All Activity

- Today

-

I think thats one I've sent to the posters

-

Singer 153w103 question

Texas Leatherworks replied to Texas Leatherworks's topic in Leatherwork Conversation

Yes I can turn it when it stops and the needle will lift up to get the material out. I will check to see if the flywheel is lose. Great suggestion. Thank you -

Water Spots

fredk replied to Historicalbeltworks's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

They are 'ruined' now to you. I'd suggest using clean water and giving the affected areas a real wetting and then letting it slowly dry out - days not hours That always worked on items that I had water-spots on -

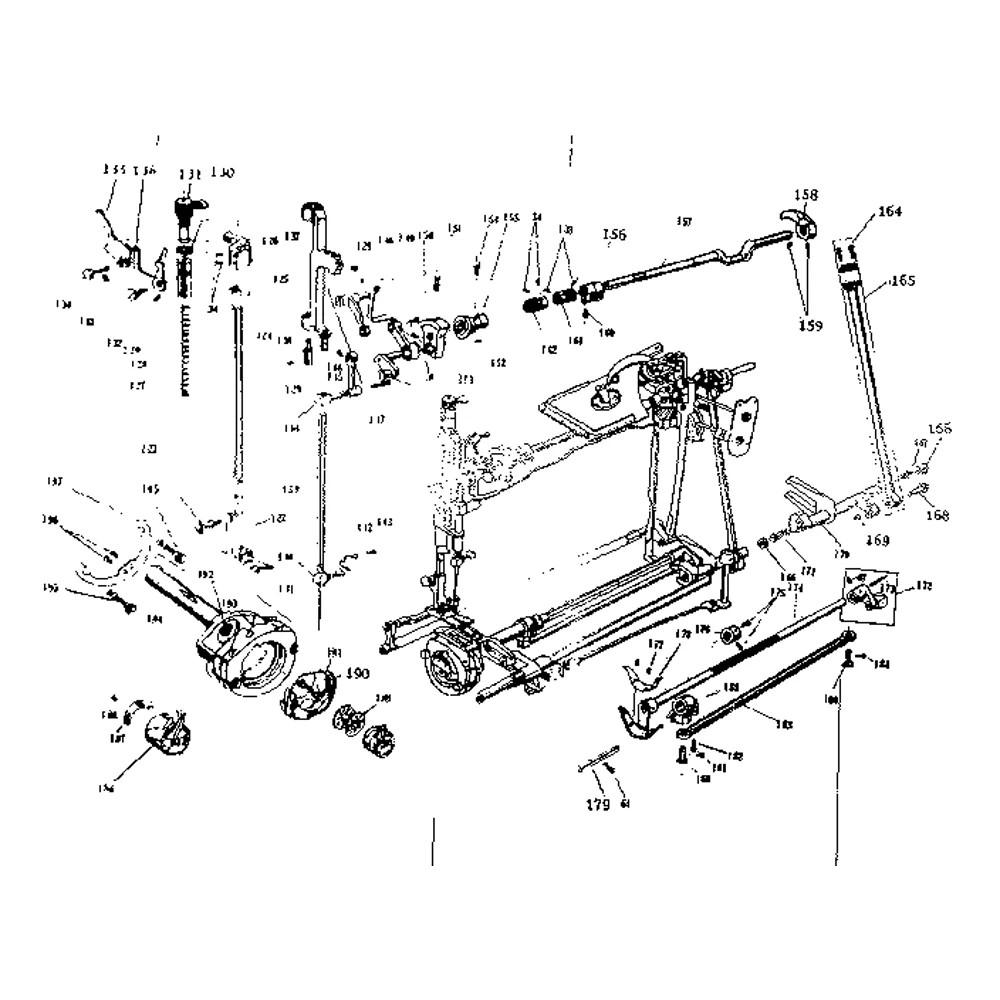

Both machines have an additional short bar connected from above to foot bar. I am not really shure about function My Singer 34(pre34 model) does not have it At 34, it seems to do nothing, until food is lifted (or not really much) The 45 lifts foot on it's own after each stitch. and so the whole device does Other models known having this are for example 16KSV11, 16KSV23, 34K5 (not all, due model change or remove), 34KSV5, 45K48, 45K53....

-

I think your tooling is incredible. But I think your paint/dye work is equally impressive. Even when enlarged I don't see any overflow on adjacent areas. You obviously are very meticulous. Maybe you could share any tips/tricks. Very good work. Something to be proud of.

-

...actually, only precice Singer source says "alternating presser" ,not "walking foot" so, same as my Singer 15-39, differences are: - 15-39 is the backside foot the pulling one, jumping after pull forward, while 78-3 front foot is pulling in a circle move. - 15-39 has feed dog (single line, as also for leather), no needle feed (see pic) Now here is the question (or are the questions): What exactly is the difference of walking foot and alternating presser? I have here two "Singer walking foot attachments", having an inner and an outer foot. But I am not shure about that. My Singer 29 (long freearm shoemaker) has, what I would call a walking foot, (pulling after stitch back, when needle entered cloth/leather, it's going up and in ordinary position) Also Singer 16 KSV 11 has a single foot, but some do not call it walking foot. ----------------------------------------------------------------- Does anybody have a picture of Singer 78-3 (maybe also other do it) from backside? My machine has close to presser lever a loose plate with 2 holes at upper end. Ok, machine lies flat on ground, I forgot to rotate the image to normal stand

-

I have a Kenmore 158 that I used to use in my shop when I had to sew cloth and linings. It is a good machine and was well built. I don't know about the availability of parts though. I think they are strong enough to sew soft leather, or to sew patches onto vests, but not over pockets. The Adler you have is a 30-70, not the other way around. ;-) It is a great machine for sewing patches over sleeves and pockets, or for sewing in zippers.

-

The cb3200 is one of the 441 class sewing machines, but, at 1/2 inch, it has less thickness capacity than the cb4500 and similar large models. The arm is shorter too, measuring in at 10.5 inches. Other than that, it uses the same needles, bobbins and thread. However, the Cowboy raised holster and stirrup plates are too tall for the 3200 due to its lower thickness capacity. Further, the optional drop-down edge guide doesn't fit on the 3200. If most of your projects will be between 1/8th and 1/2 inch thickness, this machine will serve you very well.

-

Do you mean the hand wheel just spins and the rest of the machine stops? Maybe a safety clutch problem or the hand wheel is loose on the arm shaft? If the belt is slipping, the solution is obvious ... Can you turn it through by hand when it stops?

-

@Chux I'm in the same boat as yourself was wondering if you had any luck on the Boston style, been looking for the matte and patent leather supplier but with no luck was wondering if you found a good source for these ????

-

I bought my CB3200 new from Cowboy Bob (Toledo Sewing Machine) back in late 2013 (great folks to deal with...VERY knowledgeable)...absolutely zero regrets as far as function and easy of use. If anything and I could do over, I would have gotten the "big brother" 4500 but that's another machine for another day, i reckon...if I can spare the room (I also have an antique industrial I use for light leather, canvas and cloth). That said, if you've found a good deal on a 3200 in decent working condition...close by your abode (yay, no shipping costs!!!)...I'd jump on that train car. As the experts herein will tell you (paging Wiz and Mr. Bob especially), it and its larger contemporaries have plenty of feet/accessory options and will sew a broad range of thread sizes, albeit with some setup required. Toledo Sewing Machine has the spec's on it...Google them. (for some reason my computer won't let me link it) Hope this helps! Chris

-

When I put a piece of leather in the machine it will punch the holes perfectly. When I thread the machine up the needle stops at the top of the material and won't go through to start stitching. The fly wheel just spins. What adjustments do I need to do to correct this? The machine is well oiled and free from all thread and dirt..a very clean machine. Thanks

-

.thumb.jpg.327685d8c1787fa894323fed9a6b2dac.jpg)

Desert bighorn holster is finished

DoubleKCustomLeathercraft replied to DoubleKCustomLeathercraft's topic in Show Off!!

Mclark Thanks. Yes the knot is for the hammer spur strap. I don't have a picture of the back and the pattern is from "the hand of God" pack, (3:10 to yuma) but modified a little to fit a regular belt instead of a gun fighter belt. It's stitched instead of folding over and into a "Mexican style" loop. My client has no desire to have a full rig, he just wanted the holster. So I trimmed some of the extra bulk off to make it more comfortable on a standard belt.- 12 replies

-

- desert bighorn

- holster

-

(and 1 more)

Tagged with:

-

Tutorial, replacing zippers in riding boots.

TomE replied to Mulesaw's topic in Shoes, Boots, Sandals and Moccassins

Here's the original link. https://ykk.meclib.jp/library/books/Zippers_101/book/#target/page_no=1 -

Desert bighorn holster is finished

MClark replied to DoubleKCustomLeathercraft's topic in Show Off!!

Double K it looks as good as any proressional made rig. The finish is the right color and the stitching is the right size for the project and is nice and even. I assume the knott is for the safety strap? Can we see the back and what holster pattern did you use?- 12 replies

-

- desert bighorn

- holster

-

(and 1 more)

Tagged with:

-

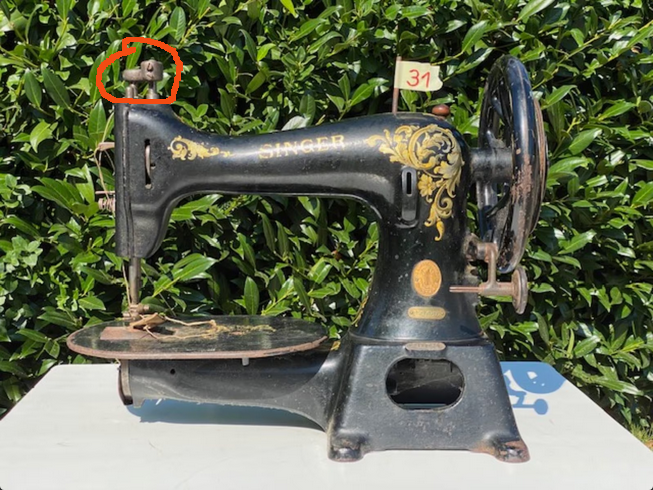

So, I moved you over to the sewing machine area. I don't see any problem talking about the old Kenmore. Ask away. @cpo1wh Is it a flatbed and the guts look something like this?

-

Aaron Leather Goods joined the community

-

Nice work. Looks great.

-

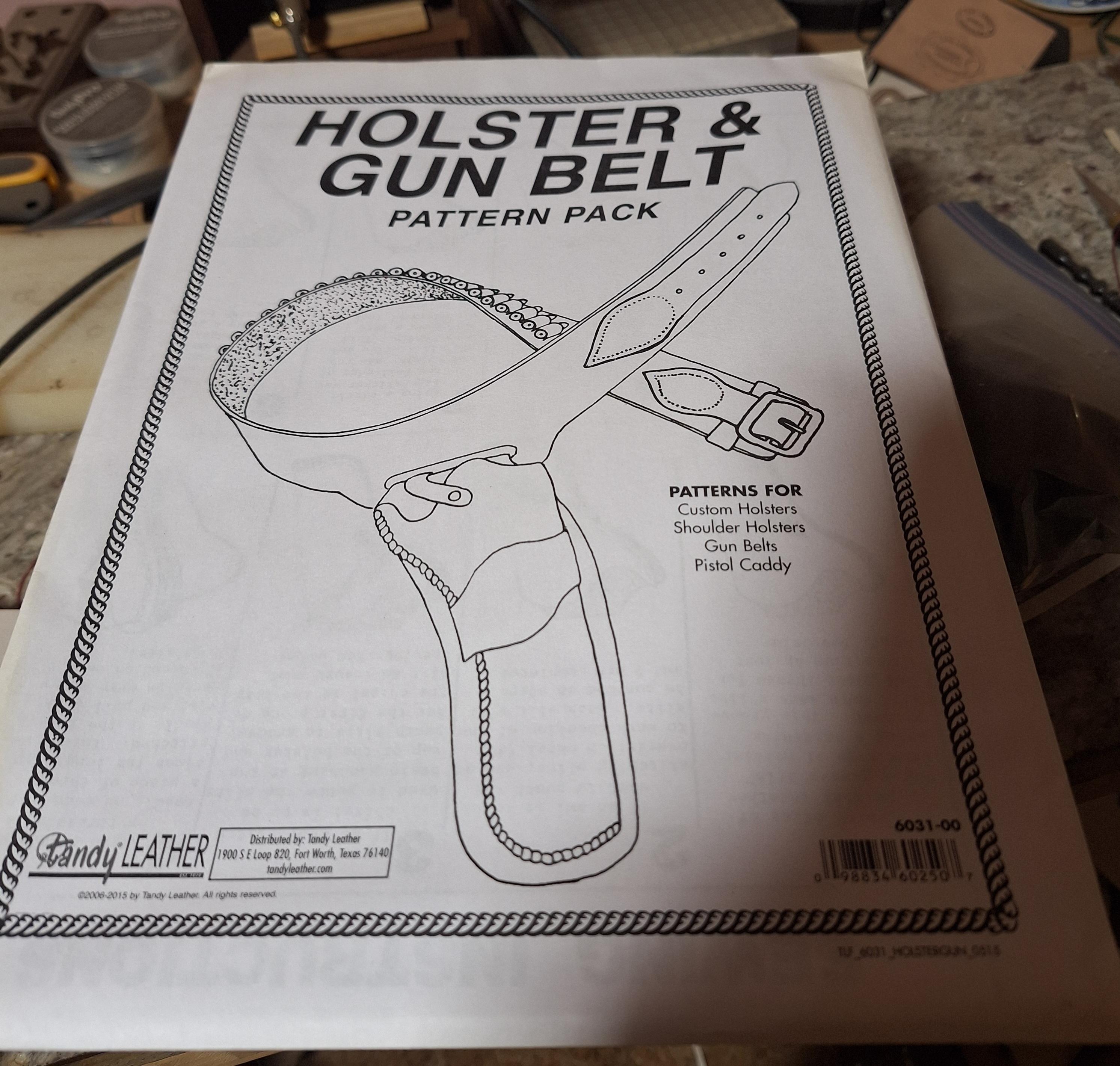

Tandy gun holster pattern wanted

DieselTech replied to Wildwest2029leathercraft's topic in Resources

-

JD78UK joined the community

-

Tutorial, replacing zippers in riding boots.

Mulesaw replied to Mulesaw's topic in Shoes, Boots, Sandals and Moccassins

Hi Tom, I can only see the first page of the document? Brgds Jonas -

I grabbed some scrap and did a few quick and dirty finish on 3/4" tape ending for example with folding pieces of 1-k cordura . and there probably other techniques also. You can just Hot Knife, cut . . You can do a double-back fold, and do a quick little zigzag or bar-tack . . you can do an inward 'tuck' fold finish . The double-fold over, and tack is pretty self-explanatory for a finish on the tail-end . Hot Knife, cut-off takes a little practice to make look clean, and also a good seal/melt . Also Nylon hot knifes different than if you using Polyester. Polyester binding. You can make both look good, but they melt/act a little differently. Personally I think nylon cuts melts nicer. The inward tuck fold on the finish. That is used a lot with ending finish. Also on binding where you bind a circumference and finish off running on top your starting point. There a couple ways you can do it, and there is some technique involved that takes a little practice . Main thing is you have to stop the binding a couple inches from the finish. leave the Needle or Needles in the plunge holding down the material . Then slide or fold back you binding Folder out of the way, and cut the binding leaving some binding to work with for making the fold-tuck. Then just sew the finish without using the Folder. Also there couple ways to work the binding with your under-tucking . You can just fold it as is, and fold inward. Or you can do a 'split' center-lengthwise in the tailing piece your tucking . - - - -

-

actually, it's not for leather, it's for sacks. And so, it has no feed dogs or such. I wonder, if anybody has informations on it. Or pictures /ideas to build transportation (stitching plate and feed dog are available on ebay, other parts not. But I could also think about something like on Singer 29) The other special about: it lifts the foot between stitches (shure, very useful, when repairing bags), maybe I can use it for fat embroidery😁

-

Not sure if this topic is acceptable, but I'll ask anyway. I am getting ready to tweak an Adler 70-30, which, in my opinion, a very solid machine for leather work. But..., I also have a Kenmore 158.352 that is capable of sewing light leather and is a lot of fun to use. My question is: Does this forum allow questions regarding sewing machines of the homemaker type, such as the Kenmore 158.352? I have a timing question if so. Thanks for yout replies.

-

Just leave the leather unlaminated?

.jpg.d7be51292b1877996883ef260553411c.jpg)

.jpg.c39f022decdd33e6ec13bd6016843d8b.jpg)