-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Gregg From Keystone Sewing

-

You can see the 241- variances on the attached pages from the Singer catalog. Singer241Class.pdf

-

111w154 stitch will not go to 5/inch

Gregg From Keystone Sewing replied to MDuggan's topic in Leather Sewing Machines

Easy enough, I wonder if anything else is going on with the feed that would prevent that from going to the maximum.- 6 replies

-

- compound

- stitch lenth

-

(and 1 more)

Tagged with:

-

111w154 stitch will not go to 5/inch

Gregg From Keystone Sewing replied to MDuggan's topic in Leather Sewing Machines

Singer 111W154 Max five stitch to the inch. It's possible that you are reading off the stitch length dial indicator; get a ruler, and count the stitches again they may be 5 SPI.- 6 replies

-

- compound

- stitch lenth

-

(and 1 more)

Tagged with:

-

Juki LU-2810S

Gregg From Keystone Sewing replied to alpine luddite's topic in Leather Sewing Machines

Juki LU-2800 series are really nice, if you think it's what you are looking for, I would jump on one for sure. -

Need help with Singer 7-33

Gregg From Keystone Sewing replied to Cferna27's topic in Leather Sewing Machines

35007 Consew Seiko balance wheel will work as a direct replacement here, all the same as the older cast iron spoked handwheel. -

Help with a Juki 562

Gregg From Keystone Sewing replied to freeturns's topic in Leather Sewing Machines

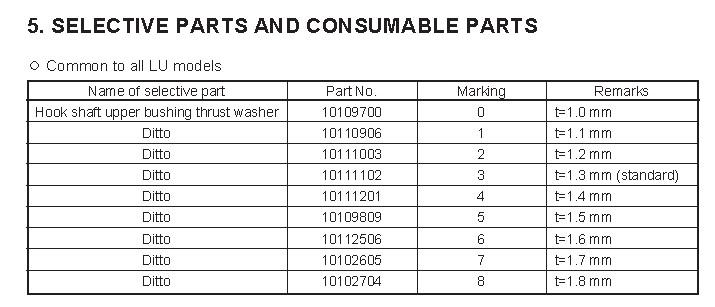

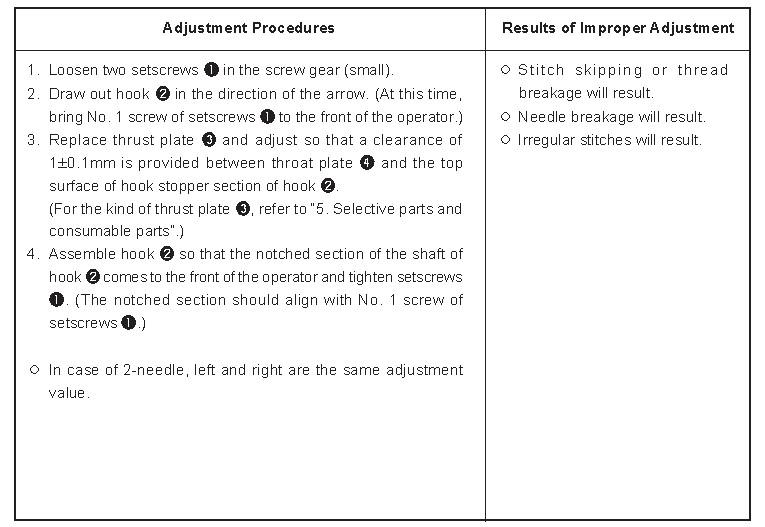

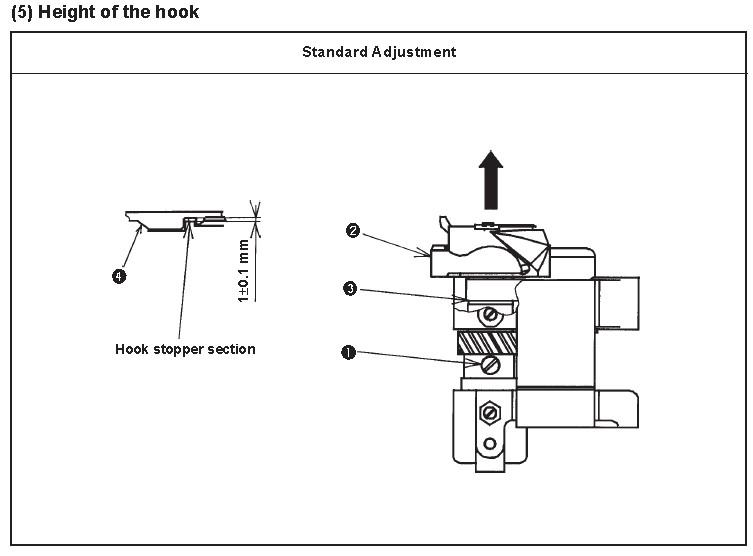

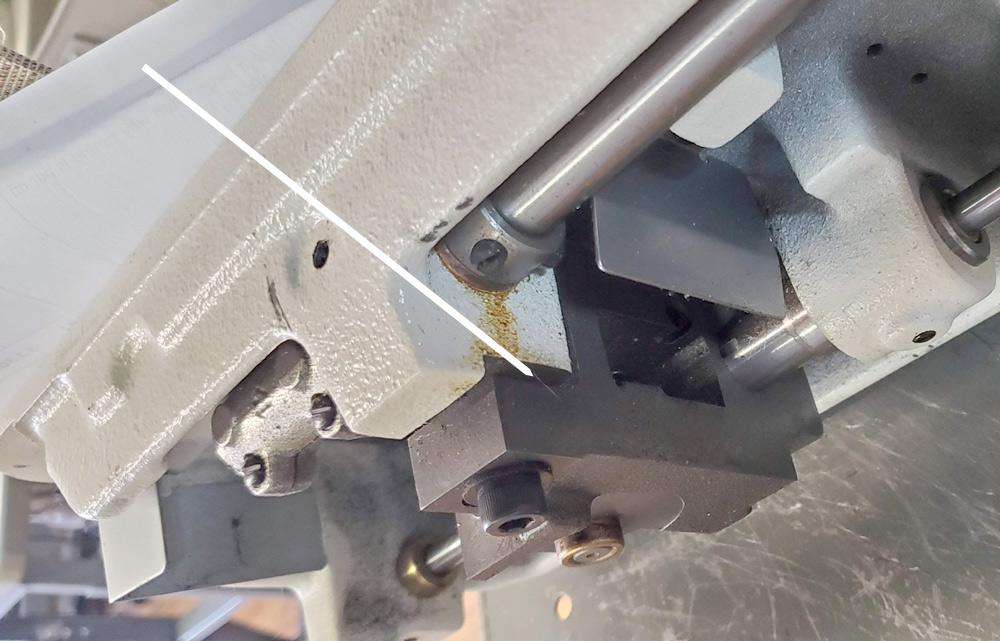

Juki offers a various size thrust washers, see the chart for reference. HOWEVER, standard is 1.3mm, and thinnest is 1mm. I really doubt this is going to get it to where we want it, but I would check the thrust washer thickness to make sure it's not way out of bounds. Another way to fix this 'out in the field' is to jamb something between the hook saddle and bed frame to bring this hook lower. Plastic from a milk carton comes to mind. You would not be the first or the last person to fix a machine of this type like this. -

JUKI 563 thread snagging on bobbin case

Gregg From Keystone Sewing replied to matcanada's topic in Leather Sewing Machines

BTW tell matcanada to give you your bobbin case opening lever back. -

JUKI 563 thread snagging on bobbin case

Gregg From Keystone Sewing replied to matcanada's topic in Leather Sewing Machines

You have no idea how much great information you just gave me to bounce off of. Needle plate to hook height can be an issue as well as burs. The LU-1508 Engineers manual will cover this. As for hook timing, this is how you do it on an LU-563; set the stitch length to zero, move the needle up 2.3mm from bottom dead center, moving the hand wheel counter clockwise until the hook point is center line with needle, your hook timing is now set. Your not just timing the hook to needle thread pick up; you are also timing when the hook will release the thread to start to form a loop. 1% off from this is 1% away from the ideal machine setup, even if you've exhausted all other options and settings. Even then something else is likely wrong. The timing is the timing, until it's no longer the timing I guess we can say. If this is set incorrectly, yes, for sure you may hear the thread snapping across the top of the hook as it tries to release. Perfect example. Here comes the best part, I understand and agree 100% about what you say with pre wound bobbins. Some people have experience with pre wound bobbins only, like embroiderers. Most embroidery machines do not even have a bobbin winder. Some sewers have only seen metal, and some mix and match. Without going into the benefits and perks of using steel vs pre wound bobbins, they both can provide sewing issues that can be vastly different from one another, even if the machine is 100% tip top. Pre wound bobbins are not going to unravel as the thread tends to stick to itself as part of the manufacturing process and tend to be lightweight. In contrast a metal bobbin wound with a polyester or synthetic made PTFE thread wants to kink up and unravel by nature. The only example that I can think of and just made up on the fly here is that if you take both of them and fling them across a room, the pre wound will maybe get a foot or two, where you send a metal bobbin to the other side of the room and out the door. Big difference when sitting in the bobbin case as you sew along. One other thing to consider is that with a fully threaded steel bobbin, many electronically controlled machines with needle positioning, the hook tends to come to very quick starts and stops when in use. This is why if you check out many model machines that are plain mechanical and then available full function, they often have two different part number bobbins. One is steel, the other aluminum. Keep the weight down and prevents over spinning. Add in an anti back lash spring and there's not much else that can be done that I can think of. Hope this give some things to think about and thanks to DC for the excellent lead in. -

JUKI 563 thread snagging on bobbin case

Gregg From Keystone Sewing replied to matcanada's topic in Leather Sewing Machines

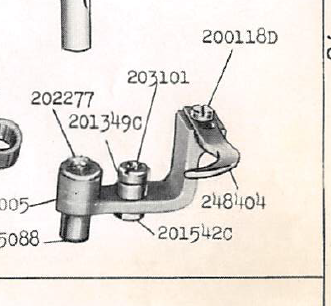

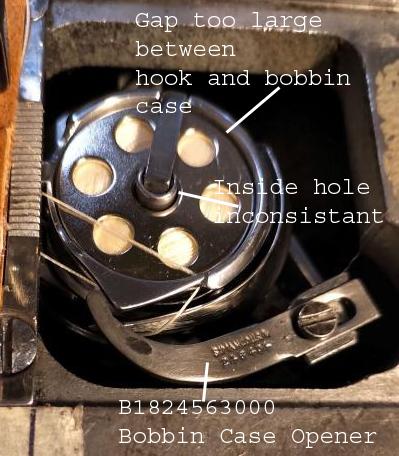

As I suspected, the bobbin case opener is for a small, or regular bobbin, or G bobbin size. This image below appears in the Singer 111W151 parts book. I would get the correct opener in there, especially if you are having sewing problems. -

When you have the correct motor setup, you are really only limited by your imagination. At that point and it's easy to tailor something to someone's particular needs. If you have a servo motor with an external actuator, you can mount it as a knee switch under the table and make something up. If you go with a higher end motor like an Efka you can have multiple input and output buttons to help make up for things like needle up position, or whatever else you can think of. Brilliant minds think alike (or at least people who watch YouTube videos about sewing machines). 1st thing I thought of.

-

JUKI 563 thread snagging on bobbin case

Gregg From Keystone Sewing replied to matcanada's topic in Leather Sewing Machines

I see two important things to look at here; There is a Simamco Singer bobbin case opening lever, this is very likely for a small or regular bobbin machine, like a Singer 111W155 or Juki LU-562. I can't read the number well enough, but I'm willing to guess this part didn't come off of say a Singer 211 with large bobbin that may work, but not likely. See correct Juki part number for this, very common part anyone can find on the internet for under $15 or so. ALSO, onto the bobbin case issue. This is becoming more common as the quality of some of the bobbins are suspect. Poor quality with tolerances all over the place. The OD of the bobbin as well as the inside hole can be all over the place, and I should know because I sell them too and see them come in and create issues like this. What happens is when the machine comes to a stop, the bobbin wants to keep spinning, and the thread pops out of the side of the bobbin. Then you go to sew, and its tangled up in the hook are and latch. Also, dropping in an anti backlash spring with a good quality bobbin may help here too. This is a VERY common hook and appears on many various makes and model machines, so finding genuine Juki or better quality parts will go a long way. This is not the 1st time I've had issues with cheap bobbins messing up the whole show. -

Adler 205 MO 25 SF Questions

Gregg From Keystone Sewing replied to Cferna27's topic in Leather Sewing Machines

Dial appears to be a rheostat for a heating element. Not sure why they would want or need it, but I also don't know a lot about shoe manufacturing either, so take that for what it's worth. -

Help with a Juki 562

Gregg From Keystone Sewing replied to freeturns's topic in Leather Sewing Machines

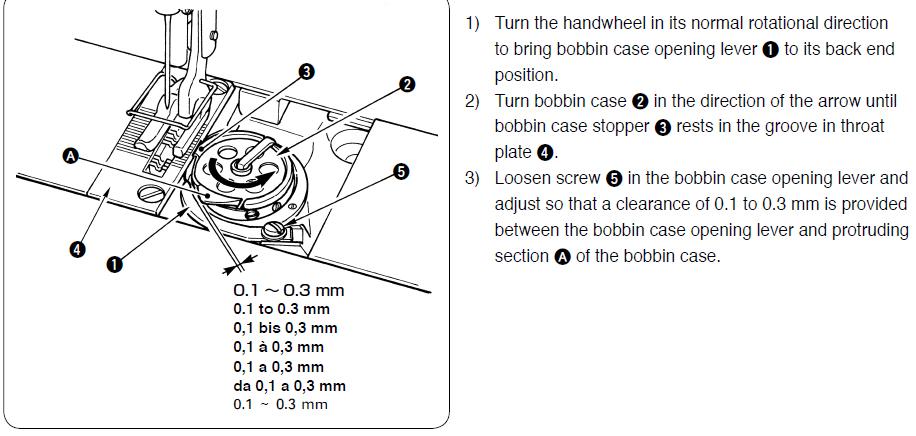

Slide plate appears correct, looks like part number 240003, same as Singer 111W, should work 100% no problem on LU-562. Information about the hook height adjustments are elusive, check out this from LU-1500N series, this may help give some indicators on how to adjust this. LU-562 book does not include this. -

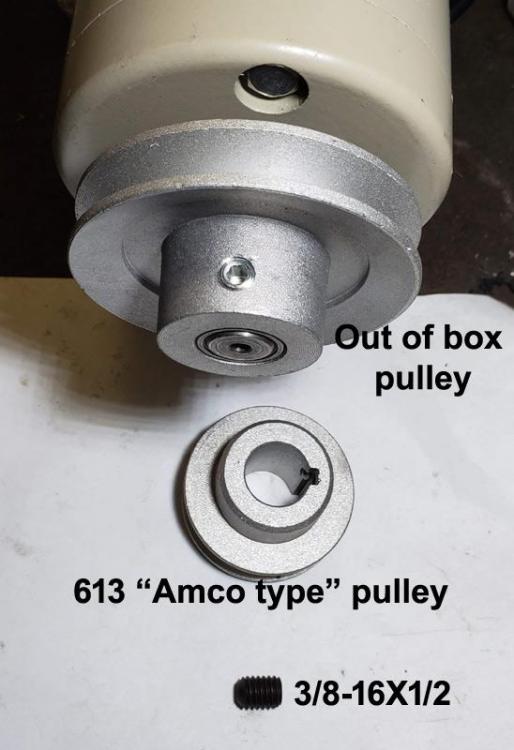

Changing pulley on a Family Sew motor

Gregg From Keystone Sewing replied to mcdoug's topic in Leather Sewing Machines

-

Best Juki LS 341 Clone?

Gregg From Keystone Sewing replied to punitor1's topic in Leather Sewing Machines

True story. However, many Japanese machine are still far more expensive, even with 25% increase, depending on model -

Best Juki LS 341 Clone?

Gregg From Keystone Sewing replied to punitor1's topic in Leather Sewing Machines

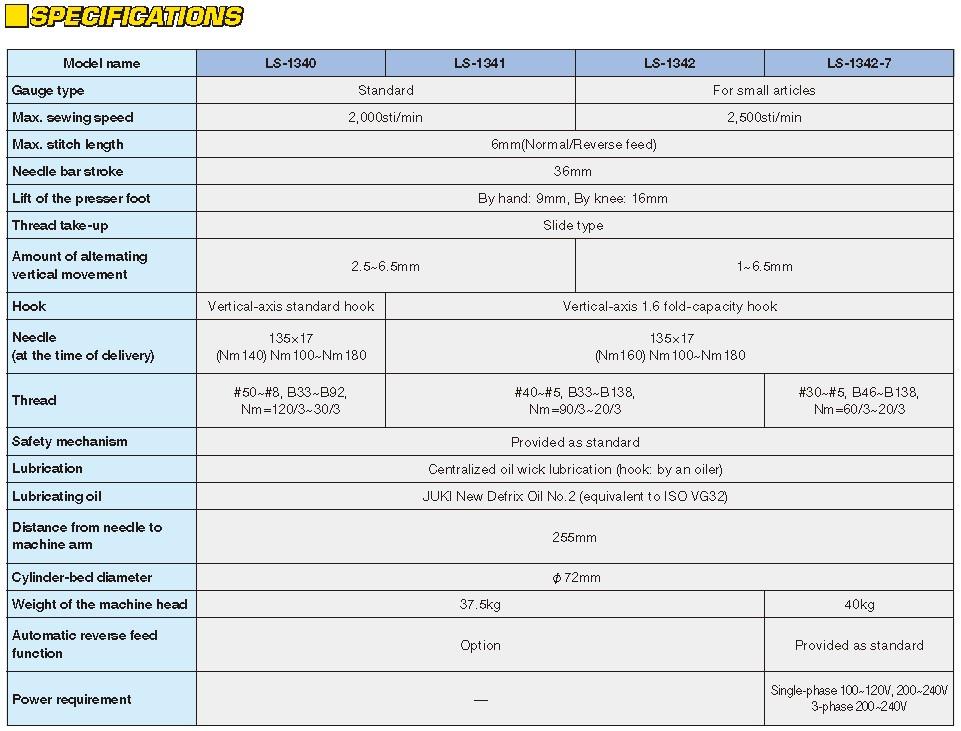

Are you referring to the genuine Juki LS-1341 series? As per spec, all four subclass machines max out at 6mm forward/reverse stitch length. However, there are some knock offs with 8mm, say Typical GC2263-1 is one of them. Hope this helps add to the conversation here. -

Best Juki LS 341 Clone?

Gregg From Keystone Sewing replied to punitor1's topic in Leather Sewing Machines

Merrow is still manufacturing in the US, not like they used to but they are still doing stuff worldwide. I'm not quite sure about where Union Special is being made at. I can't think of much else off the top of my head as I type this. -

Best Juki LS 341 Clone?

Gregg From Keystone Sewing replied to punitor1's topic in Leather Sewing Machines

I agree that DNU-1451 series price genuine vs. clone is close enough to consider both at least if you will. However, the price difference between the Juki LS-1341 and clones...can be substantial enough to consider a clone in this case here. -

Stitch length maxes out too early

Gregg From Keystone Sewing replied to cumberlandharp's topic in Leather Sewing Machines

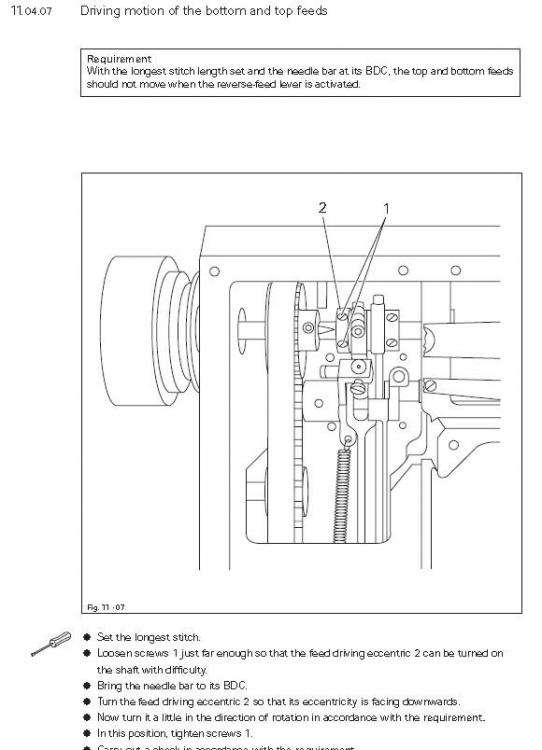

Make sure that the crank clamp with the limit screws is set correctly to give both the possibility of a 4mm SPI in both forward and reverse. It could be set so that the crank is going to give for example 6mm in one direction and 2mm in the other, if that makes sense. -

Singer 531b-8bl Info

Gregg From Keystone Sewing replied to LivnDream's topic in Leather Sewing Machines

Seiko STH-8BL, also known as Consew 206RB-2 (oil system) machine. At this time they were sold, for a short while, by Singer as a 531B-8BL. Again, NOT a copy, the real deal Seiko made in Japan. Singer 531B-8BL Parts