All Activity

- Past hour

-

You can look on eBay and see what similar parts have sold for. You do that by searching and checking the box on the side that says something like "Sold Listings". Bear in mind that ebay sellers are often at the very top of the market for uncommon parts. They set a high price and wait for desperate buyers.

- Today

-

I moved your post to the Marketplace section, under used sewing machines. Here is a good tutorial about adding photos to your post.

-

I have parts for Adler 20-2. various feet, hooks, and bobbin case and a few more parts. Someone is interested but not sure how to price them.

-

Measuring Screws for Replacement

Constabulary replied to friquant's topic in Leather Sewing Machines

But you can print it out 😆 may take a few moments... 😉 -

what parts do you have?

-

I am wondering how all of you arrive at a price if you have sewing machine parts to sell. Especially original ones made of "unobtainium" / parts no longer available. I have searched the internet and every site I could find including this one. But I can not find anywhere that has any parts that are similar. I searched for similar makes of machines and no luck.

-

Equipe saddle, repair of worn saddle flap

jrdunn replied to Mulesaw's topic in Saddle Identification, Restoration & Repair

Great work Jonas! I have one more possibility, although it probably doesn't matter. I was wondering if the previous owner may have needed the assistance of a right leg brace. This from a guy who wore one for a while. I didn't ride a horse with one though. While I agree it would be confusing to a "well trained horse", some of those therapy horses seem to sift through indications to find intent. As usual, JM2C. Jim -

Toledo Industrial Sewing Machines would be worth a call. Tolindsewmach.com I needed some pretty obscure parts last year and they had them in stock.

- Yesterday

-

For sewing machines, Superior sewing has a very extensive online catalog that should at least get you a part number. I find it difficult and slow to navigate but it has bailed me out a couple of times. There doesn't seem to be a paper or PDF version. https://supsew.cld.bz/2I4E5Zu

-

Not questioning any of the above. BUT my simple system to find a match is take a screw that fits the part or take the part to a fastening supplier and see if I can find a match. SO FAR it has worked for me. Up to now I haven't had to drill and rethread anything except on a BUSM #6 that has Whitworth threads. On it simply turning in a standard die trimmed a few 1/000ths to reshape the threads, no drilling needed.

-

If the groove moves just a little, it makes sense to smooth out the transition rather than abruptly breaking the seam. But if the choice is between a “perfectly smooth seam” and a “seam that faithfully repeats the curved groove,” the first option almost always wins.

-

Thanks for the warning.

-

.thumb.jpg.e8165e2c9278c08c5a6e44abef36e310.jpg)

Special Holster for Special Friend

Skinknife replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

It feels like it was made with soul and for a specific person. The thing is not just functional, but with character and mood. The detail with the concho looks apt — a small accent, but it really enlivens the work. I like it. -

gokuanon joined the community

-

wes4587 joined the community

-

Juki 441 sewing machine for sale. It's like new. $2,000.00 San Diego area. Call 760 855-2551 Wes Can't figure out how to add pictures. I'll send you pictures

-

@cv66seabear That starter set seems to have most of what you'll need. I'd add a razor knife of some kind and a steel rule to cut straight lines. Let me suggest that you enable email notification of responses to your threads. We've found that New users forget to check back and then drift away. As follows: "To enable email notifications when someone posts on your topics (like this one), you can visit https://leatherworker.net/forum/notifications/options/ - then click "Mentions and My Content" and make sure the "Email" box is checked."

-

Thanks Dwight! I'm in the middle of Wisconsin, I think the nearest Tandy is 2 1/2 hours away, but good ideas , I'll save up and go in person! I assume you're a vet. I'm ex-Navy - mostly on a bird farm. Any hand stitching thoughts? Thanks again everyone!

-

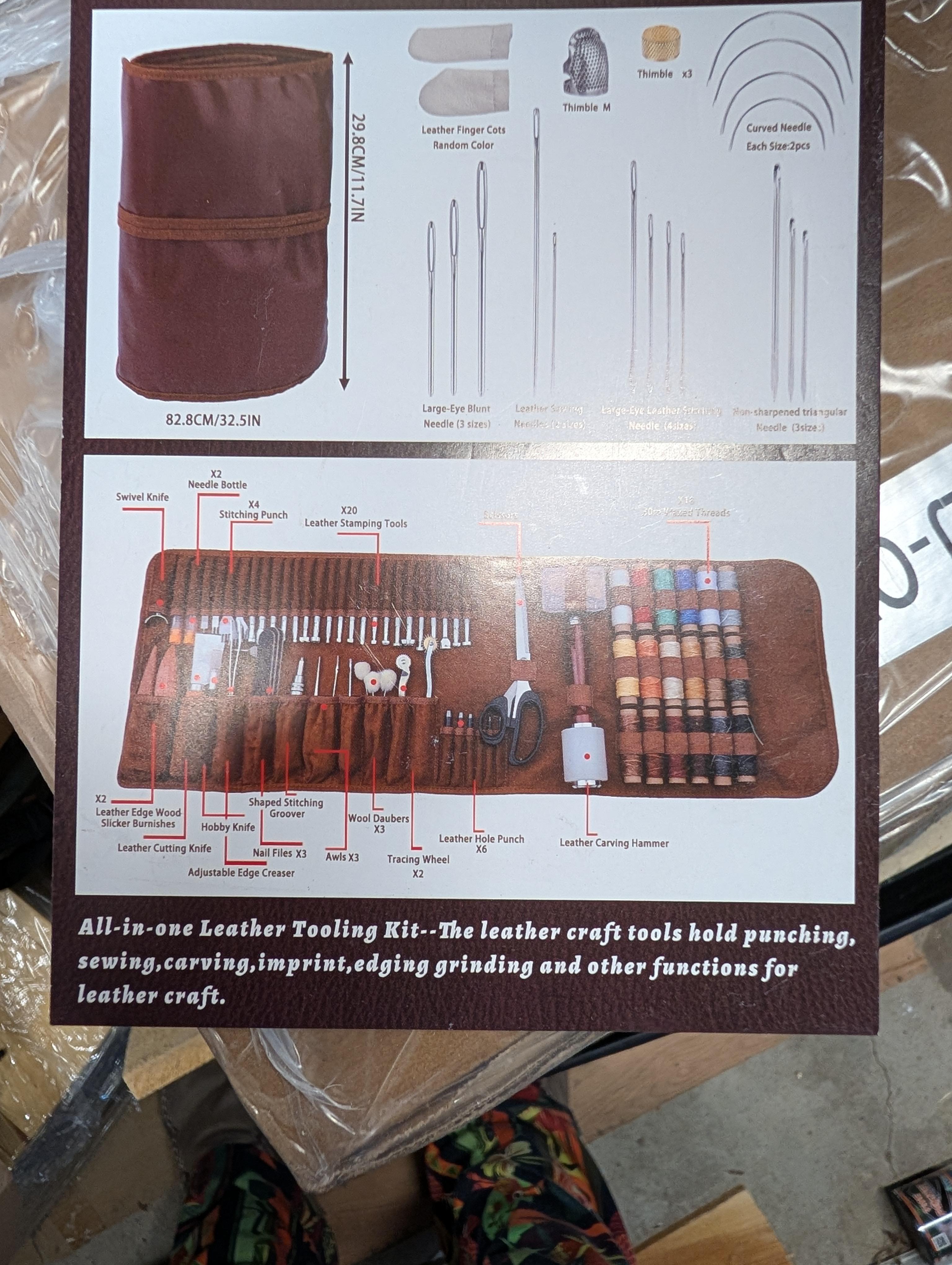

Fred, thanks for the offer! I didn't realize Tandy had a free library! I'm looking right now for a belt bag for a Western belt, so about 4" X 4", 6"X4" with a 3" loop. I have a stitching pony the kind you sit on, some skivvers, waxed thread, various needles, knife, stitching hole cutters and some pattern punches. How much room do I need? I have a VW bus, tools and some woodworking equipment already. Is a 6' bench a good size? Would 4' work? Since I'm not doing a machine now? Or should I allow for that possibility in the future? I build my benches on wheels so I can move them around. What's a good height? Do mist of you Budget wise, I can't spend a fortune, seems like leather will be pretty pricey! Here's the set I bought. Sorry the one got inserted in the middle. I couldn't delete it.

-

oPashoo joined the community

-

If you have a "friendly" Tandy store like I have . . . they'll give you more help than you can use as far as ideas are concerned . . . they also have patterns that I've found to be pretty simple and basic . They also are my "go to" store for leather. I've tried some of the expensive stuff . . . and it's like comparing a Ford to an Audi . . . both gets you down the road . . . but one is more than twice the price. I pick my own out . . . and they'll even help me there if they have time. May God bless, Dwight

-

Excellent reference, thank you. I suspected machinists would know things about this. Here is a link to a free copy of the book: https://www.tfgusa.com/wp-content/uploads/2023/11/Machinerys-Handbook.pdf Starting on page 1802 of the text, "Threads and Threading" introduces different thread systems. (There have been a few.) Page 1816 has a table of typical combinations in the american standard unified system. I think some slightly amended version of this system is still in common use today. It uses numbered sizes for anything smaller than 1/4". These numbered sizes mostly do NOT line up with 1/64" increments. Let's cross-referencing page 1816 with page 3 for details 1/16 is a little bigger than size 0 5/64 is in between sizes 1 and 2 3/32 is between size 2 and 3 7/65 is almost as big as size 4 1/8 matches size 5 exactly!! 9/64 is barely bigger than size 6 5/32 is in between sizes 6 and 8 11/64 is between sizes 8 and 10 3/16 is almost exactly size 10 13/64 is between sizes 10 and 12 7/32 is almost exactly size 12 15/64 is between size 12 and 1/4" Major Diameter of External Threads My main curiosity is how to interpret the measured major diameter and choose a nominal diameter from which to place an order. Let's look at an example from the book. Page 1818 The 1/4-28 UNF external (meaning screw thread, not nut thread) has a nominal diameter of 0.25" The least precision version (1A) has allowable major diameter 0.249" - 0.2392" This means the major diameter for the 1A series must be between 95.5% and 99.5% of the nominal diameter. From this I deduce that when I measure a major diameter to be X, I can look for a matching nominal diameter that is 1-4% bigger than X. I don't think I will always know which thread system the screws I'm searching for are from, either by my own ignorance or unavailability of data. But in general it makes sense that for a non-interference fit the screw major diameter has to be smaller than the accompanying nut major diameter. So I'll roll with the bolded deduction above until I find a more informed pathway.

-

Equipe saddle, repair of worn saddle flap

Mulesaw replied to Mulesaw's topic in Saddle Identification, Restoration & Repair

Thanks for the very nice comment 🙂 -

If installed properly they can take a lot of beating. You need a special tool to install them. It is like a tapered punch that goes into a tapered hole. At least for very big ones. You could also use some small D-rings for the paracord. On your picture #2, the black stitch on the left (closest to the edge of your bag) - every 2" (give or take), you mount a D-ring. The D-ring can be mounted using either a thin strip of your leather or a strip of webbing. You can get D-rings in many sizes and colours, I would think that a 5/8" D-ring in brass would look good. Something sort of like on this picture: