-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

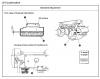

1st things first, we really need to go in and replace the broken tension release slide. After that, I'll bet someone here $1.00 I know what the issue is here with the needle bar frame feed dog hook thing. Seeing the video at 1:26 you can clearly see from the side the needle playing catch up. View attached image, then remove the gib, turn this over by hand and you'll see this problem disappear. If so, this means the gib is too tight. It can take a few tries to get this set correctly. On the longest stitch length setting, we set this by putting sewing oil all around the contact point between the gib and rock frame. When the gib is set correctly, you should be able to see an oil ooze out from around the gib with no real feel of side to side play by hand as the frame sweeps front to back. If you don't see this it means the gib is too tight, and is going to lock up and have to play catch up with the feed. Hope this helps!!

-

Juki Lu-1508 Walking Foot

Gregg From Keystone Sewing replied to stoner14's topic in Leather Sewing Machines

-

Info Needed On Singer 236G124

Gregg From Keystone Sewing replied to DarkHorse's topic in Leather Sewing Machines

The funny thing I find in some of the Singer books is that they list very specific models for very specific applications that I again, also, have never heard of. Why make a machine if there is no application for it? Singer really did set the standard, and many of these odd ball models were sold in larger quantity than many of the popular model machines today. Or, Singer would have discontinued them for lack of demand. -

Info Needed On Singer 236G124

Gregg From Keystone Sewing replied to DarkHorse's topic in Leather Sewing Machines

Here is all I have on this guy, I'm always interested when a Singer model pops up that I have never seen or heard of. Inquiring minds want to know! See attached. 236W.pdf -

This question comes up often when I speak with customers. What Eric is saying is 100% on point, when it comes to French Seams like in the pic above. The other thing that very important to consider is that if you don't have a single needle, how are you going to do cording or welting? How about zippers? I've cut down presser feet for people who want to do this anyway on double needle machines, and they understand and are willing to make the trade off. But, like Eric, would also tell you, you really would want two machines in the ideal world for this. It's up the the end user to determine what's thier best option when making a trade off. Generally, I recommend a single needle 1st, then a double needle after that.

-

Something Wrong, What Do You Think?

Gregg From Keystone Sewing replied to alexitbe's topic in Leather Sewing Machines

Always learning something new here, never heard of a 38-6, but have seen many 138- machines. And I thought the 138 was really old! The 38-6 will be around as long as any machine if it's anything like the 138s. -

Threading A Singer 7-5

Gregg From Keystone Sewing replied to Kiwishovel's topic in Leather Sewing Machines

https://www.youtube.com/watch?v=zKz-muyWjic&list=PLs4kDUDTR35W1oUpNYmXX6hYQI5GubWOb&index=7 I did this for a Consew 733R / Seiko SLH-2B machine, most of this threading should be the same or similar enough to get you through. I hope. -

Clones And Originals

Gregg From Keystone Sewing replied to PineyWoodsRooter's topic in Leather Sewing Machines

Game of Thrones and sewing machines both in the same sentence. Who knew? Nice example as well! -

Agreed, the Family FESM-550S or the like (there are many) is a very good motor, and would work great on this model, among others.

- 8 replies

-

- juki lh-515

- juki bobin case opening timing

- (and 3 more)

-

Any Value To A Clutch Motor?

Gregg From Keystone Sewing replied to Colt W Knight's topic in Leather Sewing Machines

Same here, kind of like CRT televisions, you just can get rid of them without throwing them away. -

Ron, Your website is looking great, good job!

-

Can You Identify This Singer?

Gregg From Keystone Sewing replied to MoMatt's topic in Leather Sewing Machines

Ahhh, the ball bearing trick, higher speed, higher performance... Kindly of like all the burned out 143Ws that were supposed to perform better than the 107Ws, that never really seemed to. -

441 Clone Outside Presser Foot Screw

Gregg From Keystone Sewing replied to TinkerTailor's topic in Leather Sewing Machines

<sarcasm>Funny, I've never lost a screw while working on a machine.</sarcasm> -

Can You Identify This Singer?

Gregg From Keystone Sewing replied to MoMatt's topic in Leather Sewing Machines

Singer 400W class, rotary take-up, pain in the butt, we threw away many of these long ago when we last had a dumpster at our building. -

How Not To Respond To Advice

Gregg From Keystone Sewing replied to Darren Brosowski's topic in Leather Sewing Machines

Wiz and Art, I'm laughing out loud reading that. New and improved, PM Wiz both for sewing equipment and now bdsm gear! -

How Not To Respond To Advice

Gregg From Keystone Sewing replied to Darren Brosowski's topic in Leather Sewing Machines

This is a story for a different day, but this is also why customers lie. Person shows up with a sewing machine, and tells me that it was working, it does not need much, but just get it up and running; don't put a lot of money into it. Guy then asks "What can I get for this on Ebay?" like I set the market prices. Oh, and BTW, this machine was missing a complete tension, an other critical working parts, it was not sewing. Just like the car he drove up in was not missing three tires, an engine, a transmission, or whatever else. Like we don't know what we are doing here. Like TinkerTailor said, all I'm pointing out is that situations like this truly are a two way street, if it's going to work, and the approach by the customer can have a lot to do with it. I can say with this one example, in this case, no, I was not highly motivated to help this customer in this particular case, sorry to say. -

How Not To Respond To Advice

Gregg From Keystone Sewing replied to Darren Brosowski's topic in Leather Sewing Machines

It's new school vs. old school. The story goes like this; I know by word of mouth where a customer once called "I have one of your machines, with your name on it." Dealer asks "OK, where did you get it from?" "I bought it at auction." says customer. "OK, then I can't help you." [click goes the telephone as dealer hangs up] It's a different time, guys like my Dad would be accustomed to loyal customers who would buy equipment, parts and supplies for life. They would get deeply offended and jealous when you would buy from another dealer or supplier. I have options just like you do when I buy. Often, we would 'win' these customers simply by acting in an altruistic behavior, and most often it comes back to us somewhere else. If I can't help, I'll not to dead end someone and help them find the help they can use. It's not at all uncommon for sewing dealers to act outside of social norms, and my dad's favorite stories were where he was throwing someone out of the shop. I've heard of other dealers throwing out customers (literally) by their belt loop. So it's not you, it's us. -

Hirose Rotary Hook For Cobra Class 18 Machine

Gregg From Keystone Sewing replied to ant's topic in Leather Sewing Machines

This thread contains a lot of incorrect information; Cobra 18 stock hook Koban Mfg. part number is KHS20-RM2, not KHS20-RPEM2AO like the Consew 206RB or Seiko STH-8BL type. Koban part number for bobbin case also is SC33-L, NOT same as Consew/Seiko SC33-LD. Cobra 18 stock hook from Hirose is mfg. part number HSM-A, NOT HSM-A(5) like the Consew 206RB or Seiko STH-8BL type. Hirose part numbr for the bobbin case BC-DLN, NOT same as Consew Seiko BC-STH. Hope this information helps correctly replace your hook and bobbin case when necessary. -

I'm taking a wild guess, but I think I've got it. If you have a 226R, a machine like this is going to have a standard clutch motor. On the control box, when they break, the switch box will not switch to 'ON" and stay on; it will only make contact when being depressed, but will not stay depressed, the way the on button should. What do to? Get a new box and replace it with a new one. Normally, when ordering, T75 is for the box only, T75C is the same box, but with wires, as seen in attached pic. You should be able to find these all over the place on the web.

-

Singer 211 (G156) Question

Gregg From Keystone Sewing replied to Kwild's topic in Leather Sewing Machines

These lifting lever arms on the 211s really are not a copy of anything else are really are proprietary to the 211 series. Singer 111W had many copies of Japanese that would swap out in some cases, but not this here. Best best, like said, is to find the same parts from an old 211, but this means robbing Peter to pay Paul, so to speak. Keep in mind, not all lifting levers are the same from 211 to 211 subclass, so be careful there, too.