-

Posts

2,063 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by ClayB

-

From the album: Badlands Leather Art

From another of Robb Barr's patterns.© © leatherworker.net

-

From the album: Badlands Leather Art

This is another project made from a photo taken here on the ranch of a buffalo skull emerging from the side of a washout. -

From the album: Badlands Leather Art

From a photograph taken in Rocky Mountain National Park near Estes Park, CO -

From the album: Badlands Leather Art

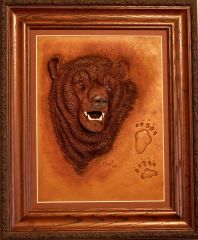

My take on Robb Barr's grizzly bear. -

From the album: Badlands Leather Art

I put the feathers on him on purpose!! -

From the album: Badlands Leather Art

This is my third version of Kate's Carolina wren pattern, started in the class I taught in Rapid City earlier this yaar. -

That's pretty awesome looking Tom!! I like the color, and the way the adjusting strap looks and the skull is pretty cool too.

-

Jim Linnell has some items for sale on his Elktracks website that would make great Christmas presents!

-

Denise wrote a step by step for loading pictures a long time back. I think it should still work after the updates to the forum. You can read it here

-

I was just wandering around the internet and saw that Silva has added a new pattern to her website along with some tracing instructions. Check it out here, Hummingbirds and Blue Glories pattern.

-

Thanks. I had looked at that before and got pretty confused, (I guess what's simple to some people isn't so simple if you are simple!) but I think I got it to work this time.

-

Skidmore's Leather Dressing is the best stuff I've ever used to soften up up leather, especially old dried out leather but it would work for this too.

-

I was using feedblitz on my blog as a way to notify people when I added a new post. A few people had asked for a feature like that and this was the one that was there on the blog site so I was using it. Now they want me to pay to use it, and the price goes up depending on how many people sign up to be notified. When there gets to be very many people the price is more than I am wanting to pay. Is there another program similar to this that is either free to use, or has a set fee to use? Or is there a way that I can set up a simple mailing list? (SIMPLE being the key word here!!)

-

You are not alone Aaron, and I think your assessment is pretty good. It's still pretty slow for me too. Maybe it's partly my computer, but it's the slowest site I go to. I've also compensated by not reading nearly as many topics or opening a lot of pictures. I know a few other people that do the same. I'm not complaining because it's still the best resource we have and I know that a lot of work has gone into making it that and continues to go into it everyday.

-

I haven't seen Shirley around here for quite awhile. I hope everything is going ok with her and that she'll see this topic revived and respond to it. The bracelets in the center picture are similar to the ones Rene Berends shows in one of his videos (used to be available from Hidecrafter, might still be) Shirley has more pictures of these bracelets on her website and in them, you can see a little better how she punched the holes for the lacing.

-

This piece of leather wont carve to save my life!

ClayB replied to anester05's topic in How Do I Do That?

I've used quite a bit of Tandy's leather and I've found that it carves better "wetter" than other leather. Some of it does cause your knife to drag quite a bit and require a lot of stropping. In my experience, the Live Oak is nicer to work with, but it seems to be a little softer leather, kind of like the difference between Herman Oak and Wicket and Craig. Once you get past the carving issue, I've been happy with how it tools and I really like how the Live Oak embosses. -

Good for you!! I bet he'd be glad to know they are being put back to use. I've got the tools my grandfather used to have and they are some of the ones I reach for the most.

-

I use kangaroo lace from Jim Downey and I dye it to get the colors I need. I would guess you could do the same with lace from Springfield Leather. Might want to ask them just to be sure.

-

untilDiscription: This is a boot and shoe last engineering course. created for making custom or model lasts. In times of old, a last was created especially for the foot pair the footwear was designed for. Continuing this tradition, we believe that good footwear design begins with the intended foot and then creating a last for it. We have optimized feet moulds and models as a beginning point to last making, and have combined scientific research done by the factories throughout the 20th century regarding proper last making theory to bring this course to you as a comprehensive instruction on last making. Our science and traditional based method of last making combined with proper lastmaking theory allows boots and shoes to be created in any heel height and toe design for beautiful walk able footwear that is truly custom. However, these boots and shoes retain the planter surface of the individual allowing a more comfortable fit and function. This process of creating a physiological/anatomical last is unique to our school. It gives boot and shoe designers a competitive edge in the comfort results to their customers and is based on traditional lastmaking practices. In this course you will learn traditional last making theory, and then how it applies to making a last beginning with a foot model. Then transform this foot model into a last that is guaranteed to replicate foot volume, breadth, planter surface replication and correction if necessary, styling, and design. By knowing these you get a better control over your designs based on what is the best look and fit, support and function for that individual foot pair. It currently remains a hand last making method and is a plastic last. This course is presented in sequence of 3 parts. Each section will be presented by different experts in thier field and by lastmakers of our school. By doing so, we bring you excellent foundational integrated knowlege. Certificate of completion will be issued at the end of the course from Lastmaking School.com Anatomy physiology and biomechanics of the lower extremities, , and how the body works with the feet, · How casting procedures assist in correcting the upper area of the lower extremities giving the last maker an winning edge in last making success, How to take a pediograph properly for analysis of gait, How to read a pediograph for valuable information in last making. You will then go on to learning Shoe fitting as it pertains to designing lasts and shoes, How to properly measure feet, Proper casting procedures for lastmaking for normal feet and problem feet How to make orthotics that relief and not damage the body followed by an overview of thermoplastics as it relates to orthothic making · Last design theory,is presented in depth with Parts of a last and how they pertain to a "walk able shoe" each part of the last is explained in detail and how the part relates to the whole. We then go on to learn how to Designing toe shapes, sole shapes,and profiles, Transforming a foot cast into a shoe shape Where to cut and adjust the foot cast for heal height, toe spring, and profile for a walk able last and shoe How to make and utilize a "trueing block" mold making techniques for copying custom and production lasts Transforming a plaster foot cast into wood or High Density Polyethylene (HDPE #2)last Special boot last considerations Prerequisite:None When: Sept 13, 2010 - November 19 2010 Class does not meet on the weekends. Class space available: 7 Extended stay Out of town accomodations are available at reasonable prices. Please contact us for further accomodation availalablity. Price: $ 5,000.00 prepayment is required for registration For more info, check out the website

-

untilDiscription: Learn how to properly make a foot impression, measure feet, Last design theory as it partains to a flat shoe,establish familiarity with foot anatomy. Since the 19th Century ( if not before) it was always prudent to get a copy of a foot before shaping a last. In this worshop you will learn proper foot casting techniques to cast a foot as a refrence for a flat shoe. Learn how to draft sole shapes for verious types of feet. Establishing Toe profiles, Shaping a last for a sandle, a flat shoe, and a thong. All in class supplies are included. Additional supplies for you to take home with you will be available for sale but are not required for class activities. If After the workshop, you are interested in a more in-depth knowlege of last making , registration sheets will be available for our consecutive courses in, intermediate last making and Advanced last making courses. Prerequisite: None When: June 1-11 2010 Class does not meet on Saturday nor Sunday.June 5th & 6th Price: $ 595.00 prepayment is required for registration For more info, check out the website

-

untilEvery foot is unique to its owners foot pair. Some feet are high arched, some are low arched some have normal arches, some feet are striaght looking others have a a "C" Shape. For which ever feet you are designing for, get a good handle on how to decifer which shape of last one should have and how to draft soles and insoles to create a custom shape for your bespoke work. Learn How many types of sole shape systems their are and which one to pick for your specific project. When: May 4-7 2010 Price: $ 595.00 pre-payment is required for registration For more info, check out the website

-

Last design theory worskshop presents an in depth look at Parts of a last and how they pertain to a "walk able footwear" each part of the last is explained in detail and how the part relates to the whole. What mistakes can be made on a last that would not be noticable if one did not understand last design theory and how to correct them. An overview of anatomy and biomechics of the lower extremities as it relates to the boot or shoe maker is reffered to in order to understand how the last get's its shape and why. When: May 3 2010 Price: $ 295.00 pre-payment is required for registration For more info check out the website

-

untilDo you have a favorate style of shoe or boot you wish you could recreate or retain it's shape but make other designs with a similar shape? In this class learn how to duplicate that last and create different toe shapes based on that particular fashion. Learn how to make a two part and/or multi part moulds. Learn what materials to use when making a test shoe last from these moulds, what materials to utilize when making the final last learn how the pro's adjust heel hieght and toe spring in a similar style. When: April 12-23 2010 class does not meet on Saturday and Sunday April 17 &18 Price: $ 950.00 pre-payment is required for registration For more info check out the website

-

untilDiscription: In this worshop you will learn proper foot casting techniques for capturing a planter surface properly. Then you will learn industry methods for how to transfer this casting technique into supportive shanks and arch support inserts. Some biomechanics of the lower extremities is presented in this class. for a more in depth education in this area, please refer to Intermediate last making. All in class supplies are included. Additional supplies for you to take home with you will be available for sale but are not required for class activities. If After the workshop, you are interested in a more in-depth knowlege of last making , registration sheets will be available for our consecutive courses in beginning last making, intermediate last making and Advanced last making courses. Prerequisite: None When: April 4-8 2010 Price: $ 595.00 prepayment is required for registration For more info, check out the website

-

untilDiscription: This workshop is designed for those interested in knowing how to shape a last. This workshop gives you a taste of what our school can offer you regarding last design. It introduces you to the physological/anatomical last that is unique to our school. You will learn one or two types out of 4 of popular industry sole shapes. for footwear, How to transform a foot model into a shoe shaped last. .We will spend lots of time shaping lasts to insure you get a good feel for last shaping. All in class supplies are included. Additional supplies for you to take home with you will be available for sale but are not required for class activities. If After the workshop, you are interested in a more in-depth knowlege of last making , registration sheets will be available for our consecutive courses in beginning last making, intermediate last making and Advanced last making courses. Prerequisite: None, but should have some knowlege of footwear construction When: March 1-12, 2010. Class does not meet on Saturday nor Sunday. March 6&7 What you will learn: workshop which introduces one to the physological lastmaking process. Price: $ 595.00 prepayment is required for registration For more info, check out the website