-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Gregg From Keystone Sewing

-

Ferdco Pro-2000 ... Which Machine Base?

Gregg From Keystone Sewing replied to bcurrier's topic in Leather Sewing Machines

This is the one we were emailing about, looks pretty good. -

consew Consew 206RB-5 setup?

Gregg From Keystone Sewing replied to DacianFalx's topic in Leather Sewing Machines

Correct, replacement break lining cork and motor brushes. Even in production, these should not be needed for quite some time.- 9 replies

-

- 206rb5

- sewing machine

-

(and 3 more)

Tagged with:

-

Eagle walking foot info needed

Gregg From Keystone Sewing replied to BatCity's topic in Leather Sewing Machines

Eagle brand machine sold by Hoffman Bros. made in Taiwan. The quality of the machine is good. -

-

Maybe it's possible someone is confused where they installed a single presser foot for drop feed use?

- 21 replies

-

- 111w155

- needle feed

-

(and 1 more)

Tagged with:

-

Consew 206RB-4 Reverse Stitch Length

Gregg From Keystone Sewing replied to garypl's topic in Leather Sewing Machines

It's kind of locked in without anyway to adjust this area. I would look for something else here, really have to see the machine. -

Modifying Juki 563 For Larger Thread.

Gregg From Keystone Sewing replied to johnbigsby's topic in Leather Sewing Machines

They are 100% interchangeable from LU-563 to LU-1508, just as long as the see attached. KobanHookPages.pdf -

Instruction Manual for Consew 206RB-1

Gregg From Keystone Sewing replied to JJN's topic in Leather Sewing Machines

Glad to help, much appreciated. -

Consew 206RB-4 Reverse Stitch Length

Gregg From Keystone Sewing replied to garypl's topic in Leather Sewing Machines

This is one rare case that a 206RB-5 does not have the same adjustment than the -4 models. They are very different, see attached parts page for the -4 machines. 206RB-4Parts_Pages.pdf -

Instruction Manual for Consew 206RB-1

Gregg From Keystone Sewing replied to JJN's topic in Leather Sewing Machines

See attached, they really don't have a different book other than this addition. Some models with -1 and all models with -2 had the oil system, so it's confusing. This book is stamped with ABCO, our former company name from 1977~1980 before we became Keystone Sewing, so this is some type of indicator as to when this machine was new. Consew206RB-1SupplementaryInfo.pdf -

The clutch motor....

Gregg From Keystone Sewing replied to Dakotanorth's topic in Leather Sewing Machines

Uwe, No secrets here, modified PF-2 is what I use for this setup. I don't do anything with how the mechanism works, but I do some customization to the mounting bracket to get the proper height for the machine it's being installed onto. The rod eye, aligning coupler and linkage is something I put together here. -

The clutch motor....

Gregg From Keystone Sewing replied to Dakotanorth's topic in Leather Sewing Machines

There are more than one servo motors on the market that are on the less expensive end that have a 24V output like this, Consew had a CS-3001 model, however we no longer carry this one. Of course, Efka and Mitsubishi motors have these type of outputs as well. -

The clutch motor....

Gregg From Keystone Sewing replied to Dakotanorth's topic in Leather Sewing Machines

Could be. Or it could be used to do this, YouTube demo of SP-1100NPFL 24V output signal -

Consew 226/Singer 111W Backfeed

Gregg From Keystone Sewing replied to Framsden's topic in Leather Sewing Machines

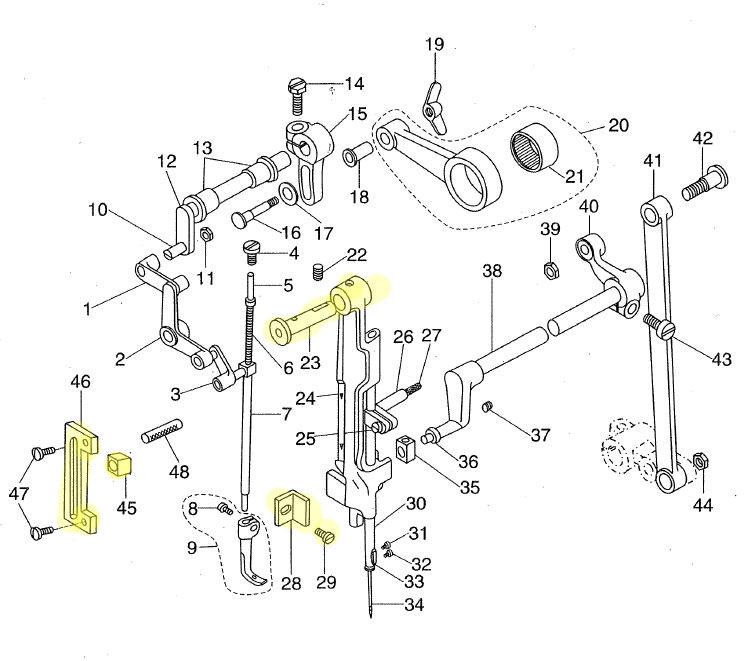

See attached. STH- Owners page should help correct this feed dog and inside presser foot issue. As for the vibrating rock frame, check the #23 pin, yours on your machine is going to be a cone shape. Make sure this is is pushed in as far as it can go. Index #28 below that will take up any side to side play, make sure we have at least an oil clearance here as we push this frame side to side as it goes front to back. Just for reference, this image that differs from your machine has the #46 and slide #45 slide block that would help eliminate this issue. often, after years of use, the inside presser bar frame and or presser bar shaft wear and then this play develops. This usually occurs after many years of using a cording or welting foot that does not hit the feed dog flat. In order to correct this, we would need a new needle bar frame, presser bar, or both. STH-8BLD-3 Owners_Pages.pdf- 3 replies

-

- consew 226

- singer 111

-

(and 3 more)

Tagged with:

-

Singer 111w155 stitch length issues

Gregg From Keystone Sewing replied to Glaciersew's topic in Leather Sewing Machines

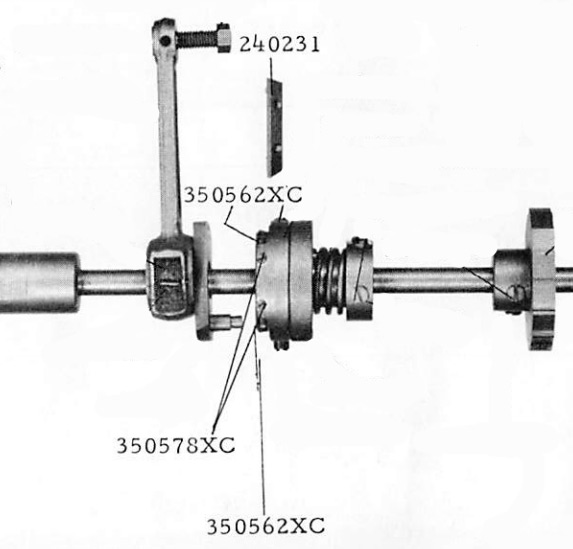

Using a small flat head screwdriver loosen the two #350562XC set screws on the feed driving eccentric regulator, then use the #350578XC adjusting screws to add friction. Too much and you will not be able to use the push down button on the bed of the machine to adjust stitch length. Too loose and it will fly in the wind out of adjustment like you stated. Once you seem to have it corrected, tighten down the #350562XC set screws and you are done. -

Service is important.

-

Thread guide Adjustment & function

Gregg From Keystone Sewing replied to brmax's topic in Leather Sewing Machines

Great stuff as always from gottaknow and Uwe. gottaknow has a more real world who would bother to think of this and let's just keep going and this is very correct. This is not the type of adjustment that most mechanics or repair people want to sit around thinking about. There's usually better things to do in a factory setting. When they put numbers on an adjustable guide, I wanted to find out what they were about. Actually what I attached above was recently new to me, I didn't have anything like it on hand. -

Thread guide Adjustment & function

Gregg From Keystone Sewing replied to brmax's topic in Leather Sewing Machines

It's funny, I too have longed for a detailed explanation, and I even went as far as contacting Durkopp Adler, as they have this regulator with numbers on them for index. I didn't get much. This page has the most detailed information I could find for any type machine that has this adjustment, and I've looked everywhere. See attached. DurkoppAdler867Instruction_Pages.pdf -

Bought a Used Consew

Gregg From Keystone Sewing replied to garypl's topic in Leather Sewing Machines

Very nice machine and motor. -

Another absolutely fantastic video by UWE. I watched that video like it was a really good movie.