All Activity

- Past hour

-

You forgot to post the price. It is required.

-

You should tag or quote the user you want to correspond with as not all users have properly setup their notifications. To tag, type the @ symbol followed by the user's screen name and pick it from the popup box. Like this @Radam you have someone interested in your clicker press, see above.

- Today

-

Since you want a steel rule die bender, I split your post off its initial location and moved it to the Marketplace > Wanted. This is where it belongs.

-

I have not used that needle system, but for my machine there are at least two names for the needle system. So if the needle packaging includes the needle system you're after, I would tend to believe it. Also I found this old post that has a little bit of info on 7x3: https://leatherworker.net/forum/topic/1830-needle-help/ If you do end up going with an alternate needle system in order to get the size/point you are after, at least it's only the needle bar height that needs to change. (Much easier to adjust than hook timing on my machines at least)

-

Scoutmom103 started following Hook to Needle Distance: A Compromise

- Yesterday

-

AlZilla started following Hook to Needle Distance: A Compromise and Consew 206RB-2

-

@Phil Royce I moved you to the Marketplace. We also require location, shipping info and a picture for machinery. Rules are linked here, FYI: https://leatherworker.net/forum/forum/71-items-for-sale/ .. Thanks

-

Phil Royce joined the community

-

Hook to Needle Distance: A Compromise

friquant replied to friquant's topic in Leather Sewing Machines

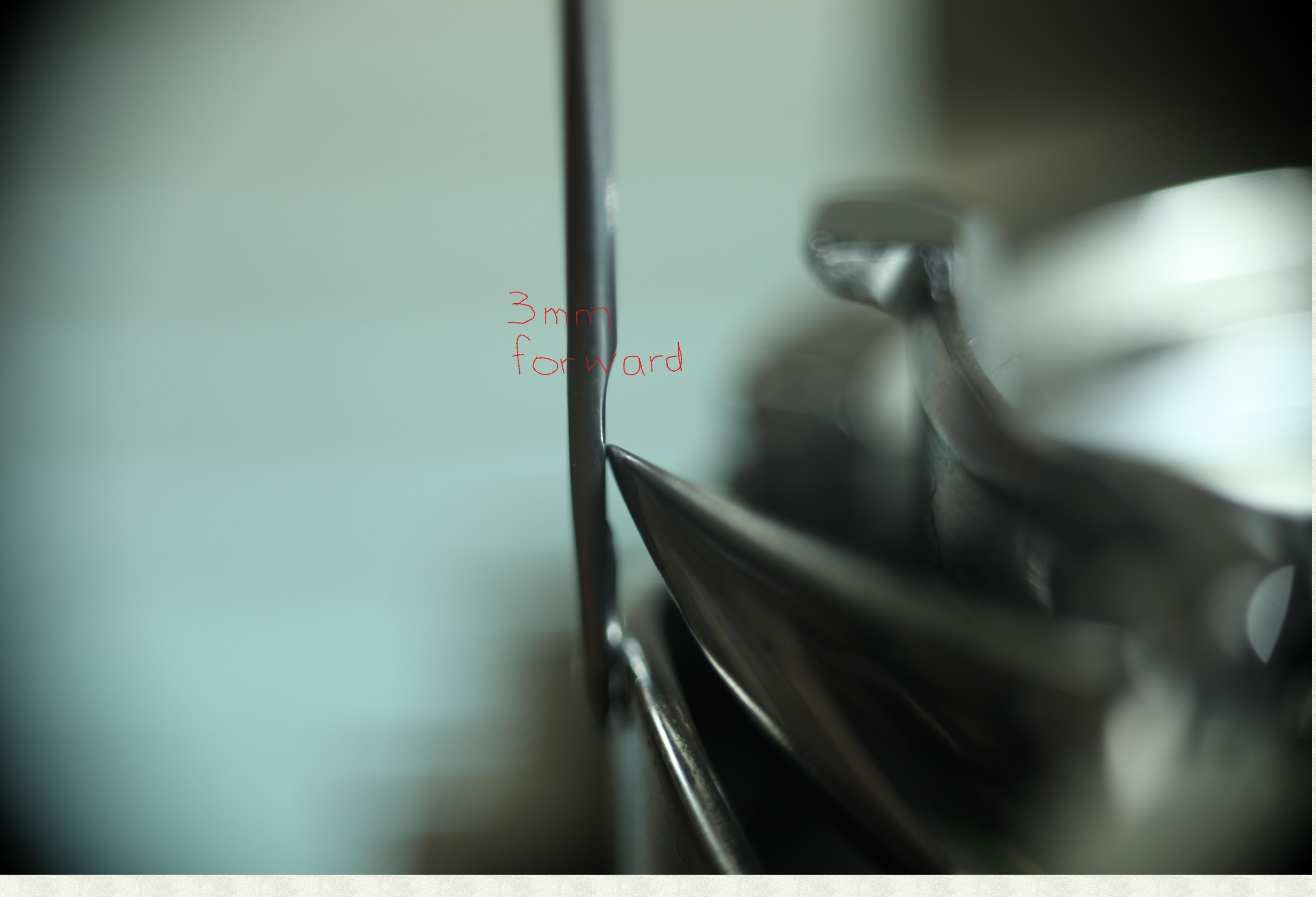

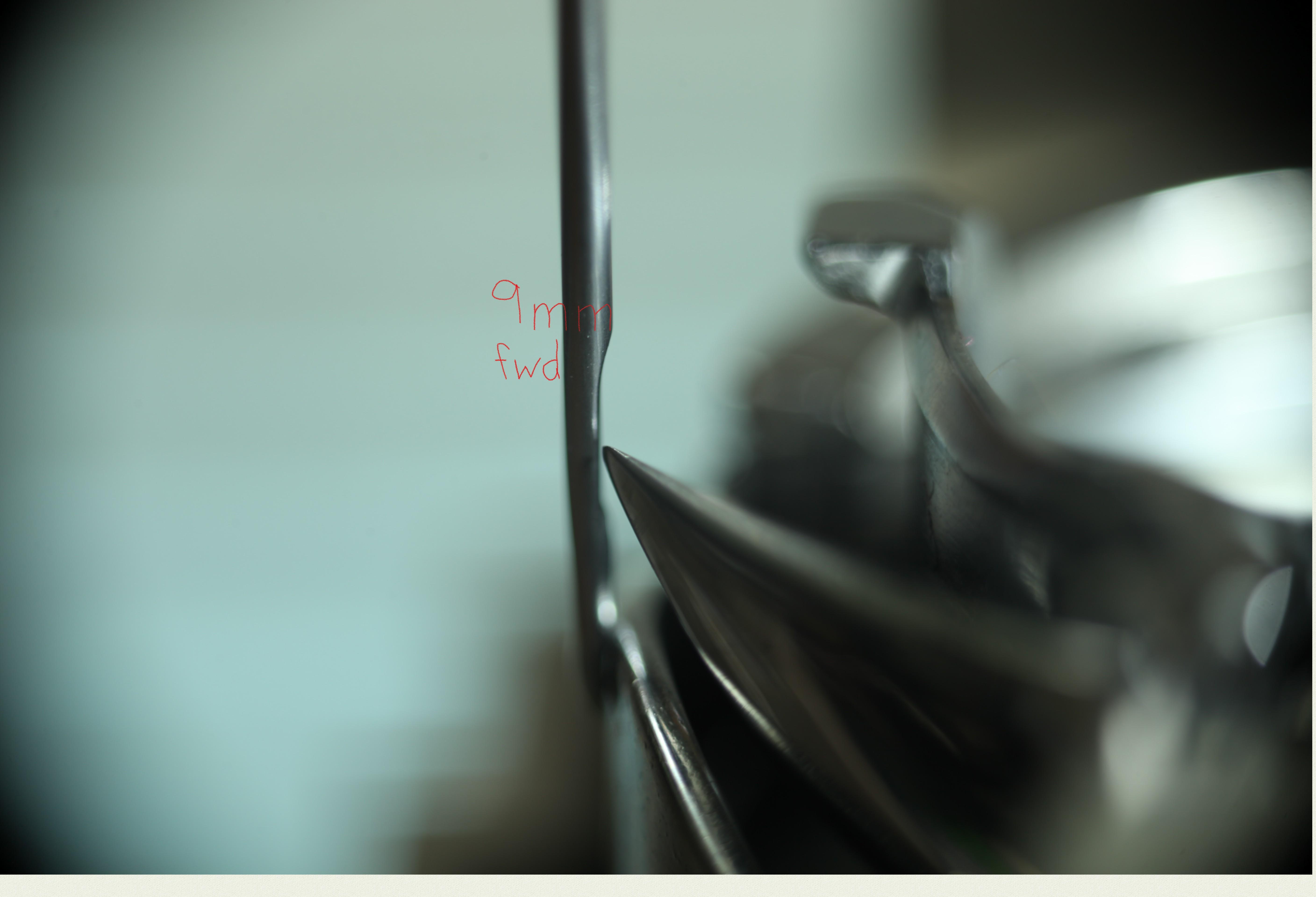

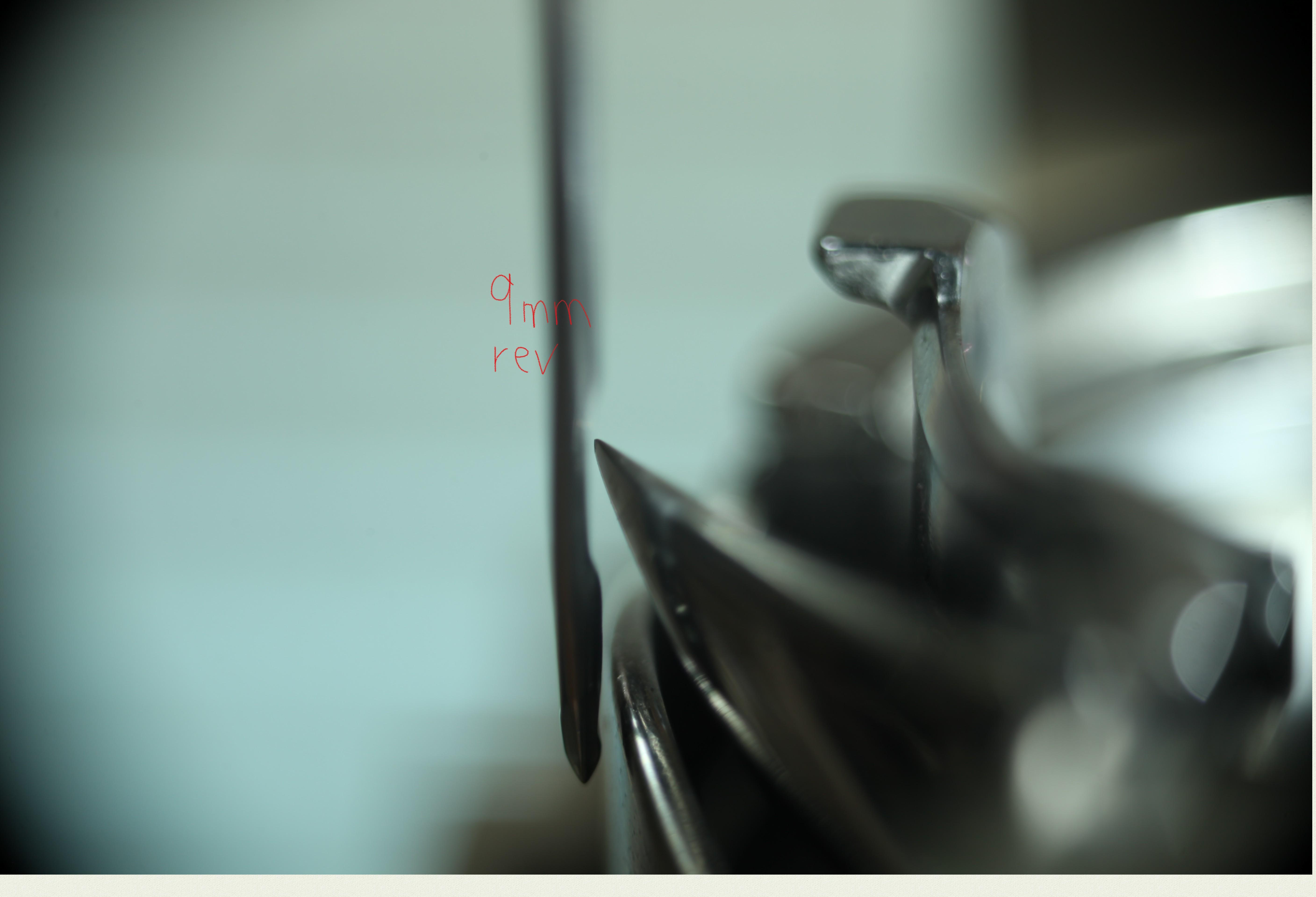

Original question, continued... I spent some time moving the hook saddle over to reduce the hook to needle distance. The Juki 341 manual says to make the adjustment with the stitch length set to 3mm, but the Juki 341 has a maximum stitch length of 6mm. One could interpret this at least two different ways: A. Set stitch length to 3mm, or B. Set stitch length to half of the maximum. (The Jianglong 341 that I'm actually working on can make 8mm stitches) Here are photos after my hook to needle adjustment, with stitch length and forward/reverse shown in red text. You will notice that long stitches in reverse prove to give the largest hook-to-needle distance, and I conjecture it was this large hook-to-needle distance that previously had the hook only catching one or two strands of the UNbonded thread. Since the adjustment, it seems to be doing fine with long stitches in reverse. (Not bisecting the thread anymore.) It makes sense that if you must optimize for either forward or reverse, one would almost always optimize for forward stitching. But here's another avenue I have not used but am considering: "Set the hook-to-needle distance to zero for long stitches in reverse, and use the hook needle guard to keep the hook from clobbering the needle in all other scenarios." This might get us down to zero hook-to-needle distance in all scenarios. But we'd also be deflecting the needle (elastic deformation) a little bit on all but the long reverse stitches. I'd be curious to hear how others have achieved a satisfactory hook-to-needle-distance compromise on machines that can make long stitches in reverse. -

dikman started following Adaptability for 1 hand? and Hook to Needle Distance: A Compromise

-

How to always have the hook to needle distance be next to nothing? At first I thought the thread was shredding when I stitched in reverse with long stitch lengths. (Thread is Selric brand TEX 135 UNbonded polyester) (Machine is Jianglong 341 (clone of Juki 341 but with even longer stitch lengths)) On closer inspection, the thread wasn't being torn actually, but in reverse with long stitch lengths (about 8mm) the hook was not catching all three strands of the thread. It might catch one or two. Here are some photos (recreated) of what it can look like when the hook tries to bisect the thread. Then I will continue my question in the next message..

-

Lots of youtube videos to watch and learn more about leatherwork.

-

Nakajima 321L is this worth the $1400 price tag?

kgg replied to leatherforge's topic in Leather Sewing Machines

I would run not walk away at that price. Buy something from a manufacturer that is still in business. Nakajima 321L is a needle feed machine and for leather work you really need at least a walking foot machine. The Nakajima 321L is what the old Juki LS-341 was based on, according to the info I have seen, with some changes. The first Juki LS-341's if I'm not mistake began in the early 1970's. From that the Nakajima 321L is going to be will over 50 years old. With the Nakajima sewing company being part of the Juki company since the 60's or 70's finding the different parts could be difficult. What are you planning on sewing???? kgg -

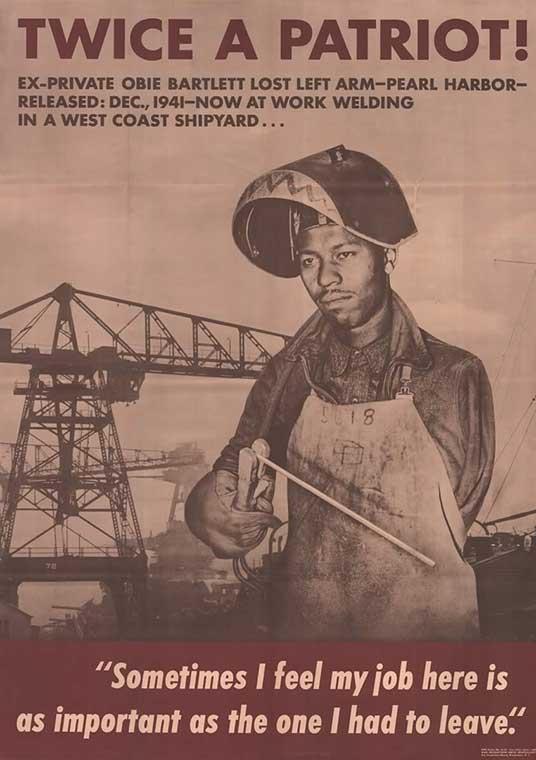

This is why you have kids! Put them to work! You might look at amputee prosthetics, as I've seen some ingenious stuff done to keep guys busy. Most of it doesn't restore full use of the arm, but rather makes it easier to use the arm for simple stuff. If your arm is in a cast, you might be able to fashion a hook, ring, or spring clamp to help hold stuff while you work on it with the other arm. Don't let life get you down. Where there's a will there's a way. Double Arm Amputee Welding

-

Seiko STW-8B Seam length and presser foot height -

Constabulary replied to Zonker62's topic in Leather Sewing Machines

The Seiko STW-8B basically is a later / more modern clone of the Singer 111G156 with some differences but it basically is a very similar machine. How long is your maximum reverse stitch length? Usually when the reverse stitch is longer the forward is shorter (and vice versa). With other words, usually F & R are equal at approx 5mm at this type of machine (Singer 111 and later clones) so when the F is 3.5mm then usually the R is longer and I guess it is 6.5mm. -

If you have a bench vise tighten your wrench in the jaws Grab the grinder with your one hand holding the lock button with a finger Match up the grinder with your wrench and twist improvise adapt overcome hooraaaaa!!! goodluck 👍

-

Sorry to hear you broke a wing As chuck says; read books Eventually as the break heals you may get the use of your fingers again and you can do some sewing using a stitching clamp to hold the work

-

jwoldsr started following Homemade Clicker Press and Steel Rule Bender

-

I'd like to find a used steel rule die bender. Any ideas?

-

Sewing machine oil is light mineral oil. The drug store stuff is heavy mineral oil, not good for machines. I personally use 5 w 20 synthetic motor oil for industrial sewing heavy web strap, 6" wide and you can hear the difference at full speed. So much quieter, all the little clicks go away. Color is close to clear, but wouldn't use around vegtan.

-

friquant started following Seiko STW-8B Seam length and presser foot height -

-

Seiko STW-8B Seam length and presser foot height -

friquant replied to Zonker62's topic in Leather Sewing Machines

Perhaps you could post a video of the walking foot in action so we can diagnose -

Dang, bad luck. I hope you recover quickly !!! You may not be able to pound leather, but you can still read, study, and practice drawing patterns and such. maybe even some swivel knife practice. Get well soon!!!☺️

-

Hello all, I recently purchased this Seiko STW-8B, because of the triple feed, or walking foot, that I need in certain cases (sewing crystal windows on sprayhoods for example). I didn't find any interesting manual like I usually do for Durkopp, Adler, Singer...Seen the ione for the Consew 226RB but no particular procedure for these items. And my maximum stich length at the moment must be something like 2.5-3mm...And I thought it would be nuch more than that. And also the presser foot height, it was set in such manner that the foot wasn't pressing the material (was probably set for some 1/4 inch thickness) and after lowering the bar I barely get 9-10mm (lower than 1/2'). Could anyone help me mainly to set correctly this machine, stitch length and maybe a word or 2 on pressr foot height? Thanks in advance, Cheers!

-

ThisIsMyFirstRodeo started following Adaptability for 1 hand?

-

Hey all, So I broke my arm a couple weeks ago, and I’m tired of teasing myself by just staring at my workbench. I do at least have use of my dominant hand, so I did luck out in that department, but all of my hobbies seem to require 2 hands. I’m sure there are some of you with a similar experience, but how do I modify leatherwork to be conducive to 1 working arm until I get my cast off? Is it even feasible? Unfortunately, my bandsaw is disassembled to repair, and I can’t break the nut loose on my grinder to replace the stone with a buffing wheel, so I feel like I may be SOL (hope im not censored) on the power tool side. Any tips/tricks/hints/advice welcome, even if it’s not to bother. Guess it’s back to my first rodeo, AZR

-

martol joined the community

-

friquant started following needle help for highlead GA-2688l

-

Something I just remembered, while in Inkscape be sure your page size is as large as you need to fit your whole pattern. Inkscape will only export whats within the page boundaries

-

Claire H joined the community

-

Hello, This looks like the model that we use. Is this item still for sale? If so, I would like to discuss. We are not local, so I would need to assess the cost of freight and someone to come pack it. Best, Claire H.

-

@BlackDragon I use Libre office so I will try that. Thanks for the tip.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)