-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Thread Lube?

Gregg From Keystone Sewing replied to Gregg From Keystone Sewing's topic in Leather Sewing Machines

Thanks for the input, Eric put a lot of information down there. I'm really surprised about using lube on denim chainstitch machines. I wouldn't think this would help at all, but I don't really know production equipment for denim that well, it's really specialized equipment when you really get into it. Not everyone wanted to work on feed off the arm Union Specials, they were a specialty. -

I'm interested in learning a bit more about thread lube and who uses it. The idea for this is that it helps prevent thread breaks, skipped stitches, snagging, and heat build-up in difficult sewing situations. Normally I don't recommend for people to use it over all in general, but this may be a mistake.

-

Manufacturer's Mark on Sewing Machine Hooks

Gregg From Keystone Sewing replied to Uwe's topic in Leather Sewing Machines

-

Laser guide for Cowboy 4500?

Gregg From Keystone Sewing replied to bartleby's topic in Leather Sewing Machines

If you like, I can sell you the same thing, made specific for the needle trade, only costing 1,000% more! -

Consew 206-Rb5 With Speed Reducer

Gregg From Keystone Sewing replied to mcn's topic in Leather Sewing Machines

Ha, that's great, and I'll bet works very well. -

Need 206RB help, advice

Gregg From Keystone Sewing replied to Dave4's topic in Leather Sewing Machines

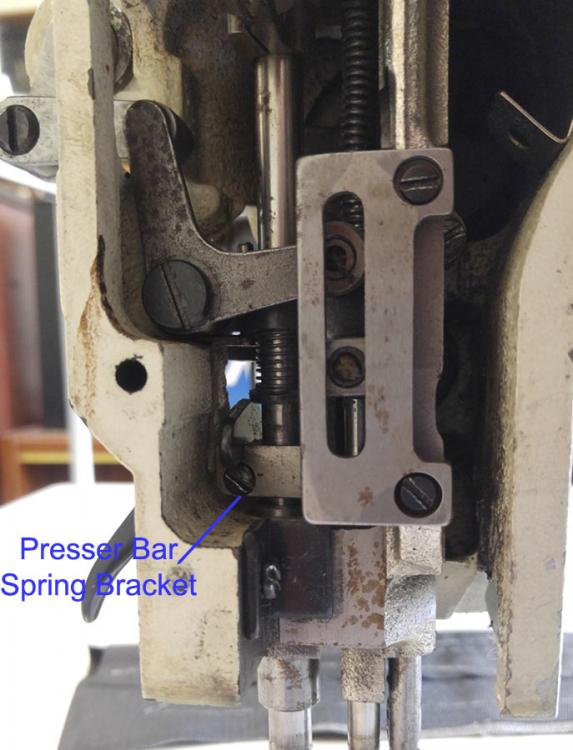

See attached, your presser bar spring bracket is incorrectly adjusted. This is not in the book so here it goes; The bracket, if not adjusted correctly, will bottom out, and relieve proper presser bar spring pressure. Make sure that, with the presser feet down in a normal sewing operation, that the bracket clears both the presser bar bushing as seen in the picture, and also clears your machine's frame. This will provide constant pressure to the presser bar in order for this to work correctly. To adjust, cycle the machine by hand to where both presser feet are in contact with needle plate and feed dog, use a flat head screw driver to loosen the bracket clamp screw, lift the still under spring pressure bracket, also with a tool, I would use a flat head screw driver also to lift and then and the same time tighten with another screw driver the bracket screw. -

Need 206RB help, advice

Gregg From Keystone Sewing replied to Dave4's topic in Leather Sewing Machines

I've attached the part of the owners manual that 'explains' how to adjust this feed fork. Pretty useless, but here it is! Like CowboyBob, set this so there is at least oil clearance. -

Getting Control Of Your Servo

Gregg From Keystone Sewing replied to Evo160K's topic in Leather Sewing Machines

That's GREAT, I've tried this a few times on my own without any success. After viewing this, I'll definitely try again. -

Restoring a Singer 7-33

Gregg From Keystone Sewing replied to sabre1700's topic in Leather Sewing Machines

We do have these in stock, along with any other parts for a Singer 7-31, 7-33, or 7-34 model. We fully support this machine, sales, support and service.- 2 replies

-

- restoration

- 7-33

-

(and 2 more)

Tagged with:

-

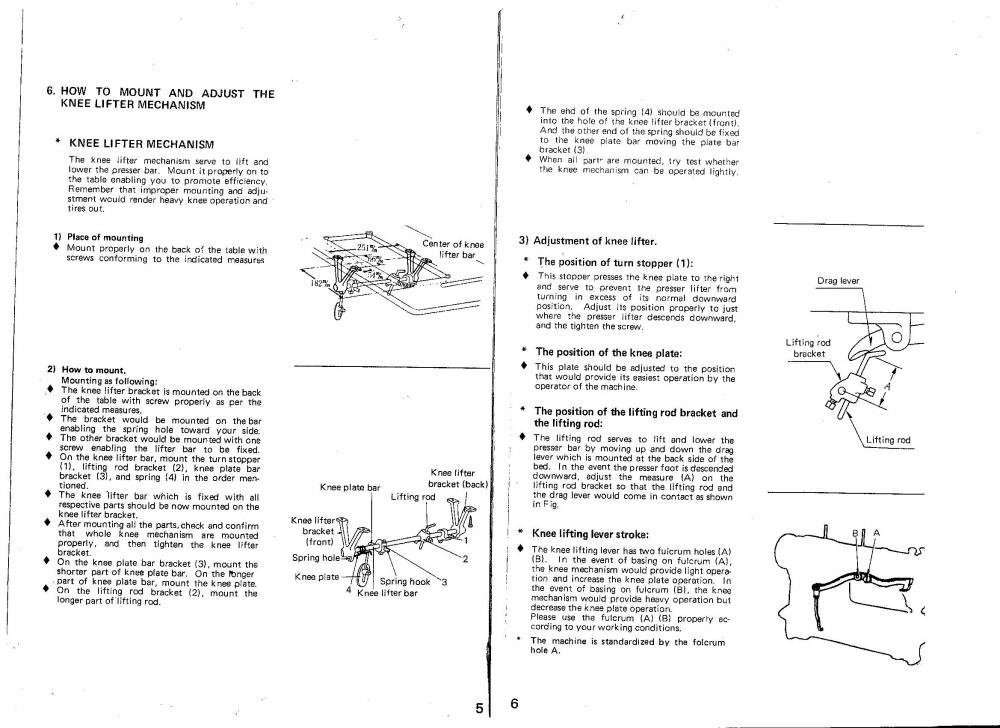

These knee lifters are a total pain to install correctly, and I've installed a lot of them. They either want to hit the drip pan, hit the bell crank off the roller, all kinds of stuff. It's not fun to be stuck up under the stand to make these adjustments the way you need to on the machine. See attached, make sure that we have the knee lifter bracket "A" arms mounted in such a way so that it engages the bell crank on the machine head correctly. Also, pay close attention to the bend on the "Lifting Rod", see attached image, that pushes the machine's bell crank, we usually like to bend these in a vice close to a a 90 degree. It's really a see touch feel thing, but I think if you check the A arm alignment this may help a lot here. Hope this helps.

-

I just sold two for just above scrap prices, as is where is. Customer said he popped them onto his existing tables and they worked like a charm. We both couldn't be any happier.

-

True that, we don't claim to service or support Reece S2s or 101s. We used to have a guy who worked for Reece for many years, and would do some work for people in the area, and we would go through him when he was available. I love getting into things myself, and have never turned a screw on a Reece machine. As a matter of fact, I can't think of really anyone who wants to or is willing to get into service or support of these models. This must be factored in when trying to get started with a key hole button hole machine.

-

Walking Foot Material Feed Problem -- Shifting

Gregg From Keystone Sewing replied to JJDD's topic in Leather Sewing Machines

This is what I was thinking as well. Often the presser feet and feed dog do not match, and the points of contact tell the story. On some feed dog and presser feet combinations, the feed dog and presser foot are not even or hardly coming in contact with each other. This happens often with cording or welting feet where the foot print is smaller. Again, this depends on the setup, not machine, if you will.- 20 replies

-

- edgesewing

- materialfeed

-

(and 2 more)

Tagged with:

-

I'm using Web.com for hosting and email, and yes, they also have a maxiumum limit of 500MB, that sounds like a lot, but it's really not. Then, if I push it up to one gig, it becomes more difficult to delete and clean up due to...the file size. I've even deleted the account and recreated it, just to get rid of the emails.

-

Bobbin Issue - Juki 1541S

Gregg From Keystone Sewing replied to piera's topic in Leather Sewing Machines

Piera's pics above tell most of the story. -

Bobbin Issue - Juki 1541S

Gregg From Keystone Sewing replied to piera's topic in Leather Sewing Machines

Machine has been repaired and is ready for pick up. -

I fully agree with everything being said here in terms of oil, BUT if you really must, why try and find 'the equivalent' and just buy what you are asking for? Juki part number is MDFRX2700C0 for NEW DEFRIX OIL NO.2, comes in a 700ml bottle for about $20. Not the best 'value' as a gallon of stainless lilly white is about the same price, but if you want OEM original, get the Juki oil for peace of mind.

-

Bobbin Issue - Juki 1541S

Gregg From Keystone Sewing replied to piera's topic in Leather Sewing Machines

Piera sent some pics to us yesterday, I logged on this morning and then seen the hook image in the top gallery. Now the machine is in here this morning for service with us! Small world, we usually check this before machine leaves when we sell these as this is a known issue, but this 1451S was not purchased by us, just for the record! -

Singer 7-33 Stitching problem & parts

Gregg From Keystone Sewing replied to hackish's topic in Leather Sewing Machines

We normally put these into our 1960s Bridgeport to cut the frame away, but hacksaw has and may be done in the future as well! I've seen my dad cut the frame away on these with a hacksaw more than once, and is perfectly acceptable. Looks like someone did this highlift with a hacksaw as well, and machine may have shown up to us in that condition. Kindly note this is not the only thing we do to get this machine to one inch of presser foot clearance from Singer factory standard 9/16" -

Singer 7-33 Stitching problem & parts

Gregg From Keystone Sewing replied to hackish's topic in Leather Sewing Machines

Sweet, it takes effort on both sides, and you were able to understand and articulate what parts you were after to make this machine work. You never know how these things are going to go when I send out parts and someone else does the work, glad I was able to be a part of getting your machine back up and running. -

Good info., first thing I would look at is a top and bottom feed zig zag, here are two; Consew 347R Series (WS is for wet suit) feed off the arm type Consew 146RB-1A-1WS flat bed type