All Activity

- Past hour

-

Couple of questions: i) How wide are the belts?? On this side of the pond the typical width is 1 1/2" (38mm) for say jeans while 1 1/4" ( 32mm) is more for dress pants. ii) How thick is the leather, 8 / 9 oz?? iii) Did you glue, staple, sew or rivet the belt loop? kgg

-

2 oz. calfskin is a decent choice for interiors as well. Also not as cheap as regular cowhide, but it's cheaper than kangaroo.

-

Latest Holster for single action 22

dikman replied to Hildebrand's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks good to me. -

Always good to hear ideas from others. I thought of the angle grinder/cut-off wheel but because I've welded this one up I didn't want to take the chance of slipping and buggering it up! I'm still pondering the best way of mounting the die itself. Wood "block" to screw it to, cut the shape in wood with an engraver and rebate it into the wood, cut a slightly oversize shape from sheet metal and tack weld the die to it, a few options there. I've noticed that a lot of the die makers only use one set of basic bending tools, tape a pattern to the steel rule and then bend bit by bit until they get the angle/shape needed. I may be overthinking this (not unusual for me!).

-

Now that makes sense, almost idjit-proof to use!

-

Functional, should do to keep your pants up while you make yourself some fancier ones.

-

Veg tan tooling with chrome tan projects

dikman replied to Blitz Thunderlungs's topic in How Do I Do That?

I would think using either contrasting or complementary colours would be best, trying to match stained veg with pre-coloured is always going to be iffy - plus you're going to end up with a large collection of stains! - Today

-

Same here, I'd like to try the water-based stuff but for the money they're asking they can keep it, the solvent-based stuff has always worked well for me (plus as a bonus there are the fumes.....).

-

I once made a couple of notebook covers for members of our police force (SAPOL), they have their own logo of course but it is very detailed and finicky. There's no way I could have manually copied that logo but the little laser I had was perfect for that job. But yeah, it does make it easy for anyone to copy almost anything.

- 20 replies

-

lonsdaleleather I did check out the Makers which lead me down the contact cement cost rabbit hole. The cost for i) Makers is $23 USD ($31 CAD) for 16 oz, water based ii) Aquilim 315 for 16 oz is $45 ($62 CAD), water based iii) Weldwood for 16 oz is about $23 USD ($31 CAD), solvent based That said in Canada we can get i) Lepage heavy duty contact cement is $29 ($40 CAD) for 32oz, solvent based ii) L.L. ( Lonsdale) contact cement is $26 ($36 CAD) for 32oz, solvent based which is advertised as using the same "recipe" as Barge. iii) Zelikovitz 1882 contact cement is $39 ($54 CAD) for 32oz, water based My conclusion is the water based contact cements on either side of the border are a fair bit more expensive. Contact cement (water or solvent based) are cheaper in Canada. kgg

-

Where can I order thread for a Landis 12K to be shipped to me?

-

Me too! Lol I just don't make enough holsters or sheaths to warrant the price. It would be different if I made them to sell on a regular basis.

-

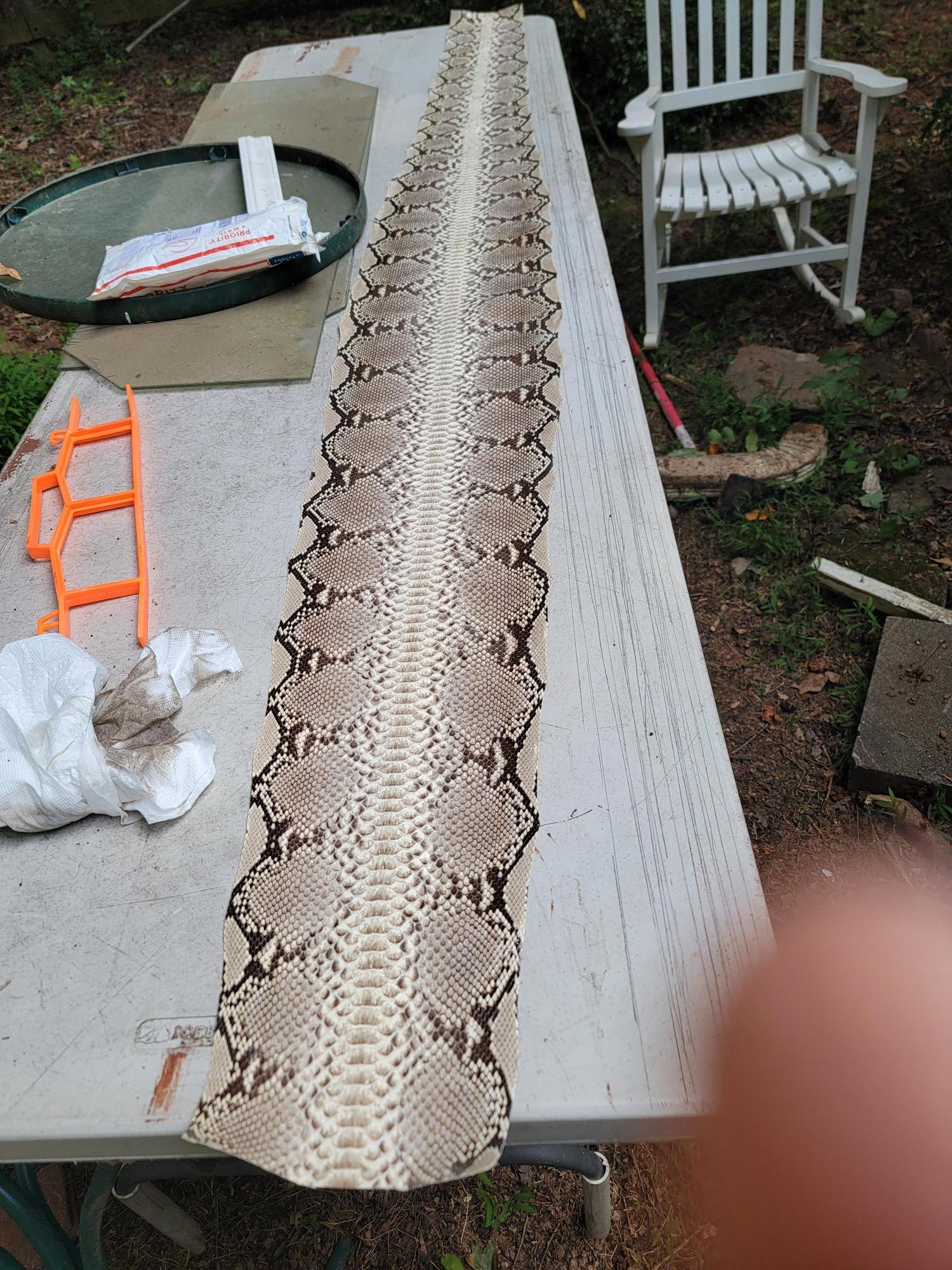

I bought these many years ago and don't even remember what kind of skins they are. The large one is 8 feet long and 9.5 inches wide at mt hand span. The smaller Tandy skin is probably 2 feet or so. The product number is no longer listed in Tandy's ever-changing catalog. In the near future, I am going to be selling off stock that I no longer need. Can anyone tell me what I have and the possible value?

-

One issue I have had with the Aquillim 315 is it is difficult to get good smooth edges. It's like it leaves a rubber cement type of substance on the edge when you are trying to sand it. I have not been able to get rid of it. Which is too bad because and odorless contact cement would be awesome especially in the winter since I have to go out to the shop to use the regular stuff due to the fumes. Todd

-

Veg tan tooling with chrome tan projects

BlackDragon replied to Blitz Thunderlungs's topic in How Do I Do That?

Antique is used as a top layer after the leather is dyed. The leather is tooled, then dyed to a color of your choice, then you add a coat of clear finish like Resist or Resolene, then add antique and wipe it down. This will leave the antique in the crevices. Then add another coat of your clear finish to lock in the antique. Trying to match dissimilar leathers is going to be really, really tough. If you're going to use chrome tan pick a color then try to match the vegtan the best you can. Using a contrasting vegtan can work perfectly as well. Take a dark brown chrome tan then add a light tan or natural vegtan, it will work well together. I found this on pintrest; -

8oz is pretty think for a wallet. I would go with 5oz, it will still tool but you'll have to use a lighter hand. For the interior I use either 2/3oz vegtan or English bridle. When tooling remember to use blue painters tape on the flesh side so help minimize stretching.

-

I have and do both. I love the look of hand tooled leather. Also: I have laser engraved leather photos that adjust the shading etc. and look pretty doggone classy. In every endeavor there are many ways to incorporated what is liked. That said: when you engrave mostly "sketch lines" it isn't nearly as impressive.

- 20 replies

-

Kangaroo is probably the best, but expensive. I use 2oz vegtan leather for my card pockets.

-

Some folks commented on Youtube that Makers sells a less expensive water based contact adhesive that is comparable to Aquilim 315.

-

Latest Holster for single action 22

Samalan replied to Hildebrand's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's a beauty, love it. -

For me, something tooled by hand looks so much better, and here is why I think that when you carve something by hand, you create depth with beveling, and stamping creates that certain color and shaded look that can't be replicated with a machine. Also, working a piece of leather by hand, each Artisan develops and establishes a style of their own, a style of work that people recognize. Laser engraving is okay on hats and patches, but not on something of high quality. IMHO

- 20 replies

-

My recent builds have been with Timberline, Double L, and Swanke. I've been happy with all of them, but there are differences in cost and quality. Depends on what you want. Randy

-

Customer just picked up this holster. His son had me make him one a few years ago for a .41 magnum and he wanted one similar to it for his 22 lr. I have a love hate with white thread, if you don't die and finish before stitching it takes on the color of the die. In this case with it being lined I needed to sew the top edge before assembly so I did without it being died and paid the price when the top stitches disappeared in the die. White edge stitches still popped pretty good. He is tickled with it, I was able to use my 3-D printer to print his initials rather than hand cut them. The 3-D stamp is much cleaner and easier.

-

A new to me Pfaff double needle 346-H2. Won't pick up the bobbin thread. Ya, I've tried moving the rotary hook closer to the needle scarf. Used the needle bar clamp and gauge. (1.8mm). finally called in a repair guy from the local sewing machine shop that serviced industrial machines. No joy, couldn't "fix" it. There has got to be something I'm missing here. The repairer say the hooks are probably worn out? No, it has never sewn for me. Just now starting to get it recommissioned after picking it up a couple years ago. . SOOOO... what am I missing? OR, anyone know of a replacement part for these rotary hooks? I can't find any info on interchangeable parts/modern made. Are any Pfaff single needle machine parts interchangeable? I found a resource that suggests that the 335 machine shares many parts with the 346, such as rotary hooks. Can someone confirm this?

.jpg.4ca174e83819fbfeb81ed3127f87e562.jpg)