield and helmet will allow lots of water to hit the back of it . . . and you don't want water to go in the back and ruin the rest of it. Resolene in several coats on a product that does not flex . . . is the next thing to waterproofing . . . good stuff. May God bless, Dwight

-

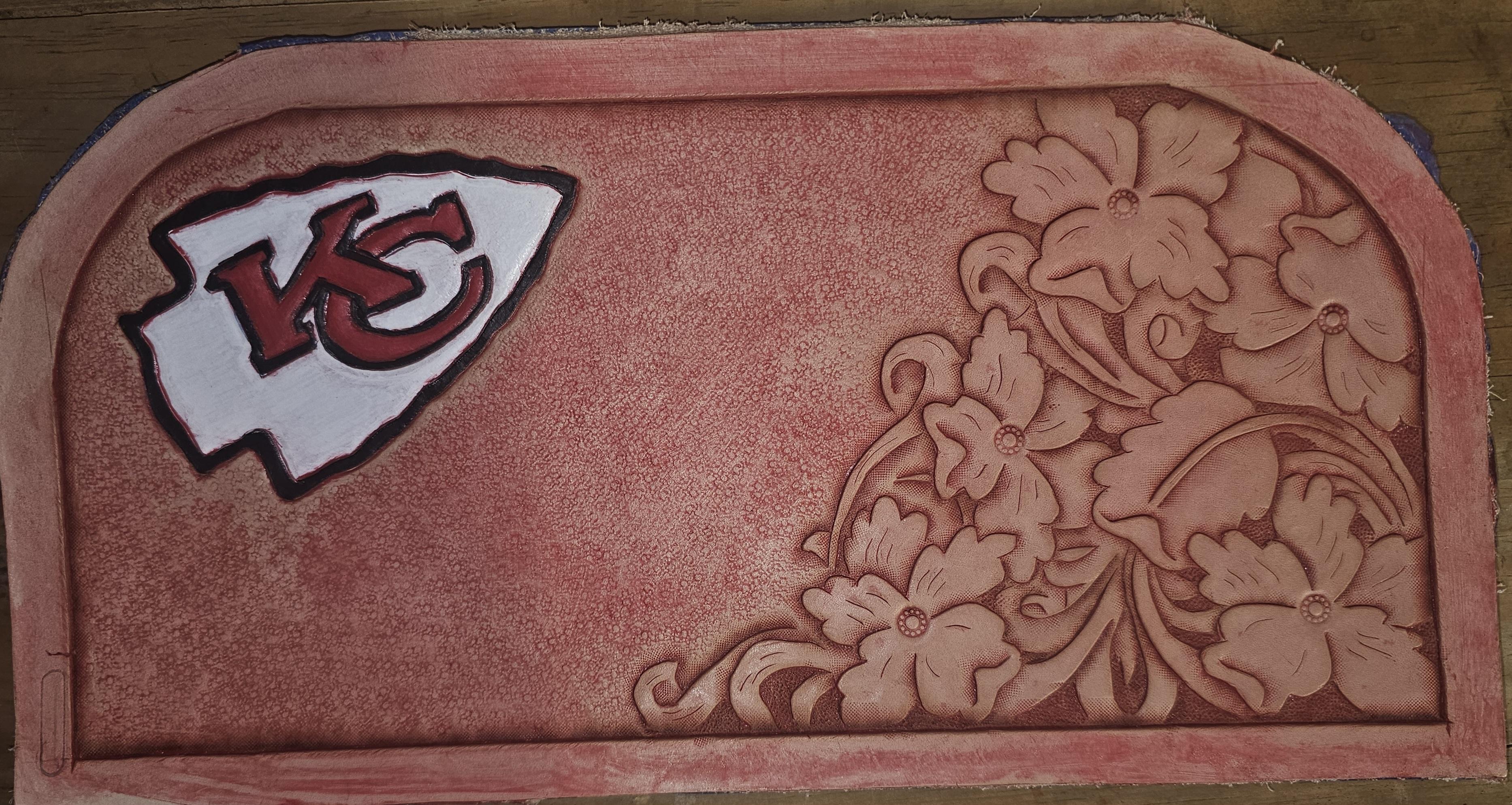

The KC carving was my first project piece, GB is my second. I have done some practice pieces on scrap but these are actually intended to be full pieces. I started using a regular cheap swivel knife and could not get the hang of swiveling with the barrel. I went ahead and got a DW yokeless and it has helped immensely. All of my knife work has improved as I go and I like seeing the progress with the same pattern.

-

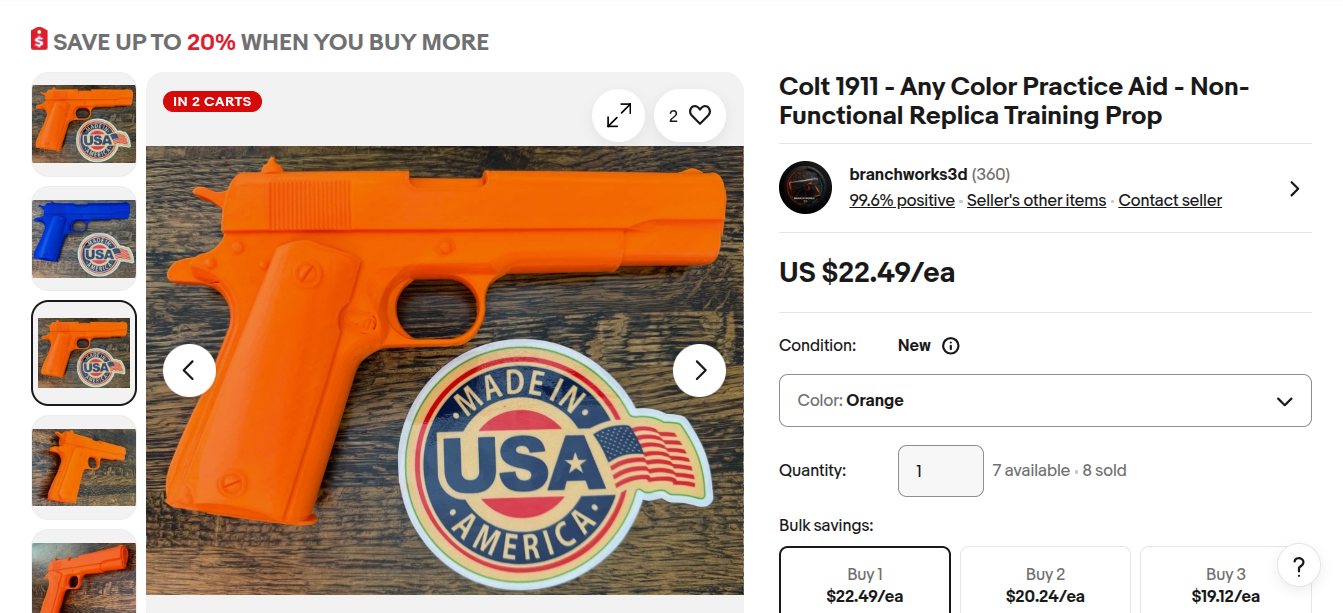

Dummy gun

GatoGordo replied to KillDevilBill's topic in Gun Holsters, Rifle Slings and Knife Sheathes

If you want a 3D printed Colt 1911 dummy gun, you can download the STL files from Thingiverse for free and print it yourself. -

One of the first ones I did was an old Bible. I used 5/6 oz. leather for it. I did some tooling on it as well. It is somewhere between a soft and hard cover.

-

To All, thank you so much for your help. I asked a manual from Hightex EU and they sent me the attached leaflet (CB7243 is the other name of CB243)... Also, I took pictures and made videos of my machine, I hope it will cover all the pics you asked for, but in case not, I will take some more ! In order to ease overview of the machine, I did an album : https://photos.app.goo.gl/zaPGY3vKViruLiBZ9 7243.pdf

-

"That makes sense about dyeing the shield for black. I did burnish the edges to make it clean and last longer one thing I’m curious about is for other shields that are white or red for painting if there is ways to protect it better. " You could use Saddle-Lac spray lacquer. It's pricey, but lasts a long time.

-

Chest Rig for Smith X-frame

Samalan replied to BigBore's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Beautiful design and execution. -

That's a good find. I screenshotted the page so when it goes away, people have some idea what we were talking about way back in '25. And lament the good old days.

-

Dummy gun

KillDevilBill replied to KillDevilBill's topic in Gun Holsters, Rifle Slings and Knife Sheathes

This is the one I bought https://www.ebay.com/itm/396977964819 I haven't started on the holster yet, so I can't say how it does wet forming, but just looking it's really well made. No "flash" or seams to contend with. Ready to use as is for our purpose. When I need another dummy gun I'll definitely look up this brand. -

Mike L joined the community

-

Chest Rig for Smith X-frame

Mike L replied to BigBore's topic in Gun Holsters, Rifle Slings and Knife Sheathes

@BigBore your holsters/rigs look amazing. I am looking for custom chest rig and belt slide for hunting with my Smith & Wesson 350 Legend X-frame revolver. I have a Trijicon RMR optic mounted to the firearm using a Jack WEIGAND Smith Wesson K,L,N,X Frame Revolver Direct Attachment MINI MICRO Red Dot Mount. Is this something you are interesting in making and, if so, how can I contact you? Best regards, Mike L -

Dracroig joined the community

-

That looks sharp chuck!!

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)