-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Singer 97-10 video

Gregg From Keystone Sewing replied to torrbuidhe's topic in Leather Sewing Machines

That's an AWESOME video, thanks for sharing. I have a few people in mind I would like to share this with. -

Yep, I bought another one - 111W117

Gregg From Keystone Sewing replied to dikman's topic in Leather Sewing Machines

We have four or five of these machines, sold one in the past 18 years, and the guy was looking for one and happy to have it. We were happy to sell it! It was with a 1/4" gauge, and I think the knives are available. Machine has some added stuff on it, like said, not sure at all what that stuff if about. See attached parts book and sale catalog information. 111W116,W117.pdf Singer Bridgeport Wheeler Wilson 111W Class.pdf -

I know very (Very) little about this Pfaff model, but this is the correct hook, see attached, and part of this is from the parts book linked here.

-

In this case, "N" means "New and not so improved". Juki LU-563 over the years had made three castings, including the LU-563N. Some of the the internal non consumables are different than the LU-563. I've seen next to new machines that were hardly used, and when we got our hands on them, we could see why; the machines were not working properly out of the box, something unheard of with the older LU-563s. Kindly keep in mind, this is a very limited experience we've had, but this did happen a few times. LU-563Ns were only made for a short period of time. All of that said, If the machine is setup and working great, it's certainly not at all a bad machine that you would be unhappy with. If it's working and doing great, no reason that it will not hold up as long as any other Juki. To answer you question as in terms of price, no, we would not ask or pay any more or any less for this machine than a regular Juki, even though this is the latest in the LU-563(N) series.

-

I hear that, Standard Tap is usually open all of the hour we are closed; they open at four during the week. It's funny, but Standard Tap has some of our old school sewing lamps over their point of sale terminals, or they used to anyway. I traded a handful to the one of the owners, Will, and he hooked us up big time. Sewing lamps for beer and (the best) burgers and pulled pork, works for me! This message board is the last place I though I would bring this to anyone's attention, but what a small world, really.

-

Looking for help to ID machine from ad.

Gregg From Keystone Sewing replied to Gecko's topic in Leather Sewing Machines

Looks like a 153W, the model tag is under the "S" on the arm of the machine. -

Consew 226 has three frames over the years, and some were tagged as a model 226, or 226R, and newer 226R-1. 226R-2 is I think where they left off. Consew 226, by model number ALWAYS had reverse, or it would then be a Consew 225. The reverse is going to be seen with a push down lever across the front bottom arm of the machine, with a least a silver shaft protruding from the side of the machine, below the handwheel in case the lever is missing here. Hope this helps. Quick Google search of images for Consew 226 will show this.

-

The clutch motor....

Gregg From Keystone Sewing replied to Dakotanorth's topic in Leather Sewing Machines

....And that's what we call a jackrabbit start, this occurs when the belt is too tight. Easy to do on the longer post bed machine drive belts. If the belt is too tight, it will go from 0 to 60 in no time, with very little in between in terms of a power band. Try backing off on the motor belt tension, this should help. Also...if the clutch lining (cork) is worn, or glazed over, this could be an issue, as well. Taking off the end bell of the motor to expose the cork, you can hit it with some light sandpaper to break off the glaze, and then put a thin layer of axle grease (we use Castrol multipurpose wheel bearing grease here). These two things may help go a very long way to getting the motor under control. Again, we like to sell servo motors as replacements, but people have been successfully doing may things on machines like these with standard clutch motors for many many decades without too much issue. -

On that note, a massive welcome from Northern Liberties section! 2 street for life!

-

Sewing shoe upper using a zigzag machine

Gregg From Keystone Sewing replied to George1520's topic in Leather Sewing Machines

See attached, this is what you are looking for, however, I am not even sure if this is in Seiko's production, and if so, it's big money for sure. Seiko SKZP Series.pdf -

Box X Or Bartacker Advice

Gregg From Keystone Sewing replied to suem's topic in Leather Sewing Machines

Jado Sewing is alive and well making these up these Singer 68 class conversion pattern tackers to order, for sure. Frank Friedman & Sons, Inc./Gellman are long gone, and a lot of their cam patterns were taken over by Jado as well. All I can tell you that when these machines are converted, they are built from cam up. These machines are really only going to do what the cam is cut for, so if the actual pattern is not what you are looking for, it's not at all like you can go out, have a new cam cut, swap it out, and start to do something different. These machines do not work like that. The nice thing about these type of machines is that they are very capable of sewing heavier threads and materials, think of like cargo nets with a box cross pattern for example, or a WW pattern for a seatbelt. -

Durkopp Adler 8967 issues

Gregg From Keystone Sewing replied to BurkBags's topic in Leather Sewing Machines

I may be incorrect, but it sounds like it's jumping to the longest stitch length because the control box is telling it to do so? Just a guess tossed out there. What model is the motor? -

Don't know why folks are referring to the LG-158 in the past tense, this is still a new, current model machine from Juki. Just to put it out there, LG-158 is not a direct copy of any Singer 144W / 145W type machine, however specs are nearly identical. I don't think I've ever seen anything but a 30" LG-158, where Singer had thier models in 10, 20 and 30" types, as well as Consew/Seiko who now have 20 and 30" only.

- 24 replies

-

- juki

- consew 206rb

-

(and 1 more)

Tagged with:

-

How to attach a binder to a Singer 111W155?

Gregg From Keystone Sewing replied to Willie0's topic in Leather Sewing Machines

Thanks for the kind words, I love to share information like this, and hope it helps. -

How to attach a binder to a Singer 111W155?

Gregg From Keystone Sewing replied to Willie0's topic in Leather Sewing Machines

If you are drilling and tapping holes into the bed of your machine, you're doing it wrong. I made and attached an image of Juki with LU-563 with proper base plate from T/A, 460-563J mounted using 200095 Set Screw. No mods, direct bolt on from the supplier. Hope this helps. -

Can you help me Identify this Consew?

Gregg From Keystone Sewing replied to Tim321's topic in Leather Sewing Machines

It's appears to be a Consew 205RB, made in Japan by Seiko. BUT...now I'm not so sure, this machine does not have the 205RB oil pump with oil pan. New models are white, this is hammer grey. Here are the books; CLICK HERE for Consew 205RB Parts CLICK HERE for Consew 205RB Owners -

Pedal for Servo Motor? Mine is missing.

Gregg From Keystone Sewing replied to Ian1783's topic in Leather Sewing Machines

-

Machine help- too much good info- please.

Gregg From Keystone Sewing replied to Brad2017's topic in Leather Sewing Machines

1181 is a a top bottom feed only, not a true walking foot. Needle is fixed, where a true walking foot has top, bottom and needle feed with alternating presser feet. Consew 206RB-5 is a bit less money than the Juki, but the Juki DNU-1541S runs a bit smoother. You can save $100 by getting one without safety clutch, but I don't, at all, recommend that. Both are very reliable, great machine designs. Hope this helps. -

manual presser foot lift on JUKI LU 562/3

Gregg From Keystone Sewing replied to mixmkr's topic in Leather Sewing Machines

Juki LU-562-3 Product Brochure Click above for factory specs, Presser lift at hand lifter is 4mm (11/64"), and 10mm (25/64") by the knee lifter. BTW, the brochure is old literature on file from when we, Keystone Sewing, were located in a different part of the city (Olde City to Northern Liberties to be specific). Our name was different, too, started out as ABCO Sewing Machine Company in 1977. I guess that dates this brochure as being new at least from 1977 to 1980. -

male hinge for Singer 107W1

Gregg From Keystone Sewing replied to mixmkr's topic in Leather Sewing Machines

Table top may have been cut for a Singer 95 class. -

male hinge for Singer 107W1

Gregg From Keystone Sewing replied to mixmkr's topic in Leather Sewing Machines

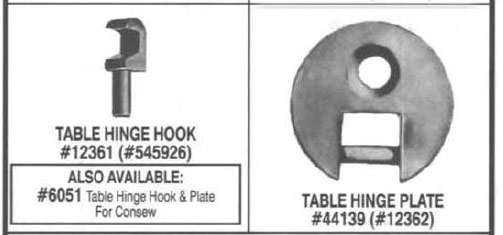

Exactly, most LU-562 machines would use this table hinge hook and table hinge plate (12361 & 44139) when new at that time on a green or tan table top. -

male hinge for Singer 107W1

Gregg From Keystone Sewing replied to mixmkr's topic in Leather Sewing Machines

Ahhh, that's not going to work; the 107W uses the same hook with two set screws as in the other image on the other thread, the table hinge is for a different style machine, table could have been cutout for a Singer 95 or something. Singer 107W does not have a spot to put this table hinge hook in, see attached. -

image.jpg

Gregg From Keystone Sewing commented on LeHoang's gallery image in Gallery- Our Leatherwork