All Activity

- Today

-

Are either of these machines any good?

timstips replied to timstips's topic in Leather Sewing Machines

Thank you friquant, Constabulary & Wizcrafts for the help! Any recommendations for a newbie machine that is more available? I don't see any 111w155 for sale locally. I am looking to dabble in the trade a little bit to see if I like it and if I can make anything intersting. -

Your threading of the top thread around the tension discs is incorrect, refer to your manual for the correct threading. kgg

-

Are either of these machines any good?

Wizcrafts replied to timstips's topic in Leather Sewing Machines

I also have a Singer 107w in my shop. It is handy for jobs requiring a zig-zag stitch. It can sew with #69 bonded thread into 5-6 ounce chrome tanned shoe upper leather, like that tanned by S.B. Foot. But, that's not all it's good for. I also use the 107 to sew linings and cloth that would be eaten by my walking foot machines. To do this I move the stitch width selector on the back to zero throw. This places the needle on one side of the presser foot. I use the stitch length knob on the rear to get a longer stitch. The maximum throw is about 1/4 inch, or slightly wider. While this wouldn't be a first machine to buy for a leather shop, it would be a good addition. Your first machine should be a compound feed walking foot machine. An example is the out-of-production Singer 111w155. -

Are either of these machines any good?

Constabulary replied to timstips's topic in Leather Sewing Machines

top and bottom picture show a Singer 107w ZigZag machine of some kind, it can sew garment leather. I have one, nice machine but not the best option for leather work. But the one shown has a lot of milage as it seems. I would not buy it as my main / first machine. -

if you are looking for small / narrow foot print feet then these feet here may be an option: https://leatherworker.net/forum/topic/132157-interesting-441-style-presser-feet-for-singer-111w-153w-and-similar-like-341-227r-and-so-forth/

-

-

-

Here’s a video of it happening. IMG_6701.mov

-

My thread keeps jumping out of this tension spring. Do I need to rotate it down to keep the thread in? Also do I remove this wool like material from this thread guide? thanksr tj

-

I don't know why they are typically wider on the left. Somewhere I read that "the softer the material, the bigger you want your foot to be". Grinding down would make your footprint smaller. As long as you are not concerned about sinking too far I don't see a problem. I actually do a fair amount of my stitching with a zipper foot, even when I'm not sewing zippers. (A zipper foot would be like grinding one entire side off)

-

Are either of these machines any good?

friquant replied to timstips's topic in Leather Sewing Machines

Don't buy these. You will want a triple feed machine. (May take some internet browsing to learn to identify triple feed) The singer in the photo appears to be a bottom-feed lockstitch machine. (Bottom-feed won't feed sticky materials) The Lewis is not a lockstitch machine at all. Maybe a blind hemmer? -

Hey everyone, I have a cb341 that has a presser foot like the one in the picture. I like to guide off the presser foot when stitching but I like to use the left side better than the right. Do they offer a presser foot that has the needle centered. My apologies if I got the terminology wrong. i guess option 2 would be to get another presser foot and modify it with a grinder. Would there be any drawbacks to that?

-

Replacement Pulley for Tapered Shaft

friquant replied to friquant's topic in Leather Sewing Machines

Genius! - Yesterday

-

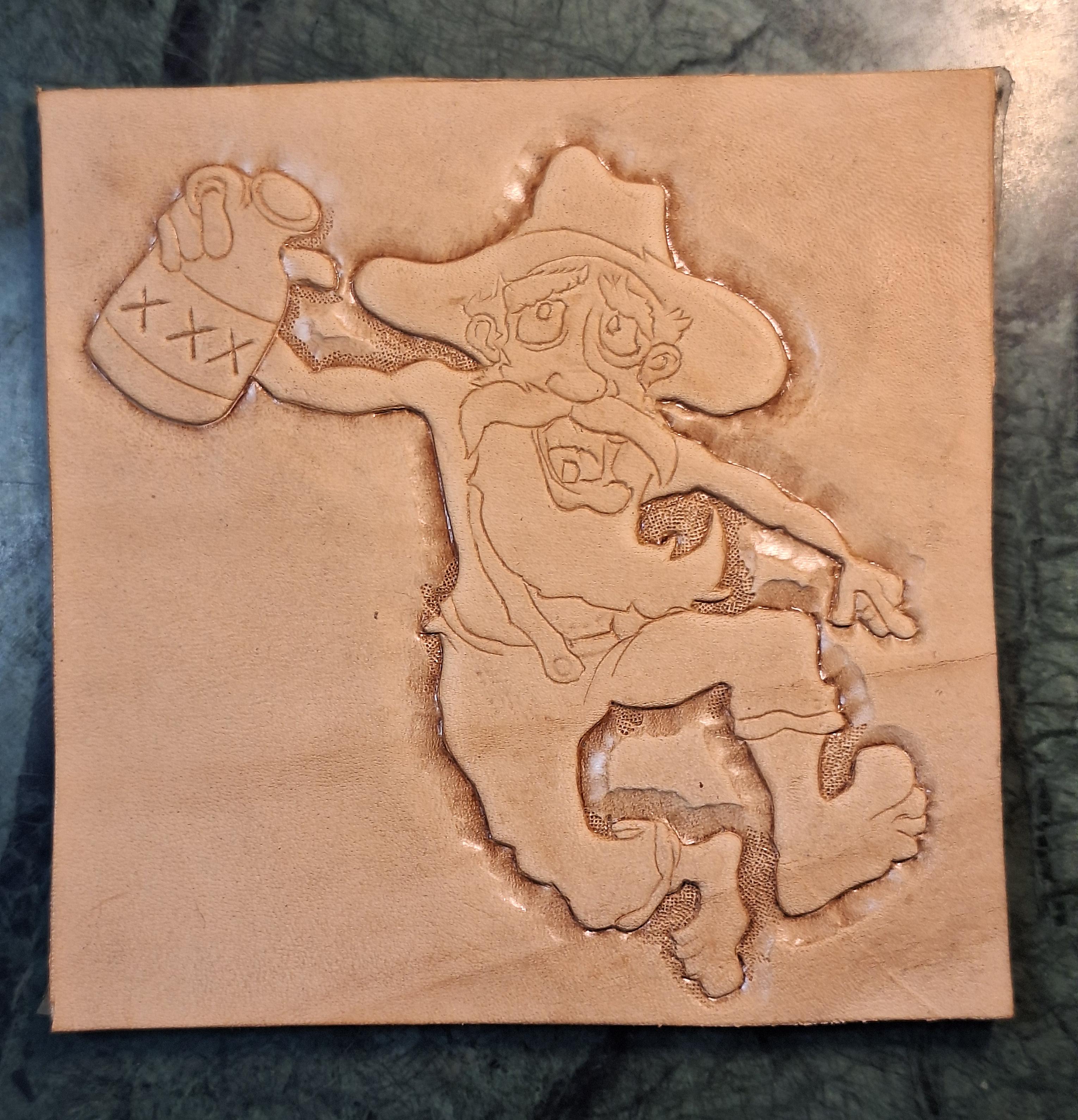

Hey, I am considering buying one of these machines. I have not looked at them yet and don't know anything about them. I would like to get something that can sew leather (belts, wallets, etc.). I think they are asking $200 each. Assuming they work, are they something that I should consider?

-

NLSA joined the community

-

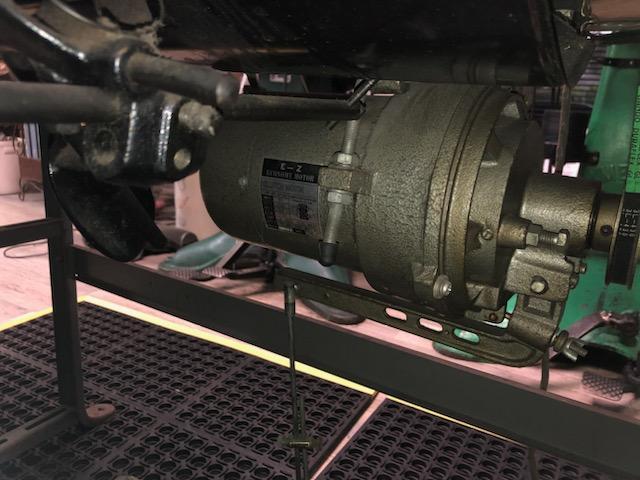

While that pulley may help. I think this is my best upgrade yet. I have a 200 rpm minimum on my servo. So this 6” pulley got me to 100rpm at the machine. Should see 70 rpm with the new motor pulley.

-

https://a.co/d/2ekgEsu

-

maca1381 joined the community

-

OGL joined the community

-

The wheel is staying as is. Taking it apart would leave a HUGE mess. It's actually made from paper! It acts and feels like wood, it's nailed together at the factory (79 years ago). I'm liking this Dwight! Got the brain wheels turning.

-

HoagyMacintosh joined the community

-

8th_Ridge joined the community

-

What's on the wheel now? Does that have to come off first? If you remove what's on the wheel, then you would have flanges on the two ends that the leather would need to be proud of, so it might not be 8 to 9 oz, but 10 to 11 oz. I would put that on with barge cement with a minimum of a 3/4 " scarf. Laid with the lap in the correct direction. Sorry had that wrong thought

-

I would cut a piece of 3.4 inch pine to fill the hole . . . nice tight fit . . . that would be screwed to a piece of 3/8 inch plywood . . . that would be the size of the outside diameter of the pulley. Tool a really nice little Farmall "M" . . . sitting atop a small plowed field . . . with clouds on the left and right . . . and the IH in the middle above the tractor. Contact cement the tooled image to the plywood . . . get nails used for attaching cloth to a wood project from Hobby Lobby . . . ring the outside of the tooled image with them. Start the tractor . . . sand the pulley real well . . . paint it bright high polish fire engine red . . . call it all done May God bless, Dwight

-

KillDevilBill, Yeah I hate messing up a $40 belt blank and I like to find ways for consistent results. Trouble is a lot of these tools don't have handles that are aligned with the cutting edges.

-

Long Arm Highlead GC20698-2 Dual Needle Sewing Machine Head

Tommy217xxx replied to mcmill45's topic in Used

How much is the skiver? Do u have any pics? thanks tj -

This is a personal project, not a customer. I'm "restoring" my old tractor. It's almost mandatory that it has a leather seat, but I also thought it would be cool to wrap the belt wheel in leather also. My first thought was to stack rings on so the edges face out and burnish the heck out of them. That's gonna take A TON of leather, wheel is 6" diameter. Next thought was flesh side out and burnish, but I'm not sold on that. Right now I'm thinking tooled with the "IH" logo facing out. Just wondering what the talent here comes up with. Looking for ideas! Thanks!

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

@chuck123wapati ive kept up on my basil and oregano, and my parsley has gone ' kapoof' almost two feet high. I also planted some capsicums, both red and green , something I use a lot of in cooking. Dam catapillers keep eating my mint, not happy. Just made a heap of sausage rolls, and curry sumosas , some for dinner tonight and the rest get frozen. I can get sausage meat from our supermarket. God bless mum for teaching me how to cook Your ' burb looks quite at home in that picture. HS -

Yes, it's the machine head only. Thanks!

- Last week

-

BUMP this up from the 2015 Necro Basement. As I just picked up a Cherry REX 26-118, ( aka: Singer 16-188 ) , made in Japan/Nakajima plant . Been sitting dry for 'years' . Even had the parts manual, and original sales receipt in the table drawer. Was bought new with one owner in 1976 . The Head is just pristine for the age. No wear, No Rust. Looks like it just sat unused far more than it was ever used to sew . I saw it sitting in the house, and a 100-$ took the head and table home. Pulled it open and OILED the hell out it . Then started Rolling it by hand last coupe days . It just a drop-feed walk, light-medium duty industrial . I got 10 other running machines and don't really need it because.. I got No More Room . BUT... I looked on-line and seen that there are some feet-sets still available . And the machine Bed is the 'standard' ( 18.75" x 7" ) and hinge pins are the standard spread also . Looks like it same as a couple flat-bed Consew tables I already have . So I just need to ditch the old Banjo Hinge/pins, and the Head will just drop into some other running tables I already got with just fitting a new drive belt to the 26-188 . I will just scrap trash the old sew table and clutch motor it sat on, and just keep the Head . So.. I thinking I just Keep Head only, and set-up for just doing some Piping trim. Then just keep and store it on the shelf out of the way till being used. . =