All Activity

- Past hour

-

Thank you! I just want to save them so they don't fall apart, and I would be devastated if I did that while cleaning them.. For wiping it down, would you say just use some warm water and a sponge? And then add the neatsfoot oil lightly to just the cracking areas or the entire thing? For the parts that are severely degraded, is there anything you would recommend? Also, for storage purposes, where would be the best place to keep these? I live in CO, and we have such a variety of weather, so I thought in the house, but didn't know if they should stay in the plastic tote.

-

The white looks like mineral deposits from sweat. The brown can be dirt or the leather is deteriorating. Since you're retiring the equipment you can wet it and lightly scrape the mineral deposits off. There is quite a bit of cracking, that cracking means the leather is failing and in pic #3 on the left side that degradation is pretty severe. I wouldn't get to deep into cleaning since it's only going to be for display. The deposits just attest to the life and use of the gear. I would just brush it off, wipe it down with a damp rag, let it dry, and add a little oil to preserve it.

-

I sew that weight with a Consew 225, which is the same class, does so with difficulty and a speed reducer. Would not do well without reducer.

- Today

-

Hi thank you so much! It wouldn't let me add photos but I have attached ones in this reply. The last photo is the test photo and I also included the brown that was coming off as well as my products I'm using. There's still horse hair and hay from the last time they were used and so I don't know if I'm taking off leather or dirt. Thank you for your help!

-

That means your table is too pretty. Make it work!

-

I forget where I saw it... During training at Juki Miami maybe? But they looped one arm through the machine and gripped the handwheel with the other hand. This is how I generally do it, it helps if you wipe it down thoroughly for any oil up top because even a little bit will make this job much harder. It occurs to me that gripping the handwheel is not going to be as useful if the handwheel is large (the DDL-8700 is small enough to be fully gripped) but anyway, looping an arm through the machine is the main support.

-

I think this thickness is too difficult for the 563. You’ll need a 244 or 246 to handle it.

-

Yeah, that's exactly the guy in going to call ...

-

@cowagonwheel I would ad a caution that leather harness that old with unknown care should most likely be retired for display only. Really bad things can happen really fast if harness gives way while pulling a load. You didn't say if you were cleaning for use or display so I thought I would throw this out there. Todd

-

It's hard to determine what the white is without pictures. It could be mold, sweat, dirt, wax, or some type of chemical. When washing down saddlery it's common for the dye to rub off. Leather becomes soft when wet and can be indented easily, let it dry completely before putting unnecessary pressure. First thing I do when a saddle comes to my shop is to brush as much of the dirt and grime I can. As I'm cleaning I start determining what needs to be replaced or repaired. I can do small repairs and replacement but if the saddle needs to be broken down I don't take on the job. Normally I remove the stirrups completely but these would not come out and if they were going to be this difficult removing they were going to be harder to get back in. I then start to wipe it down with warm water to get any mud off as well as softening any waxes. I then go at it with saddle soap, warm water, and a sponge or toothbrush. I wipe it down with warm water as I go so the soap doesn't dry on the saddle. Once I'm satisfied with how clean the saddle is I let it dry for at least a day. Then I oil it with neatsfoot oil and let the oils soak in for about a day. At this point I determine whether or not to add some dye if to much dye came off while washing it and let it dry. I then wax. I use Fiebing's Leather balm with atomic wax and get great results. Before After washing and letting it dry After

-

This is a machine type question, so I have moved your post to Leather Sewing Machines.

-

Appears not to have any interest in following up. Hasn't been back to the site since he posted. @Moscho I am locking and archiving this post.

-

I have a very worn and loose Consew 225 that I have added a belt and pulley speed reduction and pedal linkage to slow it down almost manageable. A friend passed away who had a Juki LU 562. Very pristine, been adjusted, looks brand new, has reverse which I am sure is a nice option. Juki now for sale. The Consew is inside a building with a lot of other benches that would make it very difficult to swap table and all, and also the Consew table has the speed reduction. Can I do a direct swap to the Consew table with the Juki head, and save all the table swap? Don’t use it much but the Consew requires an hour fiddling to sew 10 minutes.

-

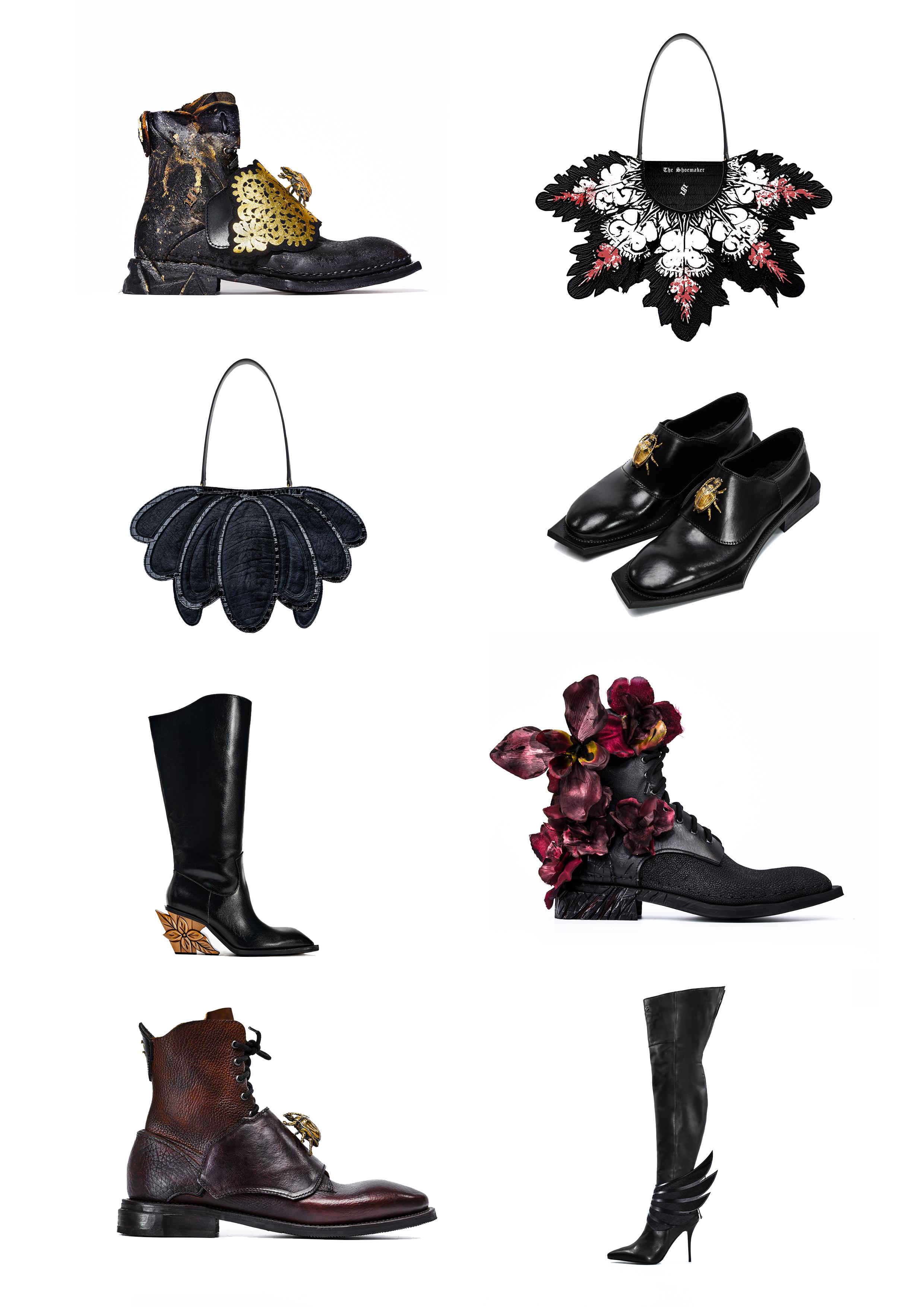

My collection of shoes and accessories combines traditional craftsmanship with artistic expression, turning each pair into a wearable statement. The designs draw from fine art and Japanese aesthetics, balancing elegance with individuality. A distinctive feature of my work is the use of interchangeable magnetic jewelry accessories, an idea I developed to let the wearer transform the form and character of their shoes — from subtle and classic to bold and expressive — with a simple change of detail. Every piece is handmade, unique, and created to celebrate both style and personal story.

-

That's the one I've got. Handles 2pt but not 3pt. Should be good on your banding dikman. I use a longer piece of tubing over mine.

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

That's it, I've committed. One of the ' lumps' is thawing out as I type. Its around 2kg . I'll cook it s-l-o-w-l-y on Saturday. It will either be nice juicy and tender , or I'll be able sole my shoes with it . I'll let you know how it goes at the weekend. Thankfully I can freeze the cooked meat if I have a lot left over, soups etc. HS -

these work pretty well. https://durston.com/product/ring-shank-bender/

-

@gordonl We stock these from size #19-#27

-

@AlZilla That guy in Toledo has them!

-

Yar-hoo joined the community

-

Brasso. Or tamarind paste. Rinse both out well once clean.

-

The Shoemaker joined the community

-

I played around with a piece of the banding and it looks promising. It's pretty tough and springy but can be hammered into a right angle without snapping. Heating it to anneal it makes no difference, as does heating and quenching. It can be filed to give a sharp edge but obviously won't be quite as hard as the proper steel rule. I also have a hand tool that is used to punch/crimp the banding to the steel house framing (I had no idea what to do with it but for $5 at the time it just looked useful ), it punches a rectangular hole but I should be able to make a new pin and anvil to punch a small round hole. My biggest challenge though is to make a bending jig/machine to shape the stuff. It won't be difficult, just a matter of digging through all my "stores" to see what can be re-purposed.

-

In the kitchen for stainless I use: 1/2 Quart Water 50ml Hydrogen Peroxide 1oz Citric Acid I don't know why the mixed units. That's just how it came to me. Do your own research. Prolonged exposure to citric acid will leach zinc from the brass.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)