All Activity

- Past hour

-

I´m on the other side of the big pond (the land where the CLAES come from 😉) and yet I only have heard of the "Cowboy Clones" of the 8346 but I have no info when the will be released and how good they will be. I´d say time will tell. I have none but from what I read here they are equal and probably come from the same factory (guessing) just with a different color and name on it. Since you are in NH I´d check with a dealer that is close to you. Toledo Sewing Machines (he is member here too - check out @CowboyBob) is not really close but probably the closest and from what I read they have an excellent reputation so maybe worth checking with them.

-

2 follow-up questions: — After thinning, do I need to wait before using it? — And should I expect any difference in how it works? I added acetone to the cement can, and I *think* I stirred it in well enough, to an even consistency with no liquid pooling. Definitely thinner, though I am on the fence about thinning further. But, as a tester, I glued up a small tab for a box (maybe ½ sq.in. if it matters), and something seemed… different somehow. Wish I had the words to describe it. Thanks again, — AZR

-

new SD28 / 308 parts are made of "unobtainium" those who have parts usually keep them except they rip apart worn / broken machines. if it was me I´d tried to look up "cheap" toothed feet for top feed machines and see if I can cut and weld the toothed end. maybe: https://de.aliexpress.com/item/32861132738.html https://de.aliexpress.com/item/1005010121787509.html https://de.aliexpress.com/item/1005009251866963.html just a wild idea.... 😉

- Today

-

I hope you find that English translation, if anyone you do, please send it as soon as possible. Please tell me how much I owe you for your time? And whose name I should write the check and where to send it? If I may ask you a couple questions I know they’re not out yet, but the cowboy clone of the Claes should be coming to the US in a few weeks, do you know or have any secondhand information if they are worth it? Also, I’m interested in starting saddle repair. In your opinion, which would be better the CB4500 or Cobra class 4?

-

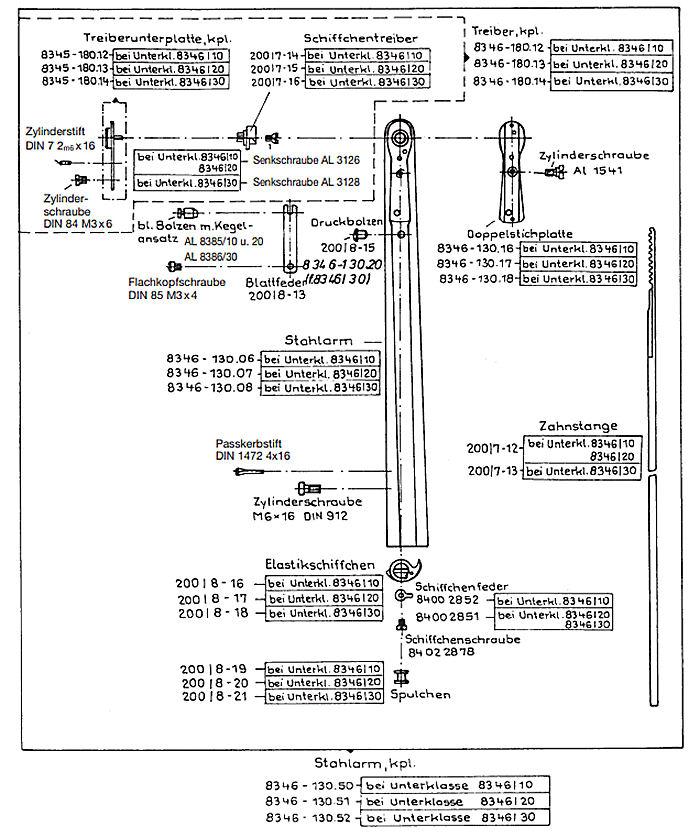

Yes, its a 8346-20 medium hook machine. Top threading seems to be okay but indeed, the "wedges" don´t belong to the machine (check the parts list - see picture below) and are probably part of the problem. I assume when the top tread goes around the hook the thread keeps handing on the wedges - somehow (maybe not but they don´t belong there anyway). Hard to tell what the guy 5 years ago did with the machine. I only can guess what he tried to achieve with the wedges. 1.) Either he tried to "rise" the hook a bit to eliminate a timing issue (Needle bar to high so he tried to bring the hook higher 🤨 or 2.) he tried to compensate wear but I doubt the machine can we worn that much already. So I assume its 1.) What I would do is removing the wedges and lower the needle bar a little bit. Some years ago I translated a 8346 mechanics manual from German to English for one of our members. I´ll check if I can find it and send you the file. It includes all values for timing and how to replace worn shuttle drivers and set the needle bar correctly and so forth. Thats the best I can do from the distance.

-

As @KillDevilBill was saying , and how I understand it. The laminated leather has 2 layers of full grain which is the strongest part of the leather. And they would be in different directions adding strength similar to how a weave or braid does.maybe better would be something like plywood. The layers are laid in opposing directions allowing for a strong end material. And the contact cement itself is strong in its own right and probably adds a bit to the overall strength of the laminated leather.

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

OMAC Leather Belt Machine for Sale

Northmount replied to BianVariani's topic in New and Refurbished to Like New

Just add the info in a new post. The "Edit Window" is only open for a few hours, somewhere between 2 and 5 hours. I haven't been able to nail down the exact number. -

The "Edit Window" times out after a few hours, from what I see, seems to be between 2 to 5 hours. So the best way is to just add the info in a new post in the same thread. Other option is to ask a moderator to make the changes to the original post. Need to provide the wording to be changed/inserted.

-

I have an old coffee grinder that hangs on a wall I will try that; they are like a grain mill but smaller. belt sander sounds good, but I will need to figure out a V- trough to hold the leather pieces and to press them into the sander. Leather dust is mixed with rubber cement and used to help create a 3D affect to a leather item like a picture. It is called embossing or extreme embossing.

-

Leather Weight for Lined Holsters.

Dwight replied to Latigo Smith's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Actually I should add a couple of "tips" to help with holsters . . . especially western / cowboy types. 1: Once the contact cement is applied . . . I like doing the liner first . . . allow the whole shebang to "almost" dry to a DRY state. The piece that makes the outside of holster and the inside of the belt flap is my dryness tester. I let all of it dry until this piece is still just a tad bit still sticky. It won't glob off on your finger . . . but you can still feel a tiny little bit of sticky there. That will allow you to take it apart if something didn't quite line up right. AND . . . yes . . . that's the voice of experience talking. 2: Go to a hardware store . . . buy a hammer handle for a typical old style 16 oz carpenter's hammer. Cut the end off of it where it would go thru the hammer head . . . sand it real smooth . . . and put some poly finish on it. You will use this tool once the two pieces are put together . . . force it down thru the holster . . . keeping the stitch edges together. It opens that sight track very well and will give you room for the ejection handle as well. Latigo Smith wrote: "Alrighty, it sounds like pre-bending is the way to go. Do you find that simply applying pressure with your hands when cementing the layers results in a strong enough bond? This was the only reason I had planned on gluing flat, that I have more confidence in the hold of the contact cement when it's had a little time with some weight applied to it while curing. You use the gun to wet mold the individual layers to the correct curve radius before glue up? That sounds like an excellent way of doing it. Do you leave the gun in the leather while it's drying like when doing final molding or do you just mold it to the proper curve, take the gun out and let it dry? " Yes . . . hand pressure is usually enough . . . have never had a problem with it. And actually . . . once it is sewn . . . it ain't gonna go no where. I only use the gun for wet molding the interior liner . . . everything else is molded over top the liner piece. The gun is in a plastic bag while doing that bit of molding . . . and once I have that mold (about 3 minutes) the gun is not needed in the rest of the process. Have fun . . . may God bless, Dwight -

Thanks for the information. I will make the adjustment and see how it goes. I really appreciate your assistance.

-

Found this because I am planning to build a pair also. Im planning to go a couple inches over the ankle though. Im planning to use mine for winter camping on those very cold nights and having to tinkle at 3AM. Yup, Im finally to the age when I cant hold it till morning.

-

I want to see this when it's done! Cool project. I'm gonna go measure my pens.....

-

I'm gonna go with Dwight on this one. Very similar to how I line my holsters, and as a bonus I may have just learned something. Holster or not, just even a test with some scraps on the bench, I can't even imagine a single layer being stronger or more durable than 2 or more pieces making up the same thickness. Multiple pieces have the grain going in multiple directions, then the glue adding a bond. Just my $.02 and some good reading in this thread. Thank you!

-

C3 Auctions joined the community

-

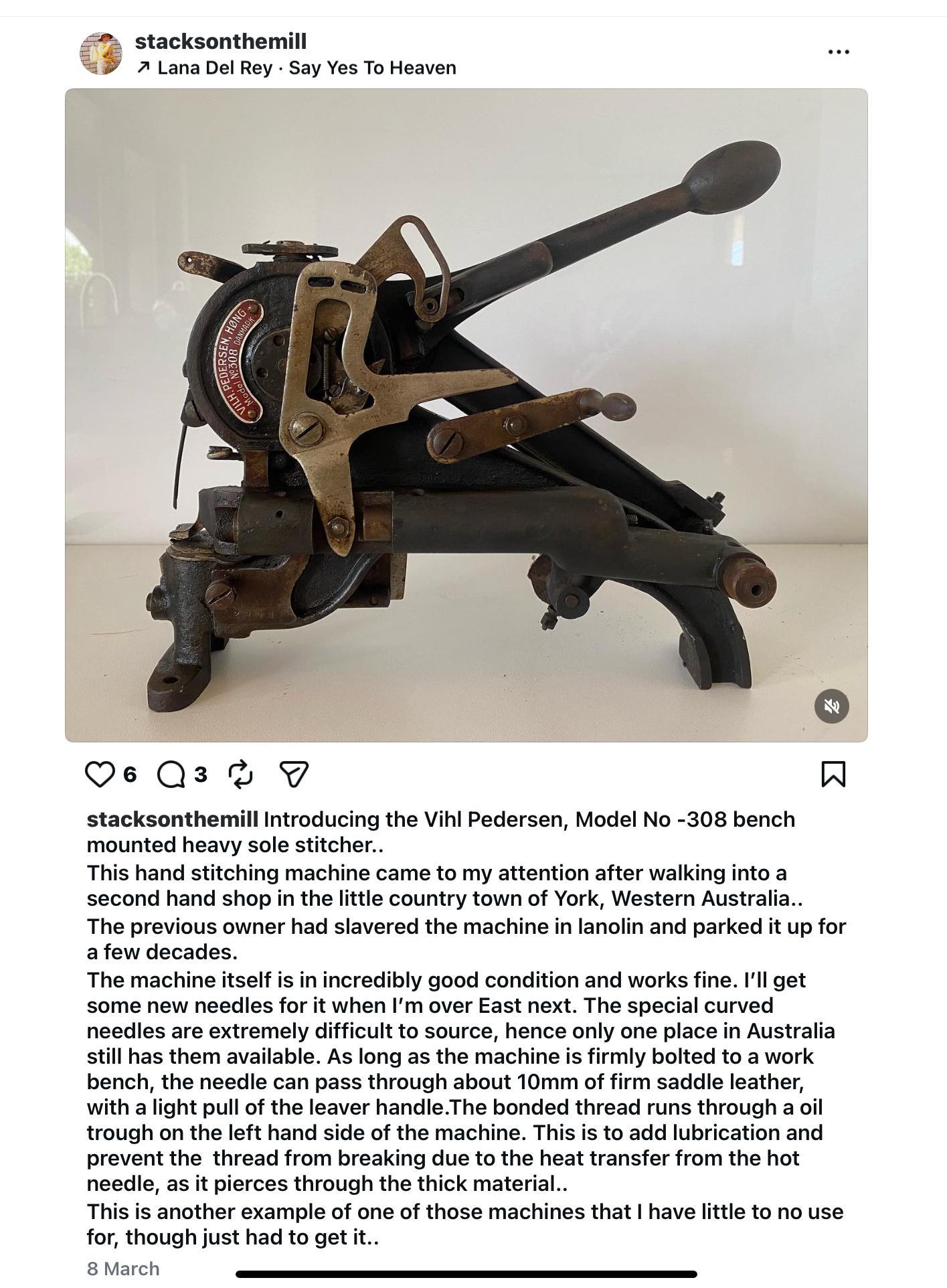

Unfortunately. I've not been able to find the parts I'm looking for. They are quite hard to find. I'm working on making them myself. For now I have been making due with manually moving the work myself without the stitch length regulator. Mine is also a Pederson 308. This and the Junker & Ruh are identical machines.

-

@Westaussie There's someone on here that was asking about parts for one of those. The name is @Calidora just wondering if they were successful in obtaining parts? or the only other place i can think of is ' good ol ebay ' i'm in the central wheatbelt, WA . I think There's one of those machines in our local museum. Not too many West Aussies come on here, welcome HS

-

Leather Weight for Lined Holsters.

Thadrick replied to Latigo Smith's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I've seen a video of a builder tooling and carving then gluing the liner on (flat). Then he went about by slightly bending it wet and letting it hang balanced over a 1.5" dowel over night to dry. Hanging over the dowel allowed the leather to bend slowly while drying. It wasn't completely bent when dry but was close enough that it reduced wrinkles when he bent it the rest of the way. I haven't tried it but it makes sense that it would work? My experience with a thinner liner seems to reduces wrinkling, just don't rush the bending process and be sure it's laminated very well (extra glue is good). -

Cowboy 4500+ Consew 206RB-5 +Claes 20(Central PA)

billymac814 replied to billymac814's topic in Used

I can’t seem to edit the post on my phone. I’ll try from a computer tomorrow. I’d prefer not to ship but I will if someone wants to pay for it, any of these will have to go LTL, I do work in a warehouse so I can accommodate palletizing any of them. -

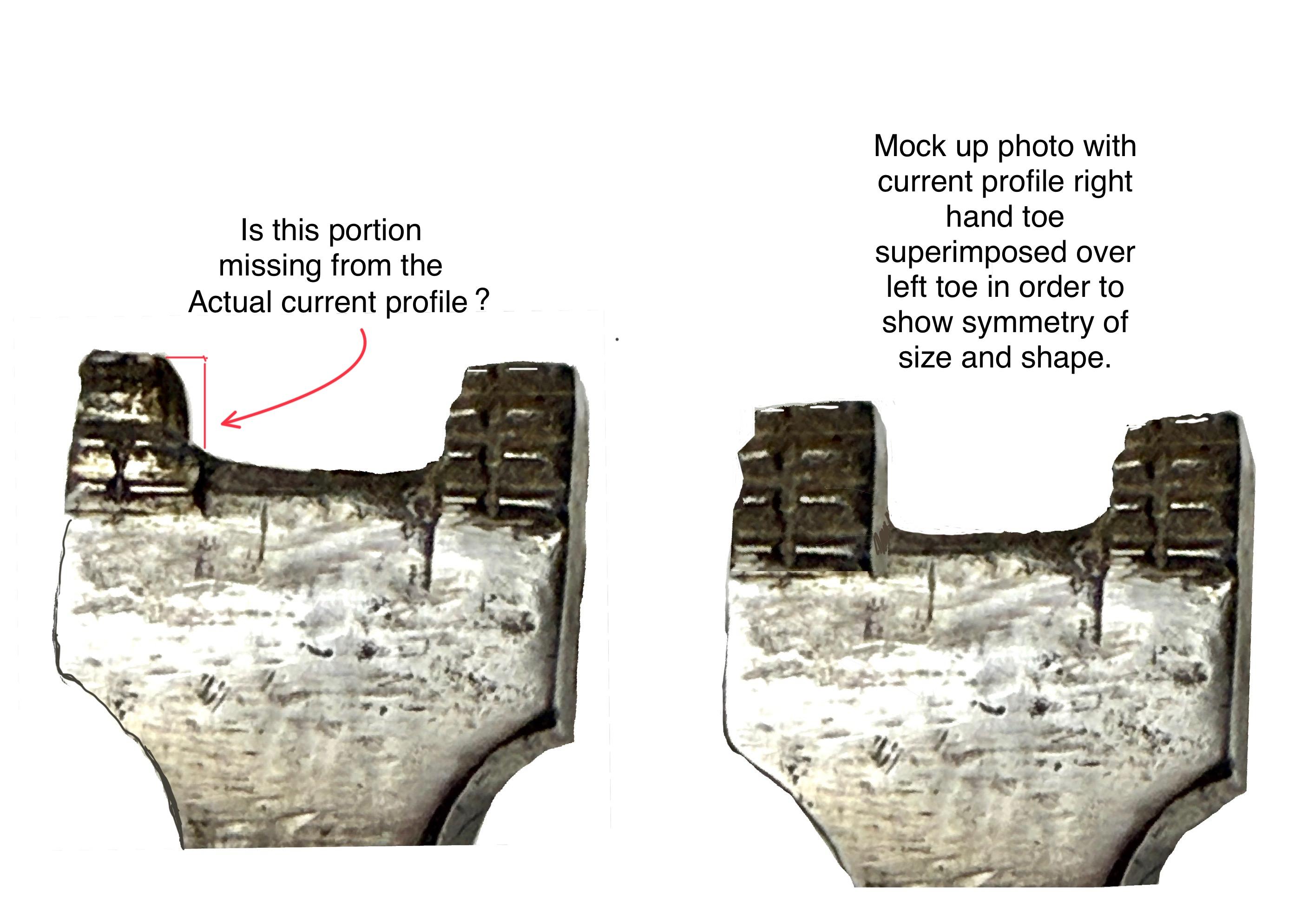

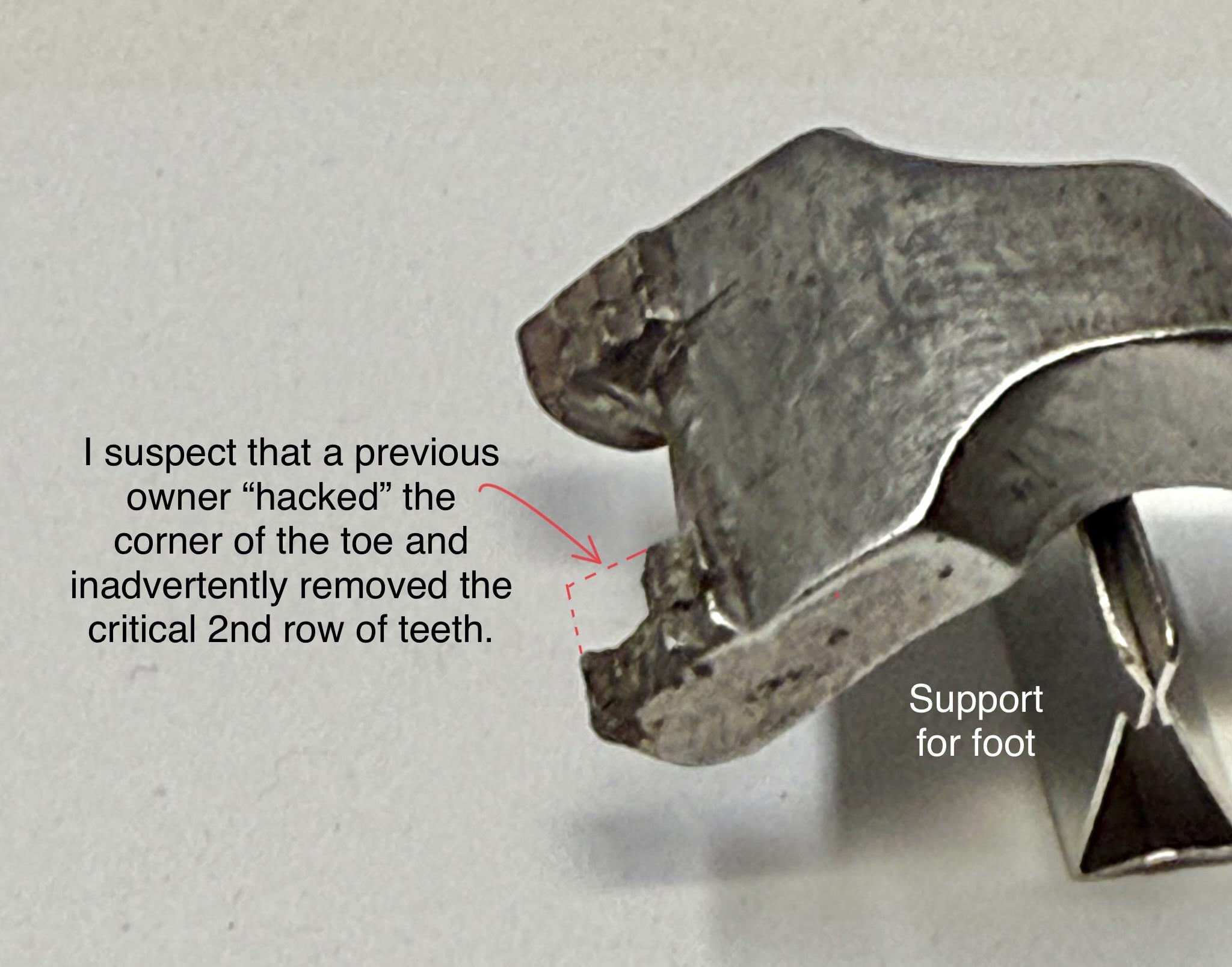

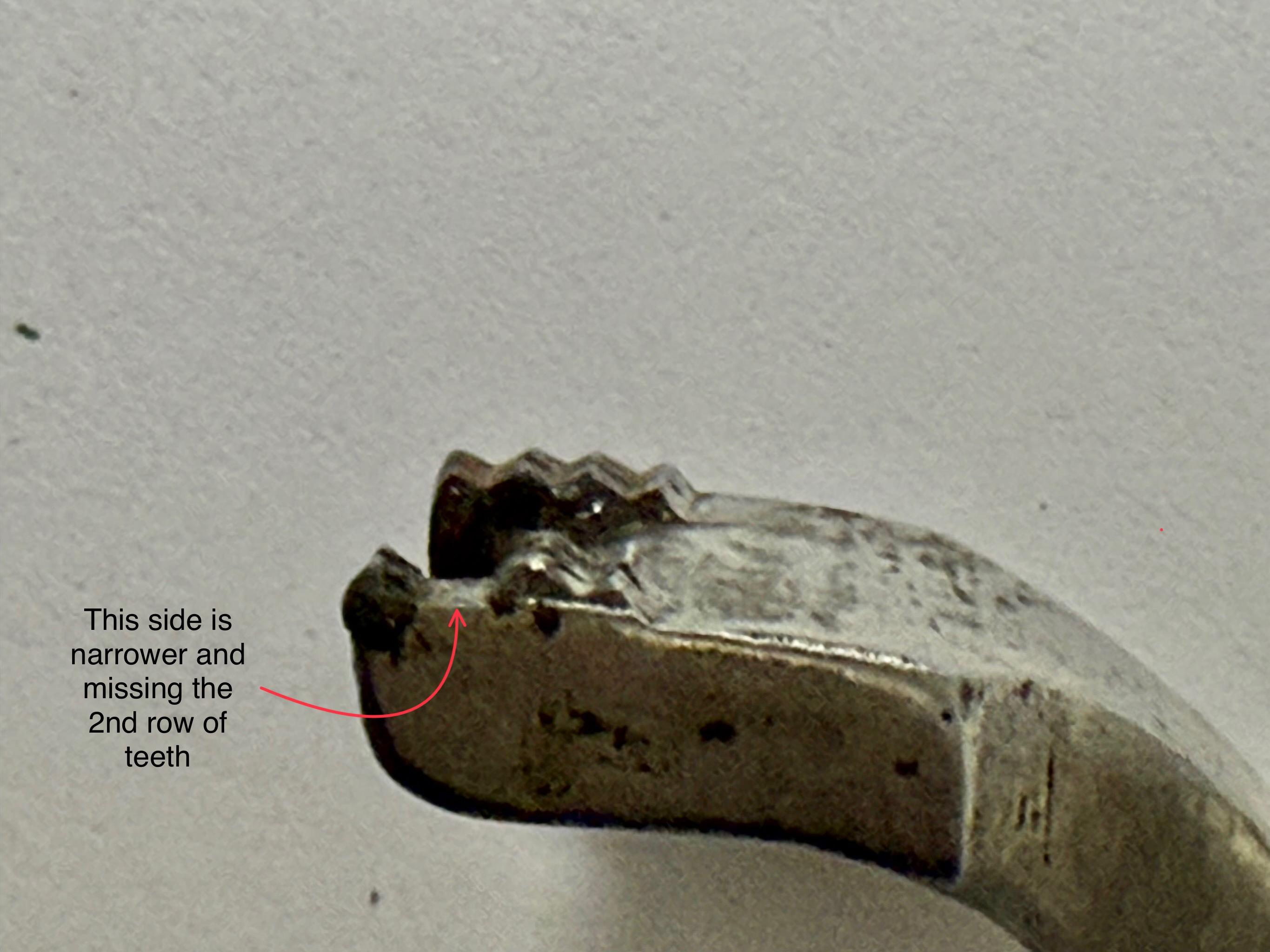

Hi leatherworkers, I have a Vilh Pedersen 308 sole stitcher. Unfortunately it is near impossible to stitch in a straight line and I suspect it may be because a previous owner seems to have “modified” the foot, possibly to get a bit more space for the needle to go into the leather without hitting the foot. Subsequently the 2nd row of teeth are missing from one side as well a about 1.5mm in width of the toe part. So I have two questions: [1] Am I correct in believing that the toes on the presser foot, that is the section with the ridges that move the leather forward are supposed to be equal in size, shape therefore perfectly symmetrical and able to move the stitches in a straight line? [2] Is there any way to rectify this problem of poor stitching as I doubt anybody has a spare presser foot to sell or is it possible to have one made, perhaps 3D printed? Thanks for all and any information so that I can get this wonderful old machine working as it should. Regards Cheryl in Perth Western Australia

-

I'm available for custom jobs such as sewing, dying, edge painting, cutting hides into belt straps, hole punching, mechanical engineering, graphic design, CNC work, Product design, 3D Printing, web design, web hosting and programming, just to name a few. I am multi-talented and well rounded. I own all of my own machines. Call Text or WhatsApp: (604) 449-0099

-

- product design

- custom work

- (and 6 more)

-

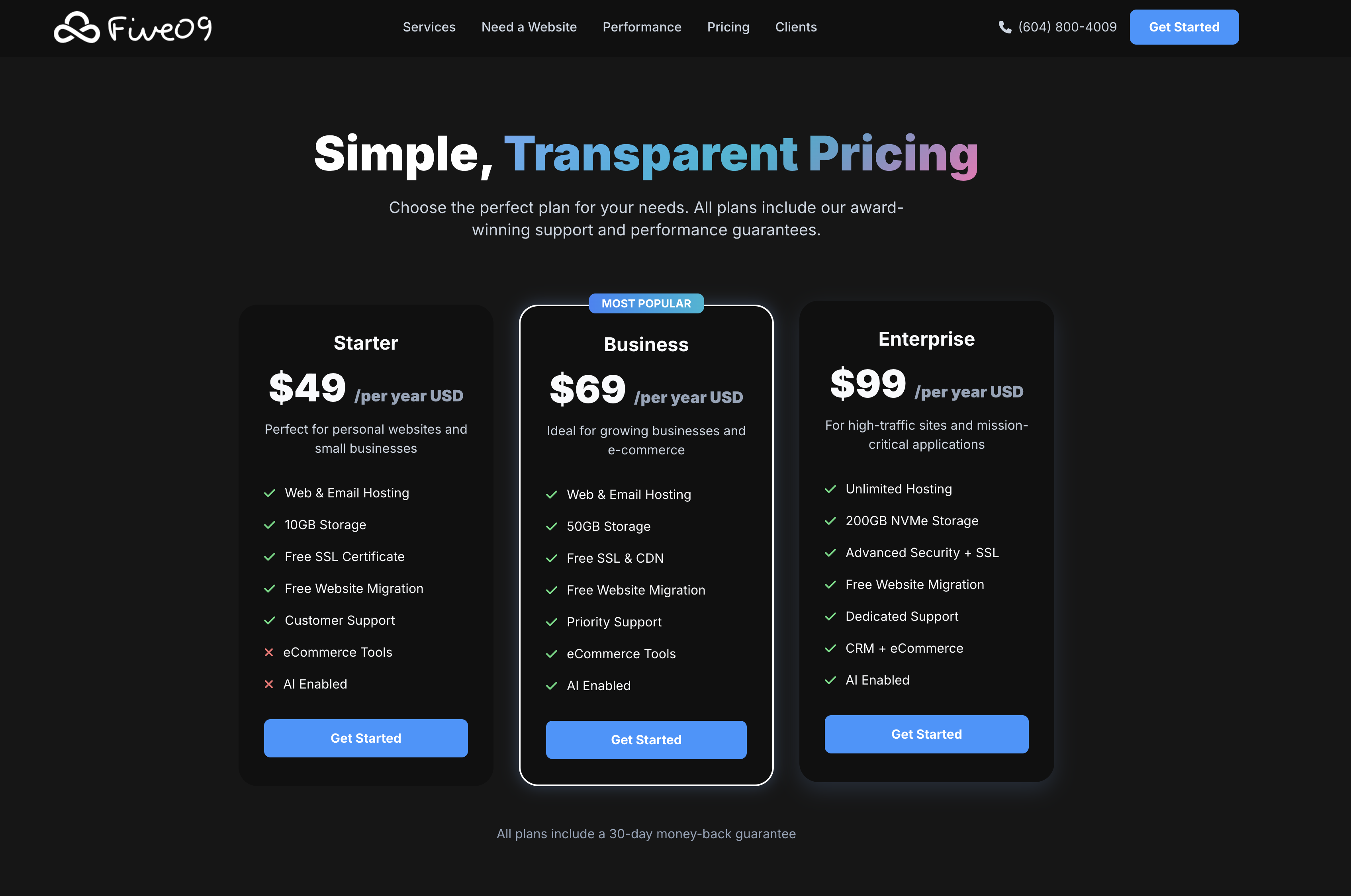

Five09.com - I offer affordable web hosting and web design services. Need eCommece, Shopping Carts, SEO, No Problem!!! Call Text or WhatsApp: (604) 449-0099