All Activity

- Past hour

-

I have a very worn and loose Consew 225 that I have added a belt and pulley speed reduction and pedal linkage to slow it down almost manageable. A friend passed away who had a Juli LU 562. Very pristine, been adjusted, looks brand new, has reverse which I am sure is a nice option. Juki now for sale. The Consew is inside a building with a lot of other benches that would make it very difficult to swap table and all, and also the Consew table has the speed reduction. Can I do a direct swap to the Consew table with the Juki head, and save all the table swap? Don’t use it much but the Consew requires an hour fiddling to sew 10 minutes.

- Today

-

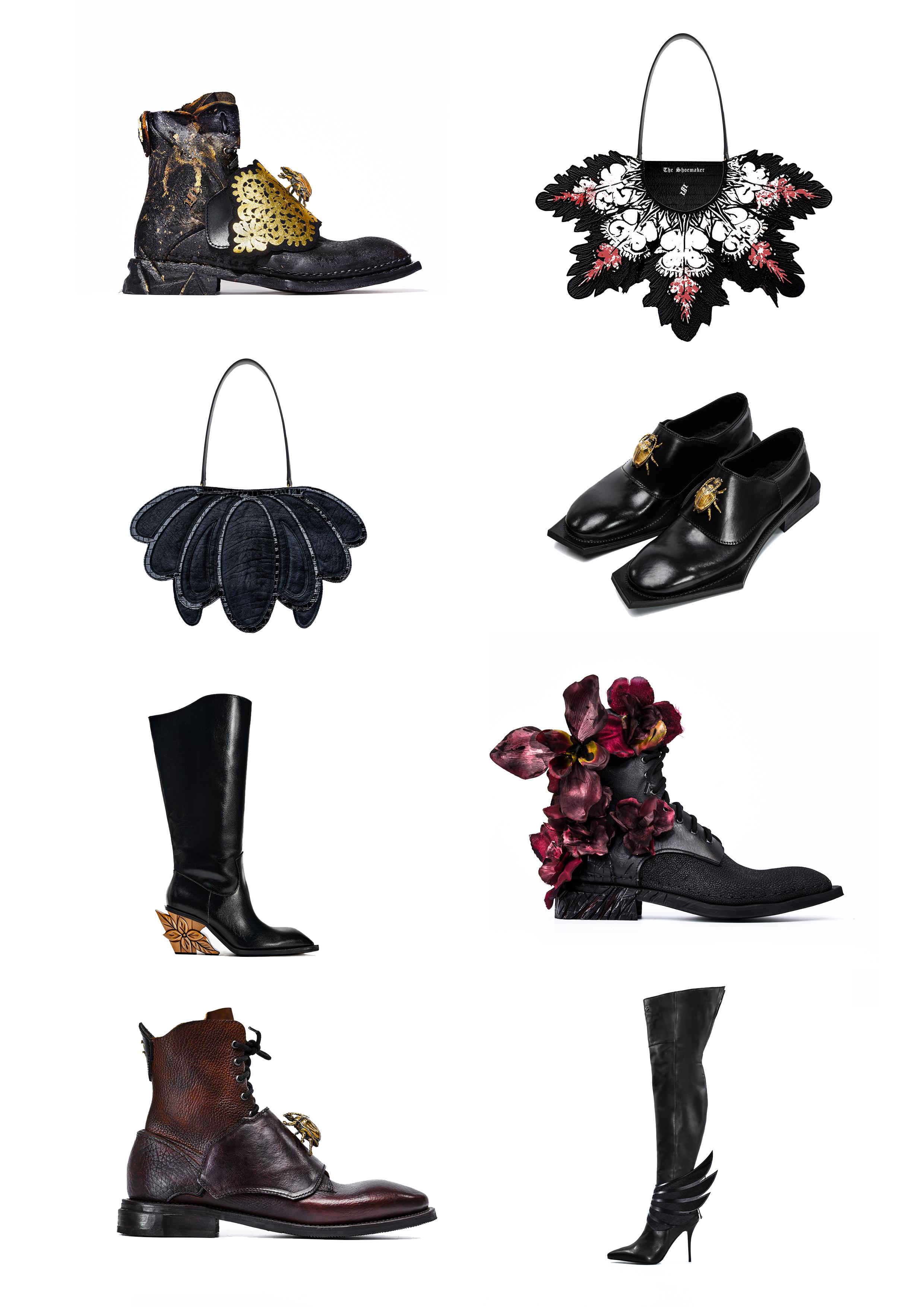

My collection of shoes and accessories combines traditional craftsmanship with artistic expression, turning each pair into a wearable statement. The designs draw from fine art and Japanese aesthetics, balancing elegance with individuality. A distinctive feature of my work is the use of interchangeable magnetic jewelry accessories, an idea I developed to let the wearer transform the form and character of their shoes — from subtle and classic to bold and expressive — with a simple change of detail. Every piece is handmade, unique, and created to celebrate both style and personal story.

-

That's the one I've got. Handles 2pt but not 3pt. Should be good on your banding dikman. I use a longer piece of tubing over mine.

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

That's it, I've committed. One of the ' lumps' is thawing out as I type. Its around 2kg . I'll cook it s-l-o-w-l-y on Saturday. It will either be nice juicy and tender , or I'll be able sole my shoes with it . I'll let you know how it goes at the weekend. Thankfully I can freeze the cooked meat if I have a lot left over, soups etc. HS -

these work pretty well. https://durston.com/product/ring-shank-bender/

-

@gordonl We stock these from size #19-#27

-

@AlZilla That guy in Toledo has them!

-

Yar-hoo joined the community

-

Brasso. Or tamarind paste. Rinse both out well once clean.

-

The Shoemaker joined the community

-

I played around with a piece of the banding and it looks promising. It's pretty tough and springy but can be hammered into a right angle without snapping. Heating it to anneal it makes no difference, as does heating and quenching. It can be filed to give a sharp edge but obviously won't be quite as hard as the proper steel rule. I also have a hand tool that is used to punch/crimp the banding to the steel house framing (I had no idea what to do with it but for $5 at the time it just looked useful ), it punches a rectangular hole but I should be able to make a new pin and anvil to punch a small round hole. My biggest challenge though is to make a bending jig/machine to shape the stuff. It won't be difficult, just a matter of digging through all my "stores" to see what can be re-purposed.

-

In the kitchen for stainless I use: 1/2 Quart Water 50ml Hydrogen Peroxide 1oz Citric Acid I don't know why the mixed units. That's just how it came to me. Do your own research. Prolonged exposure to citric acid will leach zinc from the brass.

-

Wow! I thought I looked high and low. If they're available overseas, they must be available here. Thank you!

-

cowagonwheel joined the community

-

Hello everyone! After a death in my family, I recieved my family's very old draft team harnesses. Initally, I know they were stored in a basement in a darker area in a plastic tote. And honestly I don't know if they have ever been cleaned in their entire lifetime. Upon examination, it looks like they have white spots all over. After many hours of research and gathering my materials I started with 2 tests to get the white off, only on a very tiny spot. 1st: Using a hair dryer on low heat and far away from the leather I was trying to see if the white was fat spores coming up. Some did go away while other parts of the white stayed. 2nd: I used a vinegar and water mix and let it dry on it's own, then used saddle soap. After the cleaning step, my next step was to use pure Neatsfoot oil to condition then a neutral leather shoe polish with a horse hair brush and canvas. BUT during the process of cleaning I noticed the leather was almost "molding" and moving itself very slightly( as i touched it with my finger, my finger left a very slight indention.) Also, when I was dapping up some of the moisture from the saddle soap test, the rag had brought up brown. Again I don't know if its dirt or leather. On the test part, where I had originally seen very faint stitching had disappeared. I don't believe the stitching is gone but I did not want to go any further and risk the chance of So so sorry for a long explanation I just wanna make sure I explained it correctly. Is there other methods I should try? Or should I only condition them and leave them be? THANK YOU!

-

Looking at this picture I belive the Singer 107w hinges are the same. https://www.college-sewing.co.uk/202258-210844-machine-hinge-hook-singer-107w.html?srsltid=AfmBOopJb1ilppAZoElRixRJKheoNF9ftFELvIPI6Cw_MaVvn7w75taq https://armastore.eu/210844-singer-107w-hinge-hook You will get them on your end as well just check the numbers online But I would probably buy the female part too - you never know....

-

Yes whoever invented the layback sewing machine deserves a prize 🦄

-

ShakaKahn joined the community

-

Servo motors: You can use either a brushed or brushless servo motor on any industrial sewing machine and it is a straight swap out as the mounting hole pattern is the same. You may have to move the "go" pedal slightly to the left or right. You can buy from a vendor or from Amazon / Temu / Ebay but you are not limited to the dealer should you want / have to change the motor. Brushless servo motors come in typically three puke favours. Cheap ones have 6 internal coils for the servo motor, mid grade have 9 internal coils and the better ones have 12 internal coils typical wattage ratings of 1/2 hp to 1 hp. The more internal coils the better. Brushed servo motors are simpler to repair with no computer controls, longer lasting with typical wattage ratings of 1/2 hp to 1 hp so less frustration. kgg

-

i'm kind of stuck looking for bed hinges. They're originally from a Wheeler & Wilson D12 (Singer bought W&W in 1905 and this 111w156 is related to the D12). I need to work back and forth under the bed and up top. Flopping around on the bench is a pain in the ass.

-

Many of us, including me, use this type of "brushed" servo motor: https://www.tolindsewmach.com/motors.html. Unlike the one you linked to and own, which starts at 200 rpm, this motor starts turning over smoothly from zero rpm when you move the foot pedal down. There is no jerky start, nor any complicated electronics panels to replace. The only parts that experience wear are the two carbon brushes, two of which which come extra with the motor. I've yet to go through the original brushes in a motor I installed around 2014.

-

Yeah, I'm a slow learner...

-

Update: First of all, I was today years old when I learned that Uber has a courier service and it is awesome. Spared me 3 hours of traffic. Had the pedal and controller at the store at 10 am and 10 mins later the owner called me that he fixed it. He said the problem was the cable between the controller and the pedal, there was a pc board in there that failed: he replaced it. Got my delivery from Uber and tried it and now my machine works again. So, many of you were correct in your hypotheses. I appreciate you taking time to read and trying to help me out. You are good people. For future reference, lets say that I wanted to buy a whole set of Motor, controller and pedal like @kgg and others mentioned, would I have to buy a specific one or it would not matter since replacing all 3 parts would basically replace the whole system? If yes, could anyone link me one? I might just get one to leave in the basement to hot swap it if somewhere happens again so that I can still work while they fix the broken one. This is the one i have now, but do I have to buy an Artisan or can anyone recommend a better one? Thank you. https://bobssewvac.com/product/acf-680-880-watt-servo-motor/

- Yesterday

-

I wonder if an ultra-sonic cleaner would work?

-

I have since acquired a machine that uses 7x3 needles. 7x3 seems to be the round point equivalent of 7x4 and 794. These are about 68mm long in total, 60mm from butt to top of eye. Worth reading is Wiz' blog on dumbing down a cowboy 4500, which also uses 7x3 needles.

-

Did you get this machine up and rolling? Would love to see some videos 🎥

-

Did you get your machine running? I'm not familiar with the 291. If a machine has a safety clutch, it will likely be built into the timing cog underneath the machine. Follow the timing belt from the main shaft down to the horizontal timing shaft. The cog on the horizontal timing shaft---if it has levers and pawls on the right side of it, your machine has a safety clutch. Here's a video by Uwe that shows safety clutches: https://www.youtube.com/watch?v=N-MClgDKnq4

-

Thanks Northmount, I tend to get sidetracked sometimes - I'm also very good at hi-jacking threads.