All Activity

- Past hour

-

Clicker dies, no clicker press?

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in How Do I Do That?

Thank you for tossing the idea out there. TBH, I don’t actually have a computer, anything digital that I do is through my iPhone. (I don’t dare touch my wife’s or daughter’s machines…) But, adding a $200 pc to a $300 engraver is still less than many clickers, especially if adding in the cost of the dies. Definitely not a prohibitive expense in the grand scheme of leatherwork. Thank you again, AZR -

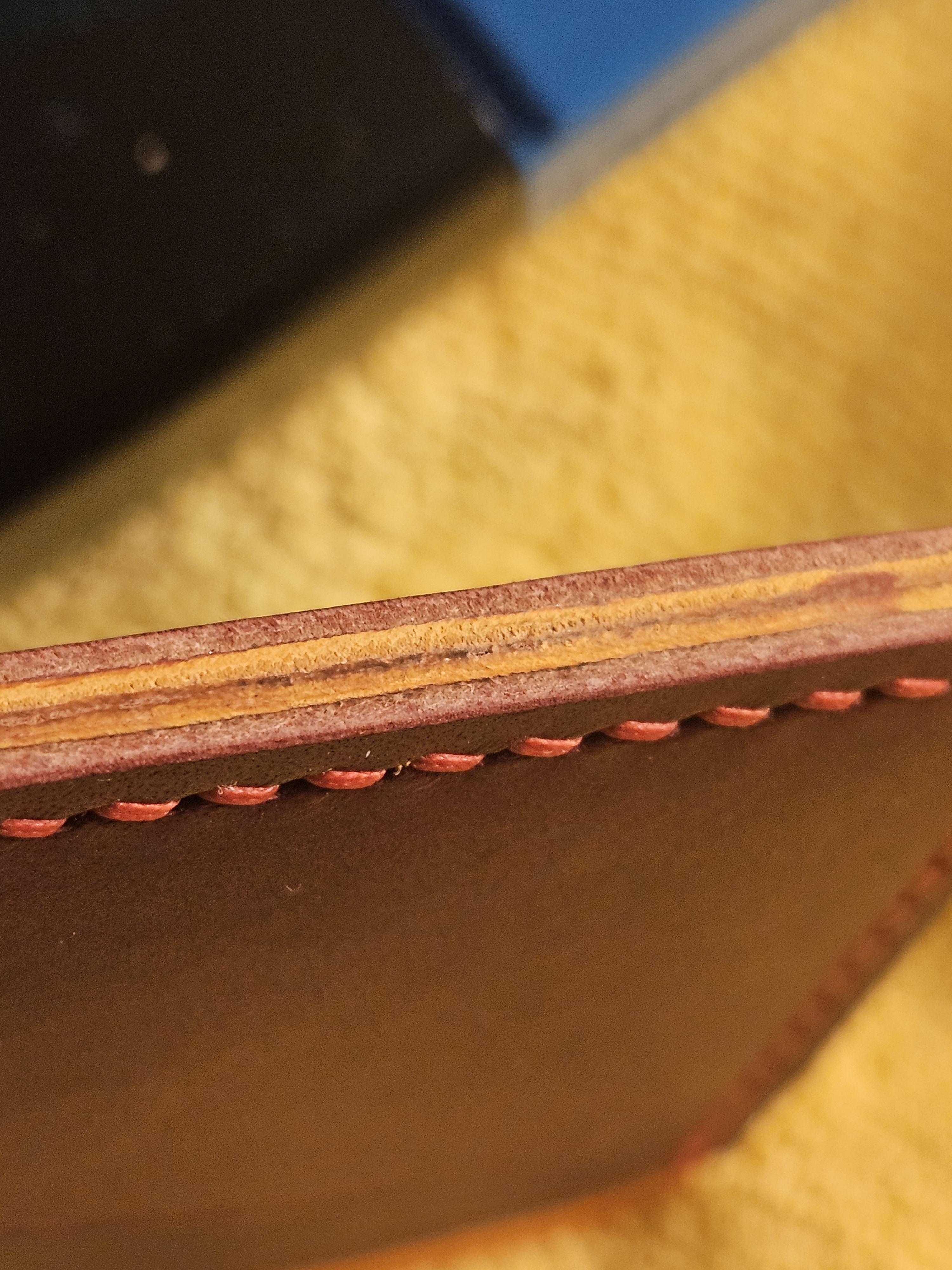

Thanks for the input guys. Here's me latest project. Sanded the edges upto 1000 grit. Shall I apply Tokonole now?

-

Black powder double shot snake need help

Mulesaw replied to DoubleKCustomLeathercraft's topic in Leatherwork Conversation

That is really a specialty item! Looking really good I must say. My best suggestion would be to use a cow horn. In Europe it was the standard thing for holding black powder, so it won't be damaged by the chemicals in the powder. Cow horn can be shaped if you heat it up first. I am unsure about what temperature, but I think 325-350 degrees Fahrenheit seems to be the spot as far as I can see on the Net. You heat it up in some hot oil, and then you shape it. I'd make a tapered piece of wood with a broom stick as a handle. The tapered piece should look like a small cartoon christmas tree, with the brrom stick out the wide end. Cut a cow horn to a length a bit longer than the tapered piece. Heat up the horn, and press the tapered piece into the horn, and when it cools down it should retain its shape. An alternative route is to take the wide part of a cow horn, cut a piece off, slit it open and heat it up. Then you flatten the piece. WIth the flat piece you mark out to form a tapered pipe. THen heat it again and shape it over a prefabricated piece of wood. I have never tried working with horn this way, I just know the theory behind it. But I guess it might be a heckuvalot of work to make something like that when no one is ever going to see it. A second option would be to form a small cone using some sheet metal brass. Brass is easy to solder and if you get something fairly thin, it is easy to shape as well. Brgds Jonas -

Black powder double shot snake need help

fredk replied to DoubleKCustomLeathercraft's topic in Leatherwork Conversation

A polythene measuring cup, with the bottom cut off. The polythene will be flexible enuf to deform but re-take its shape -

Singer 211 U166A walking foot problem

AlZilla replied to NowhereMan01's topic in Leather Sewing Machines

Does that clutch only engage in 1 position? If not, you could just be locked in the wrong place. -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

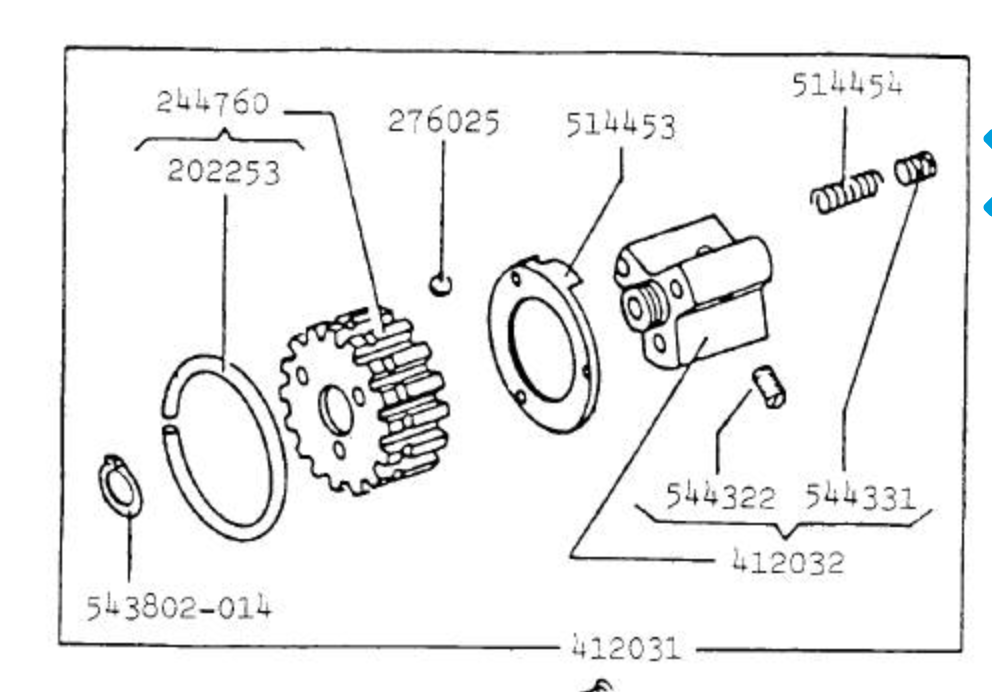

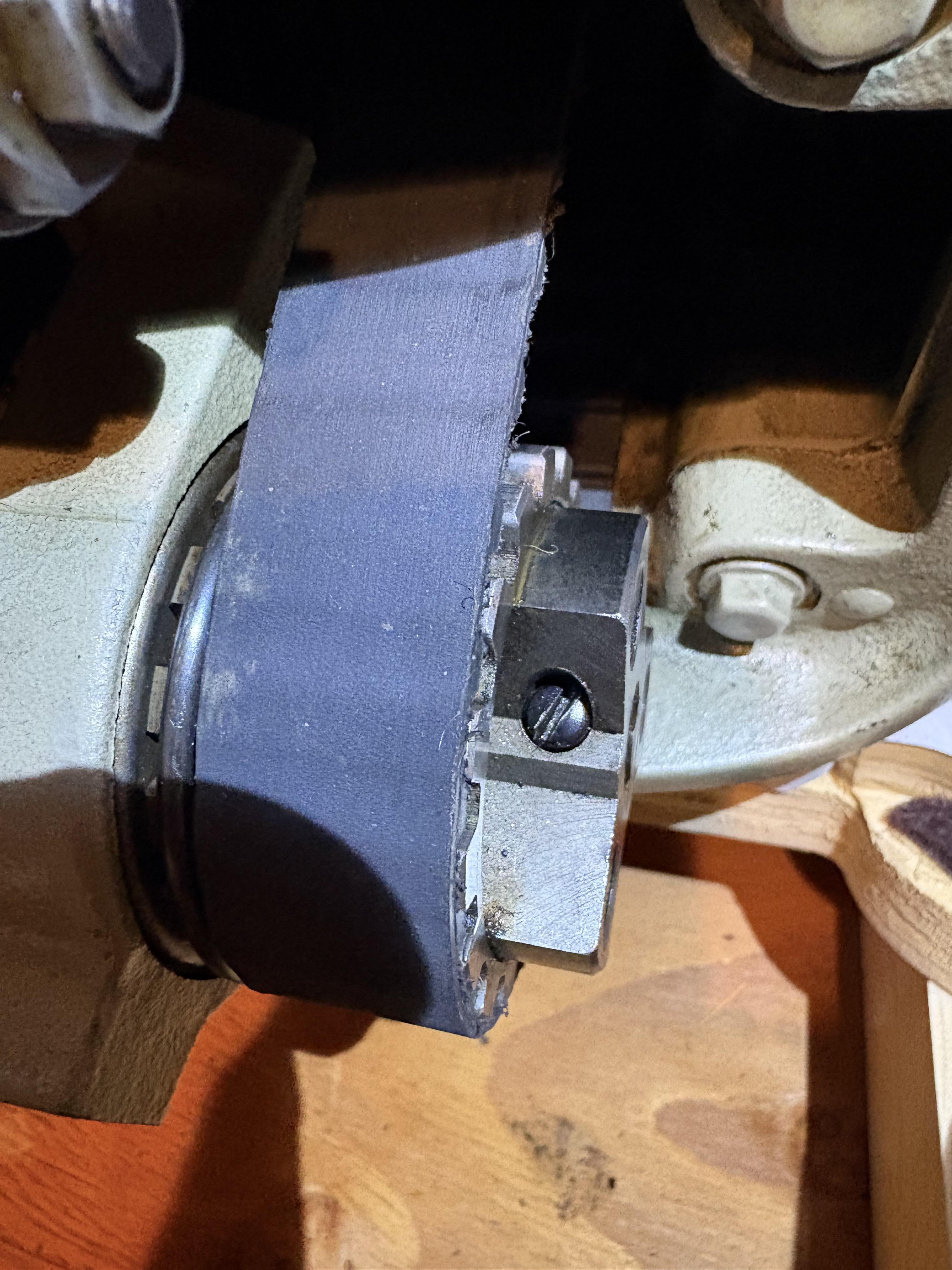

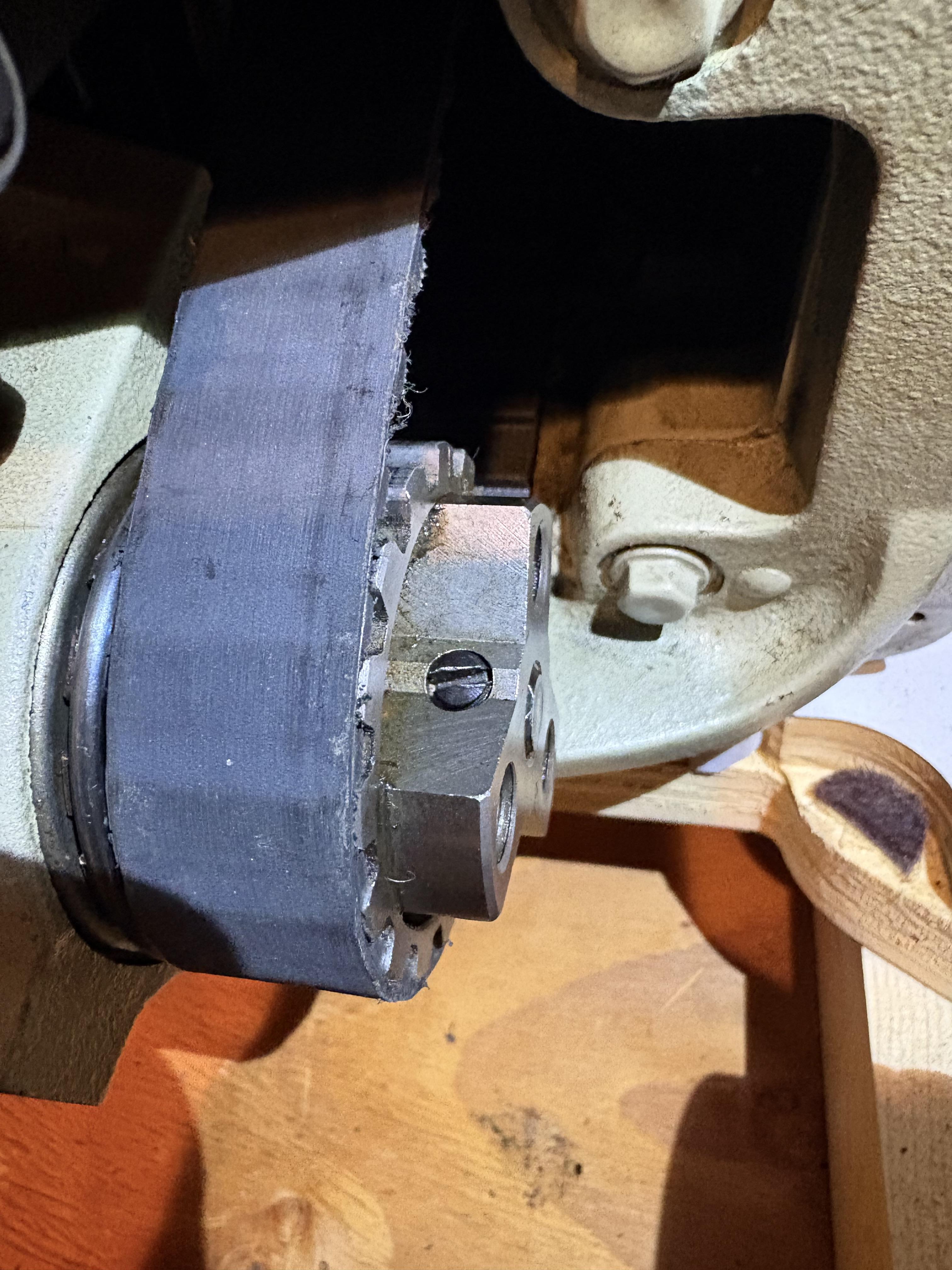

Thanks! That diagram is very helpful. I loosened the end screws and was able to kick out the safety clutch, and get it to snap back into place (with the clear, distinctive sound that I've seen on YouTube videos). I don't have any feel for how tight it should be set, so I suppose it is safer to leave it at a relatively loose setting for now. The bobbin thread is still not getting picked up, so I'll post a video of that shortly. - Today

-

Nice. Got it done, looks pretty good. Having lined pouches for blackpowder and shot I feel your pain keeping things all together and lined up. Not sure what you used for lining here? I ended up using waxed cotton canvas to keep things moving freely and mostly waterproof, although the bison was fairly water resistant anyway. Nothing, I mean NOTHING sticks well to waxes. I used heat and tried to clean the wax off the edges, and that didn't really help. But I didn't need to punch stitch holes through the canvas. I figured that out after an hour or effing around trying to get things lined up so I could punch everything. The needles go right through haha. So in the end it wasn't too bad, but it was difficult none the less. Ensuring there's at least a folded edge so the stitches don't pull through, while keeping it all nice and flat against the leather (glues and cements don't work) was really frustrating and I think I went through double the material before I got it right. Any kind of pouch with loose lining is a nightmare to make imo

-

I'll go remove it, unless someone got to it already.

-

I just got an order for a double shot snake. I've made one before, for the same costumer but it's been a few years. Definitely not a very common item, even at all the black powder supply companies online. There's no need to make any changes to my pattern, but he suggested using something on the transfer from the shot bag to the spouts to help keep their shape. I was thinking something like a funnel but not a thick piece of plastic. Was looking for something thinner but crush resistant. I have no clue what to call these tapered tubes other than that, tapered tube. That's not working for me on Google and was curious if anyone has any recommendations where to start? I could go with plastic sheeting but i think that'll crush. Anywhere here's a picture. The area I'm taking about is between the 2 powder/shot spouts connection and the main body. Any help is appreciated. Thanks

-

Belt extension, tooled English bridle

DoubleKCustomLeathercraft replied to DoubleKCustomLeathercraft's topic in Show Off!!

DG is one of the biggest influences to my work. His measurements for a belt haven't failed me either, when the right info is given. Nailed it! 😆- 6 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

-

Last week I put up a post wherein I offered my Pfaff 346 double needle cylinder arm machine for sale. Since then I put some time into inspecting and rectifying the machine and now have the left hand needle position sewing. I'd like to revise the post and add this info.

-

dentists or surgical loupes

andrew8643g replied to chuck123wapati's topic in Leatherwork Conversation

Yes i see in the post -

Hand-cast solid Brass Buckles from a small foundry

DieselTech replied to Origibelts's topic in Suppliers

-

Looks very good. Making it smaller may reduce the torque at the head. Neater will that is in the eye of the beholder. I think you did well it is clean and most importantly functional. Job well done. kgg

-

Singer 211 U166A walking foot problem

friquant replied to NowhereMan01's topic in Leather Sewing Machines

I believe you are on the right course. Here is a parts manual for a similar machine that seems helpful to understand the pieces: https://www.manualslib.com/manual/153942/Singer-211a165aa.html?page=15#manual The following page has descriptions of each part. The way I'm interpreting is that each of those three fat screws on the end has a spring underneath it. Together, those three screws through their respective springs provide pressure to the plate that has a detent for the ball. Someone may have screwed those adjusting screws all the way in, not knowing they were adjustment screws. -

Hand-cast solid Brass Buckles from a small foundry

Mulesaw replied to Origibelts's topic in Suppliers

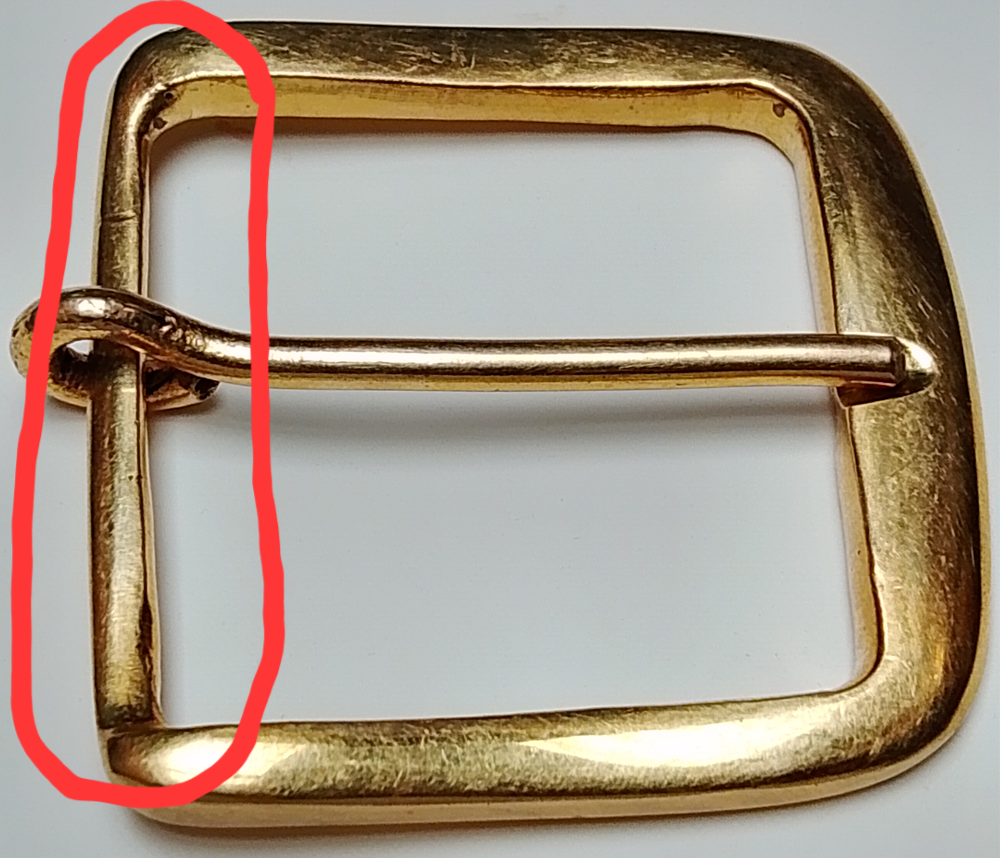

Hi John G Welcome to the forum. To me the most important points are: Strength/solidity Size Design/style Finish to me is part of the style, and I normally prefer just a regular brass finish like the one in your picture, alternatively it could be silver coloured, but I prefer no "bling" on my buckles. Prize is not especially important since I don't make 1000 belts, and compared to the time invested in making a nice belt, the prize for a buckle is only of secondary importance. But I guess that if you run a regular production of belts, it is of more importance. I like the small "dip" wehre the prong of the buckle nests. That is a nice touch in my opinion. Depending on what type of product I am making, I use either "normal buckles" like the one in your picture, or "roller buckles" or "center bar buckles" For belts I prefer sizes 1.25" and 1.5" (30mm and 38-40mm). Brgds Jonas -

Hi everyone, My name is John, I’m writing from Nairobi, Kenya. I’ve been fascinated with leatherwork and metal casting for a while, and recently started experimenting with sand-casting solid brass buckles and hardware in a small foundry and workshop. I’m still at the beginning of this journey, but my goal is to create strong, character-filled pieces that makers can use in belts and straps. Along the way, I’m also hoping to learn more about what leatherworkers actually look for in their hardware — things like finishes, dimensions, or styles that make your work easier. Outside of casting, I enjoy exploring traditional crafts and finding ways to combine them. I came across leatherworker and I’m looking forward to being part of the community, learning from you all, and (hopefully) contributing something useful as I go. Thanks for having me! — John M. near Nairobi, Kenya

-

Hi everyone, I’m new here and just getting started with a small project I’ve been working on for some time: hand-cast solid brass buckles and hardware. I run a small foundry and workshop near Nairobi, Kenya, where I make each buckle in small batches using traditional sand casting. Right now I’m at the stage of introducing these pieces and learning what makers actually look for in their hardware. Strength and authenticity are my focus, but I’d love to hear what you value most — sizing, finish, style, or price point. Here’s a look at what I’ve made so far: https://origibelts.com/collections/wholesale Any thoughts or feedback would be really appreciated as I start this journey. Thanks for letting me be part of the community. Sincerely, John G. Origibelts – Nairobi, Kenya

-

Welcome, haappy to share Thanks. Yep I am over in Cote Nord Quebec, we are neighbours

-

HEYSONG joined the community

-

Nice tooling, what did you decide to use for the liner?

-

Saying well done to you is getting tiresome. Do something wrong for God's sake man.

-

mictian999 joined the community

-

The wallet looks great! My projects used to separate on the edges as well until I started really paying attention to sanding. Now I buy one of those square sanding blocks that are kinda squishy and wrap sandpaper around it. The block has way too course a grit for my taste. The give in the block lets it sand a rounded profile on the edge complimenting the edge beveler. I used to go up to around 400 but I still didn’t get edges I was happy with so I started going to 1000 grit. 600 as mentioned before is probably good, I was just frustrated with my edges and bought 400, 1000, and 1500 grit one day and just stuck with the 1000.

-

Wanted a tobacco pouch, the catch was finding the proper liner to keep the moisture in and maintain flavor. Had to hand sew due to the one piece design. The zipper wasn't possible to seperate causing the issue, plus working on a way to hold it together while using the pricking irons my line wobble. Will try it out and think of ways to improve the process.

-

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

I will post a new-and-improved video of the bobbin, but I've been trying to figure out the safety clutch, and there does not seem to be much info on this particular style online, and I don't see it discussed in the manual. The 3 attached pictures show the 2 set screws and an end view. I assume that the 3 screws in the end view determine the force needed to disengage. The only picture of these in the manual (Fig. 65) shows them flush with the end, but on my machine they are turned all the way in. If my assumption is correct, I think I'll experiment with different settings to get a better feel for the disengagement/re-engagement. -

It finally warmed up enough to paint it so I'm calling it finished. I can now see how to make a better one, a bit smaller and neater.

.jpg.8af876c9f9fc03c31b2dc1d34e6afe5d.jpg)